centrifugal mud pump manufacturers quotation

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

Stainless Steel Pumps, Steel Pumps and SS Pumps, steel pumps, ss pumps, industrial pumps, ss pumps industrial, ss pumps industrial manufacturers and exporters india,industrial pumps Exporters, Steel Pumps and SS Pumps Manufacturers India, Stainless Steel Pumps India, industrial pumps Exporters, ss pumps Exporter india , ss pumps Manufacturers and Exporters,ss pumps india, ss pumps Gujarat, Stainless Steel Pumps manufacturers and exporters, Gujarat, India.

Self Priming Cum Centrifugal Mud Pump, Self Priming Cum Centrifugal Mud Pump, Self Priming cum Centrifugal Mud Pump, Manufacturers and Exporters, Centrifugal Mud Pump, Centrifugal Mud Pump Manufacturers, Centrifugal Mud Pump Manufacturers and Exporters,

A part of National Oilwell Varco, the Mission line of centrifugal pumps are equipped with innovative features to match the demanding nature of routine, corrosive and abrasive applications. Because of the need for a low pressure mud system, Mission 1780 Type W centrifugal pumps were introduced in 1950s to replace duplex pumps. The aim was to apply a high quality centrifugal pump with concentric systems that allowed for abrasive fluids to be mixed and transferred thereby lowering the initial and maintenance costs of drilling. As a result, centrifugal pumps with low pressure mud systems such as Mission 1780 Type W became the industry standard.

As well depths increased, so was the need for heavier mud weights and centrifugal pumps that could withstand greater horsepower load. This led to the launch of Mission Magnum- a centrifugal pump.

The Magnum has an open impeller design that contains wide-tipped vanes and a more tangential circumference of the suction allowing the pump to create a smoother flow pattern when handling abrasive fluids. The Magnum is available in Magnachrome™, hard iron, stainless steel, and aluminum bronze fluid ends. The pumps can be unitized with electric motors, diesel engines, and hydraulic motors (horizontal, vertical, or close-coupled configuration).

Our pump engineering experts have the industry knowledge to gladly assist you with any questions, concerns, or inquiries you may have regarding the pumps & pump parts we distribute @ 800.560.7867.

A centrifugal pump has a relatively straightforward design: a casing with a discharge valve houses an impeller with multiple blades which turns on a mechanically powered rotating shaft. As the shaft rotates, this pumping motion increases the pressure of the liquid passing through the casing via kinetic energy generated by the blades on the impeller. Once the fluid"s pressure is increased, it passes through the pump through the discharge valve. Centrifugal force is combined with positive displacement to sustain the operation.

This basic design allows pumps to be installed in larger mechanical systems or engines, from automotive engines to water treatment plants. Because centrifugal pumps often work with a variety of different fluids, from water to acids to oil, the casings are usually made from fairly hardy materials such as stainless steel, cast iron, or aluminum. The pumps usually have a weep hole, which is an opening on the underside of the pump that is used to help spot the first signs of mechanical seal failure. The mechanical seal is used to create a barrier between the motor and the water so that unwanted fluid does not go into the engine or motor. When the weep hole leaks, the pump will probably need repair or replacement.

High pressure or an overabundance of oxygen, specifically pockets of air within the casing that can develop when the pump is not being used and the casing is empty, can disrupt the operation of centrifugal pumps. Many pumps need to be regularly primed or checked for air pockets to ensure a seamless operation. The formation of air pockets is frequently referred to as cavitation.

The earliest conceptual incarnation of the centrifugal pump originated during the Italian Renaissance thanks to an engineer known as Francesco di Giorgio Martini, who described a mud lifting machine in a treatise in 1475. The more modern and recognizable form of the pump, with its straight vanes, did not appear until Denis Papin designed it during the 17th century. However, it wasn’t until the 19th century that the next major advance in the field was made. In 1851, John Appold unveiled his design for a centrifugal pump with a curved vane, which won him a council medal at that year’s Great Exhibition at the Crystal Palace. The curved vane was three times as efficient as any of the preexisting straight vane pumps, and had a profound influence on the industry.

While all centrifugal pumps use positive displacement as part of their operating procedure, they are differentiated from positive displacement pumps by the fact that they also increase the speed of the liquid moving through the pump, while positive displacement pumps simply move the liquid at the same speed. Positive displacement pumps include a lobe, screw, peristaltic, and a gear pump configuration.

A gear pump creates positive displacement by way of multiple meshing gears. There are two main types of gear pumps, internal and external. An internal gear pump uses a combination of an internal and external gear spur, while an external pump uses two external gear spurs. The fluid processed by these pumps moves at a steady rate per each revolution. Gear pumps are most frequently used in hydraulic fluid power operations.

Most vehicles built in the United States during the 20th century use a centrifugal water pump to provide water to the engine. The impeller of the water pump can sometimes be modified to increase the flow rate of the pump and the subsequent performance of the engine.

In fact, most centrifugal pumps differentiate themselves by modifying either the impeller or the discharge apparatus. The curvature and depth of the impeller vanes or blades has a significant impact on the operation of the pump. The impeller itself can also either be left open or closed. In a closed situation, a plate or other enclosure is affixed to the impeller blades. This has been shown to increase the flow rate in some applications, depending upon the specific fluid that the pump is processing.

The size of the discharge apparatus, combined with the speed of the shaft, can also significantly impact flow rate. However, it is vital that any modification of a pump does not unduly increase the “head” or pressure within the system. This pressure is measured in pounds per inch, or PSI, and refers to the force exerted by the fluid within the pump.

Have a vertical shaft attached to a perpendicular impeller. The lifting action of the impeller vanes pushes the liquid within the pump upwards in an axial flow pump. A jet pump aids the operation of a centrifugal pump by increasing suction, while a submersible pump is installed underground. True to its name, a submersible pump is almost constantly inundated with liquid, and therefore is a self-priming pump: air pockets rarely form within the suction line because water or another liquid is always being circulated through the pump.

While most pumps are powered mechanically, some pumps are powered by a hydraulic motor. Submersible pumps can be powered electrically. The power cords to these pumps are encased in a durable, waterproof cover, usually layered with thick rubber. Because they are more difficult to maintain, electric pumps tend to be smaller, such as a 12 volt pump, and deployed for specific operations, such as pumping out a flooded structure. The pump can be placed on a floating rig with an outbound discharge hose and allowed to gradually pump out the unneeded water. These pumps are sometimes also referred to as sump pumps.

Designed to work with abrasive fluids, including bleach, resin, acid, and an array of other toxic, often corrosive, materials. These can be useful in industrial operations. Well pumps, meanwhile, pump water from an underground region to a higher location within a given structure. Well pumps are often used to provide water for apartment buildings or other large structures, and often work in concert with a pressure tank.

Although they are primarily designed to deal with liquid, the centrifugal pumps can occasionally handle liquids that are contaminated with other materials, such as twigs, small rocks or sand, or other debris. These types of pumps are known as trash pumps, and are generally used in wastewater treatment plants or sewage operations. A trash pump is typically able to pump thousands of gallons of water per minute, a measurement that is referred to as the flow rate, and manages the thicker, more viscous liquid by way of a very large discharge opening and much deeper impeller vanes than are found on a typical centrifugal pump. There are several different subsets of trash pumps, including semi-trash pumps, and other pumps that handle liquids with specific particulate size limits. A dewatering pump, for example, can process non-hazardous water with particulate matter up to 0.25” in diameter. Some dewatering pumps are completely submersible and can operate from any position, including upside down.

A type of radial flow pump in which the fluid enters the impeller from both sides. Due to the extending of the shaft into the suction passage, double suction pumps are limited to pumping clear liquids.

Designed with wide unblocked passageways and are an intermediate pump between radial and axial flow pumps. Mixed flow pumps develop the pressure partially with centrifugal force and partially with the lift of the impeller vanes on the liquid.

Can be either horizontal or vertical, consist of two or more pumps of similar capacity that discharge into each other in a series. Progressively the pumps develop a total head, the sum of the heads that each pump has developed. A common shaft with several impellers, each with its own volute, is rotated by a power supply, building up pressure in stages.

Take in liquid through the center of the impeller and move it out along the impeller blades at a 90-degree angle to the pump shaft. Radial flow pumps develop the pressure only with centrifugal force.

A type of radial flow pump in which the fluid enters the impeller from one side, and the shaft does not reach into the suction passage. Single-end suction pumps are used in applications where there are large solids, such as rags and trash, that would normally clog the pump.

Designed to have only the casing and the impeller submerged in the pumpage for priming and the support bearings for the rotating element in a dry environment.

Have no throttle or bumper bushings or any rings at the impeller or submerged below the maximum normal water level, and they are used in applications, such as a sump or tank, in which it is necessary not to have a bearing in the pumpage.

Inefficiently designed pumps in which the impeller is recessed into the volute. However, vortex pumps are practical in applications that require pumping of excessive solids.

While a certain threshold of increased pressure is needed to make the pump operate successfully, too much head can unbalance the pump, causing damage. Depending on the amount of pressure, a pump can occasionally tear free from its moorings, known as shock mounts, and wreak havoc on an engine or surrounding assemblies. In order to avoid this unfortunate circumstance, pump owners should regularly prime their pumps to avoid cavitation, and make sure that they are not attempting to force too much liquid through their system too quickly. Operating a pump with a motor that is moving too quickly can also result in a build-up of unwanted head, thereby damaging the pump.

Frequent cavitation also damages the components within the pump. This happens because the impeller blades become pitted when the air pockets explode under pressure. Priming the pump at regular intervals will prevent undue cavitation, although over the working lifetime of a pump some amount of cavitation is likely to occur.

Because of their wide range of applications, centrifugal pumps are manufactured by a number of different companies for different purposes. Generally speaking, the pumps will increase in size and power for heavier industrial applications, while smaller pumps are used for less intensive operations. The industrial centrifugal pump manufacturing market has created pumps with 40,000 gallon per minute flow rates. This flow rate would not be necessary in a smaller application, such as in a car or in a well pump in a single family home.

Manufacturers are also experimenting with the use of thermoplastics and fluorocarbons as opposed to metal for use in the seals of pumps. These types of materials tend to resist corrosion better than metal, and therefore can increase the longevity of the pump without compromising the production of kinetic energy or centrifugal force. However, the use of stainless steel, cast iron, and aluminum is still typical for the exterior casings, although plastic is occasionally suitable as a material.

The need for jet pumps has also decreased in recent years as manufacturers have become more adept at designing pumps that provide ample suction without the need for additional assistance. However, depending on the viscosity of the fluid and any corresponding debris, a jet pump may still be needed.

In any case, a client who is attempting to find the best manufacturer for their needs should first be able to specifically articulate the application for which they will be using the pump. A client who is attempting to install a series of drainage pumps across a wide variety of low-lying properties will have different needs than a client who wishes to operate an aftermarket parts company that will sell modified water pumps for higher automotive engine performance. Similarly, it is vital that the client understands the kind of fluid they will be dealing with and its relative purity. In the case of the client who is seeking a manufacturer for drainage pumps, the water that the pumps will encounter will likely have some form of debris or small particulate matter contained within it. The aftermarket parts company, on the other hand, will likely be dealing with relatively clean water that has little to no debris. In each case, the condition of the liquid will influence what kind of pump is appropriate for the task.

Many manufacturers prefer to produce “mill runs” or large batches of a given product. This is partially because a large production batch will decrease overhead costs while also guaranteeing a substantial sum for the company. Clients who are attempting to design a new version of a pump or improve upon the basic centrifugal pump design should first make prototypes of the design. These prototypes will enable the client to instigate a thorough round of testing, which will reveal any flaws or unexpected performance quirks of the pump before it is approved for mass production. Manufacturers are often able to recommend a machinist or other fabricator for this task if they do not have a department already dedicated specifically to prototype production.

The force applied by the atmosphere to the surface of the earth. Atmospheric pressure, the standard of which is 14.7 lbs per square inch, affects the operation of a pump.

An undesirable condition in which vacuum pockets form within the pump. The air pockets eventually implode under pressure, resulting in the pitting of the impeller and volute surfaces.

An apparatus in a discharge or suction line that permits flow in only one direction so as to prevent reverse flow and isolate the material being pumped.

A stationary casing, like a volute, that houses the moving impeller. Diffusers are compact in design, enabling the pump to create higher pressure heads.

The required amount of gallons per minute (gpm) of pump flow. Flow can also be expressed in gallons per hour (gph) and in million gallons per day (mdg).

A rotating disk with vanes of varying amounts attached to the “r” drive shaft that creates centrifugal force within the pump casing of a centrifugal pump. Impellers can be open or closed.

Pump components located on the impeller between the eye and the discharge side of the impeller. Impeller vanes direct the flow of the liquid to the outside diameter of the impeller.

Allowing the pump to disperse all air from the influent line of a circulating system by causing fluid to start flowing once again. Priming the pump is usually accomplished by either manually filing the volute or turning the pump on.

Stationary casing of a centrifugal pump that separates air and water and in which the impeller rotates. Volutes are spiral-shaped in order to facilitate the partial conversion of the velocity (kinetic) energy into pressure head as the water leaves the impeller.

A small opening located on the underside of the pump at which point the engine joins the pump. Weep holes provide the means to quick detection of a leak before water seeps into the oil sump of the engine.

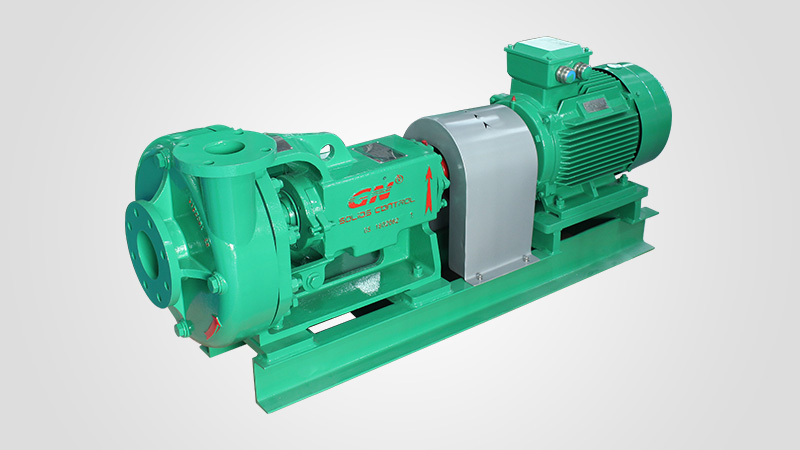

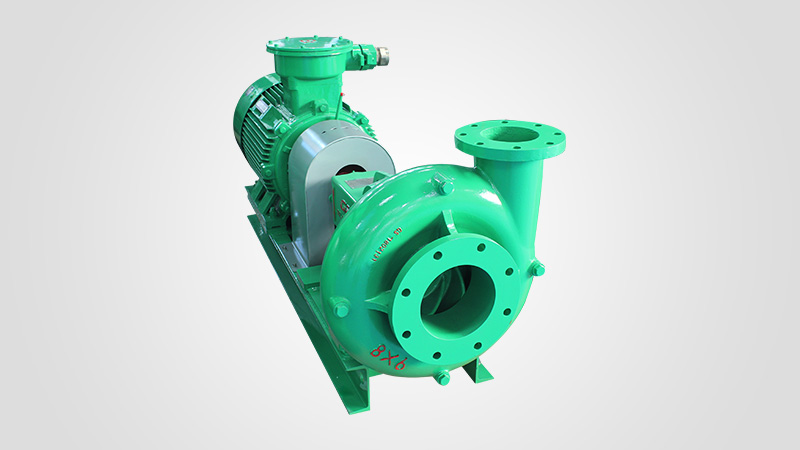

GNSB Series Centrifugal Mud Pump is designed to transfer industry slurry, waste water with solids less than 2mm. It’s widely used for drilling industry, construction mud transfer, environmental waste fluids transfer as well as mining slurry transfer industry. GNSB Centrifugal Mud Pumps have been field proven to meet the standards for rugged and demanding applications. The pump is capable to be used for high volume, high temperature slurry and pumping high abrasive, high viscosity fluids.

Fully casting pump skid instead of welding to provide stable supporting for the pump and motor, in a result to improve the operation life of the coupling and all bearings.

GN Separation and Conveying Equipment company manufacture separation equipment and conveying equipment as well as the transfer pumps for the industry process application. This allows GN to be able to provide full package solution to our clients for different applications. Both GNSB transfer Centrifugal Mud Pump and separation equipment are widely used for following industry.

There are three types of mud pumps, depending on the type of client and the size they want. For general, mud pumps, there are three basic types of mud pumps, depending on the type of client and budget. The piston pump is another compressed mud pump, which is a pushed electric compressor mud pumps and by compressed air.@@@@@

Electric mud pumps are largely divided into three categories, among them the electric mud pumps and the semi-trash mud pumps. The piston inflated mud pumps are also classified in terms of the type of mud pumps, among them are electric mud pumps and semi-trash mud pumps. In addition, the piston inflates mud and mud pumps will be inflated by the piston, which is inflated mud pumps.

The trash pump does not grind the materials that it receives. Cast iron, aluminum, steel, and stainless steel are all possible materials used to construct trash pumps. Trash pumps use a big inlet and strong power to pick up debris while delivering maximum pressure and discharge flow. A trash pump can be powered by alternating electricity, direct current, compressed air, gas, diesel, or solar energy.

When a trash pump is operating, contaminated water is sucked in. By creating a low-pressure space inside the pump cavity, the pump sucks in the fluid. A trash pump’s impeller generates the water"s kinetic energy. Water is moved axially and radially by the impeller blades" centrifugal force. To further compress the water, the filtered water is directed into the volute casing while the debris and other solid particles are transported toward the pump’s central hub.

The speed is converted into pressure energy via the volute case. This power aids in processing the fluid through the pump. A trash pump should be switched when water stops moving through a pipe. A trash pump should not be used to pump gasoline, caustic chemicals, or other fuels due to the damage these materials can have on the pump. Safety and mechanical issues could result from this process.

It is important to check the water’s temperature when using a trash pump. High-temperature water can cause cavitation issues (where static pressure forms pockets of vapor-filled cavities in a liquid), boil when pulled in, harm the pump"s impeller, and have a high vapor pressure.

Trash pumps have special capabilities that enable them to move enormous volumes of liquids that are heavily contaminated with particles and rubbish. These abilities are a result of their components; some of these components are discussed below.

Trash pumps utilize an impeller, a revolving part of a centrifugal pump, which helps limit clogging. The impeller raises the liquid"s pressure and flow by accelerating fluids away from the rotor. The fluid"s increased pressure and flow decrease the likelihood of clogging. An impeller does not grind down the garbage and other debris; they are propelled out whole. The fibrous materials, solids, and grit are directed through the pump without grinding because of the liquid vortex the impeller generates in the casing.

A pump may become clogged if materials enter that are greater than the pump’s capacity. Strainers are installed at the inlet of trash pumps to stop debris and other materials from entering which are larger than the pump"s volume. It is also essential to make sure the strainer is always submerged for it to perform its job.

Trash pumps self-prime. The priming process is performed in order to remove air and vapor from the pump and the suction line. The priming procedure entails pushing air out of the pump and replacing it with fluid, such as water. No pumping will occur if priming is not performed. A self-primer guarantees that there is always liquid in the priming chamber. If fluid levels need to be raised before starting an engine, a switch will be activated to indicate that manual priming must be performed.

Although trash pumps all serve the same general purpose, variations exist to better serve specific applications. We examine a few trash pump varieties below.

Positive displacement pumps move fluids through pistons, gears, diaphragms, and other components. A vacuum is produced when a fluid enters their fixed chamber and is pumped out. This vacuum is also useful for moving objects. Displacement pumps work well when pumping viscous liquids under high pressure.

Syringe pumps handle materials that need precise flow rates at precise times. The two types of syringe pumps are infusion pumps, which process fluid under tightly-controlled pressures, and withdrawal pumps, which are used to remove fluids.

our horizontal centrifugal pumps are easier to install and maintain with internal parts that are simple to access. You can choose the proper shaft design to provide the desired pumping pressure. Low suction applications will be best with an overhang shaft while you’ll want an in-bearing shaft for high suction pressure. Horizontal centrifugal pumps can easily be coupled securely with external accessories such as turbines, electric motors or fuel-powered engines.

8613371530291

8613371530291