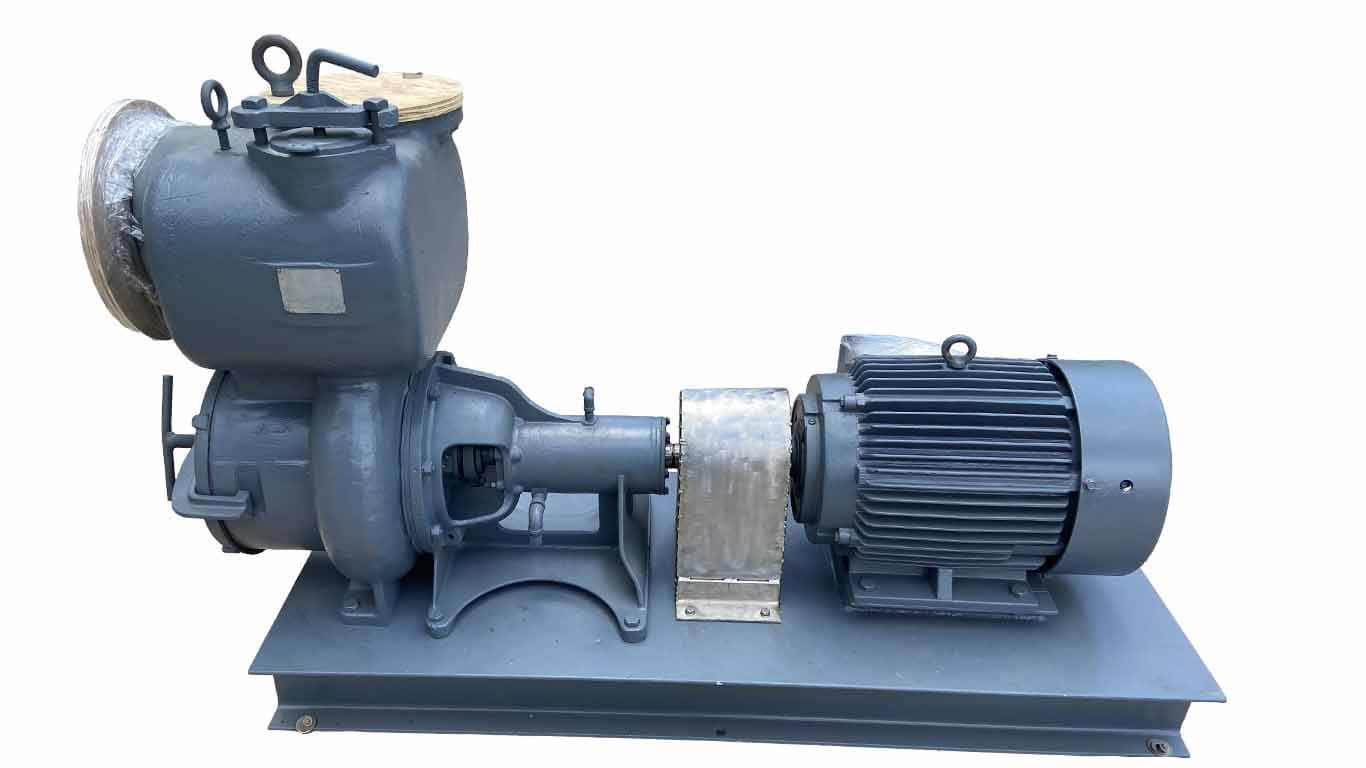

gorman rupp mud pump manufacturer

Since 1933, Gorman-Rupp has manufactured the high-performance, high-quality pumps and pumping systems required for lasting service in the municipal, water, wastewater, sewage, industrial, construction, petroleum, mining, fire, and OEM markets.

Today, Gorman-Rupp self-priming pumps are the world’s leading choice for waste handling applications in industries such as steel and paper mills, mining operations, food processing plants, power plants, automotive factories, tanneries and wineries. They are also the pump of choice in many sewage-handling applications worldwide.

Gorman-Rupp self-priming centrifugal pumps are easy to install and easy to service. Because they’re self-priming, they can be mounted high and dry at floor level with only the suction line in the liquid – there’s never a need for service personnel to enter the sump. When service or maintenance is required, it can be completed easily with common hand tools. There are no long drive shafts to install and align, and no hoists or cranes are required.

Gorman-Rupp self-priming pumps are available as basic units for connection to your power source or may be flex-coupled, v-belt driven or engine mounted. Automatic priming means dependable performance. All that’s needed is an initial priming and the pump will continue to reprime automatically. In fact, our trash handling pumps will reprime with only a partially filled pump casing and a completely dry suction line!

Our reputation for quality has made Gorman-Rupp the world’s leader in self-priming centrifugal pumps. In addition, it makes us your best solution – meeting all of your industrial or municipal waste handling needs.

Priming assisted, centrifugal, solids-handling pumps, venturi and compressor priming system for medium to high head contractor and bypass applications

Priming assisted, centrifugal, solids-handling pumps, venturi and compressor priming system for high head/high flow contractor and bypass applications

In addition, Gorman-Rupp manufactures a complete line of state-of-the-art packaged lift stations and booster stations that include pumps, motors, controls, piping, accessories and enclosures.

Effective immediately, due to supply chain challenges, Gorman-Rupp Pumps (Engineered Systems) is temporarily substituting Allen-Bradley PowerFlex 753 Variable Frequency Drives (VFD) with the Allen-Bradley PowerFlex 755 Variable Frequency Drives (VFD). At this time, there is no additional cost for the substitution. We will continue to monitor availability, and will provide notification when availability returns for

The durable performance of Gorman-Rupp pumps makes them the preferred choice for fire suppression worldwide. In countless buildings, centrifugal pumps from Patterson Pump Company and Patterson Pump Ireland meet growing global demand for hydrant-based systems. Where hydrants are not available, AMT pumps are used to siphon fire-quenching water from pools or ponds.

At Gorman-Rupp, we are committed to effective corporate governance and high ethical standards. We adhere to our ethical commitments in every aspect of our business, including our commitments to each other, in the marketplace and in the global, governmental and political arenas. These commitments are spelled out in our Code of Corporate Conduct and Ethics, which applies to all of our employees (including our principal executive and senior financial officers) and Board of Directors.

The Gorman-Rupp Super T Series pump with Eradicator™ Solids Management System are a series of self-priming centrifugal pumps designed specifically for handling municipal and industrial wastewater containing stringy, difficult-to-pump, solids in suspension (such as wet wipes, rags and feathers).

They have been designed for economical, trouble-free operation, with design features that deliver superior solids handling capability and a large inspection cover to access pump internals for service or blockage removal. Gorman-Rupp Super T Series wastewater and sewage pumps have been used for pumping of WAS and RAS and for digester recirculation with great success in wastewater treatment plants around the country, as well as food process plants, paper mills and other heavy industries. The Eradicator™ system advances the solids handling capabilities of this range.

Gorman-Rupp is the industry leader and innovator in high-quality pump design. At Envirep/TLC, we will help you choose the best Gorman-Rupp pump parts for your needs. Our goal is to provide you with easy to operate, low maintenance pump parts to ensure you are being as cost-effective as possible

Envirep/TLC is an authorized distributor of Gorman Rupp pumps and pump products and we carry a huge inventory of spare parts so our customers receive the best service possible.

When repairing Gorman-Rupp pumps, it is always best to use genuine Gorman-Rupp pump parts. Gorman-Rupp builds their parts to exact tolerances and exact material specification. Not having the right part can reduce the service life and effect the life of the pump, other parts in the pump, and the efficiency of the pump. Only genuine Gorman-Rupp parts can guarantee that your part will fit perfectly, and deliver reliable service for many years.

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

Gorman Rupp Pump manufactures of all types of trash pumps, submersible pumps, portable pumps, high-pressure fire pumps, and self-priming pumps. Centrifugal and diaphragm pumps. Electric Gas Diesel powered. Mansfield, OH. OTS Off-The-Shelf & IPT pumps program.

Gorman Rupp pumps will meet any pumping situation you may have. For more than 80 years, Gorman-Rupp has manufactured the high-performance, high-quality pumps required for lasting service in the contractor and industrial fields. Complete line of AMT pumps. Made in America

In addition to the electric motor, many pumps are powered by Honda engines. If you need durability and reliability, these GR Pumps with Honda gas powered engines are just what you are looking for.

Designed for the harshest environments, the Gorman-Rupp line of EXPlosion Proof pumps have a long history of quality and reliability. These self-priming pumps handle flammable and hazardous liquid material.

GR Pumps meet the needs of virtually any industry. From circulator pumps to hazardous material, GR Pump move water, chemicals, sludge, trash, mud, and more. Contact us to discuss your application and we will be sure your GR Pump meets your needs.

Gorman-Rupp’s ReliaSource® line of packaged, fully customizable, above- and below-ground lift stations have been the market’s most reliable option for decades.

Every component of a ReliaSource lift station–from the pumps, to the NEMA-rated controls, to the corrosion- and weather-resistant fiberglass enclosures–is 100% Gorman-Rupp custom-engineered, manufactured and assembled. With Gorman-Rupp quality inside and out, ReliaSource lift stations outlast and outperform any other lift station on the market, delivering trouble-free performance you can rely on. Guaranteed.

Every station is rigorously tested using a wide range of testing options based on customer specifications and guided by Hydraulic Institute testing standards, and are shipped complete and ready-to-go for professional installation – just add power and connect piping for years of reliable pumping!

The Gorman-Rupp Company was established over 85 years ago with a mission to manufacture pumps and motor controls exhibiting exceptional quality and technological leadership. This establishment utilizes nearly 2 million square feet of design and manufacturing space worldwide to produce over 5,000 pump models. Gorman-Rupp values research and development and has a long history of product innovation and improvement.

At Stewart-Amos Equipment, we carry a wide assortment of Gorman-Rupp pumps. These products reflect our high quality and performance standards, which is why we are proud to distribute them to our customers. Our Gorman-Rupp pump parts selection comprises water pumps specially designed for construction and mining applications.

The SludgeKat, Gorman-Rupp‘s new self-priming, positive displacement, hydraulic-piston pump, is designed to handle applications involving heavy sludges and slurries where other pumps fail.

The SludgeKat has 4-in. suction and discharge ports and is capable of flows up to 226 gallons per minute and heads up to 390-in. total dynamic head. Depending on the product being pumped, SludgeKat can pass up to 2.4-in.-diameter solids without damaging or clogging the pump, Gorman-Rupp says. Units are equipped with the latest in Kohler Tier 4 diesel engine-driven technology.

The pump end frame is mounted to a 52-gallon fuel tank base and offers a full load run time of 25.5 hours. Each SludgeKat comes standard with a Department of Transportation-approved wheel kit. The pump end frame can be detached from the unit and, when connected to optional 150-ft. hoses, provides increased portability around jobsites, the company adds.

According to Gorman-Rupp, the SludgeKat is ideal for clarifying pits, wastewater treatment, loading and unloading railcars, oil and gas drilling, mud pump applications, environmental cleanup and a variety of other heavy-duty industrial and construction applications.

Gorman-Rupp is a manufacturer of pumps and pumping systems for the municipal, water, wastewater, sewage, industrial, construction, rental and original equipment manufacturing markets.

Gorman-Rupp 10 Series Self-Priming Pumps are specifically designed for handling solids, corrosive liquids and slurries. They have few moving parts, so maintenance is minimal. If a clog occurs, it can be removed easily through the cover plate opening without disturbing piping or the use of any special tools. The 10 Series offers a variety of seal configurations to choose from to handle a number of different liquids, they make for great corrosive liquid pumps.

–Solids Handling Impeller:Two-vane, semi-open, solids handling impeller handles up to 3″ (76 mm) diameter solids, depending on pump model. Pump out vanes on impeller shroud reduce foreign material buildup behind impeller and reduce pressure on seal and bearings for extended pump life.

– Multiple Seal Options: 10 Series pumps are available with Gorman-Rupp double mechanical grease lubricated seals, self-lubricated mechanical seals and Gorman-Rupp’s exclusive tungsten titanium carbide double floating, self-aligning oil Lubricated seals. Fluorocarbon Elastomers (DuPont Viton® or equivalent) and PTFE Elastomers (DuPont Teflon or equivalent) are also available.

– Removable Cover Plate:Removable cover plate provides quick and easy access to pump interior without disconnecting piping. Clogs can be removed and pump returned to service in minutes. Impeller, seal and replaceable wearplate can also be easily accessed through cover plate opening for inspection or service.

– Replaceable Wearplate:10 Series pumps feature replaceable wearplates which fasten to the cover plate and can be removed for inspection or service. No expensive castings to replace. 10 Series pumps are available as basic units for connection to customers’ power source or may be flex-coupled or V-belt driven by an electric motor. Pumps can also be powered by gasoline or diesel engines.

Engine-driven pumps from Gorman-Rupp can be used to supply large quantities of water for hydraulic fracturing operations and centrifugal pumps used on blending and hydration rigs. Solids-handling, self-priming trash pumps can be used for drilling rig cellar pumpout, transferring drilling mud slurries, frac tank and reserve pit water transfer, tank loading and closed-loop recirculation. 419/755-1011; www.grpumps.com

D.J. Gongol and Associates, Inc. are the exclusive manufacturer"s representatives for the Gorman-Rupp lines of municipal water and wastewater treatment systems in the states of Iowa and Nebraska. The Gorman-Rupp Company is the world"s leading manufacturer of self-priming centrifugal pumps, and we are their proud representatives for municipal water and wastewater treatment applications in Iowa and Nebraska. Gorman-Rupp pumps are reliable and easy to maintain.

Wet on the inside, dry on the outside. Self-priming centrifugal pumps keep the fluids on the inside. Any pump can clog from time to time -- so why make life more difficult for the operator? Gorman-Rupp pumps stay high and dry above the sump, so maintenance and repairs are easy and safe. The easy-access coverplate on a Gorman-Rupp T-Series pump means you don"t have to disturb piping or move the pump just to clear it out. Every Gorman-Rupp pump 4" or larger will clear a 3" solid anywhere in the pump -- that"s the size of a baseball. Solids-clearing capacity like that is a huge advantage to you as an operator.

Reliability. Dozens of Gorman-Rupp applications are still working here in Iowa and Nebraska more than a decade after we first put them into place. Your operators have better things to do than fix pumps all day. Go with the reliability of a Gorman-Rupp application! See for yourself!

Our exclusive five-year guarantee. We"re so certain that your Gorman-Rupp self-priming pumps will give you trouble-free operation that we"ll offer you a five-year guarantee on service. That"s more reliability than you can expect from your own car or truck!

Proven results. We"ll put Gorman-Rupp pumps side-by-side with any competitor"s and let you make the decision. Once you see how a Gorman-Rupp self-priming pump outperforms any other pump on the market, you"ll know why we"ve earned the trust of scores of municipalities across Iowa and Nebraska.

Hands-free operation. Why spend your time doing what a reliable Gorman-Rupp system can do for you? Gorman-Rupp stations are available with auto-start controls, so when the power goes out, your system keeps working.

It gets even better: Gorman-Rupp has taken the industry-leading T-Series pump and made it even better with the Super-T! The Super-T combines classic T-Series pump performance with features designed to make maintenance even easier. Contact us for custom specifications and calculations - use our contact page.

8613371530291

8613371530291