mud pump pulsation dampener precharge in stock

A properly serviced pulsation dampener is critical for your mud pumps’ efficiency, safety, and performance. Unfortunately, there aren’t many resources available to educate personnel on executing safe and effective servicing procedures. Please review the following steps with your personnel for safe pulsation dampener maintenance.

Should you or your personnel have any questions regarding pulsation dampener maintenance, please don’t hesitate to ask. Sigma is more than happy to help you to ensure safe and proper care is being completed on your pulsation dampening equipment.

The Pulsation Dampener 3375-0015-3 from the Hypro series assures smooth discharge from piston and plunger pumps. It also reduces peak loading on pump bearings and other internal parts. The Pulsation Dampener 3375-0015-3 extends the system life and minimizes maintenance costs.

As a general guideline, when using two cylinder or four cylinder piston pumps, the dampener charge should be approximantely 1/2 of the pump operating pressure. When using a three or six cylinder pump, te dampener charge should be approximately 2/3 of the pump operating pressure. This pump is rated for up to 1500 psi.

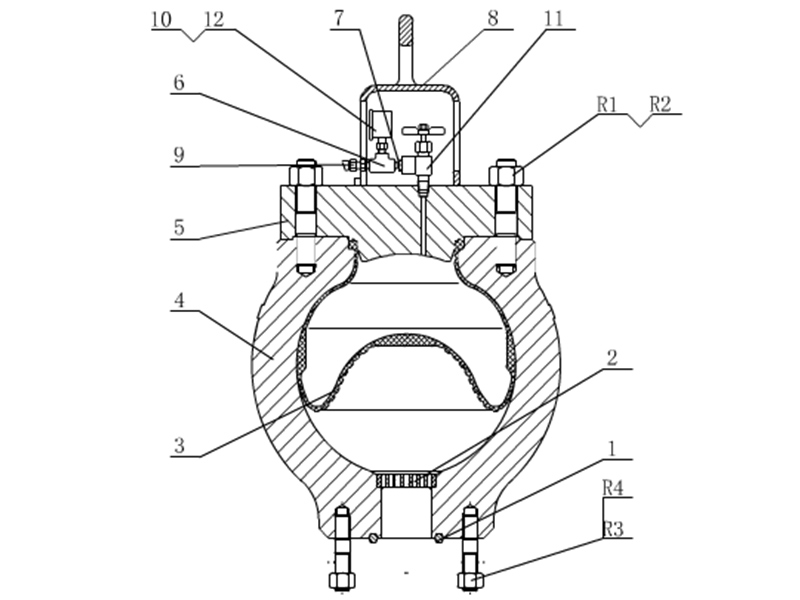

Mud pump pulsation dampeneris the mud pump discharge end main component, installs in the hydraulic end discharge pipe one end, plays the stable pressure and the pressure compensation function, the air bag work pressure is the mud pump work pressure 80%.Attention should be paid to the use of air bag, must be the first pressure relief.The mud pump of F500/F800 USES kb-45 air bag, and the mud pump of F1000/F1300/F1600 USES kb-75 air bag.The middle tie rod produced by our company is made of 35CrMo material, which has a smooth surface after chrome plating and fine grinding, greatly improving the wear resistance and corrosion resistance.

Proper installation and use of pulsation dampener can effectively reduce pressure fluctuations in the discharge system, thus achieving a more uniform fluid flow.In order to achieve a high service life of the air bag, always maintain the recommended ratio between the pump pressure and the air bag precharge pressure (generally not more than 2/3 of the pump discharge pressure, the maximum should not exceed 4.5mpa).

2. In the maintenance of air bag, air bag pressure must be zero, the pump pressure must be zero.Cannot rely on the pressure gauge to judge, because the residual pressure is small, the pressure gauge can not be displayed, but this low pressure will also lead to accidents!

The pulsation dampeners shall be installed properly to reduce the pressure fluctuation and smooth the liquid flow. In order to extend the lifespan of the air bag, it is highly recommended to maintain the suggested proportion of the pump pressure to the pre-charge pressure of the air bag for the pulsation dampeners. Generally, the pump pressure shall be 2/3 that of the discharge pressure and no more than 4.5MPa.

2. During maintenance, the pump pressure and the pressure inside the pulsation dampeners shall be zero. Since the residual pressure is generally small and can not be indicated on the pressure gauge, user shall confirm the pressure carefully to avoid accident caused by low pressure.

Pulsation problems often start on the suction side. Pulsation or cavitation is caused by the variation of fluid movement within a contained system. Since fluid is non-compressible, the energy produced by this pulsation or cavitation must be compensated for. With the introduction of pulsation equipment into a system this energy now has a place to expend itself. Without the pulsation equipment involved in your pumping system, the pulsation or cavitation that is present can lead to the following:

Our business has been focusing on brand strategy. Customers" pleasure is our best advertising. We also offer OEM company for Mud Pump Pulsation Dampener Precharge Pressure, , , , And we are able to enable on the lookout for any products with the customers" needs. Make sure deliver the best Assistance, the most beneficial High-quality, The quickly Delivery.

6500 Brittmoore Houston, Texas 77041-5109 281-931-8550 888-MUD-PUMP www.lewco-equip.com FAX 713-856-5341February 24, 2003 Page 1 of 9 Table of Contents

The Model L20-7500-DNV Discharge Pulsation Dampener....................................3Assembly Drawing ........................................................................................................4Parts List ........................................................................................................................5Mounting Instructions ..................................................................................................6Precharge Pressure Levels ...........................................................................................7Overhaul Kit ..................................................................................................................8Recommended Spare Parts ..........................................................................................9

6500 Brittmoore Houston, Texas 77041-5109 281-931-8550 888-MUD-PUMP www.lewco-equip.com FAX 713-856-5341February 24, 2003 Page 2 of 9 The Model L20-7500-DNV Discharge Pulsation DampenerThe LEWCO pulsation dampener is designed to counter the effect of pulsations often associatedwith positive displacement reciprocating pumps. The L20-7500-DNV has a dampening volumeof 20 gallons and is rated for a maximum allowable working pressure of 7,500 psi. The L20’sdesign focuses on durability and simplicity. Since the L20 uses a minimum number of parts, it iscompletely field serviceable, thereby eliminating costly shop repairs and down time. Areplaceable bottom plate having a 4 1/16” API 10,000 connection comes as a standard feature,which is ideal when working with abrasive or corrosive fluids. The large top flange allows forreplacement of the diaphragm bladder without removing the unit from the line. The stainlesssteel charge valve and pressure gage are located on the top flange and protected by a heavy-dutycover that also serves as a lifting eye. Each complete unit is hydrostatically tested to 11,250 psibefore shipment. Ask for LEWCO part number C305026

6500 Brittmoore Houston, Texas 77041-5109 281-931-8550 888-MUD-PUMP www.lewco-equip.com FAX 713-856-5341February 24, 2003 Page 3 of 9 Assembly Drawing Model L20-7500-DNV Discharge Pulsation Dampener P/N C305026

6500 Brittmoore Houston, Texas 77041-5109 281-931-8550 888-MUD-PUMP www.lewco-equip.com FAX 713-856-5341February 24, 2003 Page 4 of 9

Read All Instructions Before Attempting to Install This Dampener.Use Safe Lifting Practices Whenever The Dampener Is Installed Or Moved. The Dampener Lifting Cap Is Designed To Lift The Dampener Only. The Dampener Must Be Completely Unflanged Before It Is Lifted.

The LEWCO Model L20-7500-DNV dampener should be mounted preferably in the verticalposition. When other conditions exist, an angular or inverted installation is acceptable and doesnot impede dampener performance. However, increased corrosion could occur due to trappedfluid.

LEWCO dampeners use ANSI and API flanged connections and NPT type threaded connections.For flanged connections, position the dampener on a gasket and mating flange so that it iscentered. Install nuts hand tight. Cross-tighten nuts one turn at a time to proper torque to insureuniform load. The torque value for the 1-1/8” stud is 778 ft. lbs.

6500 Brittmoore Houston, Texas 77041-5109 281-931-8550 888-MUD-PUMP www.lewco-equip.com FAX 713-856-5341February 24, 2003 Page 6 of 9 Precharge Pressure Levels Model L20-7500-DNV Discharge Pulsation Dampeners

x For maximum operating efficiency, the precharge pressure should be 75 percent of the minimum operating system pressure or 2,000 psig* , whichever is lower.

x For normal operating conditions, the precharge pressure should be 50 percent to 60 percent of the average operating system pressure or 2,000 psig*, whichever is lower.

x For limited operating conditions, the precharge pressure should be maintained between 30 percent to 75 percent of the average system operating pressure or 2,000 psig*, whichever is lower.

PRECHARGING General Precharging Directions Model L20-7500-DNV Discharge Pulsation DampenerThe charging valve and the pressure gauge are located under the dampener lifting cap, and theyare exposed by removing the lifting cap. Before precharging the dampener, make sure all coverstud nuts are tightened evenly and no pressure is on the operating system.

Connect one end of the hose assembly to a standard commercially available nitrogen bottle andthe other end to the charging valve located at the top of the dampener. Precharge from a standard224 cubic foot 2,200 psig nitrogen bottle equipped with a pressure regulator. Open the bottleregulator valve until recommended precharge pressure shows on the regulator gauge. Slowlyopen the charging valve on the dampener by turning the top hex nut 3 to 4 complete turnscounter-clockwise.

Allow pressure to increase in the dampener until dampener pressure gauge reads specifiedprecharge pressure. This process normally takes 5 to 15 minutes. Dampener gauge and regulatorgauge should read the same and be equal to the specified precharge pressure. Close theprecharge valve, then close the regulator valve at the nitrogen bottle. The sound of escaping gasmay be heard at the charging valve until the regulator is closed.

6500 Brittmoore Houston, Texas 77041-5109 281-931-8550 888-MUD-PUMP www.lewco-equip.com FAX 713-856-5341February 24, 2003 Page 7 of 9 Overhaul Kit Model L20-7500-DNV Discharge Pulsation Dampener

6500 Brittmoore Houston, Texas 77041-5109 281-931-8550 888-MUD-PUMP www.lewco-equip.com FAX 713-856-5341February 24, 2003 Page 8 of 9 Recommended Spare Parts Model L20-7500-DNV Discharge Pulsation Dampener

6500 Brittmoore Houston, Texas 77041-5109 281-931-8550 888-MUD-PUMP www.lewco-equip.com FAX 713-856-5341February 24, 2003 Page 9 of 9

Southwest Oilfield Products is proud to offer a full line of Pulsation Dampener Solutions. Our PD series dampeners are available in 5, 10 & 20-gallon models and are rated for 5000 or 7500psi. Installed on the mud pump strainers cross, these gas-charged drilling dampeners provide optimum performance and dampening of flow variation pulsations generated by the mud pump. Key features include:

8613371530291

8613371530291