centrifugal mud pump for sale free sample

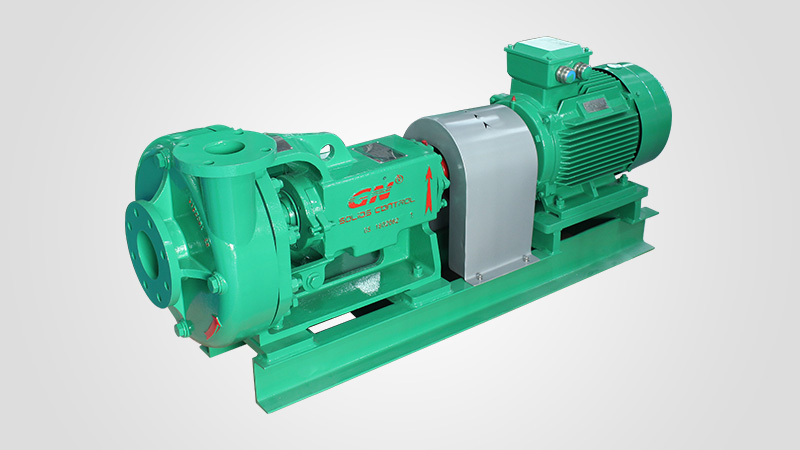

TTAAM-OM series centrifugal sand pump mainly supplies to solids control circulating system of the oilfield drill rig and can be used to provide drilling liquid with a certain discharge capacity and pressure to sand, desilter and mud mixer to assure these equipment work efficiently.

The TTAAM-OM8×6×11 centrifugal sand pump applies to under 3000-meter-long drilling Rigs and also can be used to supply mud to the triplex mud pump as a filling pump.

The pump is constituted of pump shell, impellers, bearing block, pump axle, bearing, shaft coupling, wearing plate, seal apparatus, oil seal, motor and base.

A wide variety of centrifugal mud pump for drilling rig options are available to you, such as 1 year, not available and 3 years.You can also choose from new, centrifugal mud pump for drilling rig,as well as from energy & mining, construction works , and machinery repair shops centrifugal mud pump for drilling rig, and whether centrifugal mud pump for drilling rig is 1.5 years, 6 months, or unavailable.

There are three types of mud pumps, depending on the type of client and the size they want. For general, mud pumps, there are three basic types of mud pumps, depending on the type of client and budget. The piston pump is another compressed mud pump, which is a pushed electric compressor mud pumps and by compressed air.@@@@@

Electric mud pumps are largely divided into three categories, among them the electric mud pumps and the semi-trash mud pumps. The piston inflated mud pumps are also classified in terms of the type of mud pumps, among them are electric mud pumps and semi-trash mud pumps. In addition, the piston inflates mud and mud pumps will be inflated by the piston, which is inflated mud pumps.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is applicable). Packaging should be the same as what is found in a retail store, unless the item was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller"s listing for full details.See all condition definitionsopens in a new window or tab

Since the NOV A1700-PT Triplex Mud Pump was built approximately 60 years ago, the industry has widely accepted the three cylinder or triplex style pump. Triplex mud pumps are manufactured worldwide, and many companies have emulated the original design and developed an improved form of the triplex pump in the past decade.

NOV A1700-PT Triplex Mud Pumps have many advantages they weight 30% less than a duplex of equal horsepower or kilowatts. The lighter weight parts are easier to handle and therefore easier to maintain. The other advantages include;They cost less to operate

One of the more important advantages of triplex over duplex pumps, is that they can move large volumes of mud at the higher pressure is required for modern deep hole drilling.

NOV A1700-PT Triplex Mud Pump is gradually phasing out duplex units. In a triplex pump, the pistons discharge mud only when they move forward in the liner. Then, when they moved back they draw in mud on the same side of the piston. Because of this, they are also called “single acting.” Single acting triplex pumps, pump mud at a relatively high speeds. NOV A1700-PT Triplex Mud Pump has three pistons each moving in its own liner. It also has three intake valves and three discharge valves. It also has a pulsation dampener in the discharge line.

Choose a used Emsco FB-1600 Triplex Mud Pump from our inventory selection and save yourself some money on your next shallow drilling oilfield project. This Emsco FB-1600 Triplex Mud Pump is used and may show some minor wear.

We offer wholesale pricing on new Emsco FB-1600 Triplex Mud Pump and pass the savings on to you. Contact us to compare prices of different brands of Mud Pump. This equipment is brand new and has never been used.

Our large network often has surplus Emsco FB-1600 Triplex Mud Pump that go unused from a surplus purchase or a project that was not completed. Contact us to see what Emsco FB-1600 Triplex Mud Pump we have in inventory. The surplus Emsco FB-1600 Triplex Mud Pump are considered new but may have some weathering depending on where it was stored. Surplus oilfield equipment is usually stored at a yard or warehouse.

We have refurbished Mud Pumpthat have been used and brought up to functional standards. It is considered a ready to use, working Mud Pump. Please contact us for more information about our refurbished Emsco FB-1600 Triplex Mud Pump. These Mud Pump have been used and brought up to functional standards. It is considered a working Mud Pump. Please contact us for more information about the product.

This rig features a Mission 4-by-5 centrifugal pump. Courtesy of Higgins Rig Co.Returning to the water well industry when I joined Schramm Inc. last year, I knew that expanding my mud pump knowledge was necessary to represent the company"s mud rotary drill line properly. One item new to me was the centrifugal mud pump. What was this pump that a number of drillers were using? I had been trained that a piston pump was the only pump of any ability.

As I traveled and questioned drillers, I found that opinions of the centrifugal pumps varied. "Best pump ever built," "What a piece of junk" and "Can"t drill more than 200 feet with a centrifugal" were typical of varying responses. Because different opinions had confused the issue, I concluded my discussions and restarted my education with a call to a centrifugal pump manufacturer. After that conversation, I went back to the field to continue my investigation.

For the past eight months, I have held many discussions and conducted field visits to understand the centrifugal pump. As a result, my factual investigation has clearly proved that the centrifugal pump has a place in mud rotary drilling. The fact also is clear that many drilling contractors do not understand the correct operational use of the pump. Following are the results of my work in the field.

High up-hole velocity - High pump flow (gpm) moves cuttings fast. This works well with lower viscosity muds - reducing mud expense, mixing time and creating shorter settling times.

Able to run a desander - The centrifugal"s high volume enables a desander to be operated off the pump discharge while drilling without adding a dedicated desander pump.

6. Sticky clays will stall a centrifugal pump"s flow. Be prepared to reduce your bit load in these conditions and increase your rpm if conditions allow. Yes, clays can be drilled with a centrifugal pump.

7. Centrifugal pumps cannot pump muds over 9.5 lbs./gal. Centrifugal pumps work best with a 9.0 lbs./gal. mud weight or less. High flow rate move cuttings, not heavy mud.

The goal of this article has been to increase awareness of the value of the centrifugal pump and its growing use. Although the centrifugal pump is not flawless, once its different operating techniques are understood, drilling programs are being enhanced with the use of this pump.

If you wish to learn more, please talk directly to centrifugal pump users. Feel free to call me at 314-909-8077 for a centrifugal pump user list. These drillers will gladly share their centrifugal pump experiences.

When choosing a size and type of mud pump for your drilling project, there are several factors to consider. These would include not only cost and size of pump that best fits your drilling rig, but also the diameter, depth and hole conditions you are drilling through. I know that this sounds like a lot to consider, but if you are set up the right way before the job starts, you will thank me later.

Recommended practice is to maintain a minimum of 100 to 150 feet per minute of uphole velocity for drill cuttings. Larger diameter wells for irrigation, agriculture or municipalities may violate this rule, because it may not be economically feasible to pump this much mud for the job. Uphole velocity is determined by the flow rate of the mud system, diameter of the borehole and the diameter of the drill pipe. There are many tools, including handbooks, rule of thumb, slide rule calculators and now apps on your handheld device, to calculate velocity. It is always good to remember the time it takes to get the cuttings off the bottom of the well. If you are drilling at 200 feet, then a 100-foot-per-minute velocity means that it would take two minutes to get the cuttings out of the hole. This is always a good reminder of what you are drilling through and how long ago it was that you drilled it. Ground conditions and rock formations are ever changing as you go deeper. Wouldn’t it be nice if they all remained the same?

Centrifugal-style mud pumps are very popular in our industry due to their size and weight, as well as flow rate capacity for an affordable price. There are many models and brands out there, and most of them are very good value. How does a centrifugal mud pump work? The rotation of the impeller accelerates the fluid into the volute or diffuser chamber. The added energy from the acceleration increases the velocity and pressure of the fluid. These pumps are known to be very inefficient. This means that it takes more energy to increase the flow and pressure of the fluid when compared to a piston-style pump. However, you have a significant advantage in flow rates from a centrifugal pump versus a piston pump. If you are drilling deeper wells with heavier cuttings, you will be forced at some point to use a piston-style mud pump. They have much higher efficiencies in transferring the input energy into flow and pressure, therefore resulting in much higher pressure capabilities.

Piston-style mud pumps utilize a piston or plunger that travels back and forth in a chamber known as a cylinder. These pumps are also called “positive displacement” pumps because they literally push the fluid forward. This fluid builds up pressure and forces a spring-loaded valve to open and allow the fluid to escape into the discharge piping of the pump and then down the borehole. Since the expansion process is much smaller (almost insignificant) compared to a centrifugal pump, there is much lower energy loss. Plunger-style pumps can develop upwards of 15,000 psi for well treatments and hydraulic fracturing. Centrifugal pumps, in comparison, usually operate below 300 psi. If you are comparing most drilling pumps, centrifugal pumps operate from 60 to 125 psi and piston pumps operate around 150 to 300 psi. There are many exceptions and special applications for drilling, but these numbers should cover 80 percent of all equipment operating out there.

The restriction of putting a piston-style mud pump onto drilling rigs has always been the physical size and weight to provide adequate flow and pressure to your drilling fluid. Because of this, the industry needed a new solution to this age-old issue.

Enter Cory Miller of Centerline Manufacturing, who I recently recommended for recognition by the National Ground Water Association (NGWA) for significant contributions to the industry.

As the senior design engineer for Ingersoll-Rand’s Deephole Drilling Business Unit, I had the distinct pleasure of working with him and incorporating his Centerline Mud Pump into our drilling rig platforms.

In the late ’90s — and perhaps even earlier — Ingersoll-Rand had tried several times to develop a hydraulic-driven mud pump that would last an acceptable life- and duty-cycle for a well drilling contractor. With all of our resources and design wisdom, we were unable to solve this problem. Not only did Miller provide a solution, thus saving the size and weight of a typical gear-driven mud pump, he also provided a new offering — a mono-cylinder mud pump. This double-acting piston pump provided as much mud flow and pressure as a standard 5 X 6 duplex pump with incredible size and weight savings.

The true innovation was providing the well driller a solution for their mud pump requirements that was the right size and weight to integrate into both existing and new drilling rigs. Regardless of drill rig manufacturer and hydraulic system design, Centerline has provided a mud pump integration on hundreds of customer’s drilling rigs. Both mono-cylinder and duplex-cylinder pumps can fit nicely on the deck, across the frame or even be configured for under-deck mounting. This would not be possible with conventional mud pump designs.

The second generation design for the Centerline Mud Pump is expected later this year, and I believe it will be a true game changer for this industry. It also will open up the application to many other industries that require a heavier-duty cycle for a piston pump application.

Since the NOV A1700-PT Triplex Mud Pump was built approximately 60 years ago, the industry has widely accepted the three cylinder or triplex style pump. Triplex mud pumps are manufactured worldwide, and many companies have emulated the original design and developed an improved form of the triplex pump in the past decade.

NOV A1700-PT Triplex Mud Pumps have many advantages they weight 30% less than a duplex of equal horsepower or kilowatts. The lighter weight parts are easier to handle and therefore easier to maintain. The other advantages include;They cost less to operate

One of the more important advantages of triplex over duplex pumps, is that they can move large volumes of mud at the higher pressure is required for modern deep hole drilling.

NOV A1700-PT Triplex Mud Pump is gradually phasing out duplex units. In a triplex pump, the pistons discharge mud only when they move forward in the liner. Then, when they moved back they draw in mud on the same side of the piston. Because of this, they are also called “single acting.” Single acting triplex pumps, pump mud at a relatively high speeds. NOV A1700-PT Triplex Mud Pump has three pistons each moving in its own liner. It also has three intake valves and three discharge valves. It also has a pulsation dampener in the discharge line.

Please try again in a few minutes. If the issue persist, please contact the site owner for further assistance. Reference ID IP Address Date and Time 1ae14a39416563d7fd137514e0bafc1d 63.210.148.230 02/25/2023 12:45 AM UTC

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

[300 Pages] According to Persistence Market Research, the Water Pump market will generate revenue of US$ 50.2 Billion by 2023. The demand for Water Pump will accelerate, with the top market players holding a prominent share of the global water pump market in 2022. The global market for Water Pump is expected to reach US$ 77.2 Billion by 2033, growing at a 4.4% CAGR from 2023 to 2033.

Global agriculture industry is projected to witness a significant growth over the forecast period and is expected to have a high impact on the growth of the pump market. The wastewater management is gaining importance due to the severe changes in the world"s climate and the widespread occurrence of droughts. Wastewater treatment is a critical requirement in industrial, commercial, and residential areas. Hence, the growth in wastewater treatment in several end use industries has positive impact on the global water pump market

The adoption of advanced water pumps (IoT based) is still at the nascent growth in the global market except countries whereas government initiatives are looking to encourage water pumps in irrigation, municipal facilities and wastewater treatment plants.

From 2018 to 2022, the market for Water Pump increased at a 3.1% CAGR and is anticipated to grow at a CAGR of 4.4% in the forecast period of 2023 to 2033. This increase in CAGR is higher because of factors including the wide applications of centrifugal and positive displacement pumps in wastewater treatment and water supply activities.

The water pump market has been adversely affected by the COVID-19 outbreak. This is attributed to the fact that the supply chain was disrupted by the lockdowns in several nations, which also had an impact on the distribution and assembly of household pumps. Additionally, organisations are putting a lot of effort into research and development because of the lack of funding. In addition, many small businesses have slim profit margins. The scenario is anticipated to alter with the lifting of the lockdowns, and sales of water pumps are anticipated to increase in the upcoming years.

Key players estimate the rising global water pumps market to represent a stable growth rate during the forecast period owing to product developments and investments in new manufacturing plants. Acquisitions, partnerships, and mergers among the leading players in the global pumps market are estimated to boost the market. Adoption of IoT is one of the prominent trends gaining traction among end use consumers, especially in the oil & gas sector. Oil & gas has been implementing IoT in their operations to improve overall efficiency and for remote monitoring of operations and has become one of the most prominent trends in the global water pumps market.

The market for Water Pump is anticipated to expand at a 4.4% CAGR between 2023 and 2033. By the end of 2033, the market is projected to increase from US$ 50.2Billion to US$ 77.2 Billion.

Infrastructure development initiatives are directly associated with the need for water pumps on a global scale. In emerging countries, urbanization is a priority for their governments, which is expected to increase demand for water pumps, notably for residential, irrigation, and water and wastewater treatment applications. The global market for water pumps is also being driven by the increased demand for solar-powered water pumps, particularly in irrigation and agricultural applications. Water scarcity is a serious problem that affects many areas of the world. Governments of many nations, especially in industries, are implementing regulations requiring water recycling and reuse. In the near future, this is anticipated to increase demand for water pumps.

Governmental organizations in developing countries like India, China, and Brazil are emphasizing the improvement of drinking water infrastructure in both urban and rural areas. Additionally, the discovery of new water sources is predicted to boost sales of water pumps for home and agricultural uses that are more powerful and efficient. Since most places on earth still do not have access to the most fundamental convenience of running water, desalinization initiatives are also anticipated to aid in the adoption of water pumps. Around 60% of the globe still lacks access to flowing water.

The presence of both global and local competitors distinguishes the water pump industry in European market. The regional market participants are well versed in manufacturing processes for producing energy-efficient products that can compete with those of the market"s major competitors. It is projected that this element would lead to price competition in the market, which will eventually cause overproduction and a reduction in profit margins by businesses in order to maintain a competitive advantage in the market.

In several countries, the number of local manufacturers and local vendors on water pumps is increasing rapidly, which offered low quality product at comparatively low price, which may challenge the growth water pumps market.

Due to their straightforward design, broad capacity range, smooth flow rate, ease of maintenance, and operational effectiveness, centrifugal pumps are among the most often used pumps. For high-pressure applications that require the same quantity of flow to be produced at the same pace, positive displacement pumps are appropriate.

One of the primary end-use industries for pumps is construction, and with rising investment in this industry, the pumps market is expected to expand rapidly over the next several years. The next ten years are predicted to see many new development projects undertaken by governments and other private companies, which will result in increasing demand for pumps.

The key market participants offer a wide range of products in their portfolio and offer customization at a quicker turnaround time. Customers have reported that customization is their preferred option as their needs have shifted from general to niche applications. Manufacturers can capitalise on the opportunity of optimising the speed of large centrifugal pumps, which can save energy and reduce wear and tear on water pumps. Hence, most global players such as Grundfos, KSB AG, Wilo AG, and Xylem Incorporation aim to expand their local network by increasing tie-ups with regional as well as local distributors worldwide, which pave the way for futuristic growth of the targeted market.

The industry is expanding in India primarily due to rising investments in agricultural infrastructure. Water pumps help move water from the source to the agricultural area and can be used for drip irrigation, hose pipe irrigation, etc. In order to increase farmers" incomes and the country"s overall agricultural output, the Indian government is also putting plans, changes to policies, and programmes into action. This, together with the growing reliance on groundwater for other agricultural needs, are what are driving the market. Sewage treatment facility (STP) building has also considerably grown in India. The majority of the time, these facilities depend on municipal wastewater pumps, also known as sewage pumps, to transfer sewage, sludge, storm water, and wastewater from treatment tanks.

In addition, due to severe water shortages, various governments across the nation are concentrating on expanding desalination plants. Water pumps are also used on building sites to remove extra water that has accumulated because of high water table. This is accelerating the need for water pumps in India, together with the expanding building industry. Rapid industrialization and the growing demand for clean drinking water are two factors that are expected to drive market expansion.

Over the forecast period, rising energy costs and rising environmental consciousness among end users are anticipated to fuel demand for energy-efficient and cost-effective centrifugal pumps. For end-use businesses that depend on centrifugal pumps, increasing water pump efficiency and lowering energy consumption and costs are crucial challenges. Centrifugal pumps that are energy-efficient lower yearly energy expenses, which benefits the environment.

Water & wastewater industry is a prominent end-use segment of the Water Pump market, witnessing a the highest growth rate of 5.5% between the forecast period 2023 to 2033.

Based on end use industries, the water and wastewater industry segment has good growth projections for global water pump market, as key market participants and governments look into technology that can turn wastewater into potable water in order to fulfil the demands of a growing population. Increased expenditures in technology like water pumps for clean water and sanitary purposes are occurring in Africa as a result of the surge in demand for high-purity production forms. The leading market players provide a wide selection of pumps that are tailored to the treatment requirements in order to efficiently and dependably pump wastewater through all stages of treatment.

The water pumps market is highly fragmented with the presence of more than 1,000 number of players across the globe. Market players are now focusing on increasing customer retention and strengthening their relationships with existing customers. Long-term relationships with customers and vendors enable companies to acquire long-term contracts for the deployment of water pumps.

In April 2021, IDEX Corporation signed a definitive agreement to acquire Airtech Group Inc., US Valve Corporation, and related entities from investment funds managed by Eagle Tree Capital for a cash consideration of USD 470 million. Airtech manufactures and designs a wide range of engineered pressure technology, including positive displacement vacuum pumps, regenerative blowers, compressor systems, and valves.

A well-placed suction stabilizer can also prevent pump chatter. Pump chatter occurs when energy is exchanged between the quick opening and closing of the reciprocating pump’s valves and the hammer effect from the centrifugal pump. Pump isolation with suction stabilizers is achieved when the charge pumps are isolated from reciprocating pumps and vice versa. The results are a smooth flow of pumped media devoid of agitating energies present in the pumped fluid.

8613371530291

8613371530291