mud pump power end parts for sale

FET manufactures a full range of valves and seats for every drilling and well-servicing application as part of our full line of Osprey® mud pump system solutions. All of our valves and seats can be used in water, water base, oil base and synthetic base mud applications. FET offers additional valves and seats not listed below, including drilling valves, frac valves and well service valves. FET’s QC standards for the dimensional and material specs are extremely rigid in comparison to other manufacturers. Contact your FET representative to learn more.

Pump Parts - Ajax T-150, Pumps & Parts, Used crankshaft for Ajax T-150, crankshaft journal diameter 4.5", crankshaft extension diameter 4" , More Info

Pump Parts - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Pump Parts - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Pump Parts - BUTTERWORTH T-375M Triplex Water Blaster Pump, Pumps & Parts, Used Butterworth T-375M Triplex Water Blaster Pump, 1.4375" plungers x 3.75" stroke, max 10,000 PSI, missing... More Info

Pump Parts - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Pump Parts - Chinese 3DS-18.5/21.5, Pumps & Parts, Brand new triplex pump, 1.921" plungers, 4.117" crank extension, 5.285" stroke, 4"#150FF suction flange, 2" 5000 PSI API discharge f... More Info

Pump Parts - DOWELL PG03 4.5x5 Triplex Cementing Pump, Pumps & Parts, Used Dowell PG-03 Triplex Cementing Pump, 4 1/2" Metal Plungers x 5" Stroke, c/w Factory Chain Case, Magnesium Po... More Info

Pump Parts - DOWELL PG03 4.5x5 Triplex Cementing Pump, Pumps & Parts, Used Dowell PG-03 Triplex Cementing Pump, 4.5" metal plungers x 5" stroke, steel block fluid end for cementing or... More Info

Pump Parts - DOWELL PG05 4.5x5 Triplex Cementing Pump, Pumps & Parts, Used Dowell PG-05 Triplex Cementing Pump, 4 1/2" Metal Plungers x 5" Stroke, Steel Fluid End c/w Factory Chain Ca... More Info

Pump Parts - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Pump Parts - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Pump Parts - EMSCO D-300, 4.75-7.25 x 14 Duplex Mud Pump Package, Pumps & Parts, Used Emsco D-300 Duplex Mud Pump Package, 5.5" liners x 14" Stroke, c/w Detroit Series 60 Diesel Engin... More Info

Pump Parts - EMSCO F650 Triplex Mud Pump, Pumps & Parts, Used Continental Emsco F650 Triplex Mud Pump, 5 1/2" Pistons x 8" Stroke c/w Mud Gauge, Relief Valve, Pulsation Dampener, Quic... More Info

Pump Parts - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Pump Parts - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Pump Parts - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Pump Parts - Gardner Denver GD45T Triplex Injection Pump, Pumps & Parts, Used frame for Gardner Denver GD45T (PS-25) triplex pump, bare case , More Info

Pump Parts - Gardner Denver PA-8 Triplex Mud Pump, Pumps & Parts, Used Gardner Denver PA-8 Triplex Mud Pump (predecessor to the Gardner Denver PAH), 4.5" metal plungers x 8" stroke, c... More Info

Pump Parts - Gardner Denver PAH 4 1/2 x 8 Triplex Mud Pump, Pumps & Parts, Used Gardner Denver PAH 4 1/2 x 8 Triplex Mud Pump Package, 4.5" Metal plungers x 8" stroke, Detroit 8V-71 d... More Info

Pump Parts - Gardner Denver PE-5 3x5 Triplex Mud Pump, Pumps & Parts, Used power end for Gardner Denver (SMC) PE-5 (T-165-5) triplex pump, 5" stroke, no fluid end , More Info

Pump Parts - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Pump Parts - Gardner Denver GD45T Triplex Injection Pump, Pumps & Parts, Used frame for Gardner Denver GD45T (PS-25) triplex pump, bare case , More Info

Pump Parts - Gardner Denver PA-8 Triplex Mud Pump, Pumps & Parts, Used Gardner Denver PA-8 Triplex Mud Pump (predecessor to the Gardner Denver PAH), 4.5" metal plungers x 8" stroke, c... More Info

Pump Parts - Gardner Denver PAH 4 1/2 x 8 Triplex Mud Pump, Pumps & Parts, Used Gardner Denver PAH 4 1/2 x 8 Triplex Mud Pump Package, 4.5" Metal plungers x 8" stroke, Detroit 8V-71 d... More Info

Pump Parts - Gardner Denver PE-5 3x5 Triplex Mud Pump, Pumps & Parts, Used power end for Gardner Denver (SMC) PE-5 (T-165-5) triplex pump, 5" stroke, no fluid end , More Info

Pump Parts - Gardner Denver PE-5 3x5 Triplex Mud Pump, Pumps & Parts, Used power end for Gardner Denver PE-5 Triplex Mud Pump, 5" stroke, no fluid end , More Info

Pump Parts - Gardner Denver PE-5 3x5 Triplex Mud Pump, Pumps & Parts, Used fluid end for Gardner Denver PE-5 3x5 Triplex Mud Pump, steel, c/w valves, covers, suction manifold , More Info

Pump Parts - Gardner Denver PE-5Y 3x5 Triplex Well Servicing Reversing Mud Pump Package, Pumps & Parts, Used Gardner Denver PE-5Y 3x5 Triplex Well Servicing Reversing Mud Pump Package... More Info

Pump Parts - Gardner Denver PG-3 Triplex Mud Pump, Pumps & Parts, Used powerend for Gardner Denver PG-3 Triplex Pump, c/w factory gear box 3.79:1 ratio , More Info

Pump Parts - Gardner Denver PQ-2 Triplex Injection Pump, Pumps & Parts, Used bronze fluid end for Gardner Denver PQ-2 triplex pump, bare, no internals , More Info

Pump Parts - Gardner Denver PS-25 Triplex Injection Pump, Pumps & Parts, Used stainless steel high pressure fluid end assembly to fit Gardner Denver PS-25 triplex pump, 1 1/4" plunger... More Info

Pump Parts - Gardner Denver TEE 4 x 5 Triplex Mud Pump, Pumps & Parts, Used Gardner Denver TEE 4 x 5 Triplex Mud Pump, "POWER END ONLY, NO FLUID END", 4" metal plungers x 5" stroke, c... More Info

Pump Parts - Gardner Denver TEE 4 x 5 Triplex Mud Pump, Pumps & Parts, 6 used frames for Gardner Denver TEE triplex pumps, 8 used chaincase housings, 2 crankshafts , More Info

Pump Parts - Gardner Denver TEE 4 x 5 Triplex Mud Pump, Pumps & Parts, Crate of parts for Gardner Denver TEE / PE-5 triplex pumps, bearing housings, crossheads, oil pumps, covers, man... More Info

Pump Parts - Gardner Denver TEE 4 x 5 Triplex Mud Pump, Pumps & Parts, Used frame & parts for Gardner Denver TEE 4 x 5 Triplex Mud Pump, c/w bearing housings, conrods, crossheads, pon... More Info

Pump Parts - Gardner Denver TEE 4x5 Triplex Mud Pump Package, Pumps & Parts, Used Gardner Denver TEE 4x5 Triplex Mud Pump Package, 4" Metal Plungers, x 5" Stroke, Bronze Fluid End, Ch... More Info

Pump Parts - 2007 Gardner Denver THE 5.5" x 5" Triplex Mud Pump, Pumps & Parts, Used Gardner Denver THE Triplex Mud Pump, 5.5" Pistons x 5" Stroke, Steel fluid end, c/w 4.75:1 ratio p... More Info

Pump Parts - Gardner Denver TQB Triplex Injection Pump, Pumps & Parts, Used bare power frame for Gardner Denver TQB Triplex Injection Pump , More Info

Triplex: This mud pump is used for drilling applications needing high pump pressure. This model works by decreasing the working fluid volume being discharged to generate pressure for producing the flow. There are three pistons in the triplex pump, with the middle piston generating more pressure on the crankshaft. High piston load can lead to excessive pressure and crankshaft failure if the components are not properly sourced.

Quintuplex:Quintuplex mud pump is perfect for pumping fluid at the time of drilling operations. It works as a continuous duty return piston. This is used in terms of its external bearings to provide crankshaft support to ensure the proper functioning of the sheaves.

Duplex: These mud pumps ensure that the mud circulation reaches the well"s bottom from the mud cleaning system. Duplex pumps have binocular floating seals as well as safety valves.

Saigao offers high-quality OEM mud pump spares, consumables, expendables and spare parts. Our mud pump parts are made with the highest standards of quality, offering competitive pricing and exceptional durability.

It’s time for piston mud pumps to enter the 21st century. Centerline Mud Pumps utilize common, industry-proven, and easily obtained fluid end parts. Designed to give you better flow capacity, pressure, size and weight advantages, that you won’t find anywhere else. Centerline Mud Pumps are built to exceed the most demanding specifications in the industry. These pumps are built to last.

Centerline Manufacturing is pleased to introduce their line of hydraulic drive mud pumps. Since 1983, Centerline Manufacturing has been involved in the design, manufacture, and production of drilling equipment, support equipment, and tooling for the water well industry. Our line of mud pumps include several new milestone technologies not found anywhere else in the industry.

Provides 150-180* GPM (Gallon Per Minute) of standard mud flow at 350 psi continuous. The 180 GPM is a provisional condition that requires the mud pressure to be below 275 psi and the hydraulic oil temperature below 165 degrees F.

Provides 300-360* GPM (Gallon Per Minute) of standard mud flow at 350 psi Continuous. The 360 GPM is a provisional condition that requires the mud pressure to be below 275 psi and the hydraulic oil temperature below 165 degrees F.

Provides 450-540* GPM (Gallon per Minute) of standard mud flow ar 350 psi Continuous. The 540 GPM is a provisional condition that requires the mud pressure to be below 275 psi and the hydraulic oil temperature below 165 degrees F.

BRAND NEW SURPLUS mud pumps for immediate sale. These are (3) three New National NOV 12-P-160 Mud Pumps 1600 HP, 7-1/4″ bore x 12″ stroke, single acting. 5000 PSI fluid ends. 1600 HP Bare Mud Pumps are currently configured for Offshore Service. These NOV 12-P-160 Mud Pumps are located in Houston and ready to be unitized for service. The pumps have never been installed or used.

Forged Steel crankshaft, Individual forged steel two piece interchangeable standard modules, 6-1/2” mission fluid king liners, Standard polyurethane valves and seats, Two piece fast change piston rods, Supreme pistons, Metal to metal liner retention, Clamp type liner and piston rod connections, Fast change valve covers standard, Piston liner lubricant spray system, Liner spray pump, Power end lube system with filter. Mounted on Integral two runner skid, Suction Manifold with vertical suction stabilizer, Suction line pressure relief valve, set for 70 PSI

Includes: motor supports, motor frame, tensioning screws, 2 V-belt guards, 2 pump Sheaves, 2 motor sheaves, banded V-belts, Holes to be drilled to accept EDM D79 Or GE-752 Traction Motors

We stock fluid end parts for the5×6 mud pump, 5×6-1/4 FM45 mud pump, 5×8 mud pump, 5-1/2×8 mud pump, 5X10 mud pump, 4-1/2×5 mud pump, 7-1/2×8 mud pump, and 7-1/2X10 mud pump. The Gardner Denver mud pump model numbers for the above pumps are as follows: 5X6-FGFXG, 5X8-FDFXX, 5-1/2X8-FDFXX, 5X10-FDFXD, 4-1/2X5-FFFXF, 7-1/2X8-FYFXX, 7-1/2X10-FYFXD. We also handle Wheatley, Gaso, Worthington, Failing and Centerline parts and pumps. We also stock Foot Valve, Liner Puller, Valve Seat Puller, (4″ Inline Check Valve. Our Gardner Denver mud pump parts are not only competitively priced, they are also made in the USA. Oil Recommended by Gardner Denver. Call any of our experienced representatives to get the help and knowledge you deserve.

With our experience vast pool of resources and dedication to excellent customer service, we will go to the extra mile to confidently fulfill all of your pumping and equipment needs. One of our most important goals is to set the standard for great customer service. No matter if you need a seal, a gasket, or a complete new pump. We"ll treat you the same, with professional courtesy, throughout the sales process. Here"s a couple of testimonials from our customers.

At BOPM, we constantly maintain 5 million worth of mud pump parts on the shelf at our Houston warehouse location. It includes modules, liners, extension rods, piston rods, pistons , threaded rings, caps, valve covers, valve guides, valves, seats etc. for all major brands of pumps: Gardner Denver®, Ideco®, Emsco®, National®, Oilwell®, Skytop Brewster®, Lanshi(3NB1300C) ®, Bomco ®, HH ®.

BOPM offers a complete line of interchangeable fluid end modules and accessories for triplex mud pumps, such as National, Emsco, Gardner Denver, Bomco, Ideco and Oilwell. We offer both standard OEM style replacement parts and Two piece “L” Shaped fluid ends.

Our high-strength, triple reduction, forged steel triplex fluid end modules are made from highest alloy steel. Heat treated for long working life, they are machined to perfection and packaged for delivery with anticorrosion protection. The precisely made jewelry-like exterior finish reflects our superior quality.

BOPM piston rods are made with premium grade, heat treated alloy steel. The rods offer excellent resistance to fatigue, corrosion and heavy loads. A full line of piston rods are available for various pumps.

BOPM extension rods are made from high strength alloy steel, and are either heat treated or chrome plated. The rod offers excellent resistance to fatigue, corrosion and heavy loads. BOPM extension rods are machined and polished to ensure a perfect seal to protect the mud pump gear end.

All of our gear set adopt high-end carburization heat treatment and precise grinding machining to offer unparalleled durability; first we use high strength alloy steel, then adopt the Carburization heat treatment to enhance the hardness and wearability, finally adopt the grinding fine machining to ensure the smooth gear teeth surface; Resulting in consistent and rugged performance throughout pump operation.

BOPM bonded urethane pistonsare constructed of urethane, bonded to a steel hub. The double durometer urethane is designed to provide optimal performance in oil or water based mud and high drilling pressures.

BOPM Replaceable Rubber Pistonis made with tough and durable Buna N rubber for all pressures, and is ideally suited for water-base mud. A special processing of the fabric provides an unusually waterproof bond of fabric to piston which assures longer life.

BOPM Bonded Rubber Pistonis made with tough and durable Buna N rubber for all pressures, and is ideally suited for water-base mud. A special processing of the fabric provides an unusually waterproof bond of fabric to piston which assures longer life.

(2) Pumps - Triplex W/ Forged Steel Fluid End & Quick Change Caps, 5M Pulsation Dampner, Oteco 3" Shear Relief Valve, Pressure Gauge, Mission 6 X 5 Charge Pump P/B Cat C-18 Diesel Engine, Allison CLT6061 Transmission, Fitted W/ 7" Liners, & Pistons, Master Skidded, (1) Pump No Power or Transmission. Good Condition.

All New Parts In Both Gear & Fluid End, Pump Will Have New Style Gear End, Primered & Painted Buyers Choice, Hyd. Gearbox Available. Rebuilt Condition.

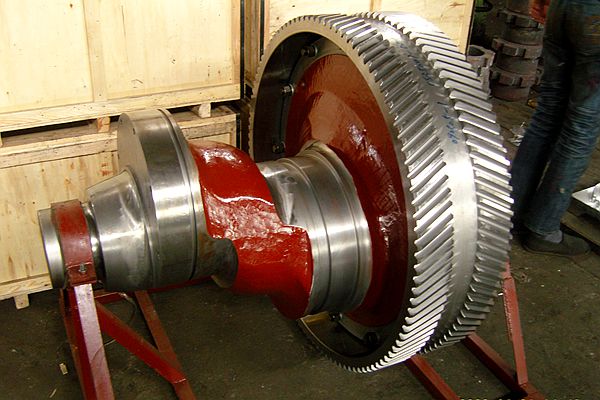

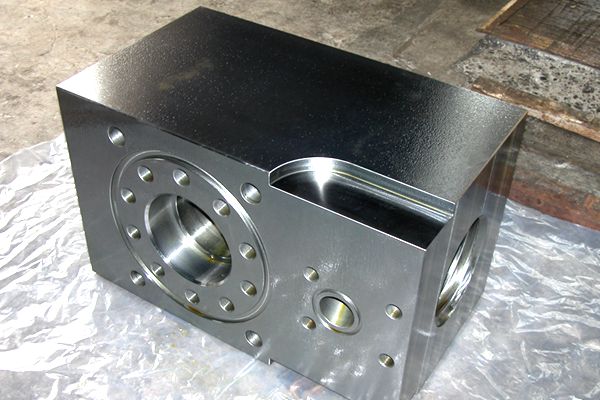

We manufacture and offer power end parts of triplex mud pumps for our clients all over the world. Power End includes frame, pinion shaft, crankshaft, crosshead and extension rod.

The frame is made of welded steel plate to provide the frame with high strength, good rigidity and lightweight. The extension rod packing is of duplex seal structure to provide the good seal result. The power end uses the combined lubrication system of forced lubrication and splash lubrication.

The crankshaft is made of cast alloy steel and is furnished with big geared ring, connecting rod and bearing. The tooth form of the big-geared ring is herringbone gear. The gear bore and the crankshaft surface is interference fitted and they are both fastened with bolts and lock nuts. The big end of the connecting rod is mounted on three eccentric straps of the crankshaft through single row short cylindrical roller bearings and the small end on the crosshead pin through double row long cylindrical roller bearing. Double row radial spherical roller bearings are mounted at both ends of the crankshaft.

Pinion shaft is made of forged alloy steel on which a herringbone gear with the medium-hard tooth surface is machined. For easy maintenance, the single row radial long cylindrical roller bearing with inner ring (without sides) is used. Both ends of the pinion shaft extend out, so that the sheave or the sprocket can be mounted on either end.

The crosshead and crosshead guide are made of ASTM A48-83 meehanite cast iron featured by good abrasion resistance and long service life. Upper and lower guides are used on F-800 and F-1000 mud pumps, so that the concentricity can be adjusted by adding shims beneath the lower guide. F-500 mud pump is the cylindrical structure. Bolted flange is used at the connection between the crosshead and the extension rod. The rigid connection ensures the concentricity of the crosshead and the extension rod. The coupling is used for connecting the extension rod to the piston rod. The lightweight coupling enables the extension rod and the piston rod to connect to each other easily and reliably.

8613371530291

8613371530291