mud pump strainer manufacturer

Explore a wide variety of pump strainer mud pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These pump strainer mud pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these pump strainer mud pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right pump strainer mud pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of pump strainer mud pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

1-1/2 inch FNPT Suction Strainer with 1/2 inch round holes. 1.5" Irrigation or sprinkler pump strainer. Also comes in the 1/8" size holes SRHS-200-SM Zinc plated steel. Good for use with sprinkler pumps, irrigation pumps and other centrifugal and semi-trash pumps which can accept limited debris.

These zinc plated round hole strainers can be used with all popular makes of centrifugal pumps for use with hoses and pipes. Drop in to liquid to be suctioned. An "open" area of 50% allows filtering out large damaging debris, yet permits sufficient water passage to keep pumps functioning at full capacity.

For Top Hole skimmer strainers see SSKS-TH or SSKS-BH for Bottom Hole series or SRHS for barrel suction strainers. Image tab belows shows some of the various strainers available from PumpBiz. Please let us know if you do not see what you are looking for or for complete hose kits.

.jpg)

... Model 92 strainer is a device temporarily installed in a pipeline to remove sediment and debris from fluids. It is used for piping start-up applications only.It accomplishes straining by directing the fluid through sized ...

... RSW refrigerant strainers collect foreign materials and dirt in a refrigerant system at minimal pressure drop in order to minimize damage to or prevent malfunction of control valves.

MAT POOL TECHNOLOGY manufactures its own pump strainer for swimming pools and waterparks to provide efficient flow rate without cavitation while at the same ...

A strainer is often used in tubes to block unwanted particles or dirt that would otherwise damage downstream equipment. Cleaning is carried out by removing the strainer ...

Cast Y Strainer take their name from their configuration. They are most commonly used in pressurized lines, gas or liquid, but can also be used in suction or vacauum conditions. They are intended for application where ...

The ST10 Strainer’s filter features a metallic mesh, which was designed to prevent solid impurities from entering into the piping and, by depositing residues, reducing the width of the passage, thus increasing losses ...

The new solution “asa-strainer-adapter” is another combination of functions. It is a simple and clever solution to create a flange connection on the tank with a suction strainer at the same time. The ...

Strainer basket without non-return valve, with plug-type or flange connection for basin and chamber installation. Suitable for use in water-treatment applications. Product features and benefits- Low friction loss- ...

... arm drop tube can be provided with a cast aluminum suction strainer when unloading tank cars. Helps prevent scale and other foreign objects from being sucked into line.

With a positive and progressive attitude to customer"s interest, our enterprise continually improves our products excellent to meet the wants of customers and further focuses on safety, reliability, environmental requirements, and innovation of Mud Pump Strainer, , , , We have been normally seeking forward to forming profitable company relationships with new clientele around the environment.

The NOV 12-P-160 Mud Pumps includes (3) Three New National 12-P-160 Triplex Mud Pumps 1600 HP, 7-1/4″ bore x 12″ stroke, single acting. 5000 PSI fluid ends. 1600 HP Bare Mud Pumps are currently configured for Offshore Service. The NOV 12-P-160 Mud Pumps are located in Houston and ready to be unitized for service.

Forged Steel crankshaft, Individual forged steel two piece interchangeable standard modules, 6-1/2” mission fluid king liners, Standard polyurethane valves and seats, Two piece fast change piston rods, Supreme pistons, Metal to metal liner retention, Clamp type liner and piston rod connections, Fast change valve covers standard, Piston liner lubricant spray system, Liner spray pump, Power end lube system with filter. Mounted on Integral two runner skid, Suction Manifold with vertical suction stabilizer, Suction line pressure relief valve, set for 70 PSI

Includes: motor supports, motor frame, tensioning screws, 2 V-belt guards, 2 pump Sheaves, 2 motor sheaves, banded V-belts, Holes to be drilled to accept EDM D79 Or GE-752 Traction Motors

Flange-blind, National, #5912392, for Strainer cleanout, 5-1/8”, 5000PSI, API 6BX blind flange, BX-169, API 60K Material, 4130 steel, PSL-1, T/C-U, M/C-DD

National Oilwell Varco (NOV) is an American multinational corporation based in Houston, Texas. It is a leading worldwide provider of equipment and components used in oil and gas drilling and production operations, oilfield services, and supply chain integration services to the upstream oil and gas industry. The company conducts operations in more than 600 locations across six continents, operating through three reporting segments: Rig Technologies, Wellbore Technologies, and Completion & Production Solutions. National Oilwell’s two main predecessors, Oilwell Supply and National Supply, were founded in 1862 and 1893, respectively. These two companies manufactured and distributed pumps and derricks.

One of the most important pieces of equipment in many different industries is the filtration system. Within each filtration system are a number of moving parts, which must all work together to ensure the system operates efficiently. Two parts that rely on each other the most are pumps and strainers. As the pump works, the strainer is in place to capture debris to ensure the pump can continue to function as designed.

Typically, when one refers to a hydraulic pump strainer, they are referring to a mesh strainer that is used as a filter at the pump inlet. The purpose of this strainer is to filter contaminants out of the hydraulic fluid as it approaches the suction side of the pump. These relatively coarse filters (about 140 microns) screw onto the pump intake, which is located inside the hydraulic reservoir.

Like we said above, the main purpose of a strainer is to filter out any solid contaminants from hydraulic fluid. If contaminants are left unfiltered, they can damage components of the pump. When the pump is damaged it can lead to lower system efficiency and a shortened lifespan.

That being said, picking the incorrect strainer for your system can also damage the pump. When selecting a strainer, it’s important to first consult the manufacturer recommendations. You also need to ensure you’ve selected the right sized filter, and one that meets your systems pressure and flow requirements. If your strainer fails to meet those requirements, you could potentially cause irreversible damage to your system.

The positioning of your strainer first and foremost depends on the type of strainer your system requires. The two most common types are pump suction strainers and inline filters. Pump suction strainers are a coarse mesh strainer that is used to collect large participles from entering the pump. They are installed at the suction inlet of the pump. Inline filters, sometimes called return line filters or spin-on filters, are installed in the fluid return line. This filter allows for a finer filtration of particles than the pump suction strainer and results in a highly efficient filtration system. Inline filters are not installed on the suction side of the pump because this can cause pump failure from high differential pressure.

Most pumps are designed to handle some number of solids, and the manufacturer can advise you on what size particles your pump can handle and may even have a suggestion on what filtration type is best for the system. Ultimately, the positioning of your strainer will depend on what type of system you have and how fine of a filtration you require.

While the strainer is an important part of a filtration system, there are instances where strainers are unnecessary. If the hydraulic fluid being placed into the system has already been filtered, it is unnecessary for it to be filtered again within the system. Additionally, some new hydraulic systems do not even require a strainer as the updated design minimizes the chance of debris. Though, if proper maintenance isn’t done on the system you could still experience pump damage.

There’s no other way to argue it: strainers are important to a pump system. It’s the choice of a strainer and the positioning of that strainer that can be up for debate sometimes. If you’re questioning where to place a strainer in your system, or what strainer to use, first consult the manufacturer for their recommendations. If you still have questions after that, consult a qualified suction strainer/filter designer.

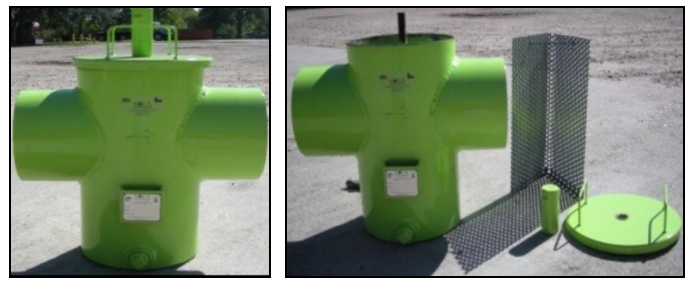

Kingwell are able to supply discharge strainer assy- the output end of the mud pump final pressure medium, whose hosing is of high corrosion resistance, wide range of heat-resistant and high intensity.

1). Technical Support and Production Ability: Although we are one relatively new company, but we have the most professional engineers with tens of years experience in mud pump. And we have hundreds of highly skilled workers working on the pump parts and pump assembling with numerous advanced machines. Our production ability has been siteaudited by supervising inspectorate like France BV (Bureau Veritas), DNV(Det Norske Veritas) and SGS-CSTC(Standards Technical Services Co., Ltd.)

2). Quality Assurance: Ten professional inspectors performstrict quality inspection from the initial forgings, castings, other rawmaterials, each finished machined parts until the final assembling of the pump. Each part assembled on the pump will be well tested and highly qualified. Andfor each pump finished, it will be running tested in our test center for atleast 4 hours. Quality certificate, Inspection report and testing report will beattached when pump is delivered. 12 Months quality guarantee will be offered for each pump.

3). Competitive Price: We are one of the top pump manufacturers in China. We have the greatest advantages in price. We can not offer you the lowest price in China, but most competitive price but with very good quality.

4). Quick Delivery: Usually we will keep some pump model in stock so that we can make fast delivery for clients with urgent need. For pump we do not have in stock, we can also deliver with 40 days.

Drilling consumables such as mud pump systems and their components can drastically increase your uptime while reducing costs and health/safety/environmental (HSE) risks. To support your drilling needs, Forum’s patented P-Quip® mud pump system offers a single-source solution that integrates high-quality fluid end components for maximum longevity and performance.

With more than 20 years of successful operation in severe environments, P-Quip offers a proven track record for the lowest cost of ownership in the industry. As part of our commitment to quality, our mud pump parts use patented Banded Bore™ technology that significantly reduces stress concentrations and leads to longer module life.

Our range of products include hydraulic suction strainer, steel nut suction strainer, nylon suction strainer, big suction strainer, tank mounted reusable strainers and tank mounted suction strainers.

Size/Dimension1/4" TO 3"Protecting hydraulic pumps and control systems from solid contaminants,Hydraulic Suction Strainer are gaining immense popularity in the market. The construction of the strainers is done in such a manner that these can be easily installed into suction lines of pumps. We always advise our clients to install the suction strainer below the minimum oil level of the reservoir. Unlike the ordinary strainers, our range of suction strainer elements are supplied with a bypass valve so that the high pressure drops caused by contaminated elements or high viscosity fluids during cold starting can be easily reduced.

We are amongst the leading manufacturers of Steel Nut Suction Strainerwhich is made available in different sizes. It is similar to aluminum and plastic nut strainer. It helps in protecting hydraulic pumps and control systems from solid contaminants. It is highly popular among our clients and manufactured as per industrial standards. It is easy to install and requires low maintenance.

Country of OriginMade in IndiaBeing the leading names in industry we are into manufacturing and supplying a quality range of Nylon Suction Strainer, These are made up of high quality raw materials. We ensure our ranges of raw materials used are of superior quality and durability.

Country of OriginMade in IndiaThese are Big Suction Strainer that screw in to reservoir suction pipes as large as six inch in diameter to handle flow rates as high as 600 GPM. Stainless steel wire screens as fine as 200 mesh and either male (Nipple) or female (coupling) connections may be ordered. Each flow size is offered in more than one length diameter ration size to better fit your available space. Standard Big strainers are made with mild steel support tubes, caps and fitting and they are epoxy bonded for leak- proof service.

Country of OriginMade in IndiaWe are reckoned as prominent manufacturer and supplier of best in class Tank Mounted Reusable Strainers. We have developed a vast range of reusable suction strainers that are designed for low and medium pressure hydraulic system. This reusable suction strainer is recognized for its dirt holding performance, as we have used pleated stainless steel in 100 mesh standard to fabricate it. Further, these strainers are equipped with rust proof steel ‘O’ rings and can be ordered from us at the best price in the industry.

Country of OriginMade in IndiaWe have been counted as major manufacturer and supplier of finest quality Tank Mounted Suction Strainers. These strainers are widely demanded to separate the ferrous and non ferrous material in hydraulic systems. Designed with 100 mesh standard from stainless steel pleated media, the offered range is widely demanded in the marketplace for its superior performance. Further, these reusable strainers can be ordered from us with mild steel or cast iron bushings at the best price.

Country of OriginMade in IndiaWe are known name in manufacturing and supplying best qualityTank Mounted Reusable Suction Strainer. It is the best suited solution for hydraulic filtration and widely demanded for oils, chemicals and water reservoirs. The offered range of reusable suction strainers is developed with superior quality stainless steel pleated media with steel hose barb fitting. Our prestigious clients can avail its reliable performance from us at the best price in the industry.

Country of OriginMade in IndiaTank Mounted Strainer (either suction or return) can be installed through a tank top by welding a standard bell reducer (coupling) over a hole cut in the top.A standpipe, threaded into the coupling, need be only long enough to stay below the lowest fluid level encountered .The strainer may be removed for servicing without draining the tank tank-mounted strainers and diffusers install through the side wall, or through the hole in which they are mounted, and access to the tank interior is three styles: for suction straining, return –line straining, or return-line diffusion. Diffusers have no wire cloth elements and pump cavitations caused by flow disturbance at the pump inlet.

We are offering a premium range of Suction Strainer that are extensively used for diverse applications, including fire fighting. These are ideal for filtering fluids and protect the equipment from getting clogged and prevent break-down. These can be used over and over again after cleaning with a suitable cleaner solution. We, Fluid Power Engineers take utmost care to produce these by using the highest-grade raw materials and by rigorously checking for quality norms. These are offered at industry leading prices to our valued customers.

Country of OriginMade in IndiaWe offer to our client a wide range ofSump Strainers. which is made available in different sizes. It is similar to aluminium and plastic nut strainer. It helps in protecting hydraulic pumps and control systems from solid contaminants.

Kraissl pipeline strainers and filters protect pumps, engines, nozzles, valves, heat exchangers and other expensive pipeline equipment from harmful flow contaminated by catching dirt and debris. These non-ferrous models are commonly specified for cooling water.

Our product lines of cast iron, bronze, aluminum, steel and stainless steel simplex and duplex strainers and filters, including flanged, NPT and weld-end models are covered in separate bulletins. Units can also be furnished in other special metals and higher pressure and temperature ratings.

8613371530291

8613371530291