application of mud pump factory

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

Mud pumps are essential equipment for any oil or gas well. They are used to move drilling mud and other fluids needed during the drilling process. To select the right mud pump for your well, you need to understand the different types available and what each one can do.

In this article, we will take a comprehensive look at mud pumps and provide you with all the information you need to make an informed purchase. We will also discuss how mud pumps are used in drilling operations and highlight some of their key features. By the end of this article, you will clearly understand what mud pumps are and what they can do for your well.

A mud pump is a type of reciprocating positive displacement pump that is specifically designed for use in drilling operations. It helps to circulate the drilling fluid (or “mud”) through the drill bit and back up to the surface. The mud pump also provides pressure to keep the drill bit from becoming plugged.

The pump creates suction that pulls the drilling fluid from the pit and then uses its piston to push the fluid back up the well. This action not only circulates the fluid but also helps to remove any cuttings or debris that may have been generated during the drilling process. Mud pumps are an essential part of the drilling process and are typically used in conjunction with other pumps, such as centrifugal pumps, to create a complete pumping system. Without a mud pump, drilling would not be possible.

There are many different types of mud pumps, each with its own advantages and disadvantages. However, pump experts generally understand the requirement and then suggest which type of pump design would be more efficient. Here are five of the most popular types:

Piston mud pumps are the most common type of mud pump. They use a piston to draw mud from the pit and then force it to the drill bit through the hose. Piston mud pumps are very durable and can handle a lot of pressure. However, they are also very loud and can be challenging to operate.

Plunger mud pumps work similarly to piston mud pumps, but they use a plunger instead of a piston. As a result, plunger mud pumps are quieter than piston mud pumps and are easier to operate. However, plunger mud pumps are not as durable and can only handle a limited amount of pressure.

Hydraulic mud pumps use hydraulic power to draw mud from the pit. They are very powerful and can handle a lot of pressure. However, these types of pumps are generally costly and can be challenging to operate.

Diaphragm mud pumps use a diaphragm to draw mud from the pit. They are less powerful than hydraulic mud pumps but are much cheaper. They are also easier to operate. These merits make such pumps more used in small scale operations.

Peristaltic mud pumps use peristaltic action to draw mud from the pit. They are the most expensive type of mud pump but are also the most powerful. Unfortunately, they are also the most difficult to operate. But given their operational power, they are used in large-scale mining and drilling operations.

Even though mud pumps are very lucrative for mining and drilling purposes, they exhibit many more merits, making them useful in other industries. Following are some of the main advantages of mud pumps:

Mud pumps help to increase the efficiency of drilling operations by allowing for fluid circulation and cooling of the drill bit. This results in faster drilling and less wear on the equipment.

Mud pumps also help to improve safety during drilling operations by providing a means to circulate and cool the drill bit, which reduces the risk of overheating and fire.

Mud pumps can also help to improve the accuracy of drilling operations by preventing the drill bit from wandering off course due to excessive heat build-up.

The use of mud pumps can also help to reduce the costs associated with drilling operations by reducing the need for frequent replacement of drill bits and other worn items.

The use of mud pumps can also help to increase the productivity of drilling operations by reducing the downtime associated with the frequent replacement of drill bits and other worn items.

Mud pumps are an essential part of the oil and gas industry, as they are used to pump drilling fluid (mud) into the drill hole. There are many different mud pumps, each with its own unique set of features and applications. A reliable pump expert will help you choose which pump to use where. Here are 10 of the most common applications for mud pumps:

Mud pumps are extensively used to circulate drilling fluid during the drilling process. This helps to cool and lubricate the drill bit and remove cuttings from the hole.

Mud pumps are also used in hydraulic fracturing operations, where high-pressure fluid is injected into the rock formation to create fractures. The pump helps to circulate the fracturing fluid and keep the pressure at the desired level.

Mud pumps are sometimes used in geothermal operations to circulate water or other fluids through the drilled well. This helps extract heat from the rock and bring it to the surface.

In coal seam gas extraction, mud pumps are used to circulate water and chemicals through the coal seam to dissolve the methane gas and make it easier to extract.

In potash mining, mud pumps are used to circulate brine solution through the ore body to dissolve the potassium chloride (potash) and pump it out of the mine.

Mud pumps are often used in water well drilling operations to circulate water through the drill hole and help flush out any cuttings or debris. Pump experts can customize mud pumps to suit this application.

In tunnelling operations, mud pumps can circulate a slurry of water and clay through the drilling area. This helps to stabilize the walls of the tunnel and prevent collapse.

Mud pumps are sometimes used in pipeline operations to help clean and inspect the inside of the pipe. The pump circulates water or other fluids through the pipe to remove any build-up or debris.

In environmental remediation projects, mud pumps can circulate water or chemicals through contaminated soil or groundwater. This helps to break down contaminants and make them easier to remove.

Mud pumps can also be used in construction projects to help remove water from the site or stabilize the ground. For this application, they are extensively used in large construction sites.

Mud pumps are an essential part of many different industries and have various applications. If you need a mud pump for your next project, be sure to consult with a pump expert to find the right pump for your needs.

The policy set forth below outlines the personal data that Power Zone Equipment may collect, how Power Zone Equipment uses and safeguards that data, and with whom we may share it. This policy is intended to provide notice to individuals regarding personal data in an effort to be compliant with the data privacy laws and regulations of the jurisdictions in which Power Zone Equipment operates.

Power Zone Equipment is committed to maintaining all reasonable precautions to ensure the privacy and security of personal data gathered by Power Zone Equipment. During your use of our website or through other communications with Power Zone Equipment, personal data may be collected and processed by Power Zone Equipment. In general, Power Zone Equipment collects personal contact information (e.g. name, company, address, telephone number and e-mail address), which you knowingly provide either by registration, requesting quotes, answering questions or otherwise for use in our commercial relationship. At times we may collect additional personal data that you voluntarily provide, including, but not limited to, job title, additional contact information, date of birth, hobbies, areas of interest, and professional affiliations.

Power Zone Equipment’s website is intended to be used by Power Zone Equipment customers, commercial visitors, business associates, and other interested parties for business purposes. Personal data collected by Power Zone Equipment through its website or by other means is used in support of our commercial relationship with you, including, but not limited to, the processing of customer orders, orders from vendors, managing accounts, learning about customers’ needs, responding to inquiries, and providing access to information. Also, in compliance with the laws and regulations of the relevant jurisdiction to support our relationship with you:

we (or a third party on our behalf) may use personal data to contact you about a Power Zone Equipment offer in support of your business needs or to conduct online surveys to understand better our customers’ needs; and

Power Zone Equipment is the commercial operator of its website and uses service providers to assist in hosting or otherwise acting as data processors, to provide software and content for our sites and to provide other services. Power Zone Equipment may disclose personal data supplied by you to these third parties who provide such services under contract to protect your personal data. In addition, where consistent with the laws and regulations of the relevant jurisdiction, Power Zone Equipment may disclose personal data if such disclosure:

For our customers in Switzerland and the European Union (EU), please note that Power Zone Equipment is a US based company. If you use our websites or web portals or, all information, including personal information, may be transferred to Power Zone Equipment (including subcontractors that may be maintaining and/or operating our website) in the United States and elsewhere and may be transferred to third parties that may be located anywhere in the world. Although this may include recipients of information located in countries where there may be a lower level of legal protection for your personal information than in your location country, we will protect your information in accordance with requirements applicable to your information and/or location. Specifically, for data transfers out of the EU, Power Zone Equipment will utilize data transfer agreements containing the Standard Contractual Clauses. By using our websites or web portals, you unambiguously consent to the transfer of your personal information and other information to the United States and elsewhere for the purposes and uses described herein.

When you access Power Zone Equipment’s websites or web portals, we may automatically (i.e., not by registration) collect non-personal data (e.g. type of Internet browser and operating system used, domain name of the website from which you came, number of visits, average time spent on the site, pages viewed). We may use this data and share it with our worldwide affiliates and related service providers to monitor the attractiveness of our websites and improve their performance or content. In this case, processing is performed on an anonymous basis and at Power Zone Equipment’s discretion.

In addition, certain online technical applications or other interactions you have with Power Zone Equipment may require the entry of business and technical data. By providing the requested information, you are consenting to the processing and storage of such information by Power Zone Equipment. Unless Power Zone Equipment is advised that you want this information removed from Power Zone Equipment’s server, such information may be retained by Power Zone Equipment and used for future commercial communications. A request for removal of this information can be made at the contact information provided below. Power Zone Equipment will take all reasonable precautions to assure that no such information will be provided or divulged to other third parties, except, if applicable, those third parties performing site hosting, maintenance, and related site service activities.

Cookies are information stored automatically on a website user’s computer. When a user views Power Zone Equipment’s website(s), Power Zone Equipment may store some data on the user’s computer in the form of a “cookie” to automatically recognize the user upon future visits to Power Zone Equipment’s website(s). Power Zone Equipment will make reasonable efforts to ensure compliance with the laws and regulations of relevant jurisdictions with regard to cookies.

Power Zone Equipment will not knowingly collect personal data from children under the age of 18. Power Zone Equipment’s website(s) is not intended for individuals under 18 years of age

Power Zone Equipment will take reasonable precautions to protect personal data in its possession secure against the risk of loss, misuse, unauthorized access, disclosure, alteration and destruction. Power Zone Equipment periodically reviews its security measures in an effort to ensure the privacy of personal data.

Power Zone Equipment will use personal data only in ways that are compatible with the purposes for which it was collected or subsequently authorized by you. While Power Zone Equipment will take reasonable steps to ensure that personal data is relevant to its intended use, accurate, complete, and current, Power Zone Equipment is also relying upon each individual to assist in providing accurate updates of his or her personal data.

Power Zone Equipment website(s) may contain “links” to websites owned and operated by third parties. By accessing these links, which are provided for your convenience, you will leave our site and will be subject to the privacy practices of the other website. This policy does not apply to any personal information you provide to unrelated third parties.

In general, Power Zone Equipment will only retain personal data for as long as needed for the specific purpose of processing and in accordance with Power Zone Equipment’s records management policy, or as otherwise required by the laws and regulations of a particular jurisdiction. For example, data will be retained during the time period that you are authorized to use Power Zone Equipment website(s), including any Power Zone Equipment tools accessible through our website(s). Upon termination of such authorization, your personal data related to use of Power Zone Equipment website(s) will be removed.

Upon request, Power Zone Equipment will grant individuals reasonable access to personal data that it holds about them. In addition, Power Zone Equipment will take reasonable steps to permit individuals to correct, amend, or delete information that is demonstrated to be inaccurate or incomplete. Power Zone Equipment also relies upon each individual to assist in providing accurate updates of his or her personal data. In order to access, correct, amend, or delete the personal data Power Zone Equipment holds about an individual, the individual should contact the following:

If your personal data is processed in the EU or you are a resident of the EU, the EU General data Protection Regulation grants you certain rights under the law. In particular, the right to access, correct, or delete the personal data Power Zone Equipment holds about you.

To the extent required by applicable law, Power Zone Equipment will grant individuals reasonable access to personal data that Power Zone Equipment holds about them and will take reasonable steps to permit such individuals to correct, amend, or delete information that Power Zone Equipment holds about them. Power Zone Equipment also relies upon each individual to assist in providing accurate updates of his or her personal data. In order to access, correct, amend, or delete the personal data Power Zone Equipment holds about an individual, the individual should contact his or her Power Zone Equipment commercial contact or contact us at the following email address:sales@powerzone.com.

If you have a comment, question, or complaint about how Power Zone Equipment is handling your personal data, we invite you to contact us in order to allow us to resolve the matter. In addition, individuals located in the EU may submit a complaint regarding the processing of their personal data to the EU data protection authorities (DPAs). The following link may assist you in finding the appropriate DPA:http://ec.europa.eu/justice/data-protection/bodies/authorities/index_en.htm.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

We have designed affordable annual subscription plans which would help you get leads for your business. You can have a look at our pricing chart by clicking on this link: https://www.energydais.com/pricing/ . These plans are customized according to the specific needs and requirements of your business.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

Yes. We use third-party companies to provide best quotations for your shipment and inspection of manufactured goods. We make sure that you get quality products from the manufacturer at the best price.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

Mud pumps are the pumps deployed in the oil and gas industry, mainly to circulate drilling fluids and other kinds of fluids in and out of the drilled wells for exploration. The mud pumps transfer the fluids at a very high pressure inside the well using the piston arrangement. The number of pistons decides the displacement and efficiency of working of the mud pumps, originally only dual piston pumps and three-piston pumps were used, but the technological advancements have seen pumps with five and six pistons to come up. Currently the triplex pumps which have three pistons are used, but the duplex pumps having two pumps are still deployed in the developing countries.

Based on its types, global mud pump market can be segmented into duplex, triplex, and others. The triplex mud pumps will dominate the mud pump marking in the given forecast period owing to its advantages and ongoing replacement of duplex pumps with triplex pumps. Based on operation, the global mud pumps market can be segmented into electric and fuel engine.

The electric mud pumps will dominate the market during the given forecast period due to the advantage of eliminating the harmful carbon emission which is done in the case of fuel engine pumps. Based on its application, the global mud pumps market can be segmented into oil & gas, mining, construction, and others.

The major market driver for the global mud pumps market is the increasing exploration activities taking place in various regions of the world to satisfy the increased energy demand. The number of drilled wells has increased in recent years, which has certainly impacted the growth of the mud pumps market in both oil & gas and mining sectors.

Key market restraint for the global mud pumps market is the drift towards the cleaner sources of energy to reduce the carbon emissions, which will certainly decrease the demand for oil & gas and therefore will have a negative impact on the growth of the global mud pumps market.

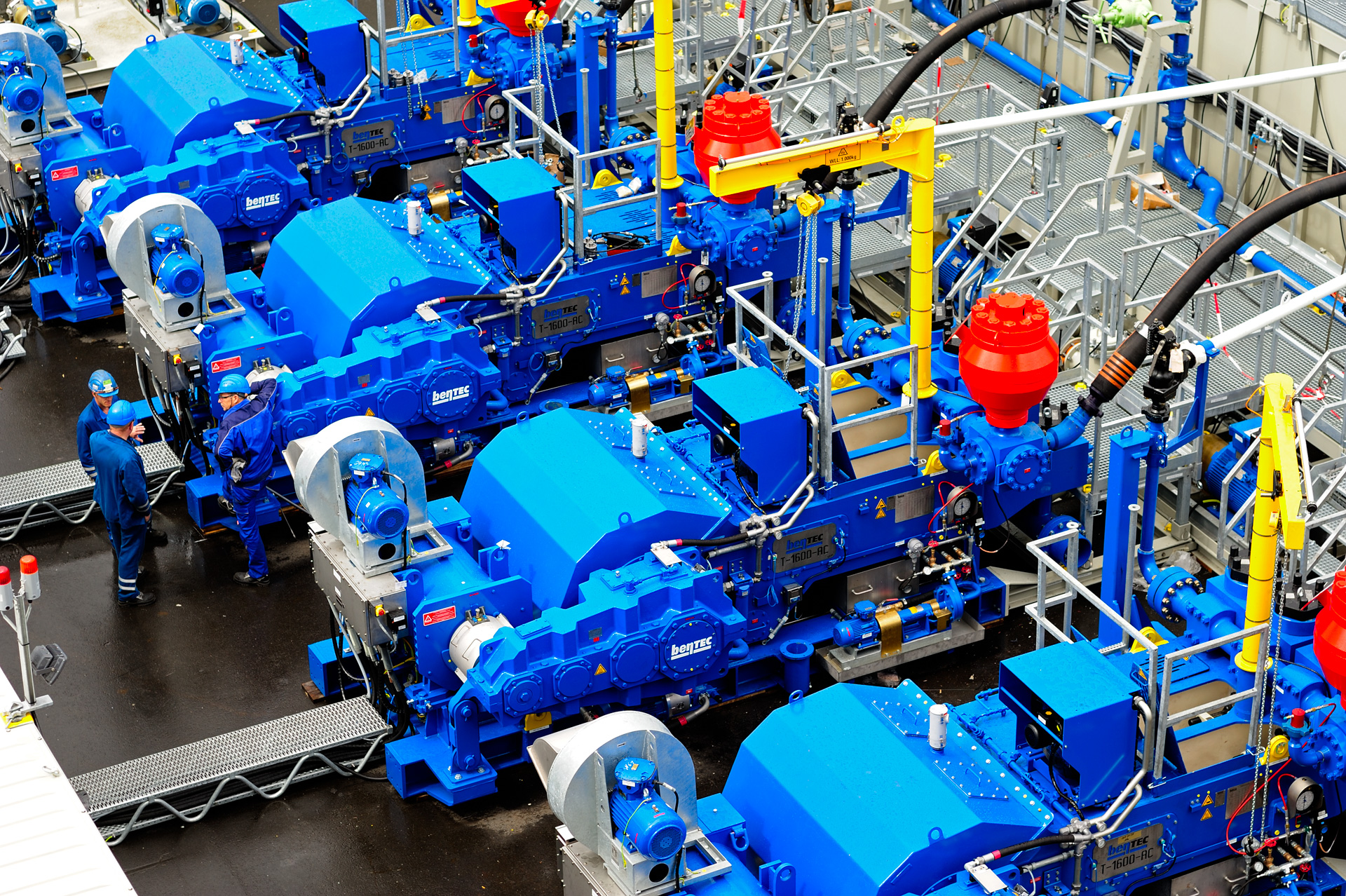

Some of the notable companies in the global mud pump market are Mud King Products, Inc. Gardner Denver Pumps, Weatherford, Schlumberger, National Oilwell Varco, China National Petroleum Corporation, Flowserve Corporation, MHWirth, American Block, Herrenknecht Vertical Gmbh, Bentec GmbH Drilling & Oilfield Systems, Drillmec Inc, Sun Machinery Company, Shale Pumps, and Dhiraj Rigs.

The global mud pump market has been segmented into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Owing to the well-established production sector and stable exploration industry North America holds the largest market for the mud pumps. The onshore exploration activities of oil & gas have increased at a good rate in the North America region, which has certainly boosted the growth of the mud pumps market in the region.

The demand from Europe and Asia Pacific has also increased due to exploration activities in both the regions owing to the increased energy demand. The energy demand specifically in the Asia Pacific has increased due to the increased population and urbanization. The Middle East and Africa also hold significant opportunities for the mud pumps market with increased exploration activities in the given forecast period.

In August 2018, Henderson which is a leading company in sales and service of drilling rigs, and capital drilling equipment in Texas signed a contract with Energy Drilling Company for the purchase and upgrade of oil field equipment’s which included three 1600hp × 7500psi mud pumps. This will be the first refurbishment completed at Henderson’s new service center and rig yard.

In January 2018, Koltek Energy Services launched the 99-acre facility for the testing of the oil field equipment in Oklahoma. This will allow the oil field equipment manufacturers to test their equipment at any given time. The company has deployed the MZ-9 pump which has a power rating of 1000Hp.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

Our 20,000 sq.m production facility in China has designed and manufactured solely quality and specialty pumps for oil exploration and refinery sin1992

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.

Maintaining /monitoring the mud pumps and mud pits during operations. Notifying the Driller immediately of any unexplained pit level increases/decreases Verify and record drilling fluid properties at ...

and decisivemanner Otherduties as required by the Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations. Previous ...

and decisivemanner Otherduties as required by the Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations. Previous ...

and decisivemanner Otherduties as required by the Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations. Previous ...

Assist internal and external customers with troubleshooting of Rig Equipment (Top Drive, Catwalk, Wrench, Drawworks, VFDs, Generators, Mud Pumps, BOP) Expeditiously work to troubleshoot and resolve downtime ...

include but are not limited to safely and efficiently performing all tasks within the Rig Operations Areas of the Platform at the direction and under the supervision of the Crane Operator. Tasks may include ...

Our Technical Sales Representative (TSR) is responsible for building on a very high level of product line & operational knowledge and experience to proactively and strategically sell specific tools, technologies ...

include but are not limited to: Safely and efficiently performing all tasks on the rig floor and B.O.P. area under the direction and supervision of the Driller. Operating the tongs, slips, and spinners ...

Please note that we are planning to come to the following countries for Recruitment Campaign in the month of May 2023 - Romania - Azerbaijan - Croatia Minimum requirement/ Basic Function Carries out the ...

as required by the Driller, Derrickhand or Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations Ability to ...

Assists the Driller, Derrickman and/or Motorman in carrying out all routine, non-routine and emergency operational activities around the rig floor areas or any other area of the rig location as designated ...

as required by the Driller, Derrickhand or Rig Manager Minimum Qualifications: Ability to perform essential functions of this position with or without reasonable accommodations Ability to ...

Assists the Crew Pusher and/or TRS Lead in carrying out all routine, non-routine and emergency operational activities around the rig floor areas or any other area of the rig location as designated by ...

Regular inspection of machinery, as well as the bilge, pump rooms, and tanks. Ensure the engine room is neatly kept and all equipment is properly stowed. Examination of equipment such as turbines, condensers, ...

The drilling mud pumps are of immense utility to the oil companies, for the purposes related to oil well drilling. The pumps have the reciprocating piston for circulating the drilling fluid. These units work at high pressure and provide for low noise, smooth operations, provisions for easy maintenance and disassembly, and stable fluid flows among other features. The drilling mud pumps should be procured from experienced and reputed Houston pump manufacturers only, because of their critical nature, and the circumstances and hazards oil well drilling are exposed to.

The best of drilling well pumps manufacturers in Houston and USA offers a comprehensive range of products and are a one-stop destination for many of your oil well service/drilling pumps and other needs. A good company will offer you all the popular and important pumps including the quintuplex pumps, triplex pumps, well service pumps, horizontal direction drilling pumps, false rotary tables, powered packages, and more. These manufacturers will offer you free of cost consultation upon your contact and will advise you on the best products that will suit your application precisely.

The best of well mud drilling pumps product companies in Houston have the necessary services related to oil well drilling and operations. These include welding, testing, and fabrication services. A reputed pump company offers the products at a very affordable cost and under the guidance of expert technicians. The services also include the maintenance and repair services that may be provided to the client on-site. With a proper and comprehensive inventory of spare parts, the best of drilling mud pumps manufacturers in Houston ensure that your business operations never face undesired downtimes.

A noteworthy and popular drilling well pump manufacturer will have decades of existence and experience. These companies are well known to the local and global oil companies and have a sound market base. Their high quality pumps not only offer reliable performance but also adhere to the standards like the standard pertaining to the operational regions as well as hazardous areas.

When you want to buy a drilling well pump for your well mud drilling, acidulation, cementing, and other operations, you should research on the manufacturers and choose one that has proven experience and years of existence and prominence. The company should offer you a comprehensive range of products and services and should take care of all your maintaining services needed as well.

Matched sets of Pinion gear with hardened tooth profile and single piece bull gear with modified herring bone hardened tooth to enlarged tooth to increase AMGA class rating with contact area for extended life and improved reliability

Crosshead surfaces are hardened while leaving crosshead guide un-hardened, allowing the wear to concentrate on the guides because of this hard-soft combination, thus extending the life of the crosshead

Pulsation dampeners are made of forged steel rather than cast steel, improving reliability. All high pressure parts are hydrostatically tested. Internal components are changeable with off the shelf consumables.

Loadmaster Universal Rigs, Inc. and Loadmaster Engineering, Inc. are separate corporations which manage and control their own affairs. Each of these companies has its own separate identity, but in advertising and in our brochures we may sometimes use the word "Loadmaster". The use of such term is for convenience only and is not intended as an accurate description of corporate relationships.

The report covers comprehensive information about market trends, volume (Units) and value (US$ Mn) projections, competition and recent developments and market dynamics in the global mud pumps market for the study period of 2013 to 2026.

The global mud pumps market is expected to reach a little over US$ 1,085 Mn over the forecast period, registering a CAGR of 4.4%. Growth in drilling activities in the oil & gas Industry to increase hydrocarbon production and ease of the mud circulation operation in drilling holes are some of the factors expected to lay a robust foundation for the growth of the global mud pumps market.

Mud pumps can be classified on the basis of the number of pistons into duplex, triplex and quintuplex, which consist of two, three and five pistons respectively. The triplex segment is expected to dominate the mud pumps market in terms of value as well as volume during the entire forecast period.

Triplex mud pumps find extensive usage in circulating drilling fluid with high pressure for deep oil well drilling application. These usage characteristics make them preferable for use, primarily in onshore and offshore oil well drilling applications.

By the end of 2026, the triplex segment is projected to grow 1.42X its size in 2018 by value, creating an absolute dollar opportunity of nearly US$ 234 Mn during the forecast period.

Mud pumps are widely utilized in the oil & gas industry. On the basis of the mode of operation, mud pumps can be classified as electric and fuel engine mud pumps.

Fuel engine mud pumps use petroleum oils as the key liquefying agent. These types of mud pumps release hazardous gases into the environment. In order to contain the hazardous impact of fuel engine mud pumps on the environment, regulatory authorities are compelling manufacturers and consumers to opt for electric mud pumps, which do not emit volatile organic compounds and operate with low noise and low vibration. Electric mud pumps offer smooth operations in drilling rigs and are environment-friendly, which is why they dominate the market for mud pumps.

The electric mud pumps segment is projected to grow with a 4.5% CAGR during the forecast period in view of the tightening emission control regulations and is expected to create an absolute $ opportunity worth US$ 134 Mn between 2018 and 2026.

Among all the applications analyzed in this global mud pumps market study, the onshore application of mud pumps is expected to register about 1.43X growth in terms of value between 2018 and 2026. The offshore application of mud pumps is projected to register moderate growth during the entire forecast period, led by land oil field discoveries.

In terms of incremental $ opportunity, onshore and offshore segments are expected to compete within large margins. The onshore application of mud pumps is expected to occupy over an 86% share in terms of value by the end of 2026.

Increasing oil-well exploration activities, stable economic conditions and consistent growth in oil well drilling rig sales in the region are expected to drive the demand for mud pumps in the region.

The comparatively well-established production sector in the region and increasing oil and gas industry and hydrocarbon consumption will create a healthy platform for the growth of the mud pumps market. Some regions including China and Europe are expected to gain traction in the latter half of the forecast period, owing to the anticipated growth of the oil & gas industry in these regions. North America is expected to register above-average 1.1X growth in the market. All the other regions are anticipated to exhibit moderate growth during the same period.

Apart from Europe and China, all other regions are anticipated to lose market value share over the forecast period. China and Europe are collectively expected to register a CAGR of 4.3% by value.

The global mud pumps market is consolidated with limited market players holding considerable double-digit market shares as of 2017. Globally, the top 12 players in the mud pumps market collectively hold between 53% and 58% of the market share.

Over the past few years, the mud pumps market has witnessed significant technological advancement from the competition perspective. Acquisitions, collaborations and new product launches are some of the key strategies adopted by prominent players to expand and sustain in the global mud pumps market.

In 2018, National Oil Varco signed a deal with Dubai Saudi Armaco to form a joint venture for the manufacturing of onshore rigs and equipment in Saudi Arabia

In 2015, Flowserve opened a new pump manufacturing plant in Coimbatore, India. Through this new facility, the company aims to provide pump products for the oil and gas industry in Asia Pacific

Some of the key players involved in this market study on the global mud pumps market include National Oil Varco Inc., Schlumberger Limited, Gardner Denver Inc., Weatherford International Plc., China National Petroleum Corporation, Trevi-Finanziaria Industriale S.p.A., MhWirth, BenTech GmbH Drilling Oilfield systems, American Block Inc., Honghua Group Limited, White Star Pump Company LLC, Flowserve corporation, Ohara Corporation, Mud King Products, Inc. and Herrenknecht Vertical GmbH.

8613371530291

8613371530291