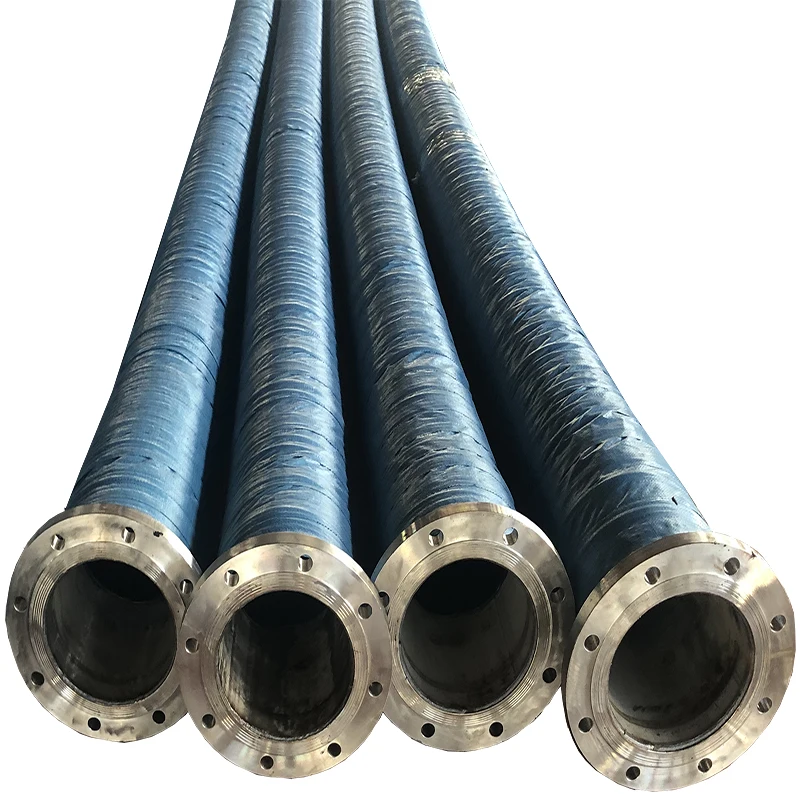

mud pump suction hose free sample

523 mud pump hose products are offered for sale by suppliers on Alibaba.comAbout 52% % of these are rubber hoses, 18%% are pumps, and 1%% are mud pump.

A wide variety of mud pump hose options are available to you, You can also choose from cutting, moulding mud pump hose,as well as from wastewater treatment, machining, and biofuel industry mud pump hose,And whether mud pump hose is low pressure, {2}, or {3}.

Explore a wide variety of mud pump suction hose on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These mud pump suction hose are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these mud pump suction hose is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right mud pump suction hose for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of mud pump suction hose to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

A well-placed suction stabilizer can also prevent pump chatter. Pump chatter occurs when energy is exchanged between the quick opening and closing of the reciprocating pump’s valves and the hammer effect from the centrifugal pump. Pump isolation with suction stabilizers is achieved when the charge pumps are isolated from reciprocating pumps and vice versa. The results are a smooth flow of pumped media devoid of agitating energies present in the pumped fluid.

Suction stabilizer units can mitigate most of the challenges related to pulsations or pressure surges, even in the most complex piping conditions. The resulting benefits prevent expensive unplanned downtime and decrease costs and inconvenience associated with system replacements and repairs.

I’ve run into several instances of insufficient suction stabilization on rigs where a “standpipe” is installed off the suction manifold. The thought behind this design was to create a gas-over-fluid column for the reciprocating pump and eliminate cavitation.

When the standpipe is installed on the suction manifold’s deadhead side, there’s little opportunity to get fluid into all the cylinders to prevent cavitation. Also, the reciprocating pump and charge pump are not isolated.

Installing a suction stabilizer from the suction manifold port supports the manifold’s capacity to pull adequate fluid and eliminates the chance of manifold fluid deficiency, which ultimately prevents cavitation.

Another benefit of installing a suction stabilizer is eliminating the negative energies in fluids caused by the water hammer effect from valves quickly closing and opening.

The suction stabilizer’s compressible feature is designed to absorb the negative energies and promote smooth fluid flow. As a result, pump isolation is achieved between the charge pump and the reciprocating pump.

The isolation eliminates pump chatter, and because the reciprocating pump’s negative energies never reach the charge pump, the pump’s expendable life is extended.

Investing in suction stabilizers will ensure your pumps operate consistently and efficiently. They can also prevent most challenges related to pressure surges or pulsations in the most difficult piping environments.

Sigma Drilling Technologies’ Charge Free Suction Stabilizer is recommended for installation. If rigs have gas-charged cartridges installed in the suction stabilizers on the rig, another suggested upgrade is the Charge Free Conversion Kits.

Heavy wall thickness reinforced with multiple woven textile plies and static wire is used by HIC Universal in manufacturing drilling rotary hose pipe product, fully tested as per IS and international standards that covers full testing in well-equipped HIC’s Testing Laboratory and stamped with identification coding.

Warranty: Manufacturer warrantees mud pump hoses to be free from manufacturing defects and shall replace or repair if found defective in workmanship within 1 year from the date of shipment.

Roll Lengths manufactured are 3 meters Min. (= 9.85 feet Approx.) and 20 m Max up to 5inch Inner Diameter size hose. Above 125mm (=5”) NB, Max. Length produced is 10 meters.

…suction tube is 100 cm. Sampler for liquid samples from precisely pre-determined depth, with hand-operated vacuum pump. Sampling using vacuum pumps has the advantage that the liquid only comes into contact with the suction hose and the original sample bottle. Suction tube PP, suction hose PVC …

… Stainless steel pump valves; aluminum cylinder and piston parts Equipped with safety pressure relief valve, intake filter and moisture trap, vacuum and pressure gauges, serrated tubing connector on inlet and outlet and carrying handle. Mounted on rubber suction feet. UL approved. …

Non-rusting metal, with both suction tube and discharge end serrated, with check valve in suction tube Usable for high, low or fluctuating water pressures 3” long

…Our pump tubing is factory-tested and optically inspected to provide the best performance from your peristaltic pump. Our High-performance precision pump tubing features a thicker wall compared to our Precision pump tubing, making it the best choice for applications involving pressure, suction lift,…

…Knob Control, 1/4" O.D. Hose barb, 1/8" NPT Exhaust Adapter, Built in Silencer. Compatible with PILOT3000 and PILOT5000 Chemical Resistant Diaphragm Vacuum Pumps. Thomas No. 1162B33 PILOT Service Kit - Rubber Suction Cup Feet - compatible with PILOT3000 & PILOT5000

1/6 hp Submersible Utility pump with corrosion-resistant aluminum pump casting, continuous duty ?oil free” motor, bottom suction design with built-in strainer to eliminate internal damage from possible debris, removable filter screen for easy cleaning, and ¾? NPT discharge.

Humboldt Aspirator Filter Pumps offer excellent performance for vacuum filtrations under both high and low water pressure conditions. The pumps feature a ball-type, positive-action valve in the suction tube which prevents water backflow if the pressure is reduced.

1/3 hp Automatic Utility pump with durable reinforced thermoplastic pump casing, continuous duty ?oil free” motor, bottom suction design with built-in strainer to eliminate internal damage from possible debris, removable filter screen for easy cleaning, and 1-1/4? NPT discharge. SP33A features an…

1/4 hp Automatic Utility pump with corrosion-resistant aluminum pump casing, continuous duty ?oil free” motor, bottom suction design with built-in strainer to eliminate internal damage from possible debris, removable filter screen for easy cleaning, and ¾? NPT discharge. SP25A features an automatic…

1/2 hp Self Priming Utility pump constructed of durable cast iron with built-in suction check valve engineered to prime itself quickly once it has been filled with water, higher than NEMA standard service factor, dual compartment motor, semi-open, cast iron impeller.

…off the pump if the back pressure exceeds the magnetic force. Units operate on any line frequency from 25 to 66 Hz without a change in output or damage to the pump. Fully modular design allows for easy repair. Pumps can handle liquids with viscosities up to 400 cp and have a suction height of…

…Scroll pumps handle water vapor better than most types of pumps and make significantly less noise during operation. Silencer for Labconco Scroll Vacuum Pumps combines filtration efficiency with noise reduction. Prevents tip seal dust from contaminating environment. Silences irritating pump…

…Consider additional vacuum tubing Ideal for all those applications where non-pulsing suction is needed. Typical examples may be rotary evaporators, vacuum filtrations, (SPE), etc. Use of common water pumps is frequently prevented by a lack of adequate water mains pressure or by its high…

…aspirator Aspiration Degassing Vacuum drying Fume suction The PILOT3000 is equipped with a 1/7 hp motor and provides a maximum 20 L/min (115V/60Hz) of free air displacement and 22 in-Hg of maximum vacuum. The pump features a vacuum regulator with gauge to adjust and monitor…

Model PILOT5000 and PILOT5000C-02 diaphragm vacuum pump are durable and chemical resistant. All contact surfaces are PTFE coated. They come with a liquid inlet trap and vacuum regulator making it a perfect choice for vacuum filtration, desiccation, and other mid-range vacuum applications. The…

…recirculating chillers that offer outstanding performance and high reliability as well as quiet operation and ease-of-use. Powerful force/suction pump provides constant flow rates, while microprocessor PID controller gives you the ideal solution when you need precise temperature control or cooling…

The compact refrigerated and heating circulator HRC 2 control is renowned for its high energy efficiency, a working temperature range from -30°C to 100°C and a powerful and infinitely variable pressure and suction pump. The on-demand and speed-controlled compressor reduces noise and operating costs.

… An adjustable centrifugal pressure / suction pump with flow rate from 22-26 L/min; pressure flow 5.8-10.2 psi; suction flow 2.9-5.8 psi. M16x1 male pump connections with 8 and 12 mm hose barbs. The Smart Pump function automatically adjusts pump rate to compensate for increases in fluid…

…and instrument reading. RS232 port for external communication and Pt100 sensor connection for external monitoring and control. A 4-speed centrifugal pressure / suction pump provides 22-26 L/min flow with 5.8-10.2 psi pressure / 2.9-5.6 psi suction. Integrated programmer with 6 x 60 program steps.

…band limit, limit setting, co-speed factor and control dynamics. A variable speed pressure / suction pump provides strong circulation for internal or external applications; Pressure 3.5-13.3 PSI, Suction 0.4-5.8 PSI; 16-31 L/min. A built-in cooling coil enables counter cooling with tap water. Baths…

…speed pressure / suction pump provides strong circulation for internal or external applications; Pressure 3.5-13.3 PSI, Suction 0.4-5.8 PSI; 16-31 L/min. A built-in cooling coil enables counter cooling with tap water. Barbed fittings for 8 and 12 mm ID tubing are included (pump connections M16x1…

…control dynamics. A variable speed pressure / suction pump provides strong circulation for internal or external applications; Pressure 3.5-13.3 PSI, Suction 0.4-5.8 PSI; 16-31 L/min. Barbed fittings for 8 and 12 mm ID tubing are included (pump connections M16x1 male). All MAGIO systems…

Two-stage diaphragm pump is made from chemically-resistant materials Suction capacity of 1.0 m³/h The Rotavac Vario Tec achieves an ultimate vacuum of 12 mbar The Rotavac Vario Tec can be combined with a condenser Power input: 160 W, Weight: 4.3 kg Dimensions: 236 x 156 x…

…flow. Check valve prevents liquid from being drawn into plastic body. Separately housed suction and pressure pump has on/off switch and is connected to filler by two 1.3-m lengths of vinyl tubing. Provides suction to 412 inches Hg (15.2 kPa). Overall 114 x 89 x 64 mm high, mounted on rubber base.…

…and external applications. Models include a 4-speed centrifugal pressure/suction pump providing 22-26 L/min with pressures from 5.8-10.2 psi / suction from 2.9-5.8 psi. The smart-pump feature adjusts pump speed with changes to fluid viscosity. Units come with M16x1 male fittings with 8 and 12…

…liquids. The filling level in the reservoir can be clearly observed through the large, illuminated sight glass. The powerful pressure and suction pump enables the simultanous operation of several small applications as well as external applications in open bath vessels in combination with a level…

…pastes, mud, creams, oils. The sample is drawn in using the pump rod and directly conveyed to the sampling container. Easy cleaning for flawless sampling. Depending on the viscosity, the removable suction tip can be fitted with suction drills of 2 mm to 6 mm. Stainless steel AISI 316L…

…details and ergonomic shape. In contrast to other manual techniques, pipetus® junior enables the defined suctioning of the pipetting medium. A single press of the pump button suctions approximately 2mL in each case. Pressing it several times multiplies this volume. The hydrophobic PTFE diaphragm…

…suction height 5 m PTFE MiniSampler for ultra-pure sampling, max. suction height 5 m MiniSampler PE Ideal for general sampling from barrels, canisters, tanks etc. MiniSampler PE complete with accessories in transport case, contents: Vacuum pump, 10 PE bottles, 100 ml, 10 m PE suction…

…anti-static set should be used, see accessories. ProfiSampler aluminium, consisting of: Vacuum pump made of aluminium, with feet, venting valve and bottle thread GL 45 with glass bottle 500 ml, 5 suction tubes PA black, 220 cm long, electrically conductive, hose cutter, brass hose weight, 20…

…hand-operated vacuum pump. Sampling using vacuum pumps has the advantage that the liquid only comes into contact with the suction hose and the original sample bottle. Suction hose PVC, 2.50 m long Complete in a handy transport case incl. sample bottle PP 1000 ml, vacuum pump, universal…

…System Designed for use with existing vacuum supplies, individual diaphgragm pumps and house vacuum systems Include mechanical regulator to control vacuum supply to provide sufficient suction for aspiration or filtration, without evaporating the collecton fluid Flexible, integrated…

Cavitation is an undesirable condition that reduces pump efficiency and leads to excessive wear and damage to pump components. Factors that can contribute to cavitation, such as fluid velocity and pressure, can sometimes be attributed to an inadequate mud system design and/or the diminishing performance of the mud pump’s feed system.

When a mud pump has entered full cavitation, rig crews and field service technicians will see the equipment shaking and hear the pump “knocking,” which typically sounds like marbles and stones being thrown around inside the equipment. However, the process of cavitation starts long before audible signs reveal themselves – hence the name “the silent killer.”

Mild cavitation begins to occur when the mud pump is starved for fluid. While the pump itself may not be making noise, damage is still being done to the internal components of the fluid end. In the early stages, cavitation can damage a pump’s module, piston and valve assembly.

The imperceptible but intense shock waves generated by cavitation travel directly from the fluid end to the pump’s power end, causing premature vibrational damage to the crosshead slides. The vibrations are then passed onto the shaft, bull gear and into the main bearings.

If not corrected, the vibrations caused by cavitation will work their way directly to critical power end components, which will result in the premature failure of the mud pump. A busted mud pump means expensive downtime and repair costs.

To stop cavitation before it starts, install and tune high-speed pressure sensors on the mud suction line set to sound an alarm if the pressure falls below 30 psi.

Although the pump may not be knocking loudly when cavitation first presents, regular inspections by a properly trained field technician may be able to detect moderate vibrations and slight knocking sounds.

Gardner Denver offers Pump University, a mobile classroom that travels to facilities and/or drilling rigs and trains rig crews on best practices for pumping equipment maintenance.

Severe cavitation will drastically decrease module life and will eventually lead to catastrophic pump failure. Along with downtime and repair costs, the failure of the drilling pump can also cause damage to the suction and discharge piping.

When a mud pump has entered full cavitation, rig crews and field service technicians will see the equipment shaking and hear the pump ‘knocking’… However, the process of cavitation starts long before audible signs reveal themselves – hence the name ‘the silent killer.’In 2017, a leading North American drilling contractor was encountering chronic mud system issues on multiple rigs. The contractor engaged in more than 25 premature module washes in one year and suffered a major power-end failure.

Gardner Denver’s engineering team spent time on the contractor’s rigs, observing the pumps during operation and surveying the mud system’s design and configuration.

The engineering team discovered that the suction systems were undersized, feed lines were too small and there was no dampening on the suction side of the pump.

Following the implementation of these recommendations, the contractor saw significant performance improvements from the drilling pumps. Consumables life was extended significantly, and module washes were reduced by nearly 85%.

Although pump age does not affect its susceptibility to cavitation, the age of the rig can. An older rig’s mud systems may not be equipped for the way pumps are run today – at maximum horsepower.

8613371530291

8613371530291