350 mud pump supplier

A wide variety of continental emsco f350 mud pump options are available to you, You can also choose from new, continental emsco f350 mud pump,as well as from energy & mining, construction works , and machinery repair shops continental emsco f350 mud pump,And whether continental emsco f350 mud pump is provided, {2}, or {3}.

Browse through more than 1,500 duplex piston rods and 200 duplex pony rods in our inventory. EC Tool gives you a quote before your order, so you know what you’re getting for your money every time. While we primarily keep connecting rods for GA550 and GA750 models in stock, there are other options at your disposal as well. This includes custom connecting rods for most duplex and triplex mud pumps.

We now offer new crossheads and capsules for both EMSCO D-375 and DB-550 duplex pumps. You can also find slides and shoes for certain models. Available parts currently in our inventory include:

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

We are a supplier of aftermarket mud pump parts. Whether it’s a duplex or triplex pump, we offer a complete line of parts and spares that interchange with most brands. We supply everything from chrome and ceramic liners, seals, crankshafts, pistons and modules and everything in between.

We mainly manufacturer Emsco F-500, F-800, F-1000, F-1300, F-1600,Gardner Denver PZ-9 and National 12-P-160 mud pumps. The quality products, competitive prices, respensive service and short delivery time earn a lot of reputation for us.

Product Instruction:we devoted to professionally manufacure and sales the mud pump in global,the quality and your satisfication are always being our achievement,we would,t say we are the best choice for u,but our product will tell u.+MORE

Product Instruction:This series mud pumps are strictly manufactured according to SY5138 standard of CNPC and are tested accordingly when leave factory.

Product Instruction:series mud pups are compatible and interchangeable with most of the F series mud pumps of other made like FB series (EMSCO, BOMCO and LSNOW), HHF/3NB-Fseries (Honghua), RSF (Huabei Rongsheng) RL-F series (Shandong Rongli), F series (Shandong Kerui), TFI F series (Texas First Industry),TSC, etc+MORE

Product Instruction:F-800light weight drilling pumpis designed for special drilling/workover application where equipment weight and dimension should be weill limited like drilling rig working onboard offshore platform,barge,drilling rig working in wetland,jungles and so on.it certainl can also work for conventional drillingrigs.+MORE

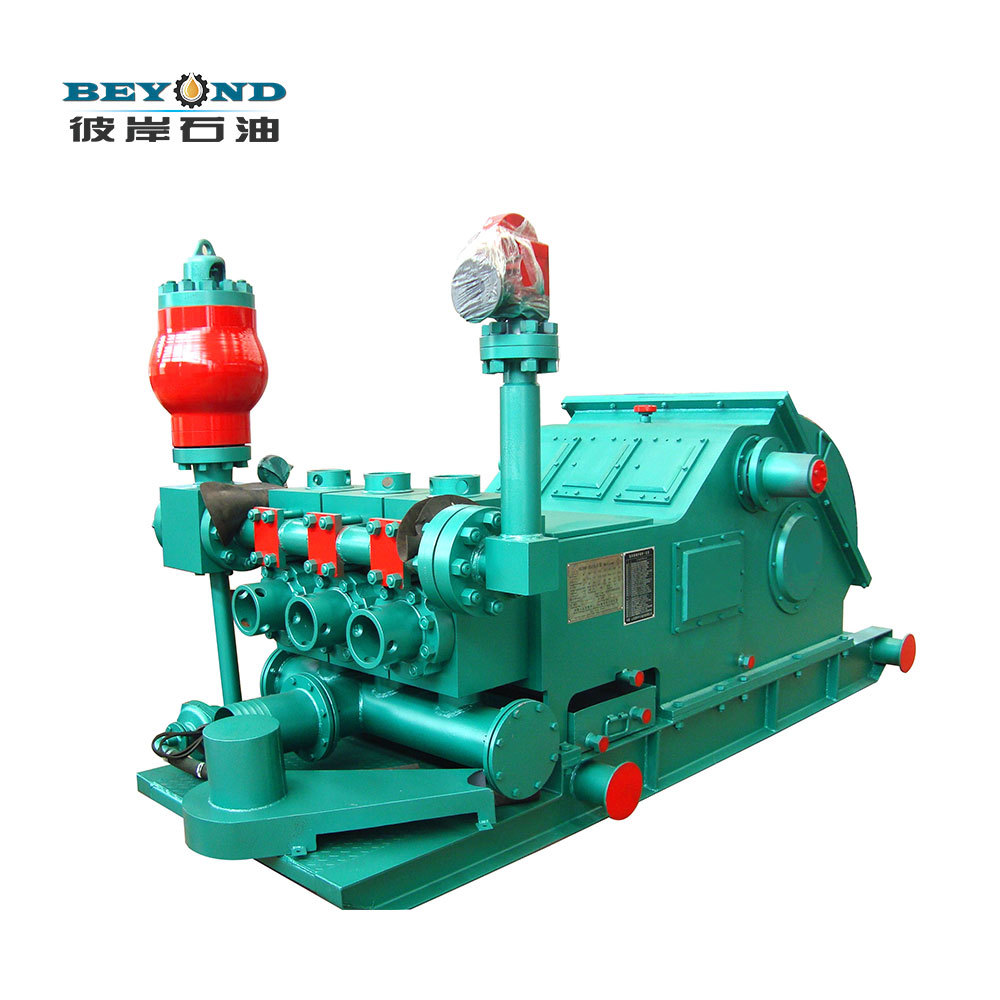

BW-350 mud pump is a horizontal, triplex, single acting reciprocation piston pump. This pump can also be used as a mud-pump cooperating hydrology sand well drilling machines and 100m car drilling machine, or be used as a injection pump which is used to affuse cement slurry into softground. It has four shifts of flow rates and four shifts of pressures. Comparing to some other pump with same specifications, it has advantages such as smooth rotation, large-scale variable rates of flow, high out-but pressures, longer service life of the wearing parts and steady performance, etc.

BW-350 mud pump is an improved type of BW-250 pump. A majority of their parts are common parts, so the structure, operation of the pump, disassembly and assembly the pump, lubrication of the pump,trouble shooting guide of the pump and prevention check are the same with the BW-250 pump.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

Browse through more than 1,500 duplex piston rods and 200 duplex pony rods in our inventory. EC Tool gives you a quote before your order, so you know what you’re getting for your money every time. While we primarily keep connecting rods for GA550 and GA750 models in stock, there are other options at your disposal as well. This includes custom connecting rods for most duplex and triplex mud pumps.

We now offer new crossheads and capsules for both EMSCO D-375 and DB-550 duplex pumps. You can also find slides and shoes for certain models. Available parts currently in our inventory include:

8613371530291

8613371530291