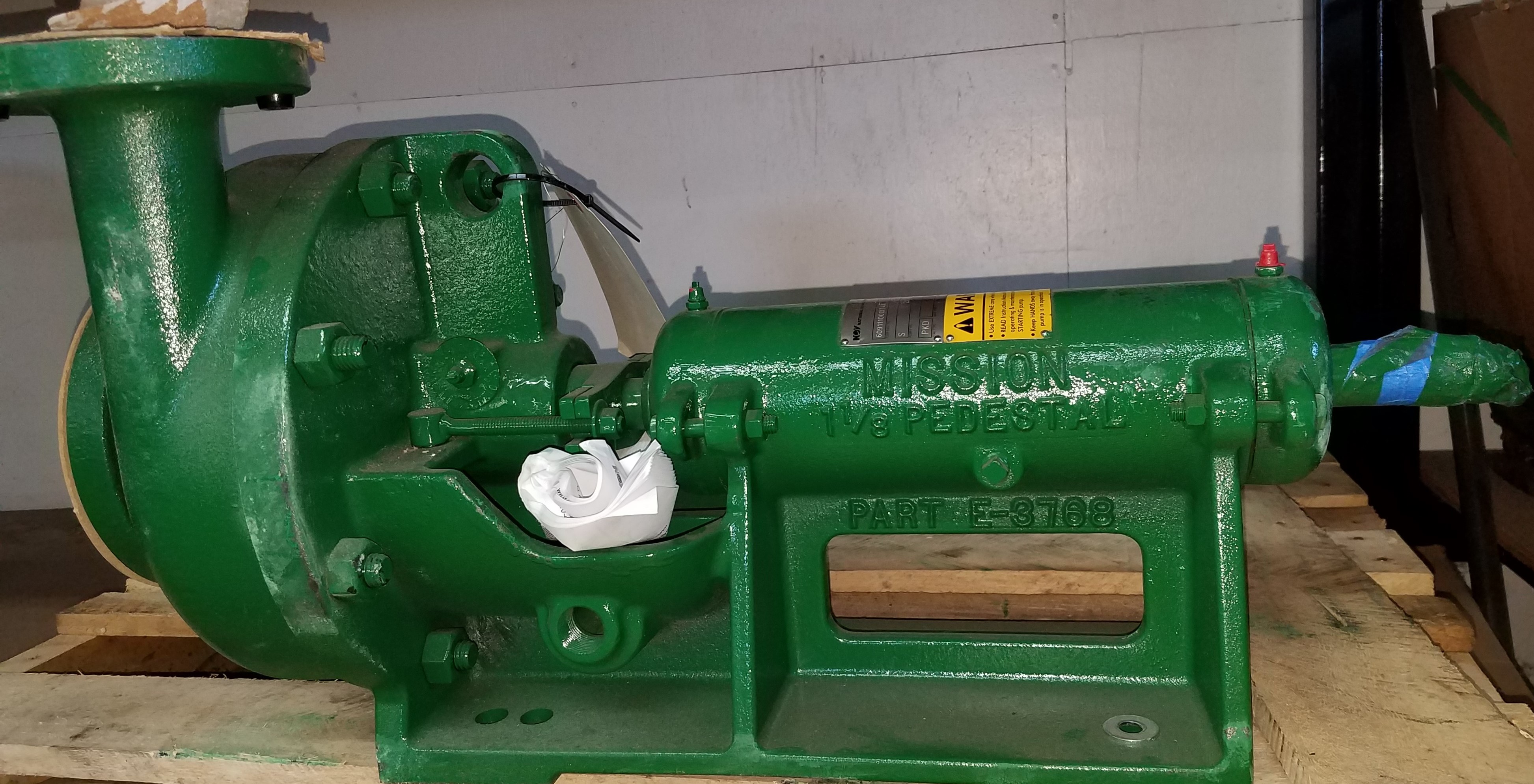

mission mud pump parts brands

A part of National Oilwell Varco, the Mission line of centrifugal pumps are equipped with innovative features to match the demanding nature of routine, corrosive and abrasive applications. Because of the need for a low pressure mud system, Mission 1780 Type W centrifugal pumps were introduced in 1950s to replace duplex pumps. The aim was to apply a high quality centrifugal pump with concentric systems that allowed for abrasive fluids to be mixed and transferred thereby lowering the initial and maintenance costs of drilling. As a result, centrifugal pumps with low pressure mud systems such as Mission 1780 Type W became the industry standard.

As well depths increased, so was the need for heavier mud weights and centrifugal pumps that could withstand greater horsepower load. This led to the launch of Mission Magnum- a centrifugal pump.

The Magnum has an open impeller design that contains wide-tipped vanes and a more tangential circumference of the suction allowing the pump to create a smoother flow pattern when handling abrasive fluids. The Magnum is available in Magnachrome™, hard iron, stainless steel, and aluminum bronze fluid ends. The pumps can be unitized with electric motors, diesel engines, and hydraulic motors (horizontal, vertical, or close-coupled configuration).

Our pump engineering experts have the industry knowledge to gladly assist you with any questions, concerns, or inquiries you may have regarding the pumps & pump parts we distribute @ 800.560.7867.

Mission Pump Casing provided with replaceable casing wear pad on 3x2x13, 4x3x13, 5x4x14, 6x5x11, 6x5x14, 8x6x11, 8x6x14 and 10x8x14 Centrifugal Pumps.

BETTER designs and produces series of heavy-duty centrifugal pumps which is equivalent to all kinds of foreign major brand design, basing on the introduced brand drawings and samples. Though our pump’s function is similar as most of factories made in China, but why we gave up the domestic common design to build a new line:

1.Mission centrifugal pump line has proven to be the best centrifugal design for handling abrasive mud to compare with other brand centrifugal pumps made in China;

2.Foreign design pumps deliver superior performance, better longevity, and these pump line offers a broad selection of innovative features for a variety of routine, demanding, abrasive and corrosive applications;

All BETTER pumps are build using the excellent quality components, and its parts are 100& identical in all dimensions to Mission™ Magnum™, 2500 supreme™, Halco™ 2500, SPD™ Baker™ Mud Hog™ 2.5, MCM™ 250 series, Double life™ 250, Derick Premium™ 250, XBSY™/Victory/Westpetro, TSC™/HCP, Mattco™, Cobra Pump, Harrisburg™, and Dragon™ 250, etc.

•Applied in Barite, ferric oxide, mineral oil, base drilling mud, glass fibers, sugar processing, Ash or coal conveyers, cement, mine de-watering, lime slurries, kaolin clay, crystalline forms;

During the 1950’s the Mission” 1780 type “W” pumps were introduced to replace duplex pumps while creating the first low pressure mud system. The use of a high quality concentric type centrifugal pump allowed abrasive fluids to be mixed and transferred while reducing initial and maintenance costs for the drilling industry. The low-pressure mud system with Mission 1 780 Type “W” centrifugal pumps became the industry standard.

As well depths increased so did the need for heavier mud weights. When the mud weight began exceeding 14 ppg the need for a pump that could withstand greater horsepower loads arose. During the 1970’s Mission organized a design team that engineered the Mission Magnum. The Magnum was designed to have the same footprint, flange locations, and drive shaft diameter as the 1780 “W”. This allowed a 1780 to be replaced by a Magnum without any skid modifications. The Magnums were originally engineered with a 2-1/2″ shaft (3″ between the bearings), double row bearings with an engineered life of over 2 years at 200 HP, larger impellers and heavier frames. The Magnum allowed drilling contractors to upgrade their centrifugal pumps and mix heavier fluids.

The National Oilwell Varco” Mission centrifugal pump line has proven to be the best centrifugal design for handling abrasive mud. This pump line offers a broad selection of innovative features for a variety of routine, demanding, abrasive and corrosive applications. These pumps are designed for a wide range of flow rates, from a few gallons per minute to thousands of gallons per minute.

Each pump contains the finest materials, engineering and craftsmanship available in the industry. Described are like features of these pump lines and unique features are described on the following pages.

National Oilwell Varco utilizes unique design features developed for slurries. Three major differences from most pump designs include the concentric casing, wider impellers and increased re-circulation areas. Each feature contributes to reducing wear when handling abrasive fluids.

All of the pumps feature a concentric casing. This casing averages 37% thicker than conventional pump casings, and up to 50% thicker for the larger, mud pumping models. They are pressure rated at 1 .5 times the flange rating and are designed with a 1 /8″ erosion allowance. The concentric style casing has proven to offer the greatest pump life and reduced downtime. The walls of a concentric style casing are an equal distance from the impeller throughout the impeller circumference, which results in a smooth flow pattern. A volute style casing has a cutwater point that disturbs the fluid flow pattern creating an eddy. The concentric casing eliminates vibration, turbulence and aeration that is caused by the cutwater point in conventional volute pumps. It also reduces the high bearing loads and shaft deflection even at near shutoff flows.

The shaft is much larger in diameter than conventional pump shafts for heavy-duty performance, minimum deflection and increased operating life of the seal or packing. With a 2-1/2″ diameter at the seal area and 3″ diameter between the bearings these pumps can be direct connected or belt driven.

We provide oilfield spares and spare parts for many major U.S. manufacturers and equipment, including: Airesearch, Elliott, Emerson Process, Continental Emsco Mud Pumps, Gardner Denver Triplex Pumps, Gaso Mud Pumps , Garrett, Harrisburg , Centrifugal Pump, Honeywell, Mission Centrifugal mud pumps, Mud Pump Expendables, National Mud Pump , NOV, Pratt & Whitney, Trico, Rosemount Analytical, Union Pump, Varco, Veritrak, Web Wilson, Wilson Snyder, Wheatley Mud Pumps, and Westinghouse Transmitters and obsolete and hard to source items.

From annular blowout preventer’s parts to RAM BOPs, from mud pump parts to Drawworks spares our goal is to provide our customers with the best quality and value in aftermarket, OEM, and reverse engineered replacement parts for such commodities as oil field equipment, refineries, and pipelines.

Titan Oil Tools understands our customer"s critical need for high-quality USA made oil tools and parts, delivered on time, when and where you need them. Titan Oil Tools will provide the highest quality oil tools and oilfield parts and equipment made in the USA. We offer a complete line of oilfield supplies; equivalent repair parts and used equipment for Garret, Mission, Elliott, Varco, Airesearch, Continental, Guiberson type replacement parts and more.

Mud Pump Spares; Mud Pump Consumables - "L" Modules - We sell high quality mud pumps spares, mud pump parts, and mud pump expendables including; mud pump liners and mud pumps pistons. They are competitively priced and have an outstanding service life. Manufactures include; Brewster, Continental Emsco, Ellis Williams, Gaso, Gardner Denver, IDECO, National, Oilwell, OPI, Wheatley, and Wilson.

Mission type mud pump liners. We are one of the few companies worldwide specializing in; and stocking “Mission” type high temperature mud pump liners. Our "Mission" type liners are formulated with two rare metals not found in common everyday liners. All of our "Mission" type mud pump liners include the seal ring and are individually packed for immediate export, offshore or domestic oilfield use. Manufactured to OEM specifications, our Mission type Discharge Module and Mission type Suction Module come complete with studs and nuts installed.

Titan Oil Tools is major supplier of expendables for mud pumps. We stock pistons, seats, valves for popular brand duplex mud pump parts and triplex mud pump parts. Call us for all your mud pump expendables.

We supply Wheatley mud pump parts, Ideco mud pump parts, Emsco mud pump spares and Gardner Denver mud pump parts and many more manufacturers. Call us for quality and the best prices.

Mission “L” Module for A-1400-PT / A-1700PT Fluid End Module. Manufactured to OEM specifications, our Mission type Discharge Module and Mission type Suction Module come complete with studs and nuts installed.

We supply quality swabbing equipment which may include the swabbing assembly, shut-off valve on the well, also called a swabbing valve and also the lubricator. Parts may include Guiberson style oil tools replacement parts under the Titan name. Titan brand has equal specifications to Guiberson oil tools and is made in the USA. We can provide replacements for Guiberson Rope Sockets, Guiberson Hydraulic Oil Savers, Guiberson Safety Tools, Guiberson Sinker Bars, and Guiberson Tubular Jars.

Blowout preventer parts, Blowout preventer spares and blowout preventer replacement parts made in the USA. Our BOP parts , BOP spares, feature outstanding quality. We have Cameron BOP parts, Hydril BOP parts and Shaffer BOP parts.

Downhole tools for high-performance torque reduction and hole enlargement. These tools also will provide a major resistance reduction. Call us for genuine GE drilling motors, motor optimizers, mud motors, shock subs, drilling jars, downhole tool data loggers and more.

Elliott steam turbine parts have a reputation as one of the most reliable and versatile in the industry. Elliott steam turbine parts have rugged designs and are built to perform for years of reliable service. Steam turbines have extreme value and work well in a broad range of mechanical and power generation applications, around the world 24X 7 365 days per week.

OIlfield supply parts include: Hydraulic gate valves, hydraulic check valves, blowout preventer parts, BOP parts, mud pump parts, mud pump spares, drawworks parts, drawworks tubing drum, drawworks bearings, drawworks seals.

Need Shaffer BOP parts or USA equivalents, then call Titan Oil Tools. If we do not have what you need in stock we will get it for your Shaffer LWS BOP parts quickly. Buy seal kits, sealing parts, rings, pistons and more for Shaffer LWS BOP.

Cameron BOP parts or USA equivalents are field-replaceable and the system may be field removed change-out without removing the BOP from the stack. Call for parts needed for the BOP Stack, Choke Manifold, BOP Control Systems, and Pressure Gauges.

We sell only the best quality, high durability valve parts for Cameron Valves. All of our Cameron valve parts are made in the USA. Our valve spares offer exceptional quality and peformance.

Hydril invented the first hydraulically operated BOP in about 1933 and has been making innovations since that time call us for Hydril Blowout preventer parts and Hydril BOP parts.Call us for Hydril Annular BOP parts or USA equivalents, Hydril Type Ram BOP parts or USA equivalents.

Titan Oil Tools can provide AiResearch gas turbine parts and AiResearch gas turbine industrial turbochargers. Make your gas turbine the most efficient combustion turbine with our AiResearch turbochargers and gas turbine parts. AiResearch Gas turbine turbocharger parts achieve a higher degree of efficiency than other types of gas turbines.

We are your source to get Garrett turbine parts and Garrett gas turbine parts. We specialize in industrial Garrett turbine components that will improve the operating quality of your operations. Call if you need help for your Garrett turbine.

An easily removable stuffing box allows these pumps to be customized to meet customer needs. The different options available are stuffing boxes to accommodate:

Compact dimension design make the fracking pump ideal for mobile or stationary applications. All the pump fuild ends spare parts are made of hard iron or high chrome , ASTM532, Class III, Type A, with hardness 65HRC, ensures the pump maximum life time. The Magnum XP pumps can deliver flow rates from 3000 - 7500 gpm at 75 - 410 feet of head at low speeds. The compact overall dimensions of the MAGNUM XP make it an excellent choice for high volume mobile and stationary applications where a small footprint is critical.

Rig Parts Oilfield Supply Co., Ltd ( RPS ) is committed to providing the world with the best drilling equipments and services at the best prices, especially mud pump and parts, plunger pump parts, handling tools and solid control equipments.

Mission pump rebuild kits built by Mesco Corporation to manufacturer’s specifications. Contact Mesco directly for questions on model numbers and installation. We keep all of these Mission Pump Seal Kits and parts in stock.

8613371530291

8613371530291