airlift mud pump factory

The pumps PM are made of corrosion-proof materials conforming to conditions for conveying potable water (GENOVA system). During air flow cut-off the pump’s construction provides separation of the supply system from the media pumping zone by means of a diaphgram perforated valve, closed by hydrostatic pressure.

The pumps are highly reliable and easy to assemble owing to the use of PVC hose as an intake end. The hose can be formed depending on the shape of the tank.

The capasities of the pumps (specyfied in laboratory conditions for clean water and constant depth Hz=1,5 m) are presented in the diagram showing the dependance of air demand supplied to the pump on the lifting height “H” of the medium being pumped (see data sent by fax).

The capasity of PM 110, at immersion depth Hz= 4m, is 15-20m3 (at H=0,5 m). The pumps can operate in a complex system allowing for multiplication of capasity. The lenghts of ends, intake L2 and exhaust L1, and air supply hose are specyfied by the buyer. We suggest the purchase of the very “heart” for individual assembly.

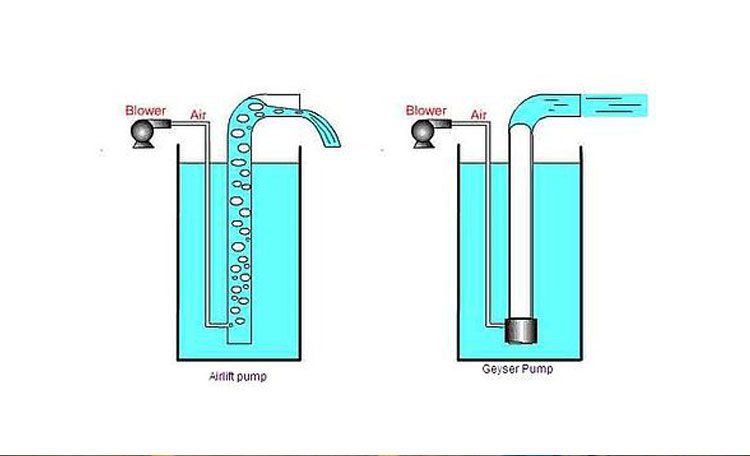

Air Lift pump or Air Lift pump is one of the simplest equipment in the field of wastewater treatment and aeration of aquaculture pools, which with the help of air pressure, tries to transfer fluid to the top of the ponds. Airlift pumps or air pumps are designed on the basis that the presence of air bubbles in the fluid will reduce their density and eventually lead to their upward movement. Seven Industrial Group; Manufacturer of airlift pumps and other water treatment equipment designs and manufactures this group of products in compliance with various standards. In the following, we will provide a comprehensive guide including how air pumps work, standards and important points in the design, production and manufacture of airlift pumps and everything you need to know about the price of Air Lift pumps and their purchase.

An airlift pump is a pump with low suction power that consists of two very simple pipes that are transferred from a compressed air pipe by a compressor or blower to the lowest point of the pond or treatment plant or pool and in the next pipe water droplets or Sewage moves up with the air. This type of pump actually reduces the density of the fluid by moving air into the sewage and fluid in the ponds and moves easily to the highest level of the pond.

To better understand and become more familiar with the Air Lift pump, it is better to first describe how this type of pump works and introduce each of the steps that go through it. The operation of the airlift pump is as follows:

The entry of air into the fluid or sewage creates multiple bubbles that reduce the density of the fluid and move upwards through the second pipe of the pump.

Due to aeration and bubbling in the sewage and its transfer to the top, solid particles deposited in the floor may also move upwards. A very important issue in aeration or transfer of sediments by this pump is the non-use of mechanical or electronic energy, which is a great advantage for it.

Due to their simple structure, Air Lift pumps have low suction power and low fluid transfer speed upwards. Therefore, different types of this pump are designed. We introduced its common type in the first part of the text and explained how it works. In order to improve and increase the efficiency of the device, changes were made in its structure and another type called geyser pump was designed and produced.

In order to improve the suction power and transfer of air and fluid flow upwards to sedimentation ponds or aquaculture ponds, changes were made in the structure of conventional air-pump pumps. geyser pump is actually an improvement of old pumps that in their general structure, in addition to air transfer pipes, a kind of pipe is also considered as an air supplier. This pipe eventually causes fluid and air in the transfer pipe create larger bubbles. The formation of larger bubbles and their presence in the sewage or water in the ponds and the liquid source greatly affects the density reduction and therefore the speed of their transfer to the highest level of the pond increases.

In designing an airlift pump, it is necessary to consider several very important issues in order to increase the efficiency of this group of equipment. One of the most important things in designing an air lift pump is the height and length of the pipes. The air transfer pipe should be considered at the height of the pond and the liquid source in order to perform aeration and fluid transfer from the lowest point. In addition, it is necessary to determine the material of the pipes according to the organic matter in the wastewater to prevent corrosion and decay. Stainless steel and fiberglass, cast iron and composite are among the materials that can be selected according to the conditions of sewage and the environment of installation and use of Air Lift pump.

Seven Industrial Group, as the oldest manufacturer of water and wastewater treatment equipment, has designed and manufactured Airlift pumps in its activities. It should be noted that in the process of manufacturing the airlift pump, the environmental conditions and the treatment plant are considered and the required standards are determined by the development and research team and a group of professional engineers, and finally the design is done. To know the features of each of the products in this collection, experts are ready to provide the necessary advice before buying an airlift pump.

The price of airlift pumps, like other water and wastewater treatment equipment, is determined by various factors, and that is why the variety of these pumps is high. Pipe body material, pipe height and size, type of pump and compressor, etc. are among the factors that affect the price of the airlift pump. To inquire about the price of Air Lift pump, all you have to do is contact the experts of Seven Industrial Group through the communication channels mentioned at the bottom of the page.

The reasons for using air pumps are so varied that in some cases they may be used to transfer sludge deposited in sedimentation ponds or to aerate aquaculture ponds. It is very important to note that if you use this pump to transfer sludge and sediment from the bottom of the ponds, it is necessary to consider the diameter of the fluid transfer pipes up large enough.

The use and purchase of airlift pumps in the field of water and wastewater treatment is very high, the main reason for its great popularity is the numerous advantages of this equipment, some of which are:

Despite the many advantages of this type of air pump, there are limitations in their use, in other words, like other equipment, it has disadvantages, some of which are:

Centerline Manufacturing is committed to the highest level of customer service quality. Every Centerline pump is comprehensively and repeatedly tested at diverse pressure levels to assure that it goes to our customer in perfect operational order. Centerline technicians work to ensure that our customers fully understand the operation of the model being delivered. If a customer"s pump is down, we understand the importance of timely response and parts availability. Centerline technicians will assess the problem and make repairs to bring the pump back into new specification. The Centerline mud pump technicians are well versed and qualified to operate and repair any product that is provided to the customer.

In 1904, the company built its first mud pump, and since then, more than 1500 mud pumps in different designs have followed. MHWirth legacy of drawworks dates back to the 1950s, and also is history to deliver Pyramid masts and substructures for land rigs. In the following decades the firm added piston diaphragm pumps to its portfolio serving the mining industry as well as pile top drill rigs with Reversed Circulation Drilling (RCD) technology for the construction of foundation structures. That technology also laid the foundation for a later involvement in subsea mining. At that time, the Germany-based company was well-known in the industry under the name of “Wirth”.

During mining operation, a MHWirth drill bit with up to 7.2 m in diameter loosens the material from the seabed. The material is then transported vertically through a large diameter airlift drill string (up to 700 mm in diameter) to the drilling vessel for further processing. Core of this technology is MHWirth’s efficient and environmentally-friendly reverse circulation technology, also known as airlift technology. Compared to other solutions, MHWirth’s airlift technology uses only robust components with limited complexity under water, thus maximizing equipment availability and optimizing operational costs (OPEX). Thus, MHWirth drilling equipment allows the vessels to operate even under severe sea conditions.

The purpose of this utility model is to overcome the above-mentioned defective of prior art, and a kind of reliable performance is provided, the air lift mud pump that the life-span is long.

For achieving the above object, the utility model air lift mud pump comprises the transducing chamber of cone-shape, the riser, compressed air hose and the supply pipe that link to each other with the transducing chamber, and riser and supply pipe be positioned opposite up and down, and the cross section of riser is greater than the cross section of supply pipe.Riser and supply pipe positioned opposite up and down help making material to rise, reduce energy loss smoothly and improve transfer efficiency.So design does not have mechanical moving element, does not have impeller and bearing wear problem, is power with the air only, has reliable performance, and the life-span is long, the advantage that operating cost is low.

Before the utility model airlift pump work, open circulating pipe earlier, play stirring action, because precipitate, need the stirring action of circulating pipe that bits are floated at most of bits of slag bath, just can close circulating pipe about about one minute kind.After opening circulating pipe, open pressurized air,, pressurized air is moved upward along riser by the refraction action of transducing chamber skew wall.Pressurized air can form a depression near the riser mouth of pipe like this, and slag-water slurry produces initial velocity under the effect of atmosphere negative pressure, and is raised in the guiding gutter along riser.Be raised to the interior slag-water slurry of guiding gutter under the effect of seal bowl, guiding gutter falls back; Guiding gutter collects these slag-water slurries, flows to appointed positions along honeycomb duct.Existing blade type slag stock pump is used to promote the metallurgical slag slurry and has only 3-4 month the life-span, and need often change parts and maintenance; And the utility model air lift mud pump can reach half a year in working life under same operating conditions, and need not change parts.

After adopting technique scheme, the utility model air lift mud pump has simple in structure, reliable performance, and wear-resisting property is good, and the life-span is long, and operating cost is low, is convenient to safeguard advantage applied widely.

8613371530291

8613371530291