mud pump manufacturer price

There are three types of mud pumps, depending on the type of client and the size they want. For general, mud pumps, there are three basic types of mud pumps, depending on the type of client and budget. The piston pump is another compressed mud pump, which is a pushed electric compressor mud pumps and by compressed air.

Electric mud pumps are largely divided into three categories, among them the electric mud pumps and the semi-trash mud pumps. The piston inflated mud pumps are also classified in terms of the type of mud pumps, among them are electric mud pumps and semi-trash mud pumps. In addition, the piston inflates mud and mud pumps will be inflated by the piston, which is inflated mud pumps.

If you are supplying pump supplies, you can find the most favorable prices at Alibaba.com. Whether you will be working with piston type or diaphragm type systems, reciprocating or centrifugal, Alibaba.com has everything you need. You can also shop for different sizes drilling mud pump price wholesale for your metering applications. If you operate a construction site, then you could need to find some concrete pump solutions that you can find at affordable rates at Alibaba.com. Visit the platform and browse through the collection of submersible and inline pump system, among other replaceable models.

A drilling mud pump price comes in different makes and sizes, and you buy the tool depending on the application. The pump used by a filling station is not the one you use to fill up your tanks. There are high flow rate low pressure systems used to transfer fluids axially. On the other hand, you can go with radial ones dealing with a low flow rate and high-pressure fluid. The mixed flow pump variety combines radial and axial transfer mechanisms and works with medium flow and pressure fluids. Depending on what it will be pumping, you can then choose the drilling mud pump price of choice from the collection at Alibaba.com.

Alibaba.com has been an excellent wholesale supplier of drilling mud pump price for years. The supply consists of a vast number of brands to choose from, comes in different sizes, operations, and power sources. You can get a pump for residential and large commercial applications from the collection. Whether you want a water pump for your home, or run a repair and maintenance business, and need a supply of dr drill mud pump prices, you can find the product you want from the vast collection at Alibaba.com.ther it is for refrigeration, air conditioning, transfer, or a simple car wash business, anything you want, Alibaba.com has it.

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

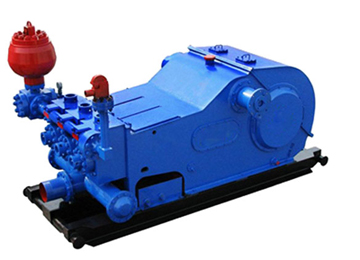

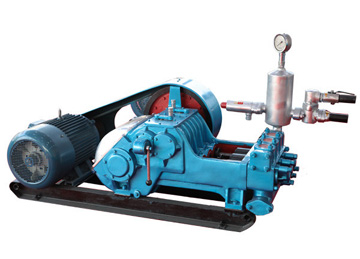

The crank gear and connecting rods drive a rotary movement that is transferred by the motor transmission. The pressure is produced by the piston in the cylinder due to which the mud is sucked. Following the operation, the suction valve is closed when it moves to left. As the pressure increase in the pipeline, the valve is forced to open and mud is released.

In accordance with the operating liquid displacer type being incorporated, the pumps are subdivided into piston units and plunger-type units. The liquid discharge uniformity is independent of head. The pumping plants are used actively for the processes with the liquids containing solid inclusions in high amounts. Incorporating the self-suction function in piston unit, the liquid is sucked and discharged twice in mud pumps during the single shaft turn, making themselves the double-action pumps whereas, the mud plunger pumps are single-action pumps where the liquid is sucked and discharged only once during a shaft turn.

The single direct-action three-piston pumps prove to be better than other types of drilling. These pumps demonstrate much more uniformity in mud delivery, lesser weight, and easy mounting when compared with two-cylinder units.

Depending on the number of cylinders, the pumping plants are classified into the following categories, single-cylinder, double-cylinder, three-cylinder and multi-cylinder pumping plants. These cylinders may be vertical or horizontal. Comparatively, the multi-cylinder pumping plants will cost higher but don’t feature any significant advantages other than the single-cylinder.

When drilling, there might occur the necessity of mud pumping out- and flushing-out, so there are various types of pumps available for such operations which are required to be installed on drilling rigs.

Sucker-rod pumps: In sucker-rod pumps, the pumpjack is a driver. This pump is installed at the bottom of the well. The reciprocating movements of the pumpjack are converted into liquid flow by the pump, which results in delivery of liquid on the surface. These pumps move oil with various admixtures demonstrating high level of capacity.

Screw pumps:The screw pumps are small-sized and are generally used to deliver mud into a centrifuge. These pumps have the rotor and stator as the major structural components and the material used to manufacture these components suit right for smooth pumping of liquids with solid inclusions and high level of viscosity. The pumped liquid flows with stable pressure, shaft slowly and the flow is free of vortexes. These pumps comparatively require minimum service.

Well pumps: These pumps are submerged into wells. The ground part of the plant is a transformer substation equipped for start and adjustment. The pump has a vertical structure, with a fixed cylinder and single-action. A plunger and valve are moving parts. The pumped liquid may contain water content of up to 99% at the temperature as high as 130ºC.

All the mud pumps have few general advantages that include the capability to process liquids and substances with high level of viscosity and with admixtures. Also, enabling the smooth flow of substances, free of pulsations or suspensions mixing are counted under the major advantages of incorporating mud pumps. The pumps have high suction power and small weight, easing out the transportation and installation at remote oil fields. They are highly reliable and also affordable.

There are various types of mud pumps available for different purposes. So, it is important to incorporate the right one for your purpose. A Professional help in getting the right mud pump would be a good and safe option.

Public utilities : For pumping muddy water, sewage, polluted liquids, solid and in swimming pool.Dewatering Basements, Trenches, Construction sitesOnboard shift, as bildge, for desk wash & engine cooling.Tiles & Marble factories, effluent plants.Waste treatment: Pumping polluted, hot or corrosive waste water containing sand, mud or solids in suspension; dosing neutralising liquids; pumping out settled sludge.

We Propeller Pumps from 2009 are engaged in Manufacturing Wholesaling Exporting and Retailing the Centrifugal Pumps Axial Flow Pumps Chemical Pumps Sump Pumps PP Pumps Pump Accessories Feed Pump Slurry Pump Turbine Pump Impeller Pump Mixed Flow Pump End Suction Pump Self Priming Centripetal Pump

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

Yes. We use third-party companies to provide best quotations for your shipment and inspection of manufactured goods. We make sure that you get quality products from the manufacturer at the best price.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

Sticking for the basic principle of "Super Top quality, Satisfactory service" ,We"ve been striving to be an excellent business enterprise partner of you for Vertical Roller Mills, Horizontal Solid Slurry Pump, Centrifugal Centrifugal Pump, We warmly welcome all perspective inquiries from home and abroad to cooperate with us, and look forward to your correspondence.

Slurry pumps run as the key part in the mining process, power plant, metallurgy and other relevant industries are supposed to perform at an optimal standard. Atlas Pump guarantee to keep the slurry pumps at optimal performance throughout the entire working life by our highest quality spare parts. Atlas Pump promise to be the reliable back of the worldwide partners to provide the qualified and cost-effective spare parts to deal with the maintenance and emergency situations.

Atlas Pump manufacture multiple series slurry pumps and suitable spare parts (hard metals & rubbers). Including wet parts (impeller, volute, FPL insert, throat bush…), bearing assembly (shaft, bearing housing, ceramic coating shaft sleeve, end cover, cover shim…), and the seals (gland seal, mechanical seal and expeller seal) etc…

Aircraft Brake System Market Growth & Trends to 2023 Profiling Honeywell, Safran, United Technologies, Meggitt, Parker Hannifin, Crane Aerospace & Electronics – Press Release | High Pressure Diesel Water Pump

We intention to see quality disfigurement within the creation and supply the ideal support to domestic and overseas buyers wholeheartedly for Factory Price Mud Pump - SPARE PARTS – Tiiec , The product will supply to all over the world, such as: Poland, Puerto Rico, Zurich, Look forward to the future, we"ll focus more on the brand building and promotion . And in the process of our brand global strategic layout we welcome more and more partners join us, work together with us based on mutual benefit. Let"s develop market by fully utilizing our in depth advantages and strive for building.

"Fuel Engine Mud Pump Market" report presents a comprehensive overview, market shares, and growth opportunities of Fuel Engine Mud Pump market by product type, application, key manufacturers and key regions and countries. The global Fuel Engine Mud Pump market size is projected to reach Multimillion USD by 2028, in comparision to 2021, at unexpected CAGR during 2022-2028.

Fuel Engine Mud PumpMarket Research Report is spread across 121 Pages with 173 Number of Tables and Figures that provides exclusive data, information, vital statistics, trends, and competitive landscape details in this niche sector.

The GlobalFuel Engine Mud Pump market is anticipated to rise at a considerable rate during the forecast period, between 2022 and 2028. In 2020, the market is growing at a steady rate and with the rising adoption of strategies by key players, the market is expected to rise over the projected horizon.

Due to the COVID-19 pandemic and Russia-Ukraine War Influence, the global market for Fuel Engine Mud Pump estimated at USD million in the year 2022, is projected to reach a revised size of USD million by 2028, growing at a CAGR of % during the forecast period 2022-2028.

The USA market for Fuel Engine Mud Pump is estimated to increase from USD million in 2022 to reach USD million by 2028, at a CAGR of % during the forecast period of 2023 through 2028.

The China market for Fuel Engine Mud Pump is estimated to increase from USD million in 2022 to reach USD million by 2028, at a CAGR of % during the forecast period of 2023 through 2028.

The Europe market for Fuel Engine Mud Pump is estimated to increase from USD million in 2022 to reach USD million by 2028, at a CAGR of % during the forecast period of 2023 through 2028.

The global key manufacturers of Fuel Engine Mud Pump include National Oilwell Varco, Schlumberger, Gardner Denver, Weatherford International, Flowserve Corporation, Honghua Group, China National Petroleum, Trevi-Finanziaria Industriale and MhWirth, etc. In 2021, the global top five players had a share approximately % in terms of revenue.

In terms of production side, this report researches the Fuel Engine Mud Pump production, growth rate, market share by manufacturers and by region (region level and country level), from 2017 to 2022, and forecast to 2028.

In terms of sales side, this report focuses on the sales of Fuel Engine Mud Pump by region (region level and country level), by company, by Type and by Application. from 2017 to 2022 and forecast to 2028.

This latest report researches the industry structure, capacity, production, sales (consumption), revenue, price and gross margin. Major producers" production locations, market shares, industry ranking and profiles are presented. The primary and secondary research is done in order to access up-to-date government regulations, market information and industry data. Data were collected from the Fuel Engine Mud Pump manufacturers, distributors, end users, industry associations, governments" industry bureaus, industry publications, industry experts, third party database, and our in-house databases.

This report also includes a discussion of the major players across each regional Fuel Engine Mud Pump market. Further, it explains the major drivers and regional dynamics of the global Fuel Engine Mud Pump market and current trends within the industry.

Report further studies the market development status and future Fuel Engine Mud Pump Market trend across the world. Also, it splits Fuel Engine Mud Pump market Segmentation by Type and by Applications to fully and deeply research and reveal market profile and prospects.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Fuel Engine Mud Pump in these regions, from 2015 to 2027, covering ● North America (United States, Canada and Mexico)

Some of the key questions answered in this report: ● What is the global (North America, Europe, Asia-Pacific, South America, Middle East and Africa) sales value, production value, consumption value, import and export of Fuel Engine Mud Pump?

● Who are the global key manufacturers of the Fuel Engine Mud Pump Industry? How is their operating situation (capacity, production, sales, price, cost, gross, and revenue)?

● What are the upstream raw materials and manufacturing equipment of Fuel Engine Mud Pump along with the manufacturing process of Fuel Engine Mud Pump?

● What are the key drivers, restraints, opportunities, and challenges of the Fuel Engine Mud Pump market, and how they are expected to impact the market?

Our 20,000 sq.m production facility in China has designed and manufactured solely quality and specialty pumps for oil exploration and refinery sin1992

Application: Public utilities : For pumping muddy water, sewage, polluted liquids, solid and in swimming pool. Dewatering Basements, Trenches, Construction sites. Onboard shift, as bilge, for desk wash & engine cooling Tiles & Marble factories, effluent plants. &nbs more...

We are offering self priming mud pumps. Owing to our in-depth knowledge and vast experience in this domain, we have been able to offer premium quality self priming mud pumps. These pumps are manufactured using excellent quality components and latest technology by our skilled prof more...

Mud Pump Excellent quick automatic action without foot valve up to 8 mtrs. Back pull out design, so easy maintainance without disturbing pipe lines. Better efficiency because of good hydraulic design. Less expensive & easily available spares. more...

8613371530291

8613371530291