afermarket mud pump factory

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

Browse through more than 1,500 duplex piston rods and 200 duplex pony rods in our inventory. EC Tool gives you a quote before your order, so you know what you’re getting for your money every time. While we primarily keep connecting rods for GA550 and GA750 models in stock, there are other options at your disposal as well. This includes custom connecting rods for most duplex and triplex mud pumps.

We now offer new crossheads and capsules for both EMSCO D-375 and DB-550 duplex pumps. You can also find slides and shoes for certain models. Available parts currently in our inventory include:

The NOV Fluid End Expendables and accessories add value to your drilling rig by increasing the operating range of existing mud pumps while reducing their maintenance and downtime. Fluid End Expendables are in-stock and ready for delivery at World Petroleum Supply, Inc.

National Oilwell Varco develops the highest quality, field-proven fluid end expendables and accessories for all pump manufacturers to provide extended run times and longer service life.

Mud pump liners The ceramic, chrome iron sleeved, and hardened steel liners are manufactured using only the highest-grade materials and offer extended run times with excellent resistance to abrasion, erosion, and corrosion.

Mud pump piston rods We manufacture crosshead extension rods, quick connect rods, self-aligning rod assemblies, and piston rods for all types of mud pump manufacturers. All rods are manufactured from high-quality materials and machined to exact tolerances to provide long life and superior service

Mud pump pistons We offer pistons of all styles and compositions designed for various types of drilling applications. All pistons are designed to provide consistent run times, minimize downtime, and reduce maintenance.

American Mfg Company is a quality manufacturer of replacement parts for the wide variety of mud pumps, centrifugal pumps, rig parts, and swivel parts found on the World market today.

American Mfg Company Pumps And Parts carry over $5,000,000 of interchangeable mud pumps parts, centrifugal pump parts, rig parts and swivel parts in stock for all major manufacturers such as Gardner Denver, Failing, Wheatley, National, Emsco, Ideco and Opi, as well as OE AM pumps.

GLOBAL ENERGY INC. Supply complete mud pumps and parts for various mud pumps in the oil field industry. Well-known manufacturers are National, Emsco, Gardner Denver, Oilwell and Ideco. We supply thousands of parts whether they are fluid end expendables or gear end replacement parts. For years, we have sourced both OEM and aftermarket mud pump parts.

LeTourneau Ellis Williams Co., a unit of Rowan Cos. Inc., is partnering with a unit of Varco International Inc. to manufacture and for Varco to sell a line of general duty and heavy duty oilfield mud pumps, parts and accessories.

The agreement calls for Varco to distribute the LeTourneau"s balanced crankshaft line of pumps and provide aftermarket service and support, under the Varco brand name.

Boring underground requires drilling fluid that combines water and bentonite clay to help remove cuttings, stabilize the bore, cool the cutting tools, and lubricate pipe string. As the process comes to life, the drilling pump rotates the drill bit which then removes the material. As the drill bit is rotating, the pressure and fluid produced by the drill pump helps stabilize the tunnel. The mud extracted from this process is then filtered and reused for drilling fluid.

HDD is a process usually deployed when installing pipes and cables underneath roads, rivers and other types of infrastructure. Therefore, most jobs come with a challenging set of parameters that demand high rates of accuracy, efficiency, and effectiveness. Equipment manufacturers and end-users can trust our +160 years of experience manufacturing pumps for both petroleum and industrial industries.

Our HDD industry pumps offer higher flow rates at slower speeds, ranging from 200 to more than 1000 gpm at pressures exceeding 2000 PSI. Through this more efficient operation, we can help extend the life of our pumps and consumable parts, even in the most demanding HDD projects.

Our lineup of dedicated high pressure HDD pumps come in a lightweight design that eases the burden of transportation and setup while also maximizing their power potential. With max rod loads ratings up to 53,000 and horsepower up to 800 BHP, our HDD high flow pumps can handle tough jobs with ease.

Partnering with GD Energy Products for your HDD equipment also means having an expert team to support you throughout the lifecycle of your pump. We have field service technicians who can come to you with solutions, as well as 24-hour customer service and our Parts on Demand program that ensures you never run out of pump parts when you need them.

It’s all-in service of ensuring that every HDD pump you get from GD Energy Products meets our performance standards and exceeds yours. With easy access to aftermarket parts and consumables, HDD companies can trust they have a truly reliable pump at a lower total cost of ownership (TCO).

The global mud pumps market size is expected to grow at a CAGR of 3.80% during the forecast period of 2023-2028. The market growth is likely to be driven by the increasing frequency of exploration activities due to the rising demands for energy and reduction in harmful carbon emissions.

Mud pump is a type of piston/plunger driven pump that is capable of utilizing drilling fluids under high pressure. The mud pumps are an essential part of heavy drilling processes and are usually used in conjunction with other pumps. These pumps help circulate the drilling fluid through the drill bit and bring it back to the surface.

The increasing demand for minerals, oil, and gas has expanded the demand for mud pumps. With rising offshore mining activities and the rapidly thriving population around the world, the market is expected to expand further in the forecast period.

The mud pump market is expected to develop rapidly with the benefits provided by it. Increasing demand for directional and horizontal drilling and the mud pump’s capability to handle high-pressure drilling operations can further propel the market.

Technological advancements have enabled mud pumps to eliminate harmful carbon emissions and increase operating efficiency. With the increasing demand for electric mud pumps, the market can experience new growth opportunities.

Based on type, the market can be segmented into a duplex, triplex, and quintuplex. Based on operation, it can be bifurcated into electric and fuel engine. Based on application, the market can be divided into oil and gas, mining, and construction, among others. The regional markets for the mud pumps market can be divided into North America, Europe, the Asia Pacific, Latin America, the Middle East and Africa.

The comprehensive EMR report provides an in-depth assessment of the market based on Porter"s five forces model along with giving a SWOT analysis. The report gives a detailed analysis of the following key players in the global mud pumps market, covering their competitive landscape and the latest developments like mergers, acquisitions, investments and expansion plans.

Based on types, the mud pump market can be segmented into a duplex, triplex, and quintuplex. Among these types of pumps, triplex pumps are likely to account for the largest share of the market due to the advantages they provide over duplex pumps. The shift from duplex pumps to triplex pumps is expected to propel the market growth owing to its lesser weight and similar efficiency.

Based on operation, the mud pumps market can be bifurcated into electric and fuel engine. The electrically operating mud pump segment is rapidly developing due to its environmental advantages over the fuel engine pumps. With the increasing exploration activities conducted in all the regions around the world to meet the surging demand for energy and minerals is expected to amplify the market value.

Mud King Products, headquartered in Texas, United States, is a company operating in the oil and gas industry. The company was founded in 2000 and has been working in specialized sectors to manufacture various such as triplex mud pumps, handling tools, swivel cartridges, gate valves and butterfly valves, block hooks, and rotary tables.

GD Energy Products, LLC is an oil and gas company, founded in 1859, headquartered in Texas, United States. It is a global leader in the design and manufacturing of positive displacement pumps and associated aftermarket parts. The company provides products and services including falcon spring retainer, pump repair, redline packing, mud pumps, coiled tubing, and electric fracturing, among many other services.

United StatesAfghanistan, Islamic State ofAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaidjanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia-HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCambodia, Kingdom ofCameroonCanadaCape VerdeCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongoCongo, The Democratic Republic of theCook IslandsCosta RicaCroatiaCubaCuraçaoCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupe (French)Guam (USA)GuatemalaGuineaGuinea BissauGuyanaHaitiHeard and McDonald IslandsHondurasHong KongHungaryIcelandIndiaIndonesiaIranIraqIrelandIsraelItalyIvory Coast (Cote D"Ivoire)JamaicaJapanJordanKazakhstanKenyaKiribatiKuwaitKyrgyz RepublicLaosLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacauMacedoniaMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartinique (French)MauritaniaMauritiusMayotteMexicoMicronesiaMoldaviaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNetherlands AntillesNew Caledonia (French)New ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth KoreaNorthern Mariana IslandsNorwayOmanPakistanPalauPalestinian AuthorityPanamaPapua New GuineaParaguayPeruPhilippinesPitcairn IslandPolandPolynesia (French)PortugalQatarReunion (French)RomaniaRussiaRwandaS. Georgia & S. Sandwich Isls.Saint BarthélemySaint HelenaSaint Kitts & Nevis AnguillaSaint LuciaSaint MartinSaint Pierre and MiquelonSaint Tome (Sao Tome) and PrincipeSaint Vincent & GrenadinesSamoaSan MarinoSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSlovak RepublicSloveniaSolomon IslandsSomaliaSouth AfricaSouth KoreaSouth SudanSpainSri LankaSudanSurinameSvalbard and Jan Mayen IslandsSwazilandSwedenSwitzerlandSyriaTadjikistanTaiwanTanzaniaThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUgandaUkraineUnited Arab EmiratesUnited KingdomUruguayUzbekistanVanuatuVatican CityVenezuelaVietnamVirgin Islands (British)Virgin Islands (USA)Wallis and Futuna IslandsWestern SaharaYemenZambiaZimbabwe

We are a supplier of aftermarket mud pump parts. Whether it’s a duplex or triplex pump, we offer a complete line of parts and spares that interchange with most brands. We supply everything from chrome and ceramic liners, seals, crankshafts, pistons and modules and everything in between.

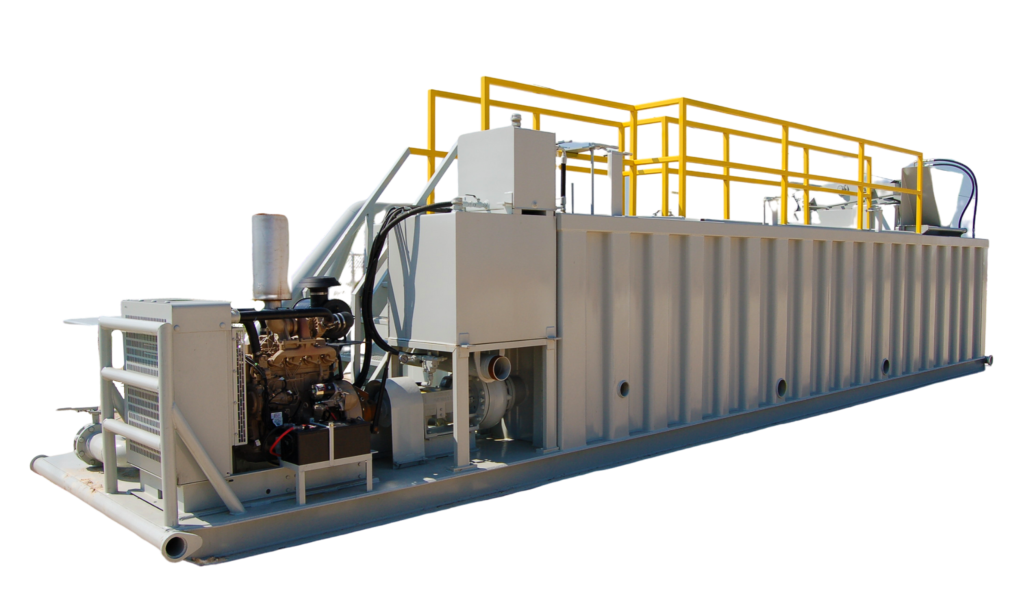

Centerline Manufacturing is committed to the highest level of customer service quality. Every Centerline pump is comprehensively and repeatedly tested at diverse pressure levels to assure that it goes to our customer in perfect operational order. Centerline technicians work to ensure that our customers fully understand the operation of the model being delivered. If a customer"s pump is down, we understand the importance of timely response and parts availability. Centerline technicians will assess the problem and make repairs to bring the pump back into new specification. The Centerline mud pump technicians are well versed and qualified to operate and repair any product that is provided to the customer.

8613371530291

8613371530291