mud pump pressure relief valves quotation

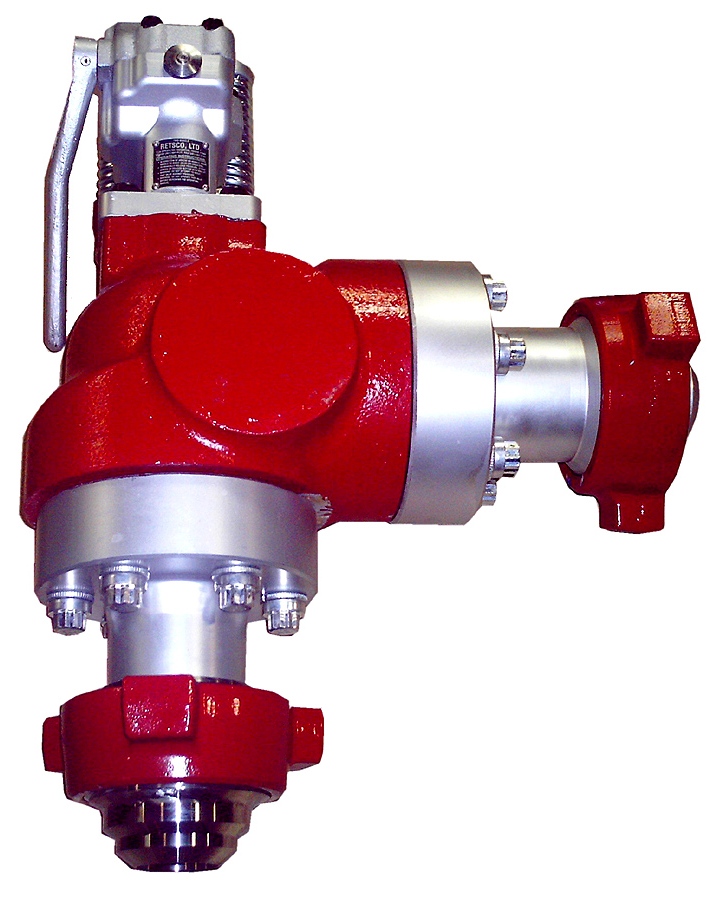

Drillmax Shear Relief valves are known for their dependability and effectiveness and are usually installed on the discharge end of the mud pump. When pressure exceeds the preset limit, the pin is sheared allowing the excess pressure to escape and be re-directed, preventing costly repairs. Different pin diameters are used to set the desired shear pressure. Once the problem is corrected, a new pin can be inserted to reactivate the valve.

30 pressure relief valve for mud pump products are offered for sale by suppliers on Alibaba.com, of which mud pump accounts for 36%, pumps accounts for 23%.

A wide variety of pressure relief valve for mud pump options are available to you, You can also choose from new, pressure relief valve for mud pump,as well as from energy & mining, construction works , and machinery repair shops pressure relief valve for mud pump,and whether pressure relief valve for mud pump is 1.5 years, or 3 months.

Pressure relief valves are installed on mud pumps in order to prevent an overpressure which could result in a serious damage of the pump and serious or fatal injury to personnel.

The discharge pressure is routed to the closer mud tank, via a 3” XXS line clamped strongly on tank side . Mud is flowing into the mud tank until line bled off, bearing in mind that minimum slope is required to avoid mud settling in pipe ( around 1 inch/meter).

Pressure relief valves are set usually to 90% of the maximum working pressure of the liners in use. Read carefully manufacturer chart for pressure setting versus size of liners.

With a low pressure setting, ie, 1000psi, by adjusting the top nylon self lock nut to move on the vertical scale to get the same setting than the scale.

Discharge pressure losses close to the maximum preset pressure.The Pressure relief valves are usually installed on a upper point of the discharge side of the mud pumps.

The pressure relief valve can be reset, if not damaged during the release of pressure. Special care should be taken if no working platform available to access the PRV.

A relief valve is a Valve which is installed on a pump or pipework to relieve excessive pressure in a positive displacement pump which could cause damage to a pump or system. Relief valves (also known as bypass valve or safety valve) are known as an Internal Relief Valve if installed on the pump itself, and if installed on the system they are known as an External Relief Valve.

Such valves are used on positive displacement pumps as the pumps are designed to prevent recirculation of fluid back to the inlet, meaning the displacement is always forward. However if a valve is closed on the outlet of the pump, or a blockage occurs the pump will continue to build pressure in the outlet pipework and within itself. This can cause pressures to reach dangerously high levels, and the pressure will vent at the weakest part of the system, causing a leak, damage or pump failure.

Such valves work in different ways depending on where they are installed. If installed on a pump the fluid is recirculated within the pump head, preventing the buildup of pressure, however the fluid begins to heat up, and is something which should only be done temporarily as it can lead to pump failure. External relief valves should be used in conjunction with internal relief valves to relieve any excessive pressure in the pipework either back to a vented tank or to dump contents in an emergency to atmosphere.

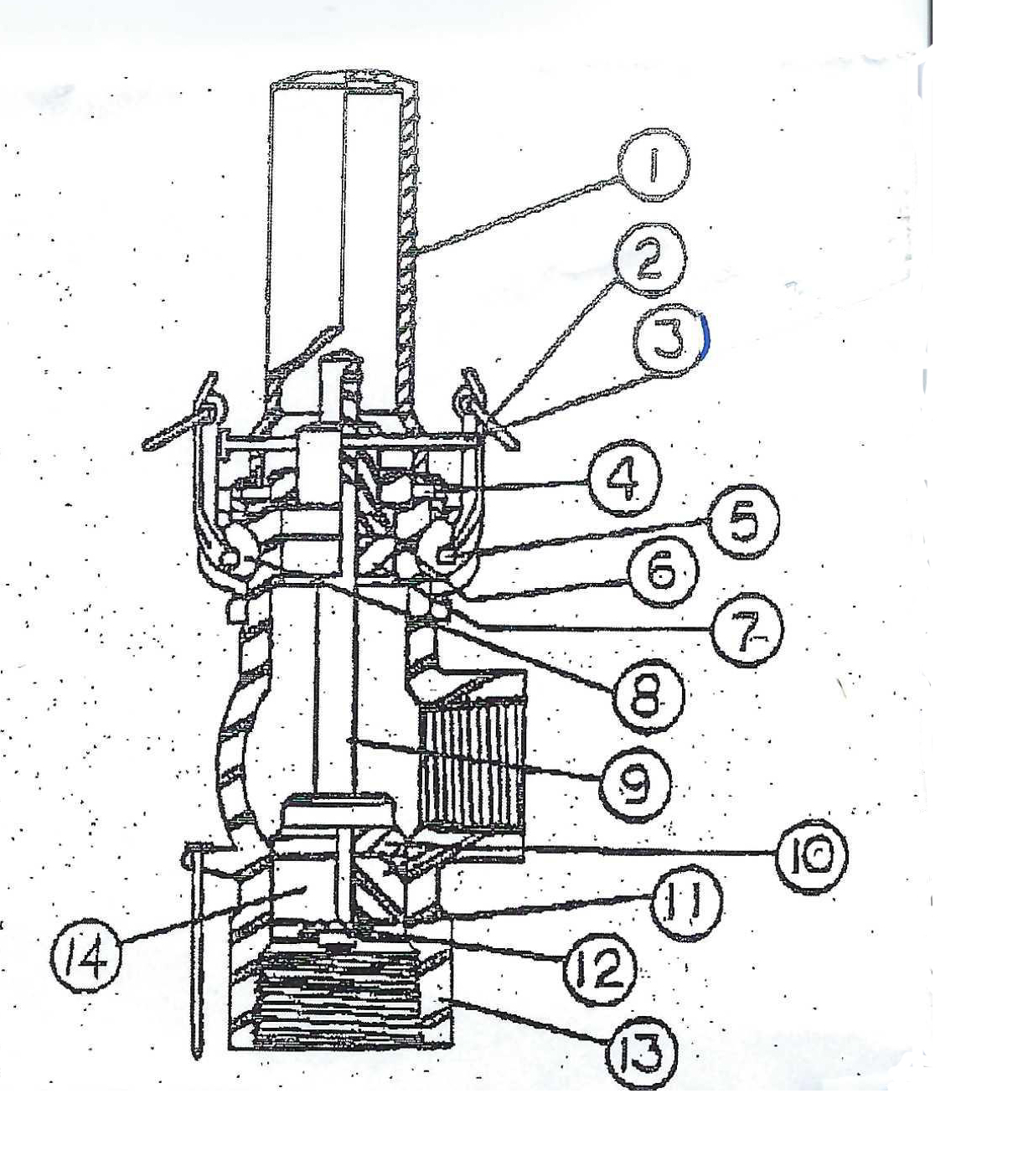

A relief valve design consists of a housing with inlet and outlet connections, a spring within a chamber which keeps a plate in place sealing the discharge. When the valve reaches the set relief pressure, the pressure plate causes the spring to compress revealing the discharge, causing the pressurised contents to vent through the discharge. A set screw or nut is used to set the relief pressure, at the top of the housing and when screwed clockwise, compresses the spring increasing the amount of pressure required to compress the spring and open the valve.

Internal relief valve set pressure is usually set at 10% above the operating pressure of the pump, and external relief valves should be set at 10% higher than the relief valve on the pump to prevent nuisance tripping. Valves are typically calibrated during manufacture and can be set on site with the use of pressure gauges during commissioning. Valves are rated in ranges such as from 0-10 bar, or 10-15 bar so should a valve pressure rating require recalibrating, checks should be made to ensure the setting is inline with the rating of the valve. Equipment should be checked at regular intervals to ensure succesful operation during an emergency.

Relief valves are not always required if the pressure capability of the pump is low, but also if used in conjunction with a product which can solidify when cooled if it enters the relief valve such as Chocolate or Bitumen. If fluid sets within a relief valve this will prevent it from operating as normal as any material which hardens will form a plug and can also cause contamination as it can be very difficult to clean thoroughly.

On some pumps a pressure relief valve is used in conjunction with a pressure regulator which regulates the pump to deliver the required pressure for the system. An analogy often used to describe a pressure regulator is akin to brakes in a car, with and the relief valve being the seat belt. A relief valve should only be relied on for use in emergencies to prevent damage to the pump or system and not as frequent protection for the system.

Since 2006, Envirovalve has been changing the game for safety relief valves. Our innovative designs for pressure relief valves have already made significant impacts on the industries we service. The most impactful of those designs has been our Accu-Shear Pin Device.

Our ASME certified Accu-Shear pressure relief devices have a revolutionary design that is different from other traditional Buckling Pin Devices and Valves like Rupture Pin, Buckling Pin, Rupture Disc and BPRV. The device does what its name implies; it shears or breaks the pin as opposed to compressing or bending the pin that you see in most pressure relief valves.

Sales and services for weight indicators, electronic weight indicators, cement recorders, six inch gauges, cylinders, torque assemblies, line pull assemblies, 1502 assemblies, wireline gauges and cylinders, depthometers, electronic depth systems, counters, diaphragms, auto drilling systems, rotary torque systems, and pump stroke counters.

Our F series mud pump are designed and manufactured on the basis of American Emsco F series mud pump strictly according to America Petroleum Institution API 7K Standard. All of its expendable parts are interchangeable with any other spare parts produced according to API standard. Therefore it is easy to repair and maintain internationally .

This relief valve can be used as a primary pressure control device or secondary (safety) pressure relief device. Many systems also use two relief valves, one set as the primary pressure control and the other set as a secondary relief. When used as a secondary pressure relief device, it is typically set approximately 200 PSI above the system pressure and provides additional protection for the pump and high-pressure system.

Pressure Relief (Floor/Wall & Wall Pipe) Pressure Relief Valves are designed for placement in the bottom or sidewall of concrete tanks to prevent damage caused as a result of the tank floating due to ground water pressure around and underneath the tank exceeding the pressure of an empty or nearly empty tank

To ensure safety, the drilling pump is equipped with a safety valve in the outlet, which is able to control the ultimate pressure of the pump within the admitted scope.

The high-pressure safety valve is forged by high-quality structural alloy steel. As a kind of protection device and human safety device, it is generally installed on cementing devices, fracturing pumps, high-pressure operation piping, pressure vessel and devices under high pressure and high flow capacity. It controls the elastic force of the valve seat by adjusting the nut on the top. Once the pumping pressure or piping pressure exceeds the pre-established pressure value, the safety valve opens automatically to release the pressure. When the pressure value reaches the normal value, the valve rod will recover the position by spring and close the valve.

Drillmax Demco® style Shear Relief valves are known for their dependability and effectiveness and are installed on the discharge end of the mud pump. The shear relief valve controls the pressure in a system to prevent potential equipment failure. When pressure exceeds the limit of the pin, the pin is “sheared” relieving pressure and preventing costly repairs.

Pressure Relief Valves are quick-opening, quick-closing valves used to protect equipment from gas pressure build up or pressure surges. Standard applications involve steam, gases, or liquids where a tight seating valve is required to prevent overpressure. Typical applications are in process industries, pressure reducing stations, and turbine bleeder lines. These valves can also be equipped with a handwheel and screw spindle for either manually opening the disc or to facilitate changing the relief pressure by changing the compression of the spring.

Pressure Relief Valves are designed to meet specific requirements. Many variations are possible as these valves are custom engineered to suit the application.

8613371530291

8613371530291