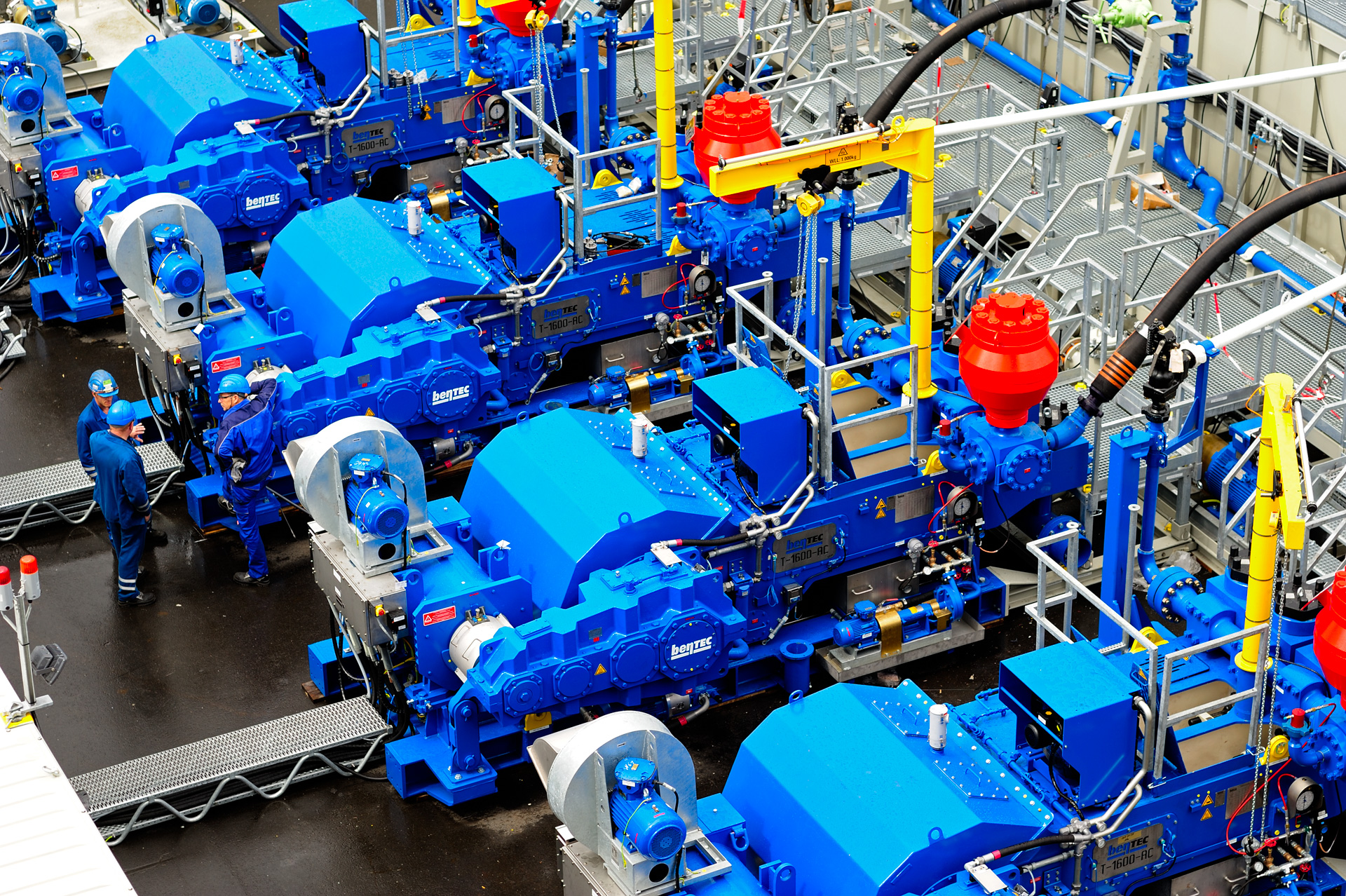

mud pump controls factory

It’s time for piston mud pumps to enter the 21st century. Centerline Mud Pumps utilize common, industry-proven, and easily obtained fluid end parts. Designed to give you better flow capacity, pressure, size and weight advantages, that you won’t find anywhere else. Centerline Mud Pumps are built to exceed the most demanding specifications in the industry. These pumps are built to last.

Centerline Manufacturing is pleased to introduce their line of hydraulic drive mud pumps. Since 1983, Centerline Manufacturing has been involved in the design, manufacture, and production of drilling equipment, support equipment, and tooling for the water well industry. Our line of mud pumps include several new milestone technologies not found anywhere else in the industry.

Provides 150-180* GPM (Gallon Per Minute) of standard mud flow at 350 psi continuous. The 180 GPM is a provisional condition that requires the mud pressure to be below 275 psi and the hydraulic oil temperature below 165 degrees F.

Provides 300-360* GPM (Gallon Per Minute) of standard mud flow at 350 psi Continuous. The 360 GPM is a provisional condition that requires the mud pressure to be below 275 psi and the hydraulic oil temperature below 165 degrees F.

Provides 450-540* GPM (Gallon per Minute) of standard mud flow ar 350 psi Continuous. The 540 GPM is a provisional condition that requires the mud pressure to be below 275 psi and the hydraulic oil temperature below 165 degrees F.

Our manufacturer Mud Pump skid is suitable for operations in rough, windy, damp and dusty oilfield conditions. Dependent upon customer horsepower requirements the engine sizes will vary.

Mud pumps are the heart of a drilling operation. TSM designs and manufactures extremely reliable and easy-to-maintain mud pumps, eliminating unnecessary maintenance and downtime.

Since 2001, TSC Manufacturing and Supply, LLC has been a leading global manufacturer and supplier of fluid end expendables, as well as mud pump spare parts for oilfield applications. Today, we continue to keep our proud tradition of excellence going, as we strive to better ourselves in order to better our customers" experience. Our global network of inventory locations provides unrivaled quality, customer service, on-time delivery, and unmatched technical integrity.

When it comes to mud pump fluid end expendable parts, TSC Manufacturing and Supply, LLC, has it all. TSC can, and will, match your needs, so that you won’t be lacking in anything. TSC mud pump liners are designed and manufactured to meet or exceed original equipment specification and API standards for almost all types of mud pumps in use today. With advanced technology, metallurgical control, and rigid inspection, we offer unmatched performance and durability, according to customer testimonies, in the most severe drilling conditions; both triplex and duplex liners are available in a wide range of sizes.

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

The X-series mud pump type PD X-3.004 SG HDD manufactured by PRIME DRILLING impresses with its robust and low-wear design. The 7-fold bearing mounted drive shaft, which is equipped with 3 eccentric wheels, replaces the conventional crankshaft. Due to the revolution of these shafts and their maximum 230 rotations per minute operational wear of rubbers and liners are reduced to a minimum.

The pump is driven by a 470 kW CAT engine. This type of mud pump is exclusively manufactured in our Wenden plant, i.e. „made in Germany“. Its electronic gearshift in combination with eccentric wheels used instead of a crankshaft make it a high- power but low- maintenance product. All valves and plungers also comply with API standards.

In order to keeping competition and developing,the basic is to improve any possible aspects such as company quality,we place an emphasis on elements includes controls,job management,defined and well managed processes,performance and integrity criteria and identification of records,on competence includes knowledge,skills,experience and qualifications,on soft elements includes personnel integrity,confidence,organizational culture,motivation,team spirity and quality relationship.

In order to keeping competition and developing,the basic is to improve any possible aspects such as company quality,we place an emphasis on elements includes controls,job management,defined and well managed processes,performance and integrity criteria and identification of records,on competence includes knowledge,skills,experience and qualifications,on soft elements includes personnel integrity,confidence,organizational culture,motivation,team spirity and quality relationship.

ENSCO 71 is a Jack-Up drilling rig which was originally constructed at the Hitachi Zosen shipyard in 1982. The original GE motor controls comprised five 1163 KVA generators and four 1800 ADC SCR units with associated auxiliary transformer feeders and jacking units. The SCRs were assignable to two 1600 HP twin-motor Mud Pumps, a twin motor 2000 HP Drawworks and a 1000 HP Rotary Table. A separate feeder drives a 1110 HP Top Drive. A fifth SCR was added by Hill Graham Controls in 1985 to power a third 1600 HP Mud Pump, which was cabled to the main busbars.

In early 2012, a decision was made to add a fifth 2500 KVA generator and an additional auxiliary transformer, to close-couple these to the main switchboard via a bus tie circuit breaker, and to include a dedicated feeder for the fifth SCR. A sixth SCR was also included in the switchboard extension to provide an alternative drive source for the third Mud Pump, effectively removing this load from the main switchboard. The switchboard extension, including full integration with the existing GE and Hill Graham equipment, was engineered and built by Zeefax.

GNSB Series Centrifugal pump is a very common device used at drilling mud solids control system. GNSB Series Centrifugal pump can be used for oil field drilling mud system, HDD and CBM drilling mud recycling system, piling and micro tunneling desanding plant. GN Solids Control is a professional manufacturer of centrifugal pump in China.

1. GNSB Series Centrifugal pump can be used as trip pump in the trip tank of the oil and gas drilling mud system. Trip tank is normally the first tank compartment inside drilling mud solids control system. The tank volume of trip tank is not big. It can be a separate smaller size tank other other tanks in the solids control system. It can also a compartment divided from shale shaker tank. Centrifugal pump size 3×2 or 4×3 are mostly used as trip tank trip pump.

2. GNSB Series Centrifugal pump can be used as feed pump for desander, desilter, mud cleaner. The pump transfer capacity should be matching the handling capacity of desander, desilter and mud cleaner. It can be a little big higher than the separation equipment, but it cannot be too much high. And the centrifugal pump transfer capacity cannot be lower than the separation equipment.

3. GNSB Series Centrifugal pump can be used as mixing pump of jet mud mixer and mixing unit. While add a T-pipe at the outlet of the mixing pump, the same pump can also be used as transfer pump.

4. GNSB Series Centrifugal pump can be used as transfer pump to transfer drilling mud or other slurries from one tank to another, or from one location to another.

All GN model centrifugal pump use tungsten carbide mechanical seal, with international famous brand Bearing. And spare parts interchangeable with most of the international Brand pump which helps customer to source spare parts easily. Open impeller design that lowers axial thrust loads, and make it easier for installation, repair and maintenance.

8613371530291

8613371530291