centrifugal mud pump for sale in stock

Centrifugal Pumps - Unused Surplus Flowserve 3x8-7 stage DMX centrifugal pump. CF3MN case material • 7-stage • 4” 600# RF suction flange • 3” 900# RF discharge flange • Mechanica... More Info

Centrifugal Pumps - Unused Surplus Flowserve 4HPX13A, API 610, OH2 pump. 952 gpm, 448 tdh, 3575 rpm with a unused surplus Siemens 200 HP electric motor with following features: 3575 rpm, 46... More Info

Centrifugal Pumps - Unused Surplus Flowserve 6HED16DS, API 610, OH2 pump. 1850 gpm, 990 tdh, 3575 rpm with a unused surplus Reliance 600 HP electric motor with following features: 3579 rpm,... More Info

Centrifugal Pumps - Unused Surplus Flowserve 6HED25DS 10 x 6 single stage API-610 centrifugal pump, 10" 600lb suction, 6" 600lb discharge, CA6NM case material. Tag reads 1327 gpm, 430 tdh, 1... More Info

Centrifugal Pumps - Unused Surplus Flowserve 6HPX23A, API 610, OH2 pump. 2917 gpm, 480 tdh, 1785 rpm with a unused surplus Teco Westinghouse 600 HP electric motor with following features: ... More Info

Centrifugal Pumps - UNUSED SURPLUS FLOWSERVE 6UZDL25 CENTRIFUGAL PUMPS WITH MOTORS. TAG READS 2,879.48 GPM, 945.86 HEAD FEET, SP. GRAVITY 0.97, HORSEPOWER 921, 1783 RPM, CUSTOMER ORDER NUMBE... More Info

Centrifugal Pumps - For Sale: Qty (1) Unused Surplus Flowserve 6x11 DMX-A 7 stage centrifugal pump. CA6NMB case material, 11.18" CA6NM impeller. Tag reads 1800 GPM, 2762 TDH, 3560 RPM. More Info

Centrifugal Pumps - Unused Surplus Flowserve 8HDX27B single stage centrifugal pump, tag reads 1794 rpm, 3412 gpm, 649 tdh, S.G .968, C6 API 610 / 12 Chrome case material. API 610 BB2 Class P... More Info

Centrifugal Pumps - Used Flowserve VTC 42 KXH Vertical Turbine Pump Only. Size 42-3 stage, CA6NM bowls, 316 stainless column and head. 27"- 9" long. Tag reads 20693 gpm, 406 tdh, 710 rpm. More Info

Centrifugal Pumps - Gardner Denver PAH equipped with 5-inch pistons and liners, powered by Caterpillar C10 diesel engine with Allison automatic transmission. With clutch manifold and centrif... More Info

Centrifugal Pumps - Unused Surplus Goulds 3700 1.5x3-9N, API 610, OH2 pump with the following features: • 316SS case material • 1-stage • 316SS impellers • 3” 300# RF suction flang... More Info

Centrifugal Pumps - Unused Surplus Goulds 3700 6x8-13A, API 610, OH2 pump with the following features: 316SS case material, 1-stage, 316SS impellers, 8â 300# RF suction flange, 6â ... More Info

Centrifugal Pumps - Goulds LF3196 Centrifugal Pump, Pumps & Parts, Used Goulds LF3196 Centrifugal Pump, Impeller Diameter 7.875, 37 GPM, 3600 RPM, 312" TDH Head, 1x1.50-8 National Constructi... More Info

Centrifugal Pumps - Grundfos CR1017, Pumps & Parts, New Grundfos CR10-17 Centrifugal Pump 638" TDH Head, 53 GPM, 3444 RPM, 60 Hz, Type CR10-17 A-GJ-A-E-HQQE, Driven by Baldor 15hp Electric M... More Info

Centrifugal Pumps - Grundfos CR16 30, Pumps & Parts, Used Grundfos CR16-30 U-G-A-AUUEV Vertical Centrifugal Pump, Model B33000063VP1 0112 US432, 84 Gallons/Minute, 169FT-TDH, 3450 RPM, 7.5HP... More Info

Centrifugal Pumps - Grundfos CR16 30, Pumps & Parts, Used Grundfos CR16-30 U-G-A-AUUEV Vertical Centrifugal Pump, Model B 33000063VP1 0112 US 336, 84 Gallons/Minute, 169FT-TD, 3450 RPM, 7.5H... More Info

Centrifugal Pumps - Halco 3 x 4 Centrifugal Pump, Pumps & Parts, Used Halco 3 x 4 Centrifugal Pump, Size 3 x 4 x 13, Model # 1780, Steel Volute, Takes Packing , More Info

Centrifugal Pumps - Ingersol Rand 2.5 CNTA-4 centrifugal pump with the following features: Carbon steel case material, 4 stages, 9.375"" Bronze Impellers, 4" 300# suction flange, 2.5" 300# d... More Info

Centrifugal Pumps - Used KSB HGC 5/7 Centrifugal Pumps. Chrome Case Material, 7 Stage, 8" 300# RF Suction, 6" 1500# Discharge. Tag Reads 1992 GPM, 2082 PSI, 3582 RPM. More Info

Power Zone is a leading global supplier of new, used and reconditioned pumps for sale. Our inventory of pumps includes multi-stage centrifugal pumps, positive displacement pumps, reciprocating pumps, single stage centrifugal pumps and screw pumps in a variety of design standards including API 610 Centrifugal Pumps, API 674 Reciprocating Pumps and API 676 Rotary Pumps. We have an assortment of pumps that are used in various applications including water treatment, pipelines, frac water supply, salt water disposal and flood control in industries like municipal, manufacturing, oil & gas, mining and agriculture. We supply pumps of all major suppliers such as Sulzer, Flowserve, ITT Goulds, Aurora and National.

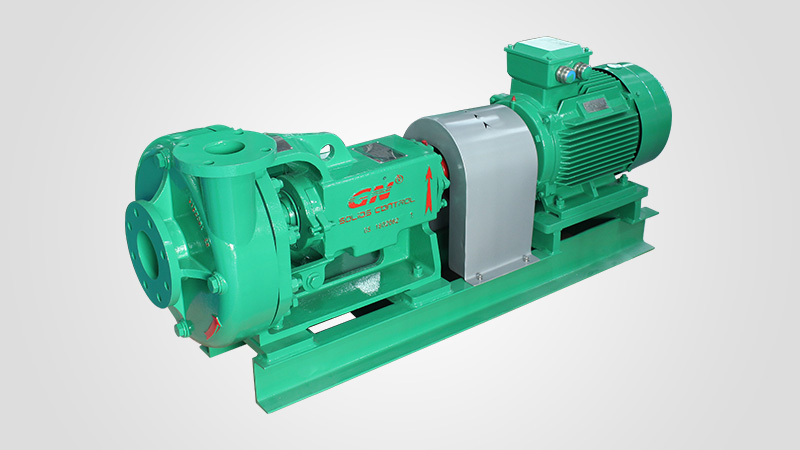

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

A wide variety of centrifugal mud pump for drilling rig options are available to you, such as 1 year, not available and 3 years.You can also choose from new, centrifugal mud pump for drilling rig,as well as from energy & mining, construction works , and machinery repair shops centrifugal mud pump for drilling rig, and whether centrifugal mud pump for drilling rig is 1.5 years, 6 months, or unavailable.

There are three types of mud pumps, depending on the type of client and the size they want. For general, mud pumps, there are three basic types of mud pumps, depending on the type of client and budget. The piston pump is another compressed mud pump, which is a pushed electric compressor mud pumps and by compressed air.@@@@@

Electric mud pumps are largely divided into three categories, among them the electric mud pumps and the semi-trash mud pumps. The piston inflated mud pumps are also classified in terms of the type of mud pumps, among them are electric mud pumps and semi-trash mud pumps. In addition, the piston inflates mud and mud pumps will be inflated by the piston, which is inflated mud pumps.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

-Select-AlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijan RepublicBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia and HerzegovinaBotswanaBrazilBritish Virgin IslandsBrunei DarussalamBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape Verde IslandsCayman IslandsCentral African RepublicChadChileChinaColombiaComorosCook IslandsCosta RicaCyprusCzech RepublicCôte d"Ivoire (Ivory Coast)Democratic Republic of the CongoDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland Islands (Islas Malvinas)FijiFinlandFranceFrench GuianaFrench PolynesiaGabon RepublicGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHondurasHong KongHungaryIcelandIndiaIndonesiaIraqIrelandIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKuwaitKyrgyzstanLaosLatviaLebanonLesothoLiberiaLiechtensteinLithuaniaLuxembourgMacauMacedoniaMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueNamibiaNepalNetherlandsNetherlands AntillesNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorwayOmanPakistanPalauPanamaPapua New GuineaParaguayPeruPhilippinesPolandPortugalPuerto RicoQatarRepublic of CroatiaRepublic of the CongoReunionRomaniaRwandaSaint HelenaSaint Kitts-NevisSaint LuciaSaint Pierre and MiquelonSaint Vincent and the GrenadinesSan MarinoSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSlovakiaSloveniaSolomon IslandsSouth AfricaSouth KoreaSpainSri LankaSurinameSwazilandSwedenSwitzerlandTaiwanTajikistanTanzaniaThailandTogoTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUgandaUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVatican City StateVenezuelaVietnamVirgin Islands (U.S.)Wallis and FutunaWestern SaharaWestern SamoaZambiaZimbabwe

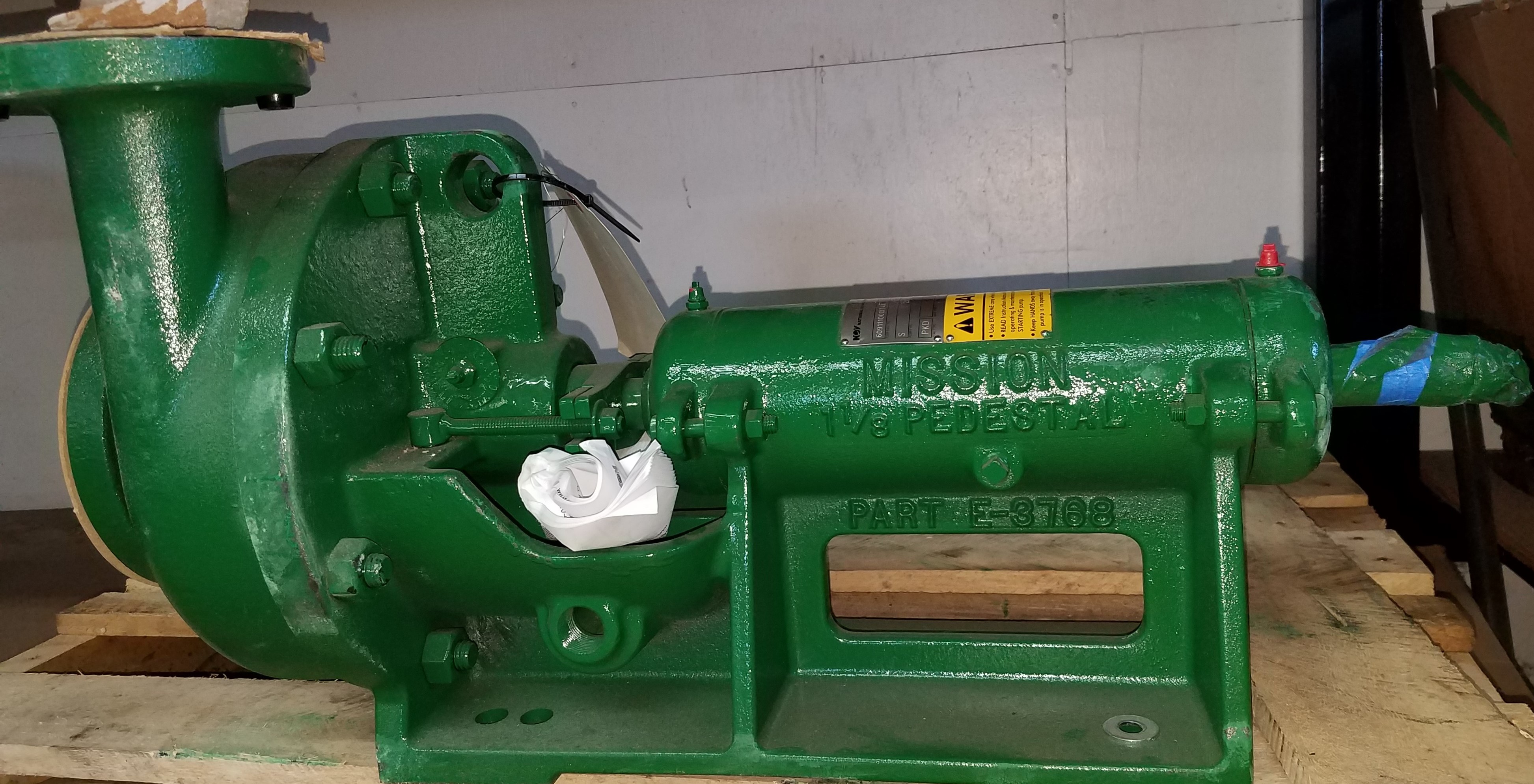

During the 1950’s the Mission” 1780 type “W” pumps were introduced to replace duplex pumps while creating the first low pressure mud system. The use of a high quality concentric type centrifugal pump allowed abrasive fluids to be mixed and transferred while reducing initial and maintenance costs for the drilling industry. The low-pressure mud system with Mission 1 780 Type “W” centrifugal pumps became the industry standard.

As well depths increased so did the need for heavier mud weights. When the mud weight began exceeding 14 ppg the need for a pump that could withstand greater horsepower loads arose. During the 1970’s Mission organized a design team that engineered the Mission Magnum. The Magnum was designed to have the same footprint, flange locations, and drive shaft diameter as the 1780 “W”. This allowed a 1780 to be replaced by a Magnum without any skid modifications. The Magnums were originally engineered with a 2-1/2″ shaft (3″ between the bearings), double row bearings with an engineered life of over 2 years at 200 HP, larger impellers and heavier frames. The Magnum allowed drilling contractors to upgrade their centrifugal pumps and mix heavier fluids.

The National Oilwell Varco” Mission centrifugal pump line has proven to be the best centrifugal design for handling abrasive mud. This pump line offers a broad selection of innovative features for a variety of routine, demanding, abrasive and corrosive applications. These pumps are designed for a wide range of flow rates, from a few gallons per minute to thousands of gallons per minute.

Each pump contains the finest materials, engineering and craftsmanship available in the industry. Described are like features of these pump lines and unique features are described on the following pages.

National Oilwell Varco utilizes unique design features developed for slurries. Three major differences from most pump designs include the concentric casing, wider impellers and increased re-circulation areas. Each feature contributes to reducing wear when handling abrasive fluids.

All of the pumps feature a concentric casing. This casing averages 37% thicker than conventional pump casings, and up to 50% thicker for the larger, mud pumping models. They are pressure rated at 1 .5 times the flange rating and are designed with a 1 /8″ erosion allowance. The concentric style casing has proven to offer the greatest pump life and reduced downtime. The walls of a concentric style casing are an equal distance from the impeller throughout the impeller circumference, which results in a smooth flow pattern. A volute style casing has a cutwater point that disturbs the fluid flow pattern creating an eddy. The concentric casing eliminates vibration, turbulence and aeration that is caused by the cutwater point in conventional volute pumps. It also reduces the high bearing loads and shaft deflection even at near shutoff flows.

The shaft is much larger in diameter than conventional pump shafts for heavy-duty performance, minimum deflection and increased operating life of the seal or packing. With a 2-1/2″ diameter at the seal area and 3″ diameter between the bearings these pumps can be direct connected or belt driven.

A mud pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi (52,000 kPa)) down the drill string and back up the annulus. A duplex mud pump is an important part of the equipment used for oil well drilling.

Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers. The advantages that Duplex mud pumps have over convention triplex pumps is a lower mud noise which assists with better Measurement while drilling and Logging while drilling decoding.

Use duplex mud pumps to make sure that the circulation of the mud being drilled or the supply of liquid reaches the bottom of the well from the mud cleaning system. Despite being older technology than the triplex mud pump, the duplex mud pumps can use either electricity or diesel, and maintenance is easy due to their binocular floating seals and safety valves.

A mud pump is composed of many parts including mud pump liner, mud pump piston, modules, hydraulic seat pullers, and other parts. Parts of a mud pump:housing itself

Duplex pumps are used to provide a secondary means of fuel transfer in the event of a failure of the primary pump. Each pump in a duplex set is sized to meet the full flow requirements of the system. Pump controllers can be set for any of the following common operating modes:Lead / Lag (Primary / Secondary): The lead (primary) pump is selected by the user and the lag (secondary pump operates when a failure of the primary pump is detected.

Alternating: Operates per Lead / Lag (Primary / Secondary) except that the operating pump and lead / lag status alternate on consecutive starts. A variation is to alternate the pumps based on the operating time (hour meter) of the lead pump.

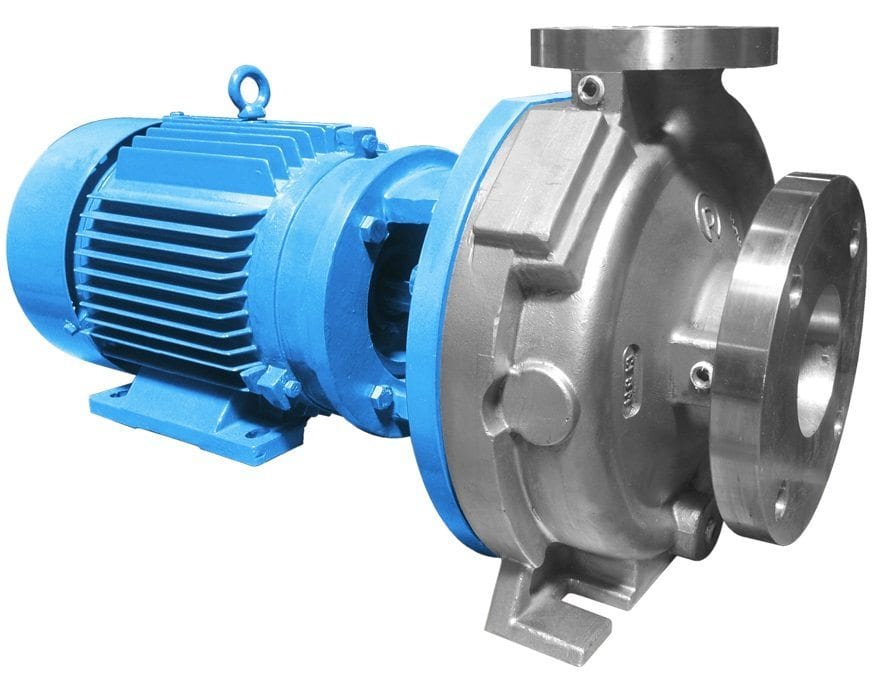

The array of ANSI centrifugal pumps are used for domestic and commercial purposes. The valuable features such as compact structure, low vibration, constant flow rate etc., make these pumps ideal to transport the liquid in different systems through the pipes. ANSI centrifugal pumps can also be used in various process applications. These pump have the capability to handle variety of challenging pumping applications. The durable and exclusive designs are carried out as per the industry standards and offers cost-effective solution.

Out of its huge repertoire of pumps & motors, ANSI centrifugal pumps are most popular among industries worldwide because of their dimensional interchangeability between its parts, easy to installation & maintenance and competitive cost.

These pumps are designed to handle non-viscous fluid from water to corrosive materials with high efficiency. ANSI centrifugal pumps are ideal for a number of different industries, including pulp and paper mills, chemical processing, food processing, refineries, and many other general services in manufacturing plants of all varieties.

The centrifugal pump is the most used pump type in the world. The principle is simple, well-described and thoroughly tested, and the pump is robust, effective and relatively inexpensive to produce.The ANSI pump that sets the industry standard for corrosive and abrasive process fluid applications. An increase in the fluid pressure from the pump inlet to its outlet is created when the pump is in operation. This pressure difference drives the fluid through the system or plant.

The centrifugal pump creates an increase in pressure by transferring mechanical energy from the motor to the fluid through the rotating impeller. The fluid flows from the inlet to the impeller centre and out along its blades. The centrifugal force hereby increases the fluid velocity and consequently also the kinetic energy is transformed to pressure.

Buy Used Mud Pumps at auction - BigIron Auctions has various makes and models of Mud Pumps for sale throughout the US so that you can find the right Mud Pumps at the right price.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

8613371530291

8613371530291