triplex mud pump animation supplier

Piston pumps can be used for low viscosity and medium-flow media (in the range of 80 m³/h). Additionally, pumping solid particles is impossible with this type of equipment because the pump can ensure proper operation only if the seal between the cylinder and the piston is perfect.

For high-pressure uses, you can opt for a plunger pump, they differ from piston pumps in that the seal does not move with the piston, it is fixed and therefore able to withstand...

... heavy duty frac pump designed to operate at higher pressures for longer periods of time. Its compact design and 11” stroke results in less fatigue cycles and extended consumable life. With a legacy of ...

The HS is a horizontal triplex and quintuplex positive displacement reciprocating pump with very high efficiency and is offered in a wide range of hydraulic, mechanical, and material options.

... cost-saving alternative to our diaphragm pump series: The LEWA plunger pump is a high-performance and versatile plunger pump for high-pressure applications in various industries.

Flojet Triplex Hi-Flow series pumps are designed for a wide range of applications and are constructed from a selection of materials suitable for handling a broad range of chemicals. ...

Three-es manufactures pumping sets with various flow and pressure characteristics, plug&play and optimised for any washing system. Each pumping unit is assembled using only high quality components.

... plunger pumps for pressure testing, large three, four or five plunger pumps of various designs are available with specific advantages for specific applications.

... plunger pumps for pressure testing, large three, four or five plunger pumps of various designs are available with specific advantages for specific applications.

... plunger pumps for pressure testing, large three, four or five plunger pumps of various designs are available with specific advantages for specific applications.

Triplex pump with connecting rod system. Pistons in ceramic-coated steel. Double gasket sealing system. Pump head in pressed brass. Automatic safety valve with pressure shut-off at pump ...

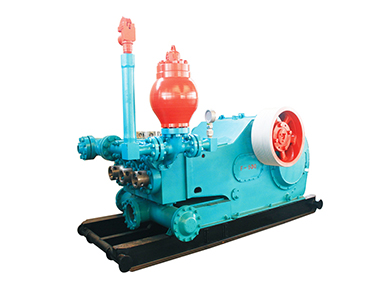

Drilling pump is also called mud pump, which transport high pressure, high specific gravity, high sand concentration drilling fluid to bottom of hole. Drilling fluid is used to cool bit, wash out bottom ...

JR500W pump is a horizontal single-acting reciprocating triplex plunger pump. Power end is self-lubricated by oil pump built onto the worm gear. Driven by worm pair, ...

Pumps of the WANGEN KL-R Triplex series impress with their consistent dosing option, as an intermittent input is compensated by the buffer volume in the collecting container. No bridge building. The small ...

... consists of 5 pump sizes in triplex execution. The 31.40 model is manufactured also in quintuplex (model 31.40/Q) and septuplex (model 31.40/S) execution, where the same components of the triplex ...

PressureJet pumps are triplex (three plungers), positive displacement, industrial high pressure triplex plunger pumps. We offer both the triplex piston ...

The RDP range of Reciprocating Plunger Pumps by Ruhrpumpen comes in various sizes and in triplex and quintuplex formats. They are designed and manufactured in accordance to the lates edition of API 674 ...

... 1600 mud pump is a single-acting reciprocating triplex mud pump that delivers increased reliability, improved maintainability, and reduced weight and footprint.

Centerline Manufacturing is committed to the highest level of customer service quality. Every Centerline pump is comprehensively and repeatedly tested at diverse pressure levels to assure that it goes to our customer in perfect operational order. Centerline technicians work to ensure that our customers fully understand the operation of the model being delivered. If a customer"s pump is down, we understand the importance of timely response and parts availability. Centerline technicians will assess the problem and make repairs to bring the pump back into new specification. The Centerline mud pump technicians are well versed and qualified to operate and repair any product that is provided to the customer.

The NOV FC-1600 Triplex Mud Pump is made of rugged Fabriform construction and designed for optimum performance under extreme drilling conditions. It is compact and occupies less space, yet delivers unequaled performance. The pumps are backed by several decades of design and manufacturing experience, and are considered leaders in the field.

NOV FC-1600 Triplex Mud Pump is conservatively rated at relatively low rpm. This reduces the number of load reversals in heavily stressed components and increases the life of the fluid end parts through conservative speeds and valve operation.

The NOV FC-1600 Triplex Mud Pump design provides an inherently balanced assembly. No additional counterbalancing is required for smooth operation. No inertia forces are transmitted to the pumps’ mountings.

A Triplex Mud Pump sometimes referred to as a drilling mud pump or mud drilling pump. NOV FC-1600 Triplex Mud Pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling.

This Triplex Plunger Pump is well known for its high sped operation and long working life. Driven by gas/electricity/diesel, this pump deserves praise for its energy efficient quality. Based on production needs, this pumping system is offered with 34 kw/55 kw/45 kw/75 kw motor. This system has built in speed reduction gear for its uninterrupted operation. Offered 1125 x 728 x 430 mm Triplex Plunger Pump can endure 75 Psi operating pressure. Air pressure of this system can be regulated easily simply by controlling its pressure regulator. It can maintain maximum 321 lpm flow rate which is truly unique.

Saigao has long been a leading supplier of pumping solutions for the energy, industrial, chemical, mining, pulp and paper, food, medical, steel/aluminum, reverse osmosis, glass, detergent, high pressure scale-washing, geological, rock mechnic, electric power, and municipal markets.

Many factors have contributed to our success, but the most important is our ability to provide unmatched overall value and true pumping solutions for our customers. We have redefined the traditional expectations in the industry by setting new standards for low cost of owner-ship, long service life, and ease of maintenance.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

You can find our high-performance mud pumps at some of the largest oil and natural gas drilling operations on the planet. Now, we’re ready to supply one of our mud pumps to you.

Looking for a mud pump for sale? Bridges Equipment has the biggest inventory of rebuilt duplex and triplex mud pumps and pump packages ready to ship. Unlike some suppliers, we completely rebuild our mud pumps to OEM standards and guarantee our work from 90 days up to six months against major failure.

Our fabrication facility customizes mud pumps, equipment, and pump packages to meet the needs of operations large and small, across the nation and around the world. Whether you need a custom-fabricated mud pit or a unitized pump package, we have the expertise to get it done.

Nothing wastes time and money like waiting on parts. With two supply stores stocked with the fluid ends and other mud pump parts you need to keep your operation running, and the field mechanics to install them, we can help keep your operation up and running.

Customizability. Functionality. Quality. Reliability. You’ll find these attributes and more in every mud pump, mud pump part or mud pump package we have available for sale or rental.

Bentec completely redeveloped the concept of Mud Pumps. Being equipped with a direct-driven gearbox, an own developed motor, and a state-of-the-art pump housing, there is no need for an internal gear coming with many disadvantages and no more belt tensioning.

Bentec Mud Pumps are light weight and have a small footprint. The AC-powered motor is top or rear mounted – suitable for any drilling rig arrangement. The pump is available with 5 000 or 7 500 psi fluid ends, and all its parts that are subject to wear and tear meet API standards and are available worldwide.

A handling crane makes it easy to handle the fluid end components. Furthermore, Bentec uses a patented liner and valve clamping technology to reduce the maintenance time significantly. A quick-change liner and piston system serves for easy maintenance. A special feature of the Bentec MUD PUMP is the side-mounted gear drive.

Liner cooling and gear oiler systems are included; a supercharge pump and a noise reduction package can be installed upon request. The Bentec MUD PUMP is the right choice especially when it comes to noise-sensitive environments such offshore or densely populated environments.

Beyond the supply of Mud Pumps, Bentec acts as system supplier. The pumps can be delivered together with a Bentec Power Control System and a Bentec Soft Pump System.

BW 160/10 triplex mud pump is one of the primarily utilized equipment for geological prospecting. During core drilling, this triplex reciprocating pump provides the drilling hole with enough slurry or cleaning water and makes it circulate in the drilling hole to carry the debris up to the earth surface, so as to clean the bottom of the drilling hole as well as cool and lubricate the drilling tools. In this way, the wall of the drilling hole can be protected and the drilling working will be faster. The performance of mud-pump directly affects the efficiency of drilling and safety in production, so users must read the user’s guide before utilizing the pump.

BW 160/10 three plunger mud pump is a new member of our portable mud pump family. It is a horizontal single acting triplex reciprocating piston pump. This triplex mud pump is small and light, and it enjoys long service life, simple operation and reliable performance. Additionally, it is equipped with a number of interchangeable parts and standard parts to facilitate assembly and repair. This triplex reciprocating pump is extensively applied to geological and engineering prospecting within a hole depth of 1,000m in industries like railway, water conservancy, metallurgy, building, geology, etc.

We have continuously adhered to improve the performance of our mud pump. If you find any discrepancy between the user’s guide and the real product, please refer to the real product.

Triplex reciprocating pump with four different levels of displacement and pressure is available to suit for drilling working of different diameters. It is also designed for core drilling, chemical engineering,oil well drainage, soft foundation grouting, etc.

Mud pumps are the heart of your drilling operation. Bridges Equipment is the leading authority on the unitization of triplex mud pumps. As an OEM distributor for Caterpillar Rig Power, Detroit Diesel, and Joliet motors, we provide our customers with a wide range of options to meet their pump needs.

A malfunctioning mud pump can throw an entire drilling operation off schedule. Our fleet of mud pump packages are available to rent while the broken unit is being repaired, so your drilling operation never misses a beat.

Our Gardner Denver, RSF, and Continental Emsco triplex pump packages range from 500-1600 HP and can be fully customized to suit your project. Contracts are offered for as few as 10 days, so whether you need to replace a broken unit or need a long-term rental to act as a backup pump, we’ve got you covered.

We “Flow Control Engineers are engaged in trading a high-quality assortment of Industrial Pumps, Automotive Oil, Woltmann Meter, Gear Boxes, Electromagnetic Flowread more... Brochure

1. Usage and Application Range SB series Centrifugal Sand Pump mainly supplies to solids control circulating system of oilfield drill rig,and be used to provide drilling liquid with a certain discharge capacity and pressure to sand, desilter and mud mixer,to assure these equipment work efficiently. The SB10×8×14...

Mud Pump Spare Parts We can offer the mud pump spare parts covers the liners, valves and seats, pistons etc to match the most types of mud pumps in the market, like Emsco, Gardner Denver, National, Oil well, Continental, Ideco, and China 3NB etc Brand Model Emsco F-350 F-500 F-650 F-800 F-1000

Carbon/ Stainless Steel Triplex 600HHP Basic Parameters: Stroke: 6” Material: Carbon Steel/Stainless Steel Plunger No.: 3 Plunger size: 2.75”,3”,3.5”,4”,4.5” Load Weight: 1,550LB Approx. Size: 28”x12”x19”(LXWXH) We provide and manufacture high pressure triplex/ quintuplex plunger pump fluid ends for the fracturing...

Carbon/Stainless Steel Quintuplex 1000HHP Basic Parameters: Stroke: 6” Material: Carbon Steel/Stainless Steel Plunger No.: 5 Plunger size: 2.75”,3”,3.5”,4”,4.5” Load Weight: 2,500LB Approx. Size: 46”x12”x20”(LXWXH) We provide and manufacture high pressure triplex/ quintuplex plunger pump fluid ends for the fracturing...

Carbon/Stainless Steel Triplex 2250HHP Basic Parameters: Stroke: 8” Material: Carbon Steel/Stainless Steel Plunger No.: 3 Plunger size: 4”,4.5”,5”,5.5”,6” Load Weight: 3,350LB Approx. Size: 36”x19”x23”(LXWXH) We provide and manufacture high pressure triplex/ quintuplex plunger pump fluid ends for the fracturing job....

Carbon/Stainless Steel Quintuplex 2500HHP Basic Parameters: Stroke: 8” Material: Carbon Steel/Stainless Steel Plunger No.: 5 Plunger size: 4”,4.5”,5”,5.5”,6”, 6.5” Load Weight: 4,800LB Approx. Size: 52”x19”x23”(LXWXH) We provide and manufacture high pressure triplex/ quintuplex plunger pump fluid ends for the...

Carbon/Stainless Steel Quintuplex2700HHP Basic Parameters: Stroke: 10” Material: Carbon Steel/Stainless Steel Plunger No.: 5 Plunger size: 3.75”,4”,4.5”,5” Load Weight: 5,500LB Approx. Size: 59”x24”x26”(LXWXH) We provide and manufacture high pressure triplex/ quintuplex plunger pump fluid ends for the fracturing job....

Carbon/Stainless Steel Y block Quintuplex 2800HHP Basic Parameters: Stroke: 8” Material: Carbon Steel/Stainless Steel Plunger No.: 5 Plunger size: 3.75”,4”,4.5”,5” Load Weight: 6,300LB Approx. Size: 63”x20”x24”(LXWXH) We provide and manufacture high pressure triplex/ quintuplex plunger pump fluid ends for the...

Trailer Concrete Pump LV-HB-20S Product Advantages: One machine with multi-purpose, it can transport mortar/fine stone concrete and spray mortar/fine stone concrete. It is small but flexible. It is mostly used for exterior wall spraying, slope protection spraying, etc. Technical Specification Maximum vertical...

Trailer Concrete Pump LV-HB-40S Product advantages: One-piece stamping hopper, no material accumulation. Electric double lubrication, no distributor, point-to-point lubrication. Panel operation and wireless remote control dual control. Super air cooling, no water cooling required. Technical Specification

Trailer Concrete Pump LV-HB-45S Product advantages: Hydraulic control equipment. One-key switch between high and low pressure, one-key return piston. Ultra-stable performance, no need for proximity switches. External junction box, wiring is more convenient. The speed is adjustable, 4-45m3 can be adjusted arbitrarily....

Merit Pump and Equipment Company is your direct Weatherford pump distributor. We offer you the complete line of Weatherford reciprocating pumps, including triplex and quintuplex. We can assist you in all your pump service needs. If you are looking for Weatherford pump repair or supplies, we are the specialist team you can count on every time.

Established in 1990, our facility in Wooster, Ohio includes a complete pump repair service center for your major or minor repairs. We also have a knowledgeable sales department ready to answer any of your questions and supply you with the right Weatherford pump equipment and guidance. Our highly trained specialists will work with you to understand your requirements and match you to a specific pump application. We will size the right pump for you and provide ongoing support.

We are a dependable, experienced Weatherford pump service and supply center, & an official Weatherford pump distributor. We are ready to assist you with any inquiry.

Weatherford T-Series and W-Series are versatile pumps, offered in a variety of material and design options that enable them to be used in a wide range of applications. The Weatherford pumps cast iron power frame ensures robust, fatigue-free durability and excellent wear resistance of moving surfaces. The fluid cylinders are made from either forged 4140 carbon steel, 2205 duplex stainless-steel, or 955 cast nickel-aluminum-bronze materials for increased durability and extended life.

Weatherford offers optional solid ceramic, or ceramic-coated plungers on request for special applications with pumping abrasive or corrosive fluids for superior durability. The oil trough is designed to evenly lubricate the crossheads and wrist-pin bearings during operation to reduce wear and extend component life. A variety of packing arrangements are available to meet the requirements of any application. Weatherford pumps are API-674 compliant upon request.

The Weatherford W-Series triplex and quintuplex plunger pumps are rated for flows from 6 GPM to as high as 688 GPM intermittent duty (533 GPM continuous duty) with pressure ranges from 600 up to 5,000 PSI.

The Weatherford’s T-Series triplex plunger pumps are smaller pumps rated for flows from 0.50 GPM to 85 GPM intermittent duty (or 56 GPM continuous duty) with pressure ranges from 600 up to 5,000 PSI.

The Weatherford’s T-Series triplex plunger pumps are smaller pumps rated for flows from 0.50 GPM to 85 GPM intermittent duty (or 56 GPM continuous duty) with pressure ranges from 600 up to 5,000 PSI. These pumps are offered with carbon steel or duplex stainless-steel fluid end cylinders.

If you need Weatherford pump services, including repair and equipment, please contact us today. We will provide you with decades worth of guidance on your current Weatherford pump or help with your future product. Our specialists are eager to work with you. Call us today at 800-700-8265.

8613371530291

8613371530291