mud pump pressure relief valves pricelist

CRS offers CRS brand replacements for directional, pressure relief, flow control, check and cartridge relief valves. Where others charge for features like light kits, it comes standard on a CRS valve. CRS combines standard valve technology for a truly unique application. Call us for a quote on one of our valves, or to get more information on our MPC solutions.

The American Wheatley Relief Valve series is designed to relieve pressure at a predetermined set in hot water heating systems. Intended for liquid systems, or emergency steam relief only. Constructed in accordance with ASME section IV, Latest Edition, rated for emergency steam discharge by National Board of Boiler and Pressure Vessel Inspectors. American Wheatley’s Relief Valve is Available in ¾” with male or female inlet, consult with our staff for availability.

Packless valves with all-metal seal to atmosphere; Working pressures up to 3500 psig (241 bar); Temperatures up to 400°F (204°C); VCR® face seal fitting, Swagelok® tube fitting, and weld end connections

Features: Working pressures up to 10 000 psig (689 bar); 1/8 to 1/2 in. and 6 to 12 mm Swagelok® tube fitting or NPT end connections; 316 stainless steel materials

Features: Modified PTFE wetted components meet SEMI Standard F57-0301 for ultrahigh-purity system components; Fine thread flare and Nippon Pillar® Super 300 end connections; Low cracking and reseal pressure

Features: Working pressures up to 3000 psig (206 bar); Temperatures up to 400°F (204°C) with standard PTFE packing, up to 600°F (315°C) with optional Grafoil® packing; Straight and angle-pattern valves

Features: High-purity PFA material; Working pressures up to 180 psig (12.4 bar); Temperatures up to 300°F (148°C); 1/4, 3/8, and 1/2 in. Swagelok® PFA tube fitting end connections

Swagelok thermal-immersion diaphragm valves offer high-speed actuation and are designed for optimum performance at 220 degrees C (428 degrees F) for high-temperature processes.

Features: Working pressures up to 6000 psig (413 bar); Flow coefficients (Cv) from 4.0 to 13.8; Fractional and metric Swagelok tube fittings; ISO and NPT pipe end connections available; 316 stainless steel body and end connections; Manual and pneumatic actuation

Features: Suitable for ultrahigh-purity applications;316L VIM-VAR stainless steel body; Low-pressure and high-pressure models; VCR®, tube butt weld, and modular surface-mount end connections; Manual or pneumatic actuation

Features: Straight-pattern flow coefficients (Cv) from 0.004 to 0.15; Low- and high-pressure service; Repeatable vernier handles available; Brass and 316 stainless steel materials

Features: Provides double-block-and-bleed (DBB) operation in a single compact module; Conventional NPT and ANSI/ISA 76.00.02 compatible designs; System pressures to 250 psig (17.2 bar) with 40 psig (2.8 bar) actuation pressure; Integrated flow loop to provide consistent outlet

ALD 3, 6, and 7 Diaphragm Valves and ALD20 Bellows: Ultrahigh cycle life, high-speed actuation; Up to 392°F (200°C) w thermal actuators; Electronic actuator position-sensing; ultrahigh-purity applications; High flow capacity, PFA seat, Normally closed pneumatic actuation, Alloy 22 available

Features: Working pressures up to 600 psig (41.3 bar); Temperatures up to 300°F (148°C); Straight and angle patterns; Vee stem standard; regulating stem available

Features: Working pressures up to 10 000 psig (689 bar); Temperatures from –65 to 450°F (–53 to 232°C) with PTFE packing; up to 1200°F (648°C) with Grafoil® packing; 316 stainless steel; alloys 400, 20, 600, and C-276; and titanium materials

Features: All-welded design provides reliable containment of system fluid; Forward flow starts at less than 2 psig (0.14 bar) pressure differential; Valve closes with less than 2 psig (0.14 bar) back pressure; 316L SS body offers enhanced material purity

Features: Working pressures up to 300 psig (20.6 bar); Shutoff, bulk-gas distribution, and isolation service; Cast, forged, and bar stock stainless steel body material; 1/4 to 1 in. and 12 to 25 mm end connections

Features: stainless steel, carbon steel, and duplex stainless steel materials; pressure ratings in accordance with ASME B16.5; flanged connections compatible with ASME B16.5; ball valve bore sizes from 3/8 to 2 in. (9.5 to 50.8 mm)

Features: Secondary containment system above the bellows; Working pressures up to 2500 psig (172 bar); Temperatures up to 1200°F (648°C); 1/4, 3/8, 1/2, 3/4, and 1 in.; 6, 10, and 12 mm end connections; Stainless steel material

Features: Packless valves with all-metal seal to atmosphere; Working pressures up to 500 psig (34.4 bar); Temperatures up to 200°F (93°); 1/4 to 1/2 in. and 6 to 12 mm end connections

Features: Working pressures up to 3000 psig (206 bar); Swagelok® tube fitting and NPT and ISO tapered pipe end connections; 1/8 through 1/2 in. and 6 through 12 mm sizes; Brass and 316 stainless steel materials

Features: Roddable, straight-through orifice for maximum flow; Working pressures up to 6000 psig (413 bar); Packing below the threads; Replaceable seat and stem tip design

Features: On-off, switching, and crossover flow paths; Working pressures up to 3000 psig (206 bar); Temperatures from –65 to 300°F (–53 to 148°C); Environmental and heated-process applications; 1/16 to 3/4 in. and 3 to 12 mm end connections

Features: 316 stainless steel construction; Temperatures up 1000°F (537°C); Medium-pressure (MP) fittings, Size range—1/4 to to 1 in., Pressure rating—up to 20 000 psig (1378 bar); High-pressure (HP) fittings, Size range—1/4 to 9/16 in., Pressure rating—up to 60 000 psig (4134 bar); NACE® MR0175/ISO15156 compliance available

Features: Limits access to manually actuated valves;Lockout accessory enables compliance with OSHA Lockout/Tagout, Standard 29 CFR Part 1910.147, Control of Hazardous Energy Bright safety orange color promotes high visibility. Other colors are available.

Stop uncontrolled release of system media if downstream line ruptures. Features: Pressures up to 6000 psig (413 bar); Temperatures up to 400°F (204°C); 1/8 to 1/2 in. and 6 to 12 mm end connections; Stainless steel construction

Features: Straight and angle patterns; Pressures up to 6000 psig (413 bar); Temperatures up to 450°F (232°C) with PTFE packing; up to 650°F (343°C) with Grafoil® packing

Features: Micrometer handle for precise, repeatable flow settings; Working pressures up to 700 psig (48.2 bar); Temperatures up to 900°F (482°C); 316 stainless steel construction

GB series ball valves; Working pressures up to 6250 psig (430 bar) with temperatures from –40 to 248˚F (–40 to 120˚C); Swagelok® tube fitting end connections, 3/8 in. to 1 in. female pipe, and fractional or metric (12 mm to 25 mm); Corrosion-resistant body materials: 316/316L, Alloy 2507, 6-Moly, Alloy 625, Alloy 825, Alloy C-276; Optional API 607 for fire-safe applications and NACE MR0175/ISO 15156 for sour gas

Features: 1/8 to 2 in. and 6 to 25 mm sizes; Stainless steel, carbon steel, brass, and special alloy materials; On-off (2-way) and switching (3-way) valves; Compensating seat design; Live-loaded, two-piece stem packing

Features: Working pressures up to 6000 psig (413 bar); Adjustable and fixed cracking pressures;Variety of end connections; 316 stainless steel and brass materials

Features: Gas and liquid service; Working pressure: 6000 psig (413 bar); Set pressures from 145 to 6000 psig (10.0 to 413 bar); All 316L stainless steel construction; 1/4 through 1 in. NPT and ISO/BSP parallel thread end connections; Certified to PED 97/23/EC Category IV

Features: 3/8 to 1 in. sizes; alloy 625, alloy 825, Alloy 2507, and alloy 6-moly materials; On-off (2-way) valves; Compensating seat design; Live-loaded, two-piece stem packing

Bleed Valves: Working pressures up to 10 000 psig (689 bar); Temperatures up to 850°F (454°C); 316 stainless steel, carbon steel, alloy 400, or alloy C-276 materials. Purge Valves: Working pressures up to 4000 psig (275 bar); Temperatures up to 600°F (315°C); 316 stainless steel, brass, or carbon steel materials

Features: Working pressures up to 10 000 psig (689 bar); Temperatures from –65 to 450°F (–53 to 232°C) with PTFE packing; up to 1000°F (537°C) with Grafoil® packing; Alloy 625, alloy 825, Alloy 2507, and 6-moly materials

Features: Working pressures up to 1000 psig (68.9 bar); Temperatures up to 900°F (482°C); 1/4, 3/8, 1/2, and 3/4 in.; 6, 10, and 12 mm end connections; Brass, stainless steel, and alloy 400 materials

Features: Working pressures up to 6000 psig (413 bar); Temperatures from −40 to 302°F (−40 to 150°C); High-flow capacity in a compact design; 1/4 to 3/8 in. and 6 to 8 mm end connections; 316 stainless steel construction

Features: Rack and pinion pneumatic actuators, solenoid valves, and limit switches; ISO 5211-compliant pneumatic actuators, solenoid valves, limit switches, and position sensors; Complete actuated assemblies and kits for field assembly available

Features: Alloy 625, alloy 825, and Alloy 2507 super duplex stainless steel materials; Available for CH4 adn Ch8 series check valves; Working pressures up to 6 000 psig (413 bar); 1/4 to 1/2 in. Swagelok tube fitting or NPT end connections;

Features: Alloy 625, alloy 825, and Alloy 2507 super duplex stainless steel materials; Working pressures up to 6 000 psig (413 bar); 1/4 to 1/2 in. Swagelok® tube fitting or NPT end connections; Compact, maximum-flow design

There may be many suppliers, but true valve specialists are rare. At KSB, variety is combined with class, a wide-ranging product portfolio with unique innovations, and passion with know-how. As your partner KSB flexibly responds to your requirements and works together with you to find the perfect solution for your specific application. A million industrial valves sold per year speak for themselves.

In the company"s 150-year history KSB engineers have continually created new innovations in the valves sector – such as the first ever ultrasound measurement valve BOA-Control / BOA‑Control IMS or the cleverly engineered BOA-CVE control valves with reversible seat.

What is this valve expertise built on? Certainly not only on the fact that as a supplier of pumps and valves it is always the complete system we look at. It is the result of many years of research and development.

No matter what your project: Our portfolio of industrial valves covers almost all applications, e.g. in building services and in the industry, water or energy sectors. Whether for a simple standard application or complex scenarios: As the only full liner of pumps and valves for these industries we offer highly efficient solutions of top quality at an optimum cost-benefit ratio.By continuously expanding our portfolio of automation solutions for valves we respond to current requirements regarding communication, energy efficiency and life cycle costs. KSB offers a comprehensive range of intelligent positioners and control units designed to handle process data, to control valves and improve their control accuracy.

The key elements of our valves are all developed, manufactured and continuously enhanced in-house, such as the elastomer materials for valve diaphragms or liners.

Valves with a flow-optimised geometry, such as our globe valves in slanted-seat design, with their low zeta values reduce pressure losses in your system.

The Premium Oilfield Technologies Caliber® RV7500 Relief Valve was designed for today"s higher-pressure drilling conditions. The valve utilizes a pin buckling system to determine the relief pressure. Each pin is designed to deform when the pressure reaches a predetermined load. All pins go through a stringent quality control process and batch testing to ensure performance at the correct pressure rating.

Different solenoid valves play different roles in the control system. The solenoid valve on ATO.com can automatically control or remote control on-off the working media such as water, oil and liquid. The solenoid valves are widely applied in medical machinery, solar energy, cleaning equipment, food machinery, burners, welding and cutting, fire safety, environmental water treatment, machinery manufacturing and other industries.

ATO provides you 2-way general purpose solenoid valves with high quality and reliability. These general solenoid valves have a large selection of port sizes, including G1/4", G3/8", G1/2", G3/4" etc. The solenoid valve has brass body or stainless steel body for your choice to meet your different requirements. Now you can first check the price list of ATO general purpose solenoid valves in the table below and then dive in the product page for more details.

Standard materialsinclude 316 stainless steel bodies and removable seat glands with 17-4PH stainless steel removable stem and stem seats. Standard O-ring material on the stem is Viton Valves may be used up to 400° F.

Inlet connections are for 9/16" O.D. tubing (HF9) with adapters for other sizes available. Outlet connections are 1/2" NPT. These valves are not recommended for use below 1,500 psi, and are not readily adjustable in the field without proper test equipment. Pressure settings are made at the factory and valves are tagged accordingly.

HiP relief valves are now available with CE marking. These products will proudly be marked with the CE symbol, signifying they comply with the stringent requirements of the Pressure Equipment Directive (PED). To order, add -CE to your relief valve part number.

Standard materials include 316 stainless steel bodies and removable seat glands with 17-4PH stem and seal ring. Standard O-ring material on the stem is Viton. The seat material is Peek. Valves may be used up to 400°F with standard Vtion O-ring or 450°F with the Kalrez O-ring option.

Inlet connections are for 9/16" O.D. tubing (HF9) with adapters for other sizes available. Outlet connections are 1/2" NPT. These valves are not recommended for use below 1,500 psi, and are not readily adjustable in the field without proper test equipment. Pressure settings are made at the factory and valves are tagged accordingly.

HiP relief valves are now available with CE marking. These products will proudly be marked with the CE symbol, signifying they comply with the stringent requirements of the Pressure Equipment Directive (PED). To order, add -CE to your relief valve part number.

HiP relief valves are now available with CE marking. These products will proudly be marked with the CE symbol, signifying they comply with the stringent requirements of the Pressure Equipment Directive (PED). To order, add -CE to your relief valve part number.

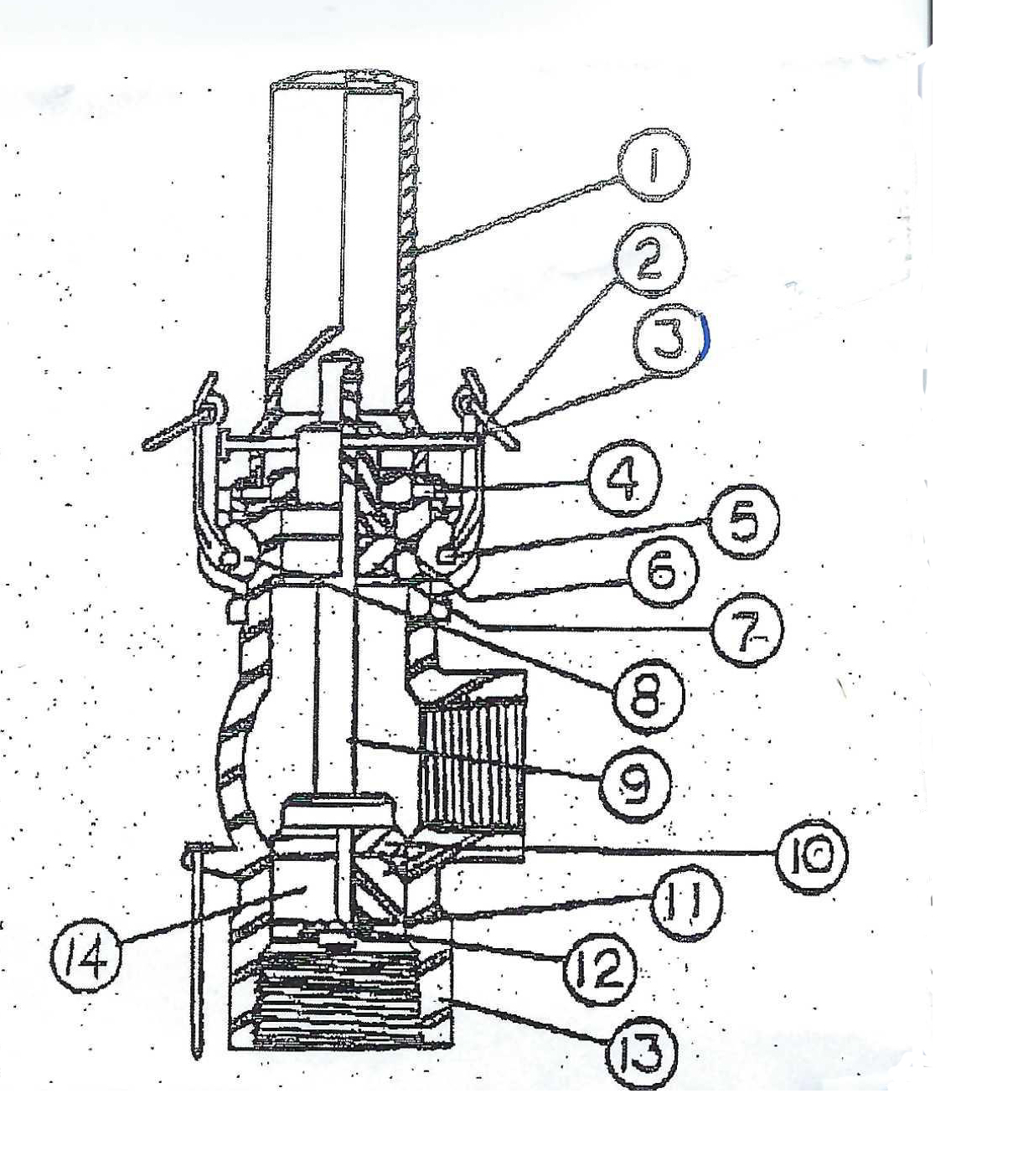

Drillmax Shear Relief valves are known for their dependability and effectiveness and are usually installed on the discharge end of the mud pump. When pressure exceeds the preset limit, the pin is sheared allowing the excess pressure to escape and be re-directed, preventing costly repairs. Different pin diameters are used to set the desired shear pressure. Once the problem is corrected, a new pin can be inserted to reactivate the valve.

KBL recently developed a large Vertical Turbine pumpset. It is a single-stage Horizontal Axial Flow Pump developed for use in the Circulation of Fermentation Broth. The pump has a

8613371530291

8613371530291