triplex mud pump output calculator supplier

Rig pump output, normally in volume per stroke, of mud pumps on the rig is one of important figures that we really need to know because we will use pump out put figures to calculate many parameters such as bottom up strokes, wash out depth, tracking drilling fluid, etc. In this post, you will learn how to calculate pump out put for triplex pump and duplex pump in bothOilfield and Metric Unit.

Pump Output per Stroke (PO): The calculator returns the pump output per stroke in barrels (bbl). However this can be automatically converted to other volume units (e.g. gallons or liters) via the pull-down menu.

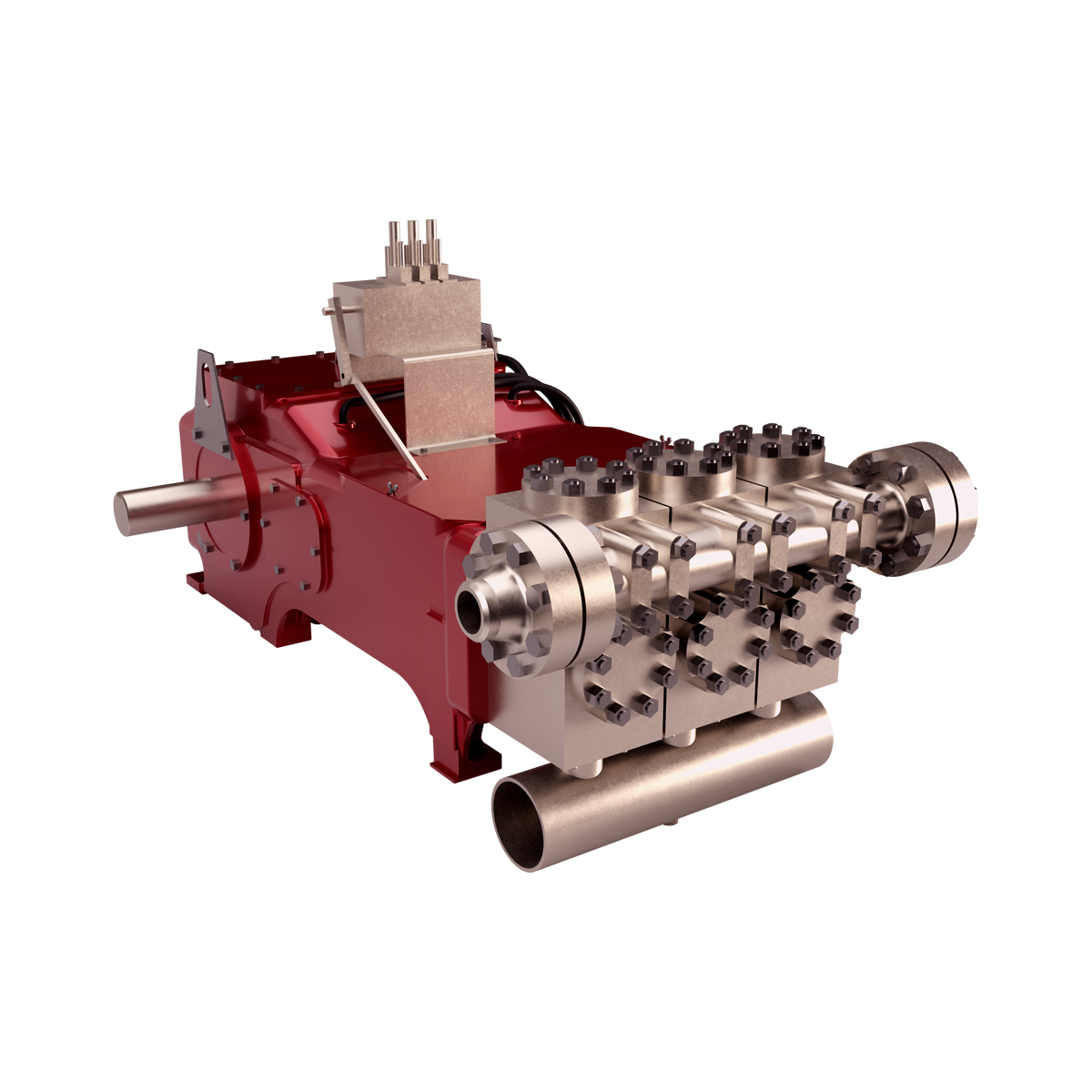

A triplex mud (or slush) pump has three horizontal plungers (cylinders) driven off of one crankshaft. Triplex mud pumps are often used for oil drilling.

This reciprocating pump rod load calculator is meant to quickly calculate the rod load of a plunger pump. By multiplying the pressure in the fluid chamber by the square area of the plunger, we can accurately calculate how much force is pushing back on the crankshaft of the pump.

Enter data into any 2 of the following 3 fields and press calculate. Note that this plunger pump rod load calculator is only for single acting plunger pumps, and not for double acting pumps.

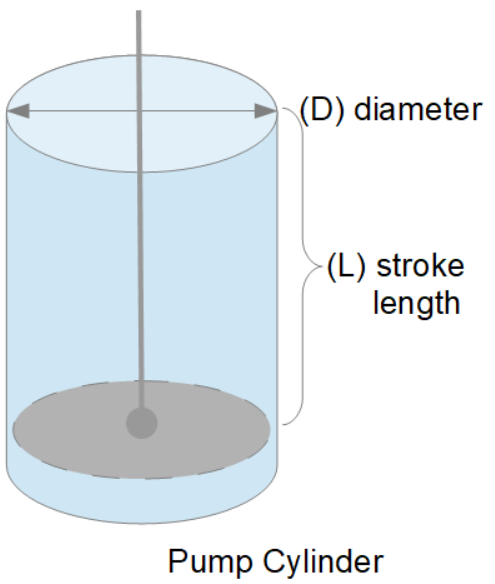

Oil and Gas drilling process - Pupm output for Triplex and Duplex pumpsTriplex Pump Formula 1 PO, bbl/stk = 0.000243 x ( in) E.xample: Determine the pump output, bbl/stk, at 100% efficiency for a 7" by 12". triplex pump: PO @ 100%,= 0.000243 x 7 x12 PO @ 100% = 0.142884bbl/stk Adjust the pump output for 95% efficiency: Decimal equivalent = 95 + 100 = 0.95 PO @ 95% = 0.142884bbl/stk x 0.95 PO @ 95% = 0.13574bbl/stk Formula 2 PO, gpm = [3(D x 0.7854)S]0.00411 x SPM where D = liner diameter, in. S = stroke length, in. SPM = strokes per minute Determine the pump output, gpm, for a 7" by 12". triplex pump at 80 strokes per minute: PO, gpm = [3(7 x 0.7854) 1210.00411 x 80 PO, gpm = 1385.4456 x 0.00411 x 80 PO = 455.5 gpm

Example:Duplex Pump Formula 1 0.000324 x (liner diameter, in) x ( stroke lengh, in) = ________ bbl/stk -0.000162 x (rod diameter, in) x ( stroke lengh, in) = ________ bbl/stk Pump out put @ 100% eff = ________bbl/stk Example: Determine the output, bbl/stk, of a 5 1/2" by 14" duplex pump at 100% efficiency. Rod diameter = 2.0": 0.000324 x 5.5 x 14 = 0.137214bbl/stk -0.000162 x 2.0 x 14 = 0.009072bbl/stk Pump output @ 100% eff. = 0.128142bbl/stk Adjust pump output for 85% efficiency: Decimal equivalent = 85 100 = 0.85 PO@85%)= 0.128142bbl/stk x 0.85 PO@ 85% = 0.10892bbl/stk Formula 2

PO. bbl/stk = 0.000162 x S[2(D) - d] where S = stroke length, in. D = liner diameter, in. d = rod diameter, in. Example: Determine the output, bbl/stk, of a 5 1/2". by 14". duplex pump @ 100% efficiency. Rod diameter = 2.0in.: PO@100%=0.000162 x 14 x [ 2 (5.5) - 2 ] PO @ 100%)= 0.000162 x 14 x 56.5 PO@ 100%)= 0.128142bbl/stk Adjust pump output for 85% efficiency: PO@85%,= 0.128142bb/stkx 0.85 PO@8.5%= 0.10892bbl/stk Metric calculation Pump output, liter/min = pump output. liter/stk x pump speed, spm. S.I. units calculation Pump output, m/min = pump output, liter/stk x pump speed, spm. Mud Pumps Mud pumps drive the mud around the drilling system. Depending on liner size availability they can be set up to provide high pressure and low flow rate, or low pressure and high flow rate. Analysis of the application and running the Drill Bits hydraulics program will indicate which liners to recommend. Finding the specification of the mud pumps allows flow rate to be calculated from pump stroke rate, SPM. Information requiredo Pump manufacturer o Number of pumps o Liner size and gallons per revolution Weight As a drill bit cutting structure wears more weight will be required to achieve the same RoP in a homogenous formation. PDC wear flats, worn inserts and worn milled tooth teeth will make the bit drill less efficiently. Increase weight in increments of 2,000lbs approx. In general, weight should be applied before excessive rotary speed so that the cutting structure maintains a significant depth of cut to stabilise the bit and prevent whirl. If downhole weight measurements are available they can be used in combination with surface measurements to gain a more accurate representation of what is happening in the well bore.

The pump horsepower calculator is used to estimate the pump power, i.e., the power transmitted to the shaft. A pump is one of the most common hydraulic machinery and is used to move fluid by the means of mechanical action by its impeller. Some of its application includes maintaining water supply across the city, heating, ventilation, and cooling systems (HVAC), hydraulics and pneumatics, and electricity generation (see hydroelectric power calculator)

The pump power is a function of hydraulic power and efficiency. Given the importance of this component, it is imperative to understand the basic characteristics of a pump to ensure greater efficiency of the larger processes. You can find more information about pump efficiency and pump power calculations in subsequent paragraphs.

The pump shaft power is defined as the power applied to achieve the head and the volumetric flow rate. It is a function of volumetric flow rate Q, differential head H, the density of fluid ρ, efficiency η, and the gravitational constant g. Mathematically, that"s:

We know that the pumps in most cases do not operate at an efficiency of 100%. Actually, cavitation drastically reduces it. The parameter of specific speed is used to compare the performance of the pump to the ideal case, i.e., a geometrically similar pump delivering 1 cubic meter of fluid per second against 1 m head. The specific speed NsN_\mathrm{s}Ns is a dimensionless quantity that is given by the equation:

Note that, while NsN_\mathrm{s}Ns is dimensionless, its value changes depending on the units system used for its inputs. The above version of the equation is used in the calculator that gives dimensionless output for specific speed. However, a simpler version of the equation was introduced without the acceleration due to gravity g to use with English units. Mathematically,

Pumps tend to be one of the biggest energy consumers in industrial operations. Pump motors, specifically, require a lot of energy. For instance, a 2500 HP triplex pump used for frac jobs can consume almost 2000 kW of power, meaning a full day of fracking can cost several thousand dollars in energy costs alone!

So, naturally, operators should want to maximize energy efficiency to get the most for their money. Even a 1% improvement in efficiency can decrease annual pumping costs by tens of thousands of dollars. The payoff is worth the effort. And if you want to remotely control your pumps, you want to keep efficiency in mind.

In this post, we’ll point you in the right direction and discuss all things related to pump efficiency. We’ll conclude with several tips for how you can maintain pumping efficiency and keep your energy costs down as much as possible.

In simple terms, pump efficiency refers to the ratio of power out to power in. It’s the mechanical power input at the pump shaft, measured in horsepower (HP), compared to the hydraulic power of the liquid output, also measured in HP. For instance, if a pump requires 1000 HP to operate and produces 800 HP of hydraulic power, it would have an efficiency of 80%.

Remember: pumps have to be driven by something, i.e., an electric or diesel motor. True pump system efficiency needs to factor in the efficiency of both the motor AND the pump.

Consequently, we need to think about how electrical power (when using electric motors) or heat power (when using combustion engines) converts into liquid power to really understand pump efficiency.

Good pump efficiency depends, of course, on pump type and size. High-quality pumps that are well-maintained can achieve efficiencies of 90% or higher, while smaller pumps tend to be less efficient. In general, if you take good care of your pumps, you should be able to achieve 70-90% pump efficiency.

Now that we have a better understanding of the pump efficiency metric, let’s talk about how to calculate it. The mechanical power of the pump, or the input power, is a property of the pump itself and will be documented during the pump setup. The output power, or hydraulic power, is calculated as the liquid flow rate multiplied by the "total head" of the system.

IMPORTANT: to calculate true head, you also need to factor in the work the pump does to move fluid from the source. For example, if the source water is below the pump, you need to account for the extra work the pump puts in to draw source water upwards.

*Note - this calculation assumes the pump inlet is not pressurized and that friction losses are minimal. If the pump experiences a non-zero suction pressure, or if there is significant friction caused by the distance or material of the pipe, these should be factored in as well.

You"ll notice that the elevation head is minimal compared to the discharge pressure, and has minimal effect on the efficiency of the pump. As the elevation change increases or the discharge pressure decreases, however, elevation change will have a greater impact on total head.

Obviously, that’s a fair amount of math to get at the pump efficiency, considering all of the units conversions that need to be done. To avoid doing these calculations manually, feel free to use our simple pump efficiency calculator.

Our calculations use static variables (pump-rated horsepower and water source elevation) and dynamic variables (discharge flow and pressure). To determine pump efficiency, we need to measure the static variables only once, unless they change.

If you want to measure the true efficiency of your pump, taking energy consumption into account, you could add an electrical meter. Your meter should consist of a current transducer and voltage monitor (if using DC) for electrical motors or a fuel gauge for combustion. This would give you a true understanding of how pump efficiency affects energy consumption, and ultimately your bank account.

Up until this point, we’ve covered the ins and outs of how to determine pump efficiency. We’re now ready for the exciting stuff - how to improve pump efficiency!

One of the easiest ways to improve pump efficiency is to actually monitor pumps for signs of efficiency loss! If you monitor flow rate and discharge (output power) along with motor current or fuel consumption, you’ll notice efficiency losses as soon as they occur. Simply having pump efficiency information on hand empowers you to take action.

Another way to increase efficiency is to keep pumps well-maintained. Efficiency losses mostly come from mechanical defects in pumps, e.g., friction, leakages, and component failures. You can mitigate these issues through regular maintenance that keeps parts in working order and reveals impending failures. Of course, if you are continuously monitoring your pumps for efficiency drops, you’ll know exactly when maintenance is due.

You can also improve pump efficiency by keeping pumps lubricated at all times. Lubrication is the enemy of friction, which is the enemy of efficiency (“the enemy of my enemy is my friend…”).

A fourth way to enhance pump efficiency is to ensure your pumps and piping are sized properly for your infrastructure. Although we’re bringing this up last, it’s really the first step in any pumping operation. If your pumps and piping don’t match, no amount of lubricant or maintenance will help.

In this post, we’ve given you the full rundown when it comes to calculating and improving pump efficiency. You can now calculate, measure, and improve pump efficiency, potentially saving your business thousands of dollars annually on energy costs.

For those just getting started with pump optimization, we offer purpose-built, prepackaged solutions that will have you monitoring pump efficiency in minutes, even in hazardous environments.

This approach works well but relying on a printed reference is not without the risk since the wrong value can still be selected from the fine print of a reference table, or the reference document can be damaged or lost (e.g., dropped in the mud pit) altogether.

The intermediate casing can be sealed using the pressure grouting technique (Figure 3) to pump cement slurry down through the drill pipe and out to the annulus through a float shoe (a drillable check valve connected to the base of the casing). The inside of the intermediate casing is kept full of water during the cement placement to equilibrate hydraulic pressures inside and outside the casing. After the intermediate casing is sealed with the pressure grouted cement, the float shoe can be drilled out and the borehole advanced for installation of the screen and filter pack in the lower part of the well.

There are several calculations that are commonly applied by drilling fluid engineers (mud engineers) to determine the time period required for the fluid to move from one location in the borehole to another. Some of the more common equations are described below.

The uphole velocity calculation provides a determination of the speed at which the drilling mud will flow as it moves up the borehole. For direct air rotary or reverse circulation drilling methods, the uphole velocity is high, so this calculation is generally applicable only for the direct mud-rotary drilling method. The formula for uphole velocity is:

We can calculate the bottoms-up time by using the uphole velocity formula with the borehole depth and drilling mud flow rate plugged in, but that flow rate is being generated by the mud pump, and positive displacement mud pumps (duplex or triplex) are almost never equipped with a flow meter. To determine the flow coming from the mud pump, we can use the formulas:

Remember the strokes are counted in both the forward and backward directions on a duplex pump, but only in the forward direction on a triplex pump. Drillers often have reference charts that provide oilfield barrels per stroke (bbl/stroke), which can be converted to gpm by timing the strokes per minute and converting barrels to gallons (1 barrel = 42 gallons).

A specified volume of drilling fluids (called a pill) can be circulated to a particular depth interval within the borehole (called spotting), so that the additives in the pill of drilling mud can address the borehole problem at a particular depth of the borehole. This is shown in Figure 6(C).

The calculation for time required to spot a pill of drillingfluid involves determining the pumping time (at the calculated flow rate) required to displace the fluid so that the drilling mud additives are located adjacent to the problematic interval. This approach is used by mud engineers to address problems such as lost circulation or stuck drill pipe.

Whether onshore or offshore, well drilling sites rely on a multitude of systems to successfully perform the drilling operation. The mud pump is a key component tasked with circulating drilling fluid under high pressure downhole. The mud pump can be divided into two key sections: the power end or crosshead and the fluid end. Proper alignment of the pump’s crosshead to the fluid end liner is necessary to maximizing piston and liner life. Misalignment contributes to

accelerated wear on both the piston and the liner, and replacing these components requires downtime of the pump. Traditional methods of inspecting alignment range from using uncalibrated wooden rods, Faro Arms and micrometers to check the vertical and horizontal alignment of the piston rod OD to the piston liner ID. These are time consuming and cumbersome techniques that are ultimately not well suited to troubleshoot and solve alignment issues.

A “Mud Pump Laser Alignment Kit” enables you to measure where the piston will run through the liner at various positions along the pump’s stroke. It will also project a laser centerline from the fluid end back towards the rear power end of the pump that can be used to determine how much shimming is required to correct any alignment issues. The kit can include either a 2-Axis receiver or a 4-Axis which accepts the laser beam and documents where it falls on the active surface of the receiver. The 4-Axis receiver can decrease alignment time by as much as 50% as it will measure angularity as well as X and Y while the 2-Axis does not and will need multiple measurement locations to get the same information. In addition, the alignment system is a non-intrusive service requiring the removal of only the piston rod which allows for much quicker service and less down time on the pump. As the mud pumps in question are located globally both on and offshore, having a small, portable system is another great advantage. Our recommendation would be Pinpoint laser System’s “Mud Pump Alignment Kit”. They are being used by many of the leading repair service companies and have been their main alignment tool for over 15 years. Manufacturers are also utilizing these for new pump set-up.

In addition to selecting the proper suction pipe diameter and having adequate NPSHA, the submergence level and suction pipe configuration must be considered. Submergence level is the depth of the suction pipe inlet below the liquid surface. If an inadequate submergence level exists, an air vortex will form that extends from the liquid surface to the inlet of the suction pipe. This will introduce air into the system, resulting in either turbulent flow patterns or vapor locking of the pump. Amount of submergence required varies with velocity of the fluid. Fluid velocity is controlled by flow rate and pipe diameter. Refer to Figure 1. to determine submergence required based on fluid velocity (fluid velocity can be found in Friction Loss (Centrifugal Pumps Velocity Measured), in the column ‘‘V (ft/sec)’’).

If a system utilizes a 6-inch suction line with a flow rate of 600 gpm, suction-line velocities will be 6.6 fps and the line will therefore require approximately 3.5 feet of liquid surface above the suction-line entrance. Once the submergence level drops below 3.5 feet, an air vortex will form, causing air to enter the pump suction, resulting in a turbulent flow pattern and/or vapor lock.

In addition to proper line size and submergence level, a suction pipe should slope gradually upward from the source to the pump suction. This prevents air traps within the suction line. There should be a straight run prior to the pump entrance of at least two pipe diameters in length to reduce turbulence. A smooth-flowing valve should be installed in the suction line that will allow the pump to be isolated for maintenance and inspection. If a suction hose is used in lieu of hard piping, the hose must be noncollapsing. Refer to Figures 3 and 4 for examples of accepted piping practices.

Triplex mud pumps are often operated at speeds at which head in the suction tank is insufficient to maintain fluid against the piston face during the filling stroke. If fluid does not remain against the face, air is sucked in from behind the piston, causing a fluid void. If a void is formed, the piston strikes the fluid when the piston reverses direction during the pressure stroke. This causes a shock load that damages the triplex power end and fluid end and lowers expendable parts life. Supercharging pumps are used to accelerate fluid in the suction line of a triplex mud pump during the filling stroke, allowing fluid to maintain pace with the piston. A properly sized supercharging pump will accelerate fluid so that fluid voids and shock loads do not occur.

Triplex mud pumps normally have shock loads at speeds greater than 60 strokes per minute (spm) (when not supercharged). Without proper equipment, this would go unnoticed until the pump exceeded 80 strokes per minute, but meanwhile the shock load is damaging the pump. Supercharging requires an oversized pump with wide impellers to adequately react to rapid changes in flow required by the triplex mud pump. When sizing a centrifugal pump for a mud pump supercharging application, the pump should be sized for 1½ times the required flow rate. Therefore, if the triplex mud pump maximum flow rate is 600 gpm, the centrifugal pump should be sized for 900 gpm. High-speed piston and plunger pumps that stroke above 200 spm should be designed with a supercharging pump that produces 1¾ to 2 times the required flow rate.

Supercharging is one of the few applications in which the centrifugal pump does not have steady flow. The flow pulsates. Small impellers operating at 1750 rpm have a tendency to slip through the fluid when acceleration is needed. This is similar to car tires slipping on wet pavement. Even though it sometimes appears that the small impeller running at 1750 rpm is providing enough head, shock loading may be occurring. Supercharging pumps should have larger impellers running at either 1150 (60 cycles) or 1450 rpm (50 cycles) and should normally be sized to produce 85 feet of head at the triplex suction inlet. Supercharging pumps should be located as close to the supply tank as possible. Mounting supercharging pumps near the triplex and away from the supply tank transfers suction problems from the triplex to the centrifugal pump. If the centrifugal pump does not have a favorable supply with short suction run, it will have an insufficient supply to accelerate fluid.

Piping for supercharging pumps and triplex pump suctions should be oversized for the flow rate. Pipe should be sized so the change in line velocity during pulsations will not be over 1.5 ft/sec during the change from low flow rate to high flow rate during the triplex pulsation cycles.

Since the change in line velocity in 6-inch pipe is less than 1.5 ft/sec, this pipe size can be used for supercharging a triplex with an average flow of 600 gpm.

There are times when a single centrifugal pump will not meet the head requirements of an application. Two pumps can be operated in series to achieve the desired discharge head, in which the discharge of one pump feeds the suction of the second pump. The second pump boosts the head produced by the first. Therefore, if an application required 2900 gpm at 200 feet of head, one option would be to run two 10×8×14 pumps in series. Each pump could be configured with a 13-inch impeller to produce 2900 gpm at 100 feet of head. When operated in series, the pumps would produce 2900 gpm at 200 feet of head.

This type of configuration is most commonly used for extremely long discharge runs. When running pumps in series, it is important not to exceed flange safety ratings. Additionally, it is not required to place pumps within close proximity of each other. If an application had a 6-mile discharge line the first pump could be located at the supply source and the second pump could be located 3 miles away.

exists that requires high volume and low head and volume required is greater than can be produced by a single pump, two pumps are sometimes used in a parallel configuration to meet the demand. Two pumps that produce the same TDH can be configured so that each pump has an individual suction but both pumps feed into the same discharge line. If the pumps are identical, head in the discharge line is equal to that of the pumps, but the volume is double what a single pump can produce. However, two centrifugal pumps will never have the exact same discharge head, and as wear occurs one pump will produce less head than the other and the stronger pump will overpower the weaker pump and force fluid to backflow into the weaker pump. For this reason, parallel operation is not normally recommended.

Two pumps can be configured in parallel but only one pump is operated at a time, thus providing a primary and a backup pump. The two pumps are separated by a valve in each discharge line that prevents one pump from pumping through the other. This type of configuration is perfectly acceptable and, in crucial applications, encouraged.

8613371530291

8613371530291