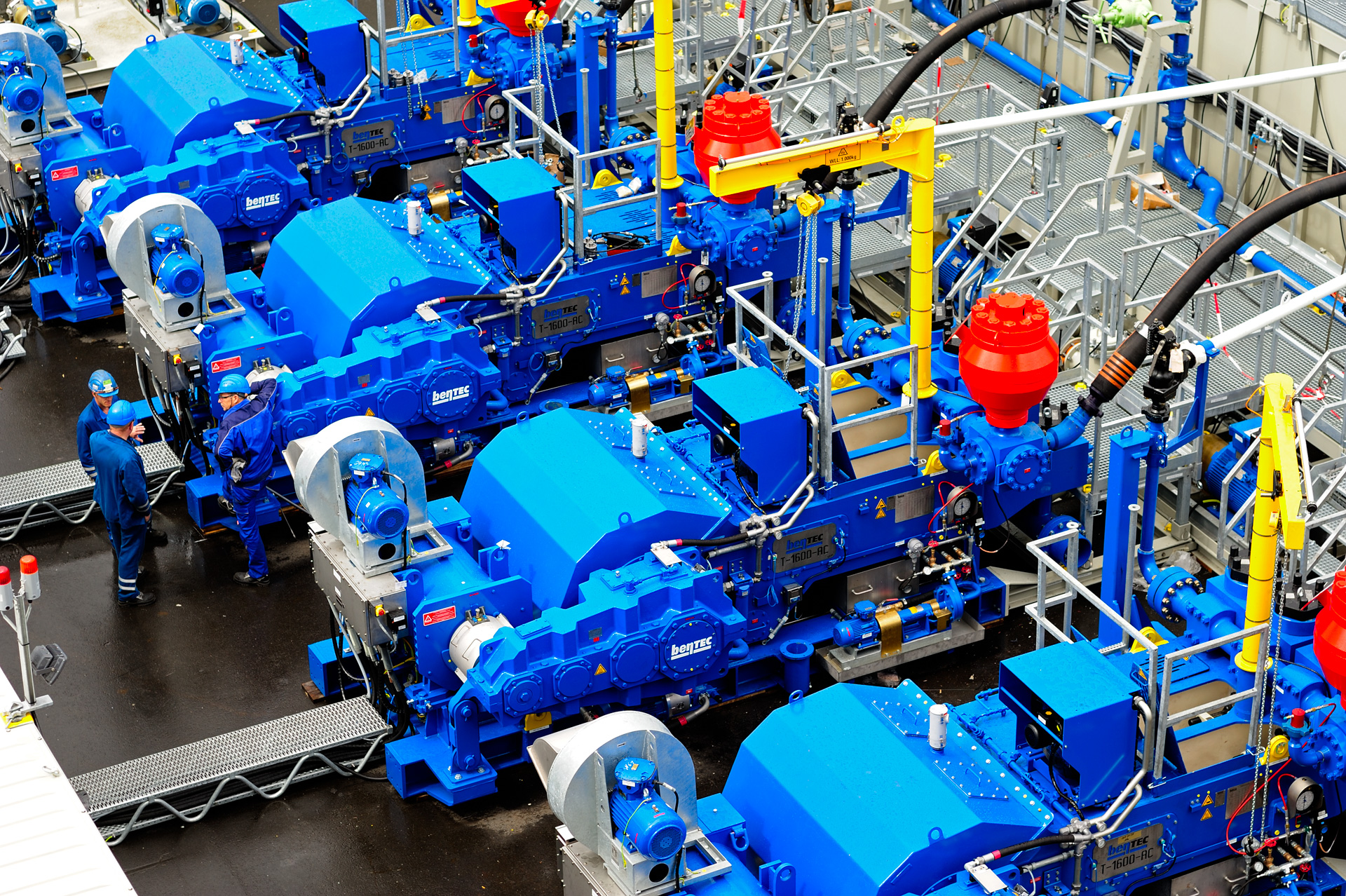

mud pump working factory

Our manufacturer Mud Pump skid is suitable for operations in rough, windy, damp and dusty oilfield conditions. Dependent upon customer horsepower requirements the engine sizes will vary.

Centerline Manufacturing is committed to the highest level of customer service quality. Every Centerline pump is comprehensively and repeatedly tested at diverse pressure levels to assure that it goes to our customer in perfect operational order. Centerline technicians work to ensure that our customers fully understand the operation of the model being delivered. If a customer"s pump is down, we understand the importance of timely response and parts availability. Centerline technicians will assess the problem and make repairs to bring the pump back into new specification. The Centerline mud pump technicians are well versed and qualified to operate and repair any product that is provided to the customer.

What is a mud pump? A mud pump refers to a machine that transports mud or water and other flushing fluid into the borehole during drilling. Types of mud pumps are an important part of drilling equipment. In the commonly used positive circulation drilling, it is to send the surface flushing medium—clear water, mud, or polymer rinsing liquid to the bottom end of the drill bit through a high-pressure hose, faucet, and drill rod center hole under a certain pressure. Cool the drill bit, remove the cut debris and transport it to the surface.

The commonly used mud pump is a piston-type or a plunger type, and the crankshaft of the pump is driven by the power machine, and the crankshaft passes the crosshead to drive the piston or the plunger to reciprocate in the pump cylinder. Under the alternating action of the suction and discharge valves, the purpose of pumping and circulating the flushing liquid is achieved.

During operation, the power machine drives the main shaft and the crank that is fixed thereon by a transmission component such as a belt, a transmission shaft, and a gear. When the crank rotates counterclockwise from the horizontal position from left to right, the piston moves to the power end, the pressure in the liquid cylinder gradually decreases and a vacuum is formed, and the liquid in the suction pool is under the action of the liquid surface pressure, and the suction valve is opened to enter the liquid cylinder. Until the piston moves to the right stop. This working process is called the suction process of the pump.

After the crank completes the above suction process, it continues to rotate counterclockwise. At this time, the piston starts to move toward the hydraulic end (left side in the figure), and the liquid in the cylinder is squeezed. The pressure rises, the suction valve closes, and the discharge valve is closed. Top open, liquid enters the discharge pipe until the piston moves to the left stop. This process is called the pump discharge process. As the power machine continues to operate, the reciprocating pump continuously repeats the process of inhaling and discharging, and the liquid in the suction pool is continuously sent to the bottom of the well through the discharge pipe.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

Mud pumps are the heart of a drilling operation. TSM designs and manufactures extremely reliable and easy-to-maintain mud pumps, eliminating unnecessary maintenance and downtime.

Centerline Manufacturing has been involved in the design, manufacture and production of drilling equipment and tooling for the water well industry. I have had the pleasure of knowing and working with Cory Miller of Centerline Manufacturing over the past 15 years. As the Senior Design Engineer for Ingersoll-Rand’s Deephole Drilling Business Unit, I had the distinct pleasure to work with Cory and integrate his Centerline Mud Pump into our drilling rig platforms. I am recommending Cory for this award and recognition because after decades in this business, I have not seen such an innovative design become a reality and commercialized such as the Centerline Mud Pump.

The true innovation is providing well drillers a size and weight solution for their mud pump requirements. Centerline Mud Pumps integrate into both existing and new drilling rigs. Regardless of drill rig manufacture and hydraulic system design, Centerline provides mud pump integration on hundreds of customer’s drilling rigs. Both Mono Cylinder and Duplex Cylinder Pumps can fit nicely on the deck, across the frame or even under deck mounting configurations. This would not be possible with conventional mud pump designs.

The design features of the Centerline Mud Pump include a matched displacement ratio between the mud pump cylinder and the hydraulic drive cylinder. This is critical to the constant and smooth transition of movement back and forth. It provides a steady discharge flow of mud.

What I dignifies Cory Miller and points to his character? It is how Centerline stuck with their original design through all of the typical trials and tribulations that come with a new product integration. The first several years were challenging. Cory found out that even the best quality hydraulic cylinders and valves and seals were not good enough quality. He then set off on an endeavor to bring everything in house. He began manufacturing all of his own components including hydraulic valves. This gave him complete control over the quality of very component that goes into the Centerline Mud Pump and the finished product.

By the late 90’s, Ingersoll-Rand had tried several times to develop a hydraulic driven mud pump. The goal was to create a mud pump that would last an acceptable life and duty cycle for well drilling contractors. With all of our resources and design wisdom, we were unable to solve this problem. Not only did Cory Miller provide a solution, thus saving the size and weight of a typical gear driven mud pump, he also provided a new offering of a mono cylinder mud pump. This double acting piston pump provided as much mud flow and pressure as a standard 5 X 6 duplex pump. It also came with an incredible size and weight savings.

The second generation design for the Centerline Mud Pump is coming out later in 2018. It will be a true game changer for this industry. It also will open up the application into many other industries that require a heavier duty cycle for a piston pump application.

These workhorses keep the mud flowing and your rig running. If theyʼre not working, youʼre not working. We make everything from the crankshaft to the liner seal to the skid. Each one is precision engineered for your rig so you can get back to turning.

These workhorses keep the mud flowing and your rig running. If theyʼre not working, youʼre not working. We make everything from the crankshaft to the liner seal to the skid. Each one is precision engineered for your rig so you can get back to turning.

Our core team is formed of Field service, Assembly, Manufacturing Technicians, Engineering & Quality Assurance that have previously worked for mud pumps manufacturing product line.

Manufactured to withstand the toughest drilling and environmental conditions, our K-Series triplex mud pumps are ideal for all drilling applications. This legacy product features a balanced forged-steel crankshaft and Southwest Oilfield Products ‘L” Shaped modules which is essential to minimize wear, noise, and operating vibrations. These attributes are essential when drilling deeper high pressure formations, long laterals and when handling corrosive or abrasive fluids and slurries.

Every American Block triplex mud pump is manufactured and fully load tested before leaving our manufacturing campus, and is available in sizes ranging from 800 HP to 2200 HP. The American Block K1600 HP Mud Pump is also available in a 2000 HP up-grade version, when more HP is needed in the same 1600 HP footprint.

8613371530291

8613371530291