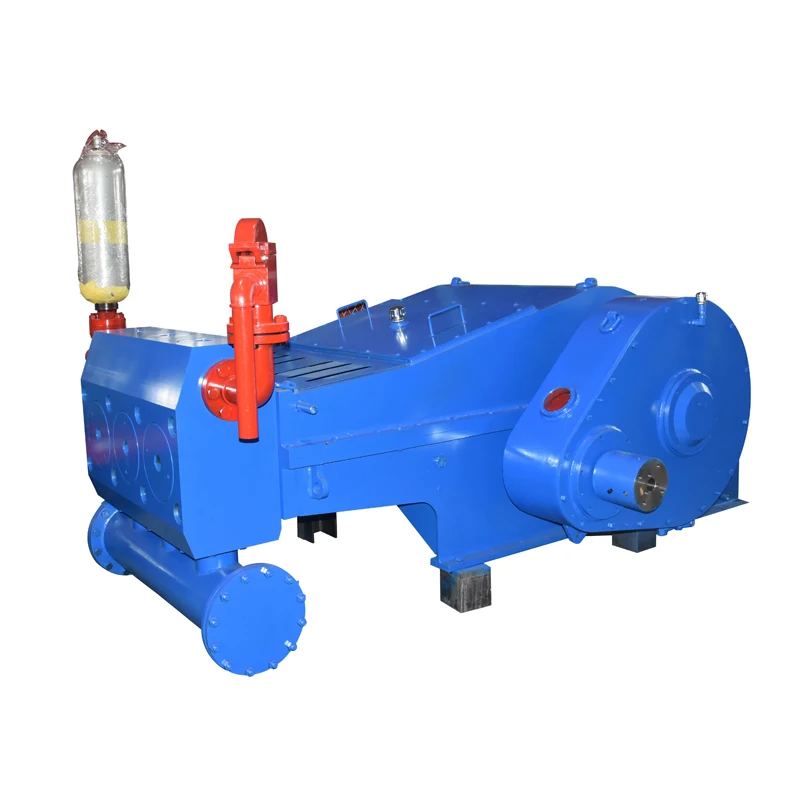

china high pressure mud pump made in china

Mud Pump is also a popular concept of a wide range of pumps. Different regions, habits, and ultimately the pump type will not be the same. The mud pump described in this entry is a pump type in most sense: Applied mud pumps in the field of oil drilling. In fact, some non-clean water pumps and mud pumps, such as sewage pumps and slurry pumps, are also commonly used when they are called.

Mud pump refers to a machine that transports mud or water and other flushing fluid into the borehole during drilling. Mud pumps are an important part of drilling equipment.

In the commonly used positive circulation drilling, it is to send the surface flushing medium—clear water, mud or polymer rinsing liquid to the bottom end of the drill bit through a high-pressure hose, faucet and drill rod center hole under a certain pressure. Cool the drill bit, remove the cut debris and transport it to the surface.

The commonly used mud pump is a piston type or a plunger type, and the crankshaft of the pump is driven by the power machine, and the crankshaft passes the crosshead to drive the piston or the plunger to reciprocate in the pump cylinder. Under the alternating action of the suction and discharge valves, the purpose of pumping and circulating the flushing liquid is achieved.

Find W series mud pump from pressure grouting pump manufacturer - Saigao gruop in China. The W series mud pump can be widely used in all kinds of works in oil field, which is su...

Dezhou Rundong Petroleum Machinery Co., Ltd is major in manufacturing oil drilling mud pump spare parts and drilling tools, in which liners, pistons and valves that developed new have got national patent certificate. Mud pump parts we manufactured can be totally exchangeable with spare parts from original manufacturer, and have excellent performance especially in drilling conditions of high temperature, high pressure, oil base mud, acid base mud and high sand content mud etc.

We have been committed to continuous optimization and upgrading of drilling mud pump products.We accumulate rich first-hand technical information through our service to drilling projects, for example different material products’ performance under different drilling conditions. Our aim is to make products manufactured can be more suitable for oilfield drilling needs, and our goal is where there is oil, there is Deshi Brand products.

Main advantages of the mud pump consumables that we manufacturedProducts are produced according to ISO9001 quality system,APISpec7K standard, and each process can be tracked, recorded and traceable

Years of production experience accumulation and continuous innovation, make parts manufacturing process more sophisticated, products service time more longer, cost performance more higher. Drilling cost can be effectively reduced by taking these products.

Import spare parts such as valve module, crankshaft, pinion shaft’s material are high quality alloy steel,The power end herringbone gear adopts the grinding process, the gear precision is high, the processing precision of the matching components is much more higher, which can make the whole mud pump can run more smoothly.

Production and quality inspection are separated, different process have different people to responsible, inspection methods are advanced, and have high-end inspection laboratories and detectors.

The owner of this website (china.tradeford.com) has banned the autonomous system number (ASN) your IP address is in (20473) from accessing this website.

HW-440/446 Pump can be widely used in all kinds of works in oil field. When the cylinder liner specification is 6”-3 1/2”, piston structure is recommended and it is suitable for Oil-Well Repair and shallow-well drilling, etc. When the cylinder liner specification is 3 1/4”-2”, axial piston structure is recommended and it is suitable for high-pressure work.

Emsco、Gardner-Denver, National oilwell, Ideco, Brewster, Drillmec, Wirth, Ellis, Williams, OPI, Mud King, LEWCO, Halliburton, SPM, Schlumberger, Weatherford

However, quality and service are always put in the priority of “fast growth”, by implementing the principle of quality control to every production process, we can ensure that every water well drilling rig and equipment we put out is a high quality one.

In oil drilling, high-pressure mud pump is the heart of drilling platform, and wear resistant cylinder liner is the main vulnerable part of mud pump. It need to withstand working conditions of high pressure, high wear and strong corrosion. At present, the mud pump cylinder liners are mainly bimetal cylinder liners and ceramic cylinder liners. The lining of the bimetal cylinder liner is made of high-chromium cast iron metal materials, the lining of the ceramic cylinder liner is made of alumina or zirconia structural ceramic material.

In 1996, Phillips China, Inc. (PCI) based in Shekou, People"s Republic of China, was faced with the decision to either submit a development plan for the Xijiang 24-1 Field in the 15/11 Contract Area of the South China Sea or to relinquish their rights to the field. The remote location of the field and the relative small size of the reservoir made this decision difficult. Several studies conducted over a number of years on various development scenarios indicated that any type of stand alone development, such as a small platform or subsea wells, would be uneconomical. It was, therefore, concluded that the only way of developing the 24-1 was to drill an extended reach well (ERW) from PCI"s Xijiang 24-3 Platform, over 8-km away. Such a well would have a world record horizontal reach.

8613371530291

8613371530291