quintuplex mud pump price

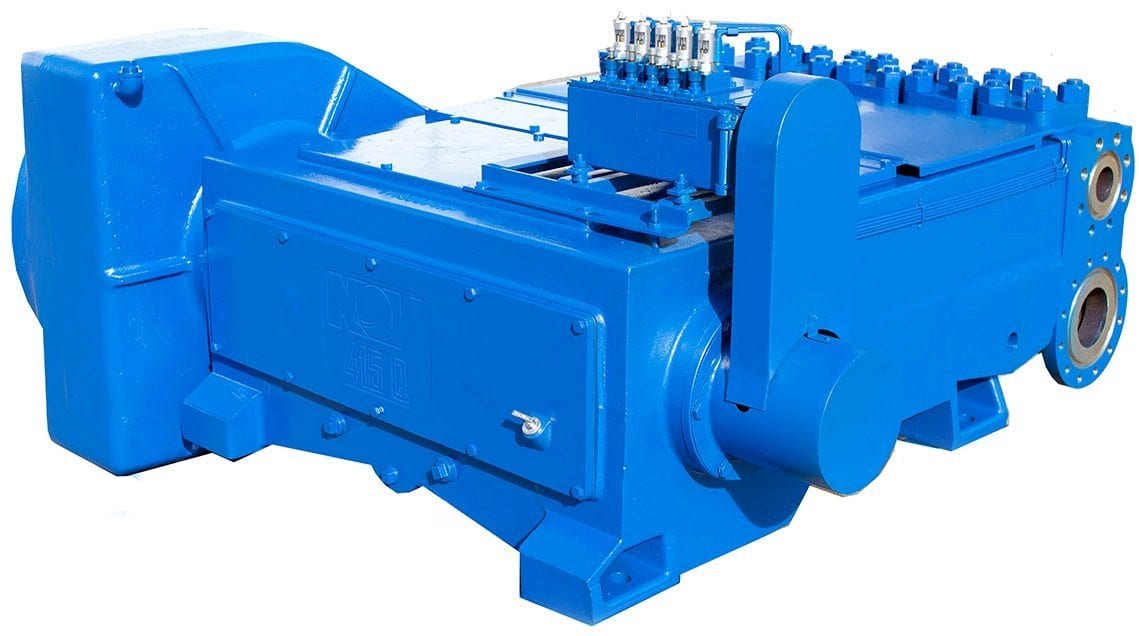

A quintuplex pump has a crankshaft supported in the pump by external main bearings. The crankshaft has five eccentric sheaves, two internal main bearing sheaves, and two bull gears.

A quintuplex pump is central to oil drilling and exploration due to the nature of operations. This pump circulates the mud to and from the surface, supporting the process for oil well operations.

The quintuplex pump is designed to circulate mud or drilling fluid under great pressure down the drill hole and back up. The pump is a reciprocating model that features five pistons, hence the name quintuplex mud pump. The right degree of pressure and precision is crucial for efficient well operations.

Despite the fact that all mud pumps have pulsation dampeners, noise levels are likely to be high and require modifications to keep noise pollution levels low. This is important, considering the long-running hours of equipment and the need to protect personnel from constant and high noise levels. With a quintuplex mud pump, the pulsation noise and the mud telemetry noise come down by as much as half, making operations less noisy.

Quintuplex pumps can be used in various applications including salt water disposal, descaling, high pressure pumping, Frac pumping, pipeline transfers in the Oil & Gas, Agriculture, Mining, Municipal and Manufacturing sectors.

Mud pumps comes in a variety of sizes and configurations but for the typical petroleum drilling rig, the triplex (three piston/plunger) mud pumps are the pump of choice. Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers.

Duplex, triplex and quintuplex pumps all have an enviable history of sound engineering, designed to exceed the rigorous requirements of API 674 and customer satisfaction.

Quintuplex Pumps - Used Bethlehem TP-6 triplex pump. 6" stroke, aluminum bronze fluid end, 4 1/2" plungers, gear reducer. 279 max gpm, 629 max psi, 225 max rpm. More Info

Quintuplex Pumps - 350 HP, 5" Stroke Quintuplex Pump, Forged Carbon Steel Fluid End With 2 1/4" plungers, 4" 300 # Suction, 2" 2500 # Discharge.155 GPM MAX, 3483 PSI MAX, 360 rpm max. More Info

Quintuplex Pumps - Used Oilwell B-558 quintuplex plunger pump, same as NOV 630Q-8L, steel billet fluid end, with 4.5" plungers, 619 gpm max, 1575 psi max, 225 rpm max. More Info

Quintuplex Pumps - Used Wheatly 5p-323 quintuplex, aluminum bronze head, 2.5"" steel plungers, power end in excellent condition, mounted on skid, bull wheel and 40 hp electric motor. More Info

Quintuplex Pumps - Used Wheatley HP-375L quintuplex plunger pump, steel billet fluid end, with 4" plungers, 500 gpm max, 995 psi max, 300 rpm max. More Info

A Single Acting Quintuplex Pump has 5 cylinders designed for high pressures and smoother flow rates. We supply new, used and reconditioned API 674 quintuplex pumps of all leading manufacturers including National, Gardner Denver, FMC, SPM and Oilwell. Quintuplex pumps can be used in various applications including salt water disposal, descaling, high pressure pumping, Frac pumping, pipeline transfers in the Oil & Gas, Agriculture, Mining, Municipal and Manufacturing sectors.

The plunger pump is an important device for the hydraulic system. It relies on the plunger to reciprocate in the cylinder to change the volume of the sealing working chamber to achieve oil absorption and oil pressure. The plunger pump has the advantages of high rated pressure, compact structure, high efficiency and convenient flow adjustment.

Piston pumps are widely used in applications where high pressures, high flow rates, and flow rates need to be adjusted, such as hydraulic presses, construction machinery, and ships.

Pivotal to drilling and production, multiplex drilling pumps for sale have increased operational efficiency through the ability to ferry large volumes of fluid. At the heart of the quintuplex drilling pump developed by ShalePumps, lies a design that exploits the output of additional cylinders to curb pulsation variance.

Packed into physically smaller dimensions, the power packed quintuplex drilling pump assures a steady flow at the surface. With proven reliability, the quintuplex pump keeps the fluid in circulation, maintaining optimal pressure and volume, fetching debris effortlessly from the wellbore.

The featured quintuplex drilling pump combines structural superiority and engineering knowhow for enhanced life expectancy in continuous operations. Additionally, Measurement While Drilling (MWD) and Logging While Drilling (LWD) operations are substantially improved by the increased data transfer rate bandwidth.

The design accomplishes the added objective of extending life of downhole tools through operational precision of the quintuplex drilling pump. Improved rate of flow helps in cutting overall costs, dispensing with the need for many pumps. ShalePumps, possessing the technical expertise with an extensive range of proven solutions, takes great care to incorporate high quality components in every quintuplex drilling pump. The crankshafts, piston rods, liners, connecting rods, bearings etc are all of the highest quality. Each quintuplex drilling pump, despite the composition of high wear components, is guaranteed to offer longer continuous life.

ShalePumps is proud to bring the quintuplex design to a new level. Built to be smaller, lighter and smoother than any conventional triplex design. The addition of a fourth and fifth cylinder decreases pulsation variance to a minimal level. This increases accuracy and precision during LWD and MWD applications and increases the life expectancy of down-hole tools.

SERVA QPA 1000 quintuplex plunger pumps are good for high-pressure well service. Each pump is equipped with a gear case. It is designed to pump cement slurries, sand-laden fluids, crude oil, acids, mud and other oil well servicing fluids.

Global Quintuplex Mud Pumps Market Report (85 Pages) provides exclusive vital statistics, data, information, trends and competitive landscape details in this niche sector.

Due to the COVID-19 pandemic and Russia-Ukraine War Influence, the global market for Quintuplex Mud Pumps estimated at USD million in the year 2023, is projected to reach a revised size of USD million by 2028, growing at a CAGR of Percent during the forecast period 2023-2028.

The USA market for Quintuplex Mud Pumps is estimated to increase from USD million in 2023 to reach USD million by 2028, at a CAGR of Percent during the forecast period of 2023 through 2028.

The China market for Quintuplex Mud Pumps is estimated to increase from USD million in 2023 to reach USD million by 2028, at a CAGR of Percent during the forecast period of 2023 through 2028.

The Europe market for Quintuplex Mud Pumps is estimated to increase from USD million in 2023 to reach USD million by 2028, at a CAGR of Percent during the forecast period of 2023 through 2028.

The global key manufacturers of Quintuplex Mud Pumps include Weatherford International, White Star Pump, Shale Pumps and Amphibian Petroleum Tech, etc. In 2021, the global top five players had a share approximately Percent in terms of revenue.

In terms of production side, this report researches the Quintuplex Mud Pumps production, growth rate, market share by manufacturers and by region (region level and country level), from 2017 to 2023, and forecast to 2028.

In terms of sales side, this report focuses on the sales of Quintuplex Mud Pumps by region (region level and country level), by company, by Type and by Application. from 2017 to 2023 and forecast to 2028.

The Quintuplex Mud Pumps Market report delivers information about market segmentation in terms of revenue generation, growth potentials, and regional demand taking place in future. It introduces the global perspective of Quintuplex Mud Pumps market by analyzing historical and future trend analysis with respect to growth.

The Quintuplex Mud Pumps Market Report provides a precise industry breakdown based on type, applications, and research areas. The report examines the growth tactics used by these organizations in great depth. The report also contains a wealth of useful data about the Quintuplex Mud Pumps industry that was gathered from numerous commercial sources. The study on the Quintuplex Mud Pumps market also examines the cost structure of manufacturing and provides numerous information, including raw materials, the total production method, and the industry chain structure.

This latest report researches the industry structure, revenue and gross margin. Major players’ headquarters, market shares, industry ranking and profiles are presented. The primary and secondary research is done in order to access up-to-date government regulations, market information and industry data. Data were collected from the Quintuplex Mud Pumps companies, distributors, end users, industry associations, governments" industry bureaus, industry publications, industry experts, third party database, and our in-house databases.

This report also includes a discussion of the major players across each regional Quintuplex Mud Pumps market. Further, it explains the major drivers and regional dynamics of the global Quintuplex Mud Pumps market and current trends within the industry.

This section of the report provides key insights regarding various regions and the key players operating in each region. Economic, social, environmental, technological, and political factors have been taken into consideration while assessing the growth of the particular region/country. The readers will also get their hands on the value data of each region and country for the period 2017-2028. Regions Covered in Quintuplex Mud Pumps Market Report: ● North America (United States, Canada and Mexico)

The readers in the section will understand how the Quintuplex Mud Pumps market scenario changed across the globe during the pandemic, post-pandemic and Russia-Ukraine War. The study is done keeping in view the changes in aspects such as demand, consumption, transportation, consumer behavior, supply chain management, export and import, and production. The industry experts have also highlighted the key factors that will help create opportunities for players and stabilize the overall industry in the years to come.

● What are the upstream raw materials and manufacturing equipment of Quintuplex Mud Pumps What being the manufacturing process of Quintuplex Mud Pumps?

The GD 2500Q Heavy Duty Frame (HDF) quintuplex pump was designed to extend pump service life through an optimized power end frame design. Stable, robust, and durable, the GD 2500Q HDF ...

The HS is a horizontal triplex and quintuplex positive displacement reciprocating pump with very high efficiency and is offered in a wide range of hydraulic, mechanical, and material options.

... plunger pumps for pressure testing, large three, four or five plunger pumps of various designs are available with specific advantages for specific applications.

JR2500Q pump is a widely used quintuplex plunger pump for high pressure and large displacement. It is suitable for continuous fracturing operation under harsh working condition such as ...

In the triplex pumps the crankshaft is supported by two roller bearings while in the case of the quintuplex or septuplex pumps intermediate bearings ...

The RDP range of Reciprocating Plunger Pumps by Ruhrpumpen comes in various sizes and in triplex and quintuplex formats. They are designed and manufactured in accordance to the lates edition of API 674 ...

The NOV 12-P-160 Mud Pumps includes (3) Three New National 12-P-160 Triplex Mud Pumps 1600 HP, 7-1/4″ bore x 12″ stroke, single acting. 5000 PSI fluid ends. 1600 HP Bare Mud Pumps are currently configured for Offshore Service. The NOV 12-P-160 Mud Pumps are located in Houston and ready to be unitized for service.

Forged Steel crankshaft, Individual forged steel two piece interchangeable standard modules, 6-1/2” mission fluid king liners, Standard polyurethane valves and seats, Two piece fast change piston rods, Supreme pistons, Metal to metal liner retention, Clamp type liner and piston rod connections, Fast change valve covers standard, Piston liner lubricant spray system, Liner spray pump, Power end lube system with filter. Mounted on Integral two runner skid, Suction Manifold with vertical suction stabilizer, Suction line pressure relief valve, set for 70 PSI

Includes: motor supports, motor frame, tensioning screws, 2 V-belt guards, 2 pump Sheaves, 2 motor sheaves, banded V-belts, Holes to be drilled to accept EDM D79 Or GE-752 Traction Motors

National Oilwell Varco (NOV) is an American multinational corporation based in Houston, Texas. It is a leading worldwide provider of equipment and components used in oil and gas drilling and production operations, oilfield services, and supply chain integration services to the upstream oil and gas industry. The company conducts operations in more than 600 locations across six continents, operating through three reporting segments: Rig Technologies, Wellbore Technologies, and Completion & Production Solutions. National Oilwell’s two main predecessors, Oilwell Supply and National Supply, were founded in 1862 and 1893, respectively. These two companies manufactured and distributed pumps and derricks.

What sets us apart? Superior customer service. Laser-focused expertise. And, of course, our comprehensive line of pumps—from the industry-standard E-447

With their superior design, Ellis-Williams pumps last longer and work harder than their competition - FACT. Each has been designed to fit customer needs, and all are rated for 24/7 continuous duty. Our Ellis-Williams premium pumps deliver the maximum performance with minimum weight at a total cost of ownership and ESG impact, that makes sense today.

Regardless of the size or scope of your project, EW Pumps has the experience and resources to handle the job. And because we’re the OEM, you can count on us for fast, flexible, and personalized service—customized to your needs, and your budget.

8613371530291

8613371530291