mud pump controls quotation

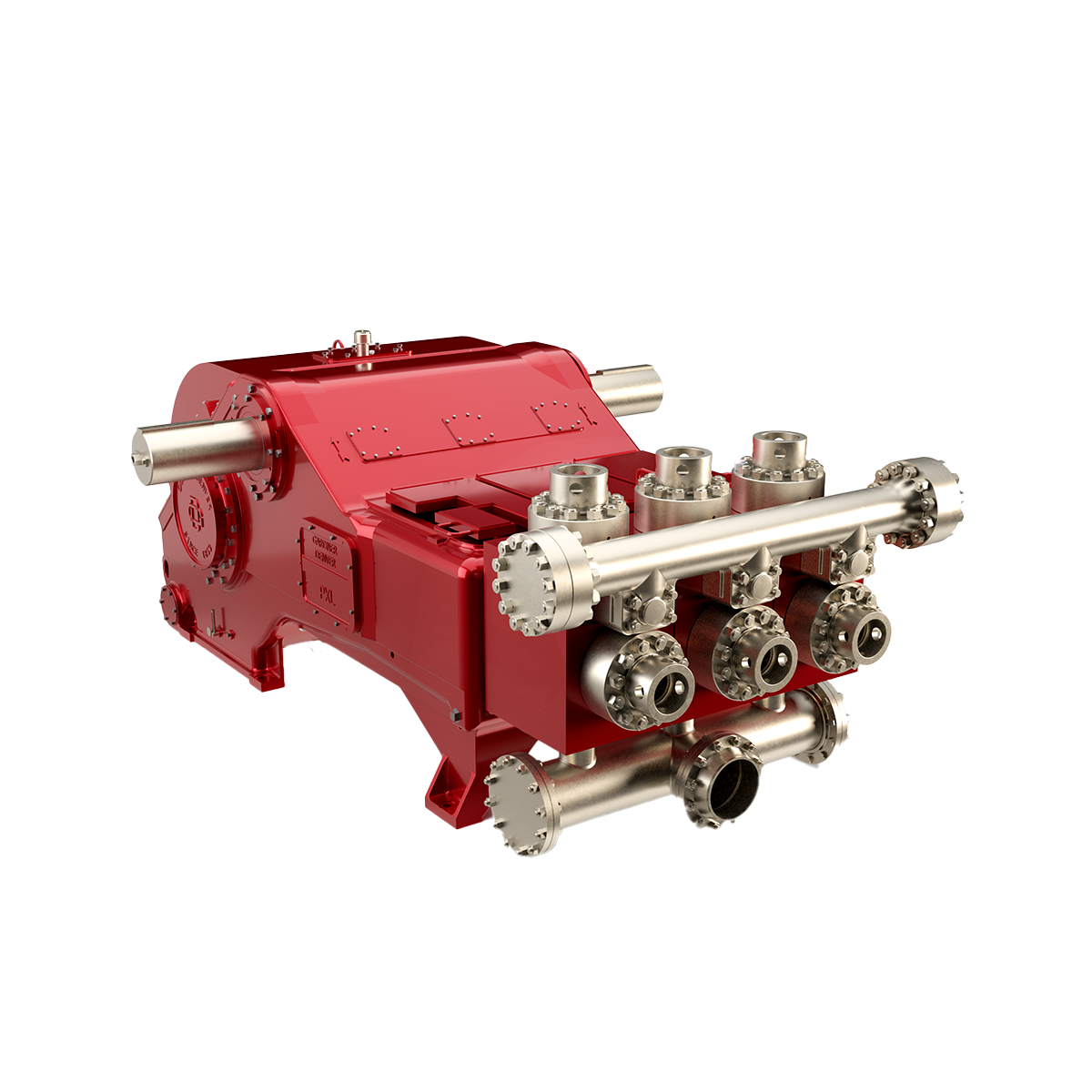

It’s time for piston mud pumps to enter the 21st century. Centerline Mud Pumps utilize common, industry-proven, and easily obtained fluid end parts. Designed to give you better flow capacity, pressure, size and weight advantages, that you won’t find anywhere else. Centerline Mud Pumps are built to exceed the most demanding specifications in the industry. These pumps are built to last.

Centerline Manufacturing is pleased to introduce their line of hydraulic drive mud pumps. Since 1983, Centerline Manufacturing has been involved in the design, manufacture, and production of drilling equipment, support equipment, and tooling for the water well industry. Our line of mud pumps include several new milestone technologies not found anywhere else in the industry.

Provides 150-180* GPM (Gallon Per Minute) of standard mud flow at 350 psi continuous. The 180 GPM is a provisional condition that requires the mud pressure to be below 275 psi and the hydraulic oil temperature below 165 degrees F.

Provides 300-360* GPM (Gallon Per Minute) of standard mud flow at 350 psi Continuous. The 360 GPM is a provisional condition that requires the mud pressure to be below 275 psi and the hydraulic oil temperature below 165 degrees F.

Provides 450-540* GPM (Gallon per Minute) of standard mud flow ar 350 psi Continuous. The 540 GPM is a provisional condition that requires the mud pressure to be below 275 psi and the hydraulic oil temperature below 165 degrees F.

Our pump stroke counter systems (CPS101 Series) measure the stroke rate and number of strokes on mud pumps. The oilfield pump stroke system is user-friendly and reliable and is configurable to measure up to three mud pumps at once. Our digital pump stroke counter systems are manufactured here in the U.S. by Crown Oilfield Instrumentation, and Crown’s Pump Stroke Counter provides easy monitoring of strokes per minute on multiple mud pumps. Each mud pumps’s stroke rate can be selected individually and the display is updated regularly for accurate monitoring. LCD displays indicate both pumps strokes per minute and the total number of strokes. Located at the bottom of the panel, push buttons provide easy operation and reseting of each pump. When you need to accurately monitor and maintain the amount of mud being pumped, you can trust Crown’s oilfield stroke counters.

Engine— New Detroit Series 60 14.0 L Tier Iii Set @ 425 Hp. Transmission— Allison 5860 Straight Thru [Wet Housing]. Charging Pump— Dragon 5 X 4 Centrifugal [Hydraulic Drive]. Triplex Pump— Dragon 360 Complete With Pulsation Dampner, Shear Relief, and Mud Gauge. Control Stand— Includes Engine Gauges, Diagnostics, Start And Kill, Throttle, Charging Pump Controls, Shifter, And Emergency Kill. Dragon 360 Pump Gear Ratio— 5.695 Maximum Speed Rating 150 Spm 8.5 Stroke And Maximum Liner Is 5”. Max Engine RPM— 2100 RPM This Will Need To Be Reduced To 1800 RPM In 3rd Gear.

Our full-open valves and seats are designed for use in GD Energy Products PZ, F-Series, and National 12P lines of triplex drilling pumps. This gives you options to use these parts across your whole fleet of pumps.

The application of safe-guards, safety triggers and automated procedures to control the mud-pumps, hoisting system and top-drive allows for safer, more consistent and more efficient drilling operations. Attempting to apply drilling automation on a floater needs to manage the impact of the unpredictable movement of the drill-string induced by heave movements.

Drilling in the North Sea is confronted with an ever more challenging pressure-management issue because of narrow geopressure windows in depleted reservoirs. Further, the occurrence of packoffs can cause serious damage to the formation and contribute to nonproductive time. To address these problems, automation of mud-pump management has been developed over the last 4 years to minimize the chance of fracturing the formation while starting the mud pumps or circulating. To account for abnormal flow restrictions in the annulus, automatic actions are also an integral part of the mud-pump automation described in this paper.

Since the downhole conditions are continuously changing (e.g., depth, temperature, flow-rate, gel time, cuttings proportion), the necessary safeguards to operate the mud pumps need to be updated constantly. Advanced transient temperature and hydraulic models are used to estimate, in real-time, the downhole situation. On the basis of the current context, evaluations of maximum pump rates and acceptable flow accelerations are performed and sent to the mud-pump control system to be used as an envelope of protection. Furthermore, to assist the driller during connections, the pump-startup procedure has been semiautomated to decrease connection time. Finally, an automatically triggered pump-shutdown procedure is also available to minimize the consequences of a packoff on formation fracturing.

A first version of the system has been tested during the drilling of one well in 2008 in the North Sea. Based on the initial experience, a revised version has been used during the drilling of three wells drilled on the Norwegian continental shelf in 2009. The feedback from the drillers involved in the testing has been used to improve the user friendliness of the system. The automation of the mud-pump management has been well accepted by the drilling crews. However, the testing has shown that additional instrumentation at the rigsite is necessary before such automation can be rolled out safely.

A mud pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi (52,000 kPa)) down the drill string and back up the annulus. A duplex mud pump is an important part of the equipment used for oil well drilling.

Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers. The advantages that Duplex mud pumps have over convention triplex pumps is a lower mud noise which assists with better Measurement while drilling and Logging while drilling decoding.

Use duplex mud pumps to make sure that the circulation of the mud being drilled or the supply of liquid reaches the bottom of the well from the mud cleaning system. Despite being older technology than the triplex mud pump, the duplex mud pumps can use either electricity or diesel, and maintenance is easy due to their binocular floating seals and safety valves.

A mud pump is composed of many parts including mud pump liner, mud pump piston, modules, hydraulic seat pullers, and other parts. Parts of a mud pump:housing itself

Duplex pumps are used to provide a secondary means of fuel transfer in the event of a failure of the primary pump. Each pump in a duplex set is sized to meet the full flow requirements of the system. Pump controllers can be set for any of the following common operating modes:Lead / Lag (Primary / Secondary): The lead (primary) pump is selected by the user and the lag (secondary pump operates when a failure of the primary pump is detected.

Alternating: Operates per Lead / Lag (Primary / Secondary) except that the operating pump and lead / lag status alternate on consecutive starts. A variation is to alternate the pumps based on the operating time (hour meter) of the lead pump.

Lake Petro provides high quality Mud Pump Parts including Mud Pump Liners, Mud Pump Fluid End Module, piston, Valve and Seat etc. With more than 10 years of experience in the oil and gas industry, we are dedicated to help and support our loyal clients with the most cost-effective and quality Liners and Pistons. We also provide mud pump price and mud pump for sale.

We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials for all common brands of the mud pump and triplex mud pump.

All Lake Petro liner products are interchangeable with O.E.M. products. Meanwhile, we provide customized Liners according to drawings. Our liners, also with our other mud pump spares, are supplied for use in Honghua, F-Series, Bomco, Emsco and National lines of triplex drilling pumps. Let Lake Petro be your one-stop shop for your whole fleet of pumps. Please refer to “Suitable Pump Models” Lable for more details.

A Mud Pump may have many changeable parts, such as liner, piston, extension rod, pulsation dampener, valve, clamp, etc. Lake Petro could provide 100% interchangeable parts of many common brands of pump. We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials. Piston assembly is the important spare parts and expendable parts of oil drilling mud pumps. Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump. Fluid End Module is an important component of the hydraulic pump end of the mud pump.

We strive to maintain our high reputation by producing drilling control systems and solutions to improve and maintain critical work environments in the Drilling industry. We provide a variety of products from variable frequency drives (VFD), programmable logic controllers (PLC), dynamic breaking systems, mud pumps, and other electrical components for your drilling applications.

8613371530291

8613371530291