mud pump impeller manufacturer

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

You can use impeller for mud pump to pump liquids in different fields such as the pharmaceutical sector, perfume productions, dairy production, canning sector, and a lot more. You should select the centrifugal pump impeller depending on the engine power. You also use motor impellers as distributors.

Pool impellers are ideal for pumping emulsions, as they can contain the small particles found in liquids. The impeller blade is connected to the adapter shaft and has a separate hole for liquid suction. The axial flow impeller is another variant that you can find in our collection of wholesale impeller for mud pump. This type of impeller provides you with top to bottom circulation, and with most energy being converted into a flow.

The available options and applications of impeller for mud pump are countless. You can select jet impellers to equip your water transport units (e.g., jet skis) with high-performance water pumping engines. Or you can go for flexible impeller pumps that can be used under different conditions and environments.

Our selection also includes solutions for people wanting to clean their pool with efficiency and less effort. The pump impellers for pool cleaning are made of sturdy materials which provides them with waterproof and wear resistance capabilities. No matter what you are searching for, you will find the right product that meets your needs at Alibaba.com!

You can use centrifugal mud pump impeller to pump liquids in different fields such as the pharmaceutical sector, perfume productions, dairy production, canning sector, and a lot more. You should select the centrifugal pump impeller depending on the engine power. You also use motor impellers as distributors.

Pool impellers are ideal for pumping emulsions, as they can contain the small particles found in liquids. The impeller blade is connected to the adapter shaft and has a separate hole for liquid suction. The axial flow impeller is another variant that you can find in our collection of wholesale centrifugal mud pump impeller. This type of impeller provides you with top to bottom circulation, and with most energy being converted into a flow.

The available options and applications of centrifugal mud pump impeller are countless. You can select jet impellers to equip your water transport units (e.g., jet skis) with high-performance water pumping engines. Or you can go for flexible impeller pumps that can be used under different conditions and environments.

Our selection also includes solutions for people wanting to clean their pool with efficiency and less effort. The pump impellers for pool cleaning are made of sturdy materials which provides them with waterproof and wear resistance capabilities. No matter what you are searching for, you will find the right product that meets your needs at Alibaba.com!

Founded in the year 1980 as aSole Proprietorship firm at Meerut (Uttar Pradesh, India), we “Khanna Impellers” are the renowned manufacturer and traderof Pump Impeller, Engine Impeller, Sewage Pump Impeller,Industrial Pump Impeller, Multistage Pump Impeller, Commet Type Impeller, Monoblock Pump Impeller, Openwell Impeller, Single Phase Pump Impeller, Centrifugal Pump Impellerand much more.We have established ourselves as one of India"s major impeller manufacturers. Today, our company is a pioneer and has retained its leadership position in producing impellers. Offered products are well-known for features like high strength, durability, and fine finish. Under the able guidance of“Mr. Akshay Khanna" (Director), we have attained an outstanding position in this industry.

Founded in the year 1980 as aSole Proprietorship firm at Meerut (Uttar Pradesh, India), we “Khanna Impellers” are the renowned manufacturer and traderof Pump Impeller, Engine Impeller, Sewage Pump Impeller,Industrial Pump Impeller, Multistage Pump Impeller, Commet Type Impeller, Monoblock Pump Impeller, Openwell Impeller, Single Phase Pump Impeller, Centrifugal Pump Impellerand much more.We have established ourselves as one of India"s major impeller manufacturers. Today, our company is a pioneer and has retained its leadership position in producing impellers. Offered products are well-known for features like high strength, durability, and fine finish. Under the able guidance of“Mr. Akshay Khanna" (Director), we have attained an outstanding position in this industry.

Our corporation puts emphasis about the administration, the introduction of talented staff, plus the construction of team building, attempting hard to improve the quality and liability consciousness of team members. Our organization successfully attained IS9001 Certification and European CE Certification of China Mud Pump Impeller Manufacturers and Suppliers - Factory Pricelist | YAAO, Centrifugal Mine Slurry Pump Parts, Slurry Pump Liners, Centrifugal Pump Parts,Slurry Pump Liner. We have been pretty proud of your superior standing from our shoppers for our products" trustworthy quality. The product will supply to all over the world, such as Europe, America, Australia,Birmingham, New York,Sacramento, Philadelphia.With the intensified strength and more reliable credit, we are here to serve our customers by providing the highest quality and service, and we sincerely appreciate your support. We will endeavor to maintain our great reputation as the best products supplier in the world. If you have any questions or comments, please contact with us freely.

The "VIRAJ" make "VSPM" series is designed in self priming Non-clog Horizontal pump of Mono Block and only pump construction. This series pumps available with semi open type impeller s per customer application. This pump future is quick self priming action, long life due to replaceable wearing parts and for priming no need foot valve and easy maintenance and spare available.

Our clients can avail from us Self Priming Mud Pump that comes with self priming action, which ensures easy maintenance. These are durable, cost effective and also provided with non-clogging impeller to handle suspended solids. Designed using latest technology, these pump optimum performance and are used in steel & thermal plants.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

The FM"s line of rotors and propellers for pumps offers durability and reliability for various applications. They are designed for high resistance to heat, out of thermoplastic material, guaranteeing efficiency in very ...

This slurry pump impeller from Excellence is designed to be an abrasion resistant unit. It is manufactured in accordance with hydraulic theories to provide operators with a long operational life. This ...

Our 20,000 sq.m production facility in China has designed and manufactured solely quality and specialty pumps for oil exploration and refinery sin1992

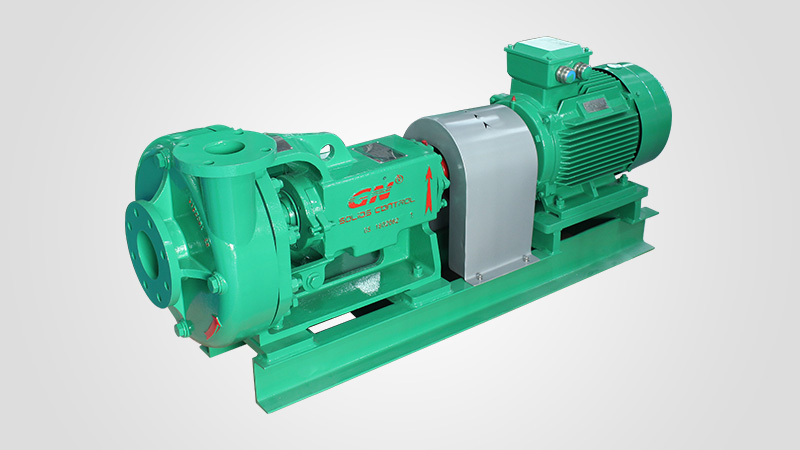

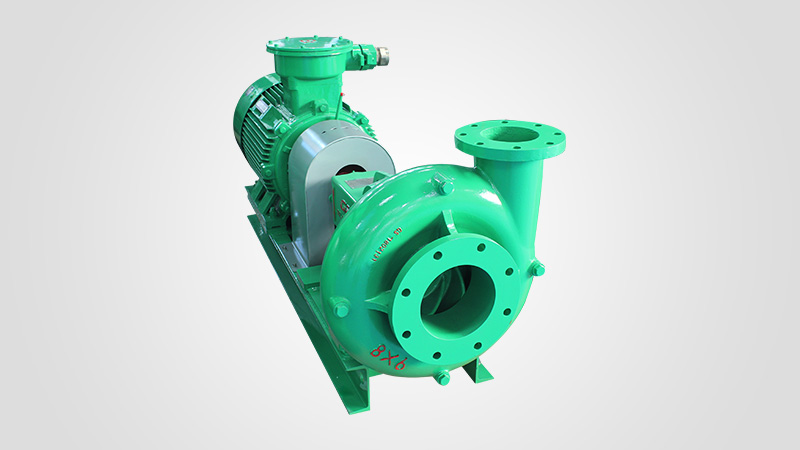

GNSB Series Centrifugal pump is used for transferring slurry or mud or water. It can be used as feeding pump for desander, desilter, or used as mixing pump for Jet Mud Mixer. Also it can be used as trip pump, and supercharging pump for rig mud pump. All GN model centrifugal pump use tungsten carbide mechanical seal, with famous brand Bearing. And spare parts interchangeable with most of the international Brand pump which helps customer to source spare parts easily. Open impeller design that lowers axial thrust loads, and make it easier for installation, repair and maintenance.

The skid for supporting pump and motor is made from casting instead of welding to provide reliable operation and less vibration in a result to extend the pump and motor life.

GN Centrifugal pump has been exported to many overseas countries. The reliable quality and cost effective solutions has helped GN Solids Control to win many orders of centrifugal pump from the world. With our branches and partners around the world, clients can get GN centrifugal pump and parts from local warehouses to save delivery time.

Serving a multitude of industrial engineering sectors, as well as the global horticulture, shipbuilding, water treatment and automotive markets, Johnson Pump has always put customer needs first. Supplying an expansive portfolio of pumps (based on positive displacement and centrifugal mechanisms), plus all the necessary accessories. Through close interaction with the global customer base, Johnson Pump is able to provide focused solutions that exactly match specific application requirements. This is facilitated by our modular approach to design - which allows greater interchangeability between component parts, thereby simplifying logistical aspects (thanks to the ordering and storing of fewer part numbers) and allowing a wider array of different pump variants to be covered using a smaller inventory. The Johnson Pump portfolio covers internal gear pumps, impeller pumps and circulation pumps. All of these items deliver strong performance and continued reliability. The Johnson Pump engineering team designs low noise operating equipment, and engineered coatings to protect against debris damage.

Plug in without having to worry about overheating. Built-in contactor and thermal sensors protect the motor from overheating. Pumps with a built-in AquaTronic unit will adjust electronically for incorrect phase order, ensuring correct impeller rotation.

The XJS is perfect for pumping sludge and water mixed with solids as it is equipped with a free-flow vortex impeller and a pump volute. The pump design, the robust construction and the premium materials ensure high wear resistance, and the impeller is available in different sizes to meet your specific requirements.

The modular design of the pump range reduces costs by ensuring maximum pump availability with a smaller spare parts inventory. The condition of a pump with a built-in AquaTronic unit can be rapidly checked without disassembly, using its service software.

8613371530291

8613371530291