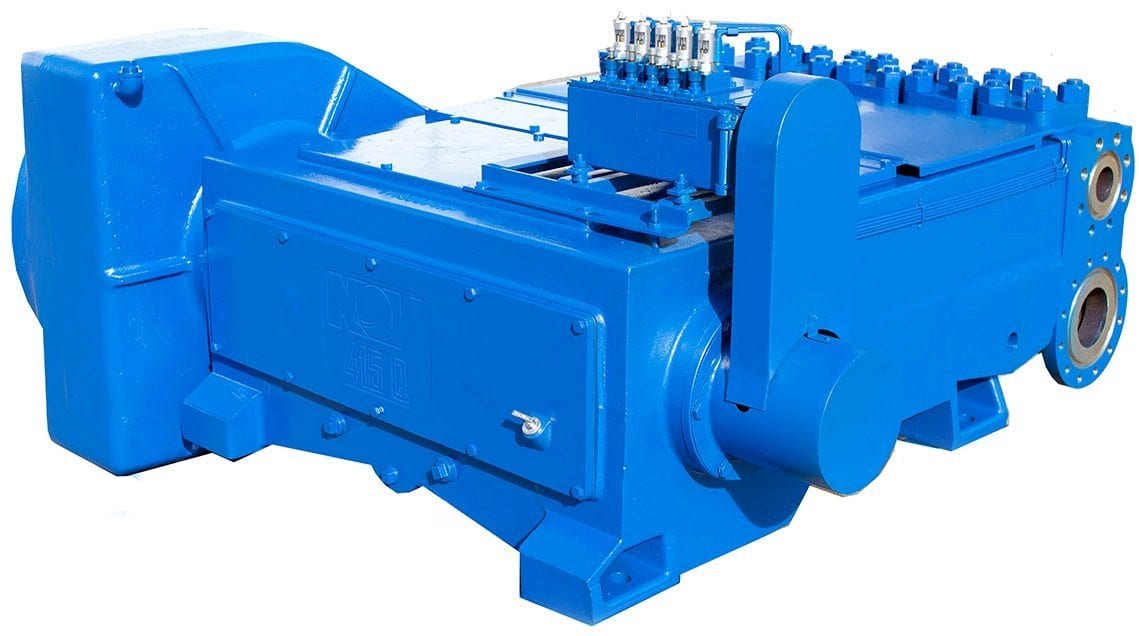

quintuplex mud pump factory

Black gold is truly the best description to sum up the value of oil. One of the most important contributors to change and industrialization, it drives the wheels of progress. ShalePumps is headquartered in Houston, the global oil capital. Headed by experts, it has a vision to support the industry with superior completion equipment. Frac operators, drilling contractors and well service companies source rely on ShalePumps for superior quality.

The key personnel of ShalePumps have a combined experience of more than a hundred years. This experience is reflected in the quality of our equipment. The fracking pumps, components and all services are much sought after for reliability and long life. This is because of the processes we follow. The design, materials, precision engineering and expertise contribute to an advanced assembly line.

After many years of thought and conscientious engineering, the team at ShalePumps is proud to add the Q5K™ 5000 HP Frac Pump to their list of many product offerings. Perfectly capable and suited for the next generation of hydraulic fracking market demands and technology. The Q5K is the only frac pump that has been designed and developed from the ground up to be capable of accepting true 5000 HP in a continuous duty frac application.

ShalePumps has consistently delivered high quality completion equipment to all stakeholders. The mission is to develop faster, rugged and efficient equipment to help the Oil and Exploration Industry. The vision is to continue leading the race with the best quality in completion equipment.

A quintuplex pump has a crankshaft supported in the pump by external main bearings. The crankshaft has five eccentric sheaves, two internal main bearing sheaves, and two bull gears.

A quintuplex pump is central to oil drilling and exploration due to the nature of operations. This pump circulates the mud to and from the surface, supporting the process for oil well operations.

The quintuplex pump is designed to circulate mud or drilling fluid under great pressure down the drill hole and back up. The pump is a reciprocating model that features five pistons, hence the name quintuplex mud pump. The right degree of pressure and precision is crucial for efficient well operations.

Despite the fact that all mud pumps have pulsation dampeners, noise levels are likely to be high and require modifications to keep noise pollution levels low. This is important, considering the long-running hours of equipment and the need to protect personnel from constant and high noise levels. With a quintuplex mud pump, the pulsation noise and the mud telemetry noise come down by as much as half, making operations less noisy.

Quintuplex pumps can be used in various applications including salt water disposal, descaling, high pressure pumping, Frac pumping, pipeline transfers in the Oil & Gas, Agriculture, Mining, Municipal and Manufacturing sectors.

Mud pumps comes in a variety of sizes and configurations but for the typical petroleum drilling rig, the triplex (three piston/plunger) mud pumps are the pump of choice. Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers.

Duplex, triplex and quintuplex pumps all have an enviable history of sound engineering, designed to exceed the rigorous requirements of API 674 and customer satisfaction.

The GD 2500Q Heavy Duty Frame (HDF) quintuplex pump was designed to extend pump service life through an optimized power end frame design. Stable, robust, and durable, the GD 2500Q HDF ...

The HS is a horizontal triplex and quintuplex positive displacement reciprocating pump with very high efficiency and is offered in a wide range of hydraulic, mechanical, and material options.

... plunger pumps for pressure testing, large three, four or five plunger pumps of various designs are available with specific advantages for specific applications.

JR2500Q pump is a widely used quintuplex plunger pump for high pressure and large displacement. It is suitable for continuous fracturing operation under harsh working condition such as ...

In the triplex pumps the crankshaft is supported by two roller bearings while in the case of the quintuplex or septuplex pumps intermediate bearings ...

The RDP range of Reciprocating Plunger Pumps by Ruhrpumpen comes in various sizes and in triplex and quintuplex formats. They are designed and manufactured in accordance to the lates edition of API 674 ...

Our manufacturer Mud Pump skid is suitable for operations in rough, windy, damp and dusty oilfield conditions. Dependent upon customer horsepower requirements the engine sizes will vary.

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

WheatleyGaso.com is your resource for Gaso pumps, Gaso pump parts and a supplier of ORIGINAL GASO PARTS and equipment, new used and remanufactured Wheatley, GASO and Wheatley/GASO plunger and piston pumps and pump parts and is not affiliated with Wheatley/GASO Inc. or its parent company, National Oilwell Varco,

▅ The max pressure for F500, F800, F1000 pump is 34.5MPa (5000PSI). These pumps are small, light and reliable. They are the best choices for shallow well and mid-deep well drilling rigs.

▅ The max pressure for F1300/1600, F22000 pump is 34.5MPa (5000PSI). These pumps are the best choices for mid-deep well and deep well drilling rigs due to its large displacement and high reliability.

▅ The max pump pressure for F1600HL and F22000HL pump is 34.5MPa (5000PSI), and the max displacement can reach 51.85L/S and 77.65L/S respectively. It is the best choice for deep well, super deep well, large displacements horizontal well, high pressure jetbit drilling, off-shore platform and other drilling rigs.

▅ The F1 series light weight pump is a new product. Under approximately equivalent power, displacement, pump pressure, and other basic conditions, the pump is 20% to 25% lighter than same model of F series. Meanwhile, all fluid end parts are forgings with outstanding quality. This pump is used when size and weight of drilling rigs are highly demanding, such as offshore platform drill rigs.

▅ QDP-3000 drilling mud pump is the largest power of quintuplex drilling mud pumps and pump package. The max pressure is 51.7MPa (7500PSI), and the largest displacement is 76.34L/S. The largest displacement under the max pump pressure reaches 55.08L/S, and the max pressure under the largest displacement is 27.0MPa, making it work better than similar products. Without pulsation dampener, the displacement and pressure fluctuation of this quintuplex pump is only about one third of triplex pump. The fluctuations are even less when pulsation dampener is installed. The pump package is inspired by ideas of modular and skid-mounted design, endowing it with reasonable layout, smooth operation, high transmission efficiency and reliability. This pump is particularly suitable for offshore platform purpose.

▅ Permanent magnet motor direct drive pump and pump package possess qualities of small volume, light weight, simple and reliable transmission, and high efficiency. It is a new energy-saving product, and also one of the developing trends for future drilling mud pump products.

Our pump manufacturing facility owns advanced paint coating production line, complete assembly production line and excellent mechanical processing equipment. There are 283 sets of various types of equipment altogether. Below are the high-lights:

The large-scale boring & milling machines group which includes XKA2840X160 CNC gantry moving milling machine, SKODA W250HD/W250G/W200G boring-milling machine, Speedram2000 CNC boring-milling machine, G60F CNC floor-type boring-milling machine and PAMA boring-milling machine. It is mainly responsible for boring and milling of drilling mud pump parts and large structural parts.

The drilling mud pump assembly line is equipped with advanced assembly tools, assembly facilities and skilled operators. There is a drilling mud pump test base. It is mainly responsible for the assembly, pressure test and factory test of the pumps.

To meet the needs of customers in a better way, our pump manufacturing facility take “customer satisfaction” as tenet and has been providing repair, test and on-site services of drilling mud pumps globally for a long time. Below are our commitments to the customers:

Global Quintuplex Mud Pumps Market Report (85 Pages) provides exclusive vital statistics, data, information, trends and competitive landscape details in this niche sector.

Due to the COVID-19 pandemic and Russia-Ukraine War Influence, the global market for Quintuplex Mud Pumps estimated at USD million in the year 2023, is projected to reach a revised size of USD million by 2028, growing at a CAGR of Percent during the forecast period 2023-2028.

The USA market for Quintuplex Mud Pumps is estimated to increase from USD million in 2023 to reach USD million by 2028, at a CAGR of Percent during the forecast period of 2023 through 2028.

The China market for Quintuplex Mud Pumps is estimated to increase from USD million in 2023 to reach USD million by 2028, at a CAGR of Percent during the forecast period of 2023 through 2028.

The Europe market for Quintuplex Mud Pumps is estimated to increase from USD million in 2023 to reach USD million by 2028, at a CAGR of Percent during the forecast period of 2023 through 2028.

The global key manufacturers of Quintuplex Mud Pumps include Weatherford International, White Star Pump, Shale Pumps and Amphibian Petroleum Tech, etc. In 2021, the global top five players had a share approximately Percent in terms of revenue.

In terms of production side, this report researches the Quintuplex Mud Pumps production, growth rate, market share by manufacturers and by region (region level and country level), from 2017 to 2023, and forecast to 2028.

In terms of sales side, this report focuses on the sales of Quintuplex Mud Pumps by region (region level and country level), by company, by Type and by Application. from 2017 to 2023 and forecast to 2028.

The Quintuplex Mud Pumps Market report delivers information about market segmentation in terms of revenue generation, growth potentials, and regional demand taking place in future. It introduces the global perspective of Quintuplex Mud Pumps market by analyzing historical and future trend analysis with respect to growth.

The Quintuplex Mud Pumps Market Report provides a precise industry breakdown based on type, applications, and research areas. The report examines the growth tactics used by these organizations in great depth. The report also contains a wealth of useful data about the Quintuplex Mud Pumps industry that was gathered from numerous commercial sources. The study on the Quintuplex Mud Pumps market also examines the cost structure of manufacturing and provides numerous information, including raw materials, the total production method, and the industry chain structure.

This latest report researches the industry structure, revenue and gross margin. Major players’ headquarters, market shares, industry ranking and profiles are presented. The primary and secondary research is done in order to access up-to-date government regulations, market information and industry data. Data were collected from the Quintuplex Mud Pumps companies, distributors, end users, industry associations, governments" industry bureaus, industry publications, industry experts, third party database, and our in-house databases.

This report also includes a discussion of the major players across each regional Quintuplex Mud Pumps market. Further, it explains the major drivers and regional dynamics of the global Quintuplex Mud Pumps market and current trends within the industry.

This section of the report provides key insights regarding various regions and the key players operating in each region. Economic, social, environmental, technological, and political factors have been taken into consideration while assessing the growth of the particular region/country. The readers will also get their hands on the value data of each region and country for the period 2017-2028. Regions Covered in Quintuplex Mud Pumps Market Report: ● North America (United States, Canada and Mexico)

The readers in the section will understand how the Quintuplex Mud Pumps market scenario changed across the globe during the pandemic, post-pandemic and Russia-Ukraine War. The study is done keeping in view the changes in aspects such as demand, consumption, transportation, consumer behavior, supply chain management, export and import, and production. The industry experts have also highlighted the key factors that will help create opportunities for players and stabilize the overall industry in the years to come.

● What are the upstream raw materials and manufacturing equipment of Quintuplex Mud Pumps What being the manufacturing process of Quintuplex Mud Pumps?

Our manufacturer Mud Pump skid is suitable for operations in rough, windy, damp and dusty oilfield conditions. Dependent upon customer horsepower requirements the engine sizes will vary.

NexGen Manufacturing & Supply keeps a wide variety of replacement parts in stock for mud pumps, plunger pumps, swivels, top drives, handling tools, and much more! Additionally, we have more than 3,000 prints and drawings of oilfield equipment and

Centerline Manufacturing is committed to the highest level of customer service quality. Every Centerline pump is comprehensively and repeatedly tested at diverse pressure levels to assure that it goes to our customer in perfect operational order. Centerline technicians work to ensure that our customers fully understand the operation of the model being delivered. If a customer"s pump is down, we understand the importance of timely response and parts availability. Centerline technicians will assess the problem and make repairs to bring the pump back into new specification. The Centerline mud pump technicians are well versed and qualified to operate and repair any product that is provided to the customer.

Danco Pump is your one-stop pump shop. We can provide complete service for all your pumping equipment. We have all power end and fluid end parts for all major high pressure reciprocating plunger and piston pumps. Wheatley Pumps; new, used and reconditioned pumps.

High pressure plunger and reciprocating piston pumps are used in many applications. Salt water injection and disposal, crude oil transfer and well servicing all use high pressure plunger pumps and piston pumps. Waste water treatment plants and sewer cleaning would require high pressure pumps as well to process the waste and water. Carwash, mud pumps and filter wash are other applications in which the pumps would be utilized.

We are the source for all your plunger and piston pump requirements. We have components for most major pump lines such as Gaso, Wheatley, Kerr, Gardener-Denver, Weatherford, National, Oilwell, Bethlehem , Tulsa Pump models.

8613371530291

8613371530291