drill your own well mud pump pricelist

Drilling a well costs $5,325 to $9,180 for an average depth of 150 feet. Most homeowners spend $3,750 to $15,300, or $25 to $65 per foot for well installation. Digging a shallow well costs $1,800 and $3,000. Costs depend on the depth drilled, soil conditions, and the well"s diameter.

Well drilling costs $15 to $25 per foot for the drilling process only. Installing a complete well water system costs $25 to $65 per foot, irrigation wells run $50 to $100 per foot, and geothermal wells are $5 to $40 per foot.

Drilling a residential water well costs $25 to $65 per foot or $3,750 to $15,300 on average for a complete system and installation. Prices include the drilling, a pump, casing, wiring, and more. Total costs largely depend on the depth drilled and the well"s diameter.

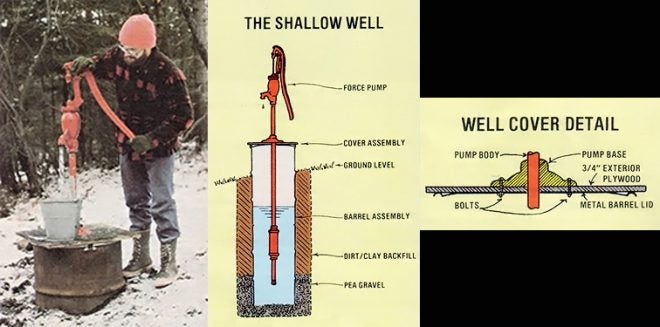

The average cost to dig a shallow well is between $1,800 and $3,000, or $5 to $10 per cubic yard depending on the depth of the water table. Shallow wells are typically 25" to 50" deep, 3 to 10 feet in diameter, and are best in areas without rocks or any bedrock.

Dug wells capture water from shallow aquifers close to the surface and are lined with brick, stone, or concrete tiles to prevent the walls from caving in. Shallow wells produce less yield and are more difficult to protect from contamination. Drilling is the most common method of well construction.

Drilling an irrigation or agricultural well costs $25 to $50 per foot or $85 to $105 per foot for a complete installation. Residential irrigation wells cost $9,000 to $15,000 on average, while many high-yield commercial wells cost $50,000 to $100,000, which typically includes the pump.

Commercial agricultural wells require a larger borehole and are drilled deeper to increase water volume to at least 6 gallons per minute per acre for a center pivot. Most states require a permit to drill and place limits called allocations on the amount of water that can be pumped out over time.

Geothermal well drilling costs $5 to $40 per foot or $3,500 to $5,000 per well. Geothermal wells are 4” to 8” wide, 100’ to 500’ deep, and spaced 10’ to 20’ apart. Most homes need 3 to 5 boreholes on average with 300’ to 500’ of piping per ton of HVAC capacity.

Installing a vertical geothermal heat pump costs $22,000 to $35,000 on average, including the drilling. The largest cost is getting the equipment to the job site, and experienced contractors are sparse.

Geothermal wells work by sinking pipes filled with an ethanol solution into a drilling location with a drill rig as a source of heating and cooling energy for a home. During colder months, the solution brings the heat back to the house; in the summer, heat is taken from the house and transferred to the ground.

An artesian well costs $35 to $85 per foot or $5,000 to $15,000 for drilling and casing to an average depth of 150 to 450 feet to hit an aquifer. Groundwater in aquifers between layers of rock is a pressurized body of water, causing water to flow naturally without pumping or electricity when tapped by a well. Although artesian wells cost more and need a specific location, they require low maintenance and ongoing expenses.

A sand point well costs $300 to $3,000 and is a good solution for temporary water needs, delivering up to 3 gallons per minute. A sand point well is the most economical way to get water, can be installed by a homeowner, but may not last long or produce clean water at the right pressure consistently.

Sand point wells are similar to dug wells in depth, with a steel pipe driven around 20" deep and a 1-1/4” to 2” diameter. A screen on the end of the point filters the water from water-bearing sand, and it’s drawn to the surface by a pump. Choose from kits with a hand pump or a jet pump. Installing a water tank is optional.

The average cost to redrill a well deeper is $3,000 to $6,000, or between $35 and $84 per foot, which is the same as drilling a new well. Hydrofracturing is another method used to increase water flow and costs $1,500 to $3,000. Explore both options before drilling.

There is no guarantee that deepening a well will yield water if the well has dried up. Many professionals only recommend deepening a well if it"s not deep enough for hydraulic fracturing (at least 200" deep), or if hydrofracturing has been performed multiple times with failure to meet the water demand.

Hydraulic fracturing has a 97% success rate, requires no excavation, and uses highly pressurized water to break up the solid rock at the lowest level of the well to open new pathways for water to enter your well. Plus, the final cost will be known in advance.

Installing a new well water system ranges from $1,775 to $30,000 or more, depending on the options you choose to power your well pump and the depth and diameter of the well. Drilling is the most expensive part, followed by the cost of the pump.

Well pumps cost $300 to $2,000 to install depending if it"s a shallow well pump or a deep well pump, and the degree of incline from the well to the storage tank. Different types of wells require specific pumps; some need to be submersed while others are placed outside the well. If your well is deeper than 150 feet, or if there is an incline, you"ll need a stronger pump.

For wells 25’ deep or less. Placed outside the well and covered with housing. A tank or a booster ensures constant water pressure, and has overload protection which prevents motor burnout.

Submersed inside wells 90’ – 300’ deep. Recommended using a 3-wire pump for easier maintenance. Repairing 2-wire pump"s requires raising it to the surface first.

For shallow wells and deep wells up to 90’ deep. Not submersible; placed outside the well and covered with housing. Useful in areas where the water table fluctuates.

Installing or replacing well casing costs $6 per foot for PVC casing to $130 per foot for stainless steel pipe casing. An average well needs 25" of casing below the surface that costs $250 to $2,500 depending on soil conditions.

There are different types of casing, depending on where you live: steel, stainless steel, PVC, or concrete. Well casing supports the wall of the well and keeps dirt and rocks out of your water. Well casing is not required when drilling through hard rock as it provides its own support.

Earthquake-prone areas require steel casing that won’t snap if the earth shifts. Casing should be at least 5 inches nominal inside diameter, and at least 1 inch larger than the outer diameter of pumping equipment installed.

A septic system costs $3,280 to $5,040 to install by itself on average. The cost to put in a well and septic system ranges from $6,000 to $20,000 depending on the type of septic system, type of absorption field, size of the septic tank, and depth of well drilling required.

Most rural or off-grid homes use a well to deliver fresh water and a septic system to dispose of wastewater. Sometimes, homeowners have a choice between digging their own, or hooking into municipal water and sewer systems.

For capped wells, the water and power lines are underground. In northern regions where the frost line is 3 – 4 feet deep, there will be a sanitary well cap on the well above ground, and the pump will be suspended on a pitless adapter below the frost line.

The cost of well water storage tanks runs from $104 for a 2-gallon tank to $714 for a 44-gallon tank. Water tanks, or pressure tanks, draw water from the well and keep it under pressure, and delivered immediately when someone uses an appliance or a faucet in your home.

Many different factors determine the cost to dig a well, such as the depth and diameter of drilling, ground conditions, water testing, your location, permits, and more.

The drilling depth to water and bedrock and the well"s diameter are the most significant cost factors. The average well is drilled 100 to 300 feet deep, while some shallow wells only go down to 25 feet to reach groundwater. The diameter of residential wells are often 4 or 6 inches, which dictates the amount of water flow.

The geologic makeup of your area dictates the difficulty of drilling, which affects the cost. Is the ground sandy soil, rock, or heavy clay? Some wells drilled through rock are 400 feet deep. Local well drillers can guess at how deep you"ll need to drill. The difference in cost can be:

The cost to drill a well depends on your soil conditions and water levels, which vary based on your location. Below are the approximate costs by state for drilling, casing, and complete well water system.

Install your well close to the house to save on piping costs for water and electricty. A main water line typically costs $30 to $60 per foot to install. Adding a power line to your well costs $1,500 on average, while a solar-powered pump costs $1,500 to $3,000 to install.

Well permits cost $350 to $700 on average, depending on where you live. A residential permit typically includes multiple inspections to ensure the well is drilled correctly, capped, and connected to the water main of your home. A permit is generally not required when a well is less than 2” in diameter.

The water will be tested to make sure it"s safe to drink, and you"ll receive a report about the mineral content and whether any contaminants are present. Different counties will have different permit fees and regulations. Check with your county clerk’s office to file a water well permit application.

Well water testing costs $20 to $150 for DIY kits or $50 to $650 to hire a government or university lab for professional testing. Lab testing checks for contaminants, chemicals, metals, and pollutants and provides an analysis with recommendations. Testing is required to make sure your drinking water is safe.

The cost of electricity to run a private well is about $3 per month and water is free. Once the water well is paid off, the average family of four saves $250 to $500 per year, or more if the well is used for irrigation.

If you are the landowner, you may drill a well on your property after meeting all local and state requirements and by filing a permit application. Your chosen location to put a well should be accessible to drilling or digging equipment.

Water wells for residential use are typically drilled 100 to 300 feet deep, although the rule is to drill until you hit water. The proper depth to drill depends on the underground water levels in your area. Local well drillers and neighbors can give you a general idea of how deep to drill.

A water well takes 1 to 3 days to drill depending on the depth to water, the drilling diameter, ground conditions, and weather. Getting equipment to the job site, drilling, setting up a pump system, running electricity, and testing the water takes 7 days for the entire process.

The average cost to maintain a well $150 to $350 per year for regular maintenance from your well company. Check with your well contractor to see if maintenance is included in the quoted price. Well maintenance includes:

After the maintenance visit, you should receive a well-written report of the findings along with any recommendations for the continued health of your well. If the water in your area has specific problems, like contamination, additional maintenance is required to keep the water clean.

The static water level is the measurement from the top of the water level inside the well to the top of the earth. When your well was drilled, the contractor noted your static water level. As long as it’s within a few feet of that number, it’s considered good. The static water level is best determined when you have not run water for several hours.

A professionally installed water well lasts up to 40 years with proper maintenance and care, although it could dry up at any time. A poorly installed well may only last 12 to 15 years. A water well pump only lasts 8 to 15 years before it needs to be replaced.

A well drys up when water levels drop below the pump intake. Water levels may return through aquifer recharge, where water moves downward from surface water to groundwater, or pumping is lessened. To determine if a well has gone dry, hire a well company to measure the water levels.

There are no monthly water bills with wells. However, there are electricity costs of about $3 a month to power the pump, and maintenance costs which average out to $10 to $20 a month to occasionally replace the well pump, pressure tank, and filters.

Since it"s impossible to know how deep you"ll need to drill, it"s difficult to acquire a set price quote before beginning work on the well. Be sure to get everything in writing first. Your contractor should provide you with a fee schedule and a list of costs for any unforeseen circumstances.

If the contractor does not find water in the drilling site, they"ll try another location, but you"ll have to pay for the drilling for both sites. When hiring a well drilling company, be sure to get at least three bids, and follow these tips:

Whether you live in a rural area or simply prefer getting your water from a private source, installing a well on your property has numerous benefits. You won’t have to pay a monthly water bill, and you’ll have some control over your water’s mineral and chemical contents. However, drilling deep enough to access clean water can be expensive, and you’ll need to store and purify the water once it gets to the surface.

On average, drilling a water well costs$3,500–$15,000, depending on several geological and technological factors. You may be able to dig a shallow well yourself, but it’s best to hire a professional contractor for a well that will provide water for an entire home. This guide outlines the well installation process and its costs.

Though $3,500 to $15,000 is a wide range, it’s hard to narrow it down without knowing the specifics of your property. The cost of your project depends on the following factors.

The deeper you need to dig, drill, or drive, the longer the job will take and the more labor it will require. Most residential wells need to be at least 50 feet deep and have an average depth of 300 feet, but how far you need to drill to hit water depends on geographic factors. Accessing state and local geological surveys and learning about existing wells in your area will give you a better idea of the depth you’ll need. The table below includes price ranges for various depths.

Shallow, residential water wells are the least expensive to dig or drill. Sand point wells, which are shallow and can be driven by hand or machine, are similarly inexpensive but don’t usually provide a home’s entire water needs. Geothermal wells are relatively inexpensive on their own, but installing one costs tens of thousands of dollars.

Artesian wells that drill into an aquifer are more costly to drill but less expensive to run. Irrigation wells are the most expensive because they handle the highest volume of water, though residential irrigation is much less pricey than commercial irrigation.

Digging is the least expensive way to create a well, but it’s limited to about 100 feet in depth. Digging can also be thwarted by highly compacted or rocky soil. You can create a shallow well of up to 50 feet by driving a small-diameter pipe into the ground and removing the soil from inside. However, most residential-scale well projects require a drill to excavate.

Modern well systems consist of much more than a hole in the ground and a bucket on a rope. Here are some mechanical components that go into a working water well.

Well-casing pipe supports and protects the well’s walls, so it needs to be sturdy. This pipe is typically made from polyvinyl chloride (PVC), the most affordable option ($6–$10 per linear foot). Galvanized or stainless steel casing is also available for a premium ($30–$130 per foot). Steel may be necessary for earthquake-prone areas, as it’s much less susceptible to cracking and breaking. Casing pipe costs $630–$2,400 depending on its length.

Most wells need electrical wiring to operate the pump and pressure switch. These components aren’t expensive ($50–$150), but a licensed electrician needs to install them, costing $150–$500.

Some people assume that well water is cleaner than municipal water, but municipal water goes through a strict treatment process that water from private wells doesn’t. If you’re using a well for drinking water or other residential applications, you’ll need a purification system to rid the water of contaminants before you can use it. Whole-home water treatment systems cost $500–$3,000, plus another $200–$400 for installation.

Once the water is brought to the surface and purified, it needs to be stored and pressurized so you can use it in your home. A 2-gallon water tank can cost as little as $100, but if you’re going to use well water for most of your needs, you’ll probably need a large pressure tank that costs between $1,400 and $2,400.

One of the most critical parts of the well system is thewater pump, which brings groundwater to the surface. A hand pump for a shallow well can cost as little as $150–$500, but most electronic pumps cost between $300 and $2,000, depending on how powerful they are. A shallow well can sometimes use an aboveground surface pump, but a deep well usually requires a powerful, more expensive submersible pump that sits below the water line and pushes the water up. Some artesian wells can get away without using a pump system since the groundwater is already under pressure and may be pushed to the surface naturally.

Your location determines your climate, water table depth, and type and condition of the bedrock. It will also affect labor costs. For example, Florida is a relatively inexpensive place to dig a well because it has a high water table and an average cost of living. The price is higher in desert states like California, Texas, and Arizona.

You’ll need to check with your state and local government about permits for any project that involves digging in the ground. Permits can cost anywhere from $5 to $500 depending on where you live, but a well drilling company can help you determine which ones you need.

The farther a well is located from your house, the more expensive materials and labor will be. You’ll require longer pipes and electric lines, usually at an additional cost of $50–$150 per linear foot.

Drilling an existing well deeper is less expensive than installing an entirely new well. Redrill fees are usually $300–$600, and a professional can typically complete the job in a day.

Dry and rocky soil conditions, as well as dense bedrock or heavy clay, can make well drilling more difficult and thus more expensive. You may require heavy or specialized machinery, which can add up to 150% of the base price to your total.

Before drinking water from your well, you’ll want to test its quality to make sure it’s safe. Do-it-yourself (DIY) water testing kitsare available for $50–$150, but if this is going to be your home’s primary water supply, you should hire a pro. This can cost between $100 and $500, but it’s well worth checking for the presence of viruses, bacteria, fungi, heavy metals, radon, pesticides, and other contaminants.

If you’re installing a well to live off the grid, you’ll also need a way of dealing with wastewater that doesn’t involve hooking up to the municipal water system. Many professional well drillers can install a well and septic system at the same time, which will save you money on labor. Aseptic tank installationcosts $2,000–$7,000 on its own or $5,000–$22,000 when combined with a well system.

One benefit of installing your own well is that you’ll no longer need to pay municipal water bills. You’ll only need to pay for the electricity to operate the pump (about $3–$4 per month), plus maintenance costs of $100–$250 per year. Compared to a monthly utility bill of $20–$40, you can save up to $500 a year.

It’s possible to install a well yourself, but it’s more complicated than digging or drilling a hole in the ground. Here’s what you can expect from the process, whether you do it yourself or hire a professional.

Well installation professionals have the tools and experience to drill plus install the casing, pump, well cap, and other hardware. They also know how to adjust the process if they encounter anything unexpected under the soil and can help you apply for permits. You’ll pay at least $1,500 in labor costs on top of the well equipment and may pay $10,000 or more for deep wells in poor soil conditions.

Digging or driving a shallow well in an area with a high water table is within the capability of dedicated DIYers. However, you must ensure you go deep enough to get to truly clean water beneath the contaminated runoff in the upper layers of soil. These shallow, driven wells also provide a limited water supply. You can rent a drill rig for $600–$800 per day for larger, deeper wells, but this will only give you the borehole; you’ll also have to install all the hardware yourself.

Wells require maintenance and occasionally require repair. Here are signs that you may need a professional well company to do an assessment. You may only have to pay a service fee if yourhome warranty covers well pumpsor well systems.

Drilled or dug wells can last as long as the walls hold up, but the equipment that runs them usually needs to be replaced every 20–30 years. The pump may fail, or the casing pipe may develop leaks. Replacements can cost up to $10,000 in materials and labor. You can extend your equipment’s lifespan by performing regular checks and maintenance or by hiring a well company to do these for you.

It’s also possible for a well to run dry. This isn’t likely or always permanent since aquifers and other sources may need time to fill back up. A well may fill with sediment over time, which will need to be pumped and cleaned out. In rare cases, you may need to dig deeper or find a different fracture to regain water flow.

It’s widely claimed that having a functional well will raise your property value, but there’s no data on how much of a return on investment (ROI) you can expect. The consensus is that a well that yields drinking water will add more value than an irrigation well, but a nonfunctional or contaminated well will be a liability. Wells are generally more valuable in rural areas or where people want to live off the grid.

Research your yard’s soil and the depth you’ll need to drill before purchasing a DIY well drilling kit. Just because the kit can go 100 feet into the ground doesn’t mean you’ll hit clean water.

It’s important to acknowledge that many DIY well drilling kits are sold within the “doomsday prepper” market. These kits are unlikely to be sufficient if you intend to use your well to fulfill most or all of your residential water needs. You’re better off at least consulting with local professionals who will know about your area’s geological features and water levels before starting the project. These professionals can help you make informed decisions about well installation.

A properly installed well can save you money on your utility bills and provide a private, unmetered water source. Make sure to budget for the drilling of the actual borehole and the equipment needed to pump and store the water, as well as water testing and purification if you intend to drink it. Your system should last for many years once it’s set up.

It can be worth it to install a well, depending on your needs and budget. Drilling a private well is a large investment, but if you live in a rural area or an area with poor water quality, it could increase your property value. Consult with local professionals before beginning to drill or dig.

The average well installation cost is $3,500–$15,000, including drilling and the casing, pump, and storage tank. Price can also depend on the depth of the borehole, ranging between $25 and $65 per foot.

The cost to hook a well up to a home’s plumbing system depends on the machinery used to pump and carry the water. Piping and electrical lines cost $50–$150 per foot, a purification system costs $300–$5,000, and a pressurized storage tank costs $1,400–$2,400.

The time it takes to install a well depends on its depth and the conditions of the soil and bedrock, but drilling can usually be completed in a day or two. Installing the pump system takes another day. After that, it depends on how long and extensive the pipes and electrical system need to be. The whole process should take about a week.

With the rising cost of water bills and the concern around local drinking water treatment, it’s unsurprising if you’re considering installing a private well on your property.

There’s no denying that installing a complete well water system can help you save money in the long run. But what’s the upfront cost of a private well?

In this guide, we’ve shared everything you need to know about the average well drilling cost, including the cost of different well types, and the factors affecting the price to drill a well.

Well casing is essential in supporting the walls of the well and preventing debris and dirt from getting into the water. The cost of 25 feet of casing for an average well is$250 to $2,500, depending on the conditions of the soil.

A well storage tank, water tank, or pressure tank, stores well water in a pressured environment before delivering it around your home. A pressure tank provides you with an instant supply of water and reduces how often the pump switches on and off.

The average well water storage tank cost is$100 to $700. The cost of a well storage tank largely depends on the size of the tank. While a small 2-gallon tank may cost less than $100, a large 44-gallon tank may cost $800 or more.

The average cost per foot to drill a well, for the drilling only, is $12 to $25. This cost depends on the type of well and the prices offered in your location. The overall cost per foot, including the cost of the well system itself, is $25 to $65.

The cost to drill a residential well is $25 to $65 per foot. This equals a total cost of $3,500-$15,000, depending on the size, depth, and location of the well. This cost covers every expense, including drilling, and all the well components, including casing, a pump, initial water quality testing, a permit, and wiring.

Shallow wells cost $15 to $60 per foot, or between $1,800 and 3,000 for the complete well. Shallow wells are usually between 3 and 10 feet in diameter and 25 to 50 feet deep.

While shallow wells are cheaper than deep wells, they become easily contaminated and produce a varying yield, so they’re not the most sustainable investment.

The cost to drill a geothermal well is $10 to $40 per foot. Ageothermal wellis typically 100 to 500 feet deep and between 4 and 8 inches wide. The overall cost for a geothermal well, including the drilling and the components, is $3,500 to $5,000.

The cost of a vertical geothermal heat pump is $20,000 to $35,000 on average. This cost includes the material cost, the cost of transporting the equipment to the drilling site, and the cost to drill the well.

Drilling a sand point well costs between $500 and $3,000 on average. Sand point wells are about 20 feet deep and 1 to 2 inches in diameter. These wells draw water from water-bearing sand, with hand pump and jet pump options.

If you hope to install your own well, a sand point well is the safest and easiest well that can be DIY installed. However, sand point wells don’t typically provide consistent water access or last long, and they only work with a shallow water table (average depth below 25 feet).

An irrigation or agricultural well costs between $25 and $50 per foot for just the drilling. A complete installation, including the components, is $85 to $110 per foot.

On average, a residential irrigation well costs $10,000 to $15,000 to dig. A commercial agricultural well with a high yield costs between $50,000 and $75,000 to drill, including the water pump.

Artesian wells cost between $30 and $85 per foot. The total cost for this type of well is $5,000 to $15,000, including drilling to an average depth of 150-450 feet to find an aquifer, and the cost of casing.

Artesian wells are cheaper and lower maintenance to operate than other types of wells. Aquifers are highly pressurized environments, so water flows naturally into the well system without the need for electricity or a water pump.

The size, depth, and type of septic tank, and the septic system’s absorption field, affect the cost of septic system drilling. The soil absorption system and the underground tank are two of the most significant costs of well and septic system installation.

Redrilling an existing well costs between $35 and $85 per foot. Overall, the cost of redrilling a well is $3,000 to $6,000 – very similar to the cost of drilling a new well.

If your well is more than 200 feet deep, speak to your local well contractor about hydrofracturing, which involves using highly pressurized water to break up rock at the bottom of the well, creating new pathways for water to enter the aquifer. This can be used to increase water flow and costs $1,250 to $3,000 on average.

The depth of the well is one of the most significant factors affecting the cost of drilling. The deeper the well, the more work that is required to drill the well, the more materials that are needed for the well, and the more structural support is required to keep the well stable.

The average well is between 100 and 500 feet deep. Shallow water wells are only about 25 to 50 feet deep, which is why they’re much cheaper to drill than deep wells. However, shallow wells are known to dry out during droughts and are more prone to E.coli or coliform contamination, while deep wells are far less likely to become contaminated and provide a consistent yield of water, regardless of the season.

So, while the cost of a deep well is more expensive than the cost of shallow water wells, deep wells tend to be worth the extra investment due to their safety and water yield benefits.

Different states have different well drilling costs. These are determined by the state’s water levels and soil conditions, and the cost of living in the state.

Idaho, Arkansas, Mississippi, New Mexico, and Nebraska have some of the cheapest average costs for drilling a well, with prices starting at $25 or $26 per foot. The most expensive states to drill a well are Alaska, Hawaii, Massachusetts, New Jersey, and New York, with prices starting at $30 or more per foot.

Your local geology affects your ground conditions, and the difficulty of drilling a well due to these conditions. The more complex and time-consuming the drilling process, the more expensive the cost of drilling.

Different regions have different ground materials. Clay, sand, rock, and soil all require different drilling processes and have different difficulty levels.

Drilling through clay, sand, or soft soil is easiest, and will cost slightly less than average or bang-on the average drilling cost. Drilling through rocky soil will cost slightly higherthan the average drilling cost, and drilling through solid rock is the most expensive.

The closer your well is installed to your property, the fewer materials will be needed to transport water from the well to your property’s plumbing system. The average cost of a main water line is $30-$60 per foot. If you need to install a solar-powered pump, this costs around $2,000, and a power line costs about $1,500.

To legally install a well deeper than 2 feet on your property, you’ll most likely need a well permit. The cost of a well permit depends on your region. In general, expect to pay $300 to $700 for a permit.

Well permits are essential to ensure that your well has been constructed in compliance with your local regulations. You should secure a permit before you begin drilling your well. Your local authority should provide information on how to apply for a well permit, and how much a permit costs in your area.

Testing your well water is one of the essential annual maintenance costs in owning a well. As a private well owner, you’re responsible for ensuring that your water is safe to drink. To do this, you need to test your water to find out what it contains, then treat your water as necessary (more on the cost of water treatment later).

The National Ground Water Association and Environmental Protection Agency recommend that you test your well water at least once a year for total dissolved solids, nitrates, total coliform bacteria, andpH levels. You can test your water in one of two ways:

With a DIY water test, costing $20-$100 per year.DIY tests are quick and convenient, but we don’t recommend them for well water as they’re not thorough or 100% accurate.

With a laboratory water test, costing $150-$500 per year.Laboratory water testing is more expensive than DIY testing, but provides much more detailed reports about what your water contains.

To ensure your well water system is in good working order, you should get your well inspected once a year by a local contractor. Your contractor will inspect the well for cleanliness and mechanical problems, and advise you on any steps you may need to take following the inspection.

The cost of a well inspection is $300 to $500. This depends on the contractor’s rates and the services offered during the inspection (such as water testing or cleaning).

The typical price range for repairing a well is $927 – $2,503. The exact cost of well maintenance or repairs depends on which component you need to work on. A well pump system is one of the most expensive items to repair or replace.

If testing indicates that your well water system is contaminated with metals, chemicals, microorganisms, or other impurities, you’ll need to factor in the cost of water treatment.

The ongoing cost of owning a well water treatment system is $0-$150 per year, depending on the type of system and the maintenance required. Systems likeUV purifiers and oxidation systems require minimal annual maintenance, while multi-stage cartridge filtration systems mayrequire three or more filter changes per year.

The initial investment in a well system is high. However, once you’ve paid for the new system installation, you’ll only need to pay for yearly maintenance and water testing, which, for a new, properly constructed well, should cost less than $350. You’ll also need to pay the electricity cost of operating the electric pump, which should be low if you have a decent water tank.

In comparison, a household that uses around 12,000 gallons of water per month can expect to pay about $850 per year for their water bill. So, a private well can help you to save at least $500 per year.

Keep in mind that old wells and septic systems incur expensive maintenance, repair, and replacement costs. Every 20 or 30 years, you’ll need to replace the water tank, pump, screen, and casing, which will set you back around $10,000.

Installing a well yourself has the potential to be cheaper than hiring a professional. However, the cost estimates for DIY installation of a deep well aren’t too different from the costs of a professional installation.

As well as paying $100-$150 per foot for pipes, tubing, and casing, you’ll also need to pay between $600 and $800 per day to rent a drill rig. Plus, you’ll need to pay for surveys, permits, and everything else required to legally drill your well.

Hiring a well drilling company might be the more expensive option, but it guarantees that your well will be properly installed, safe to use, and built to last. This will help you to save money on long-term expenses.

The benefits of instilling a complete water well system at your property are obvious: you’ll have access to a constant water supply without being reliant on a municipal water system. Once you’ve invested in a well, you’ll only have to spend money on annual testing and necessary well maintenance – no more monthly municipal water bill.

However, despite their benefits, wells aren’t for everyone.The upfront cost to drill a well is simply too high for some people. Many homeowners choose to drill a well only after paying off their other, more important, investments, such as mortgages and student loans. Make sure you’re in the financial position to pay up to $10,000 – or perhaps even more – on well drilling before you agree to anything.

If you’re interested in drilling a well, contact several well drilling companies in your area. Ask one or two contractors to survey your potential drill site and draw up a quote for the complete drilling job (including the cost of the pressure tank, the pump, and the casing). You’re not obliged to commit to a service after receiving a quote, so this is a good way to find out the cost to drill a well on your property without the pressure of following through.

You should budget at least $5,300 to $9,200 for drilling a deep well, or $1,800 to $3,000 to drill a shallow well. Some wells cost up to $15,000. Factors affecting the cost of a well include your geographical location, the well’s depth, the well’s distance to your property, and the cost of permits.

Tallying up all the included costs, the minimum cost to drill a well is $1,750. This cost assumes that the well is a shallow well. Deep well drilling costs at least $5,000.

The cost of hooking up a well is about$5,300 to $9,200. The cost may be higher than this, depending on your region and your requirements. Speak to a local contractor to get an accurate estimation of the cost to drill a well in your area.

Yes, you can drill your own shallow well. However, you shouldn’t attempt to drill a deep well for drinking water without professional support. There are tens of safety hazards involved in digging a deep hole, and a poorly constructed well could crack or collapse. For safety and peace of mind, leave deep well drilling to the experts.

Drilling a well costs a lot of money because you’re paying for expensive well components, several days of labor, and all the processes and parts required to make the well system operational.

There isn’t a set labor cost for drilling a well. Contractors may charge an hourly fee of $50-$150 and add this separately to the list of expenses, or the labor cost may be factored into the overall cost.

If you are supplying pump supplies, you can find the most favorable prices at Alibaba.com. Whether you will be working with piston type or diaphragm type systems, reciprocating or centrifugal, Alibaba.com has everything you need. You can also shop for different sizes drilling mud pump price wholesale for your metering applications. If you operate a construction site, then you could need to find some concrete pump solutions that you can find at affordable rates at Alibaba.com. Visit the platform and browse through the collection of submersible and inline pump system, among other replaceable models.

A drilling mud pump price comes in different makes and sizes, and you buy the tool depending on the application. The pump used by a filling station is not the one you use to fill up your tanks. There are high flow rate low pressure systems used to transfer fluids axially. On the other hand, you can go with radial ones dealing with a low flow rate and high-pressure fluid. The mixed flow pump variety combines radial and axial transfer mechanisms and works with medium flow and pressure fluids. Depending on what it will be pumping, you can then choose the drilling mud pump price of choice from the collection at Alibaba.com.

Alibaba.com has been an excellent wholesale supplier of drilling mud pump price for years. The supply consists of a vast number of brands to choose from, comes in different sizes, operations, and power sources. You can get a pump for residential and large commercial applications from the collection. Whether you want a water pump for your home, or run a repair and maintenance business, and need a supply of dr drill mud pump prices, you can find the product you want from the vast collection at Alibaba.com.ther it is for refrigeration, air conditioning, transfer, or a simple car wash business, anything you want, Alibaba.com has it.

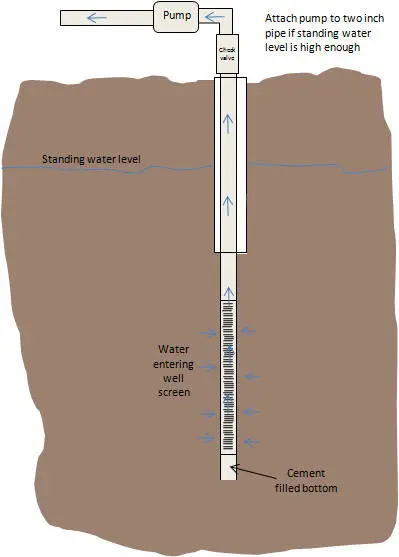

You can drill your own shallow water well using PVC and household water hoses. It is a cheap and effective way to dig your own shallow water well. Water well drilling isn’t just for the pros with huge commercial drilling rigs. Digging a water well yourself is both interesting and fun.

The water well drilling methods described here work well in digging/drilling through dirt, and clay, including really hard clay. They will not work if you need to drill through rock but, if the area you live in is flat or relatively flat, it is definitely worth a try. Many folks think they have to dig or drill their well into an aquifer. For irrigation and lawn watering, reaching an aquifer isn’t necessary. You only have to drill under the standing water level. It is very likely that you can drill your own well. Many successful wells have been drilled using this well drilling method. It is cheap. You can expect the “drilling” portion of the project to cost about $200.

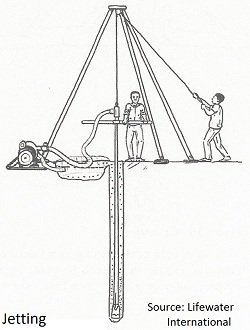

In these pages the “do it yourself water well drilling” technique is referred to as well drilling, but many call this technique “washing” or “jetting” a well. It is somewhat similar to the rotary bit method which most real water well drillers use for water bore drilling.

The DIY technique involves water pumped down the center of a PVC schedule 40 pipe used as both a drill stem and a drill bit. At the bottom end of the PVC pipe a “drill bit” is fashioned by cutting teeth into the end of the PVC pipe. The pipe is rotated back and forth as the PVC pipe is slowly worked into the ground while the cuttings are brought to the surface by the upward flow of water in the annular space around the pipe. If you want to dig your own well, try this technique.

Installing a well and a pump can save a lot of money, especially if you are now paying the local utility for irrigation water. You have probably noticed that just watering the lawn can get expensive. You can spend less money watering the lawn. Actually, you can spend almost no money watering the lawn. It is great for gardeners, too.

If you are a first time visitor to the site you will probably want to start out with either the “Background” or the “Basic Well Drilling Steps” pages. The bulk of the site is dedicated to drilling water wells using just two hoses for drilling fluid. Inexpensive PVC is used for the drill pipe, the drill bit, and the well screen. This DIY water well drilling technique is very cheap and many successful shallow wells have been installed using this technique.

When drilling a well by hand, it can be very helpful to at least be familiar with the techniques used by real well drillers – the kind with big powerful trucks and huge water tanks. What we do is extremely similar, almost identical. We can’t dig holes as wide or as deep but it is the same process. A local well drilling company was kind enough to let me video their process. Check it out at “Real Well Drilling.”

There are several enhancements you can make to the basic DIY well drilling technique. To make the technique even more effective you can use the techniques described on the pages, “Drilling Deeper with BENTONITE” and “Drill 10 Feet Deeper.” Additionally, converting to a metal drill bit will make your drilling more productive. These are all techniques that were sent in by users of the site and discovered as they drilled their wells.

A gravel pack can increase a well’s production so there is a section on them. I don’t recommend you include a gravel pack on your first well but after you get the hang of the technique this is something you will probably want to check out the pages on gravel packs.

Don’t go shopping for a pump without reading this page: Which Pump? You want a shallow well pump, also known as a suction pump. Pool pumps and other types of transfer pumps will not work.

In the “Videos” section, you will find videos that show techniques used world wide. Some of these techniques, like the Baptist Method, require very little drilling fluid and have been used for centuries.

We’ve been fortunate enough to receive some input from Bob Tabor, a real well driller who has been drilling wells all of his life. Please be sure and check out the page – “Advice from a REAL Well Driller.”

Bill Granade in Tampa, Florida has developed a very similar DIY water well drilling technique. He has been wildly successful. Bill has helped his neighbors drill a bunch of wells his protocols may be useful to you. Look under “Another Home Driller.”

Several users of this site have been kind enough to send pictures and info about wells that they have drilled. Check out “Success Stories” in the menu. For example, one of our recent success stories, Steve in South Jersey is interesting. Steve needed a way to water his Christmas tree farm and he successfully drilled his own well. Very impressive effort! We even got a wonderful email from Greg in Australia about his successful well.

For drillers interested in moving up to the next level: be sure and check out the page on Mud Pump Drilling. It is absolutely the way to go if you can buy or borrow a mud pump (sometimes called a trash pump). It costs more than the two hose method but is still a lot less expensive than hiring a driller.

There is a section for Questions and Answers where I have posted the most common questions I receive. I hope it helps you. There are also sections on Source of Supply, Well Drilling Manuals as well as Well Drilling Links.

Commercially drilled water wells tend to be very expensive. This DIY well drilling technique is very cheap. It will almost definitely work if you live near the coast and will likely work if you live in a flat inland area.It is great for saving money on watering your lawn and irrigating a garden.

As I mentioned in the video, the most interesting things I have experienced in posting this website are the enhancements and improvements that YOU, the viewers and users of this site have submitted. I figured out a few improvements to the Brady Well Kit early on and I managed to drill a functional well after several tries and that is why I posted the site. And then – users started writing me and showing me things they had discovered! At this point, I can safely say that most of the techniques presented here are not mine. They are yours! I hope they help you. I hope that if you discover an improvement or an enhancement that you will send it to me so I can post it for others to use.

Below is a video submitted by one of the users of this site. Please take a look at the DIY water well drilled by Travis of Mobile, Alabama. Travis used a 10 foot long 1.25 inch well screen. Congratulations, Travis!

This is our new Terragrinder deluxe ready-to-drill kit! It contains everything you need to buy from us to drill your well, and it is available now for only a fraction of the cost of other well drilling kits on the market!

What does it take to maintain a successful business? If you said profit, you hit the critical component to any good business. However, if you said the right equipment and team, your thought process drills deeper. I bet the rest of you were shouting, “Customers is what it takes!”

Maintaining a successful business was a top discussion point at the recent Mountain States, Maryland-Delaware, and Virginia groundwater conferences I attended as a presenter. To get a well-rounded perspective on this important topic, I interviewed a driller within our community and a custom home-builder connected to our community.

First up, Charles “Buddy” Sebastian of Sebastian and Sons Well Drilling based in Michigan is a long-time industry friend and president of the Michigan Ground Water Association. Sebastian has presented talks on job costs, company sustainability and the future of drilling companies at the MGWA’s annual conference. He also just presented at the Montana Water Well Drillers Association Convention & Trade Show.

A. The first talk I did on knowing your cost at MGWA, I had a question from the audience that said: “You have your business figured out. What"s your exit plan?” I said, the day you start your business is the day you start planning to sell your business. What I mean is, to be able to sell your business you have to be able to set your market. You can either be the market setter or market followers. You have to be able to set the market that your business is solvent. To be solvent, you have to have enough money in your profit margin to maintain, repair and replace equipment. Then, beyond sustaining the business, you can’t just work for beer and pizza. So you have to have enough profit in there to pay the team and yourself.

A. Well, we have to set the going rate for drilling in our area to have enough profit dollars to complete the job, maintain the equipment, pay the team and invest in the future.

A. First of all, we have to stop pricing our product according to our competitor. We fix that by knowing our cost per hour and cost per day for equipment and project. That thinking that my competitor is drilling for $18, so I need to drill for $17 needs to go away. We need to know our costs on the first job and be profitable because it isn’t going to get any better if you don’t.

A. It is based on how many wells you do a year. I figure today’s drilling equipment’s life as 10 to 15 years, and yes, some older conventional rigs had a longer lifecycle. You know I did a cost analysis of some of my older table-drive rigs to replace belts, bearings, bushing and drivelines. What I saw was [that having] bushing and bearing that were relatively cheap to repair was no longer the case. Replacement parts were not built as good as the originals; importing cost had increased and, overall, these parts were becoming obsolete due to American manufacturers no longer making them. Conventional rigs are not as easy or cheap to repair as they were. You have to take into consideration downtime versus complete replacement.

That’s the per-hour cost to own that rig. That’s not interest, maintenance, repairs, tires, mud pumps or wearables. It’s just the cost to own the rig. Next, you have to take into account everything to operate and maintain the rig, including the labor to repair, update and replace. A good number to start with for a new $800,000.00 rig is about $75,000 a year to own and maintain it. The best advice I can give to a new rig owner is to save $25 an hour for every hour of rig operation to replace that rig.

Q. How does the industry value water at a cost that makes the drilling business sustainable? How do we change the stigma that a water well must cost X but even interior amenities such as cupboards can cost so much more?

A. First, we, as an industry, must start teaching the end-user the same statement. Water is a necessity for life. We, as an industry, have more invested in equipment overhead than any other construction trade. I have quickly over a million and a half dollars invested in providing water; often the homes we drill wells for do not have that in the building materials and builder labor. We need to sell that point to our customers that we are invested in them, and they need to invest in us to be sustainable to continue to provide water.

Next, I turned to Cameron Fox, owner of Fox Custom Builders in Kalamazoo, Michigan. Fox has built custom homes in West Michigan, all requiring private water wells. He helped me visualize how customers and homebuilders view new water wells.

A. Homeowners view their water wells as a non-negotiable necessity. Our customer usually addresses this part of the contract to the extent of “how will you make sure I get exceptional water pressure.”

A. Pricing is consistent throughout our area, so pricing is not outrageous. The drilling companies’ professionalism and expertise exclusively drive my priority when choosing an installer.

A. It is all about location. Location of the well may seem like a no brainer, but choosing a site, particularly on nonconforming lots or lake homes, can be somewhat problematic. Distance from property lines, septic systems and sewage ejection pumps can often become a balancing act. A drilling company willing to work with the footprint I have is invaluable.

A. I have had very positive experiences with the two drilling companies I use. Both are excellent, and overall I had similar experiences. The estimates and proposals aligned, and they both researched well logs on adjacent properties to present reasonable estimated well depths. One thing that makes me use one company over the other is when they go the extra mile to educate my customers on the process and me. I have a backup drilling company just because of schedules.

A. Every homeowner has a different pricing tolerance based on what is important to them. When building a vacation home, the money will be spent to upgrade materials requiring less maintenance. Homeowners with large families are more focused on added square footage than premium kitchen cabinets or heated floors. Ultimately, each homeowner is unique, and their money is allocated toward their “must-have” items.

A. We build custom homes that meet each client’s specific wants and needs. Not only do we accomplish this but at the same time we build quality homes. Energy-efficient and structurally sound homes are the starting point for our homeowners. These are our core values and a starting point from where we build to create a functional and architecturally pleasing home that exceeds our homeowners’ expectations. Building a home is like entering into a serious relationship with someone you just met. You are going to spend hundreds of hours with them, answer multiple calls a day and then respond to their weekend emails. You have to get along, or you’ll both walk away from the process drained and upset. I have found the best way to get along is to require perfection from my employees and my subs. That’s it. I do not allow mediocrity; my customers know it, and it establishes a basis for trust.

We need customers and builders, and they 100% require the drilling industry to provide water. We have to establish our message of value to our customers. The problem cannot be solved with one company or region that cannot solve our image; it will take the entire community discussing how we make the change together. In the end, we need the same thing our builder requires, to be able to recruit and pay good men and women to progress our industry, buy the right technology to be successful, and provide the consumer with a quality product that they value.

When choosing a size and type of mud pump for your drilling project, there are several factors to consider. These would include not only cost and size of pump that best fits your drilling rig, but also the diameter, depth and hole conditions you are drilling through. I know that this sounds like a lot to consider, but if you are set up the right way before the job starts, you will thank me later.

Recommended practice is to maintain a minimum of 100 to 150 feet per minute of uphole velocity for drill cuttings. Larger diameter wells for irrigation, agriculture or municipalities may violate this rule, because it may not be economically feasible to pump this much mud for the job. Uphole velocity is determined by the flow rate of the mud system, diameter of the borehole and the diameter of the drill pipe. There are many tools, including handbooks, rule of thumb, slide rule calculators and now apps on your handheld device, to calculate velocity. It is always good to remember the time it takes to get the cuttings off the bottom of the well. If you are drilling at 200 feet, then a 100-foot-per-minute velocity means that it would take two minutes to get the cuttings out of the hole. This is always a good reminder of what you are drilling through and how long ago it was that you drilled it. Ground conditions and rock formations are ever changing as you go deeper. Wouldn’t it be nice if they all remained the same?

Centrifugal-style mud pumps are very popular in our industry due to their size and weight, as well as flow rate capacity for an affordable price. There are many models and brands out there, and most of them are very good value. How does a centrifugal mud pump work? The rotation of the impeller accelerates the fluid into the volute or diffuser chamber. The added energy from the acceleration increases the velocity and pressure of the fluid. These pumps are known to be very inefficient. This means that it takes more energy to increase the flow and pressure of the fluid when compared to a piston-style pump. However, you have a significant advantage in flow rates from a centrifugal pump versus a piston pump. If you are drilling deeper wells with heavier cuttings, you will be forced at some point to use a piston-style mud pump. They have much higher efficiencies in transferring the input energy into flow and pressure, therefore resulting in much higher pressure capabilities.

Piston-style mud pumps utilize a piston or plunger that travels back and forth in a chamber known as a cylinder. These pumps are also called “positive displacement” pumps because they literally push the fluid forward. This fluid builds up pressure and forces a spring-loaded valve to open and allow the fluid to escape into the discharge piping of the pump and then down the borehole. Since the expansion process is much smaller (almost insignificant) compared to a centrifugal pump, there is much lower energy loss. Plunger-style pumps can develop upwards of 15,000 psi for well treatments and hydraulic fracturing. Centrifugal pumps, in comparison, usually operate below 300 psi. If you are comparing most drilling pumps, centrifugal pumps operate from 60 to 125 psi and piston pumps operate around 150 to 300 psi. There are many exceptions and special applications for drilling, but these numbers should cover 80 percent of all equipment operating out there.

The restriction of putting a piston-style mud pump onto drilling rigs has always been the physical size and weight to provide adequate flow and pressure to your drilling fluid. Because of this, the industry needed a new solution to this age-old issue.

As the senior design engineer for Ingersoll-Rand’s Deephole Drilling Business Unit, I had the distinct pleasure of working with him and incorporating his Centerline Mud Pump into our drilling rig platforms.

In the late ’90s — and perhaps even earlier — Ingersoll-Rand had tried several times to develop a hydraulic-driven mud pump that would last an acceptable life- and duty-cycle for a well drilling contractor. With all of our resources and design wisdom, we were unable to solve this problem. Not only did Miller provide a solution, thus saving the size and weight of a typical gear-driven mud pump, he also provided a new offering — a mono-cylinder mud pump. This double-acting piston pump provided as much mud flow and pressure as a standard 5 X 6 duplex pump with incredible size and weight savings.

The true innovation was providing the well driller a solution for their mud pump requirements that was the right size and weight to integrate into both existing and new drilling rigs. Regardless of drill rig manufacturer and hydraulic system design, Centerline has provided a mud pump integration on hundreds of customer’s drilling rigs. Both mono-cylinder and duplex-cylinder pumps can fit nicely on the deck, across the frame or even be configured for under-deck mounting. This would not be possible with conventional mud pump designs.

Centerline stuck with their original design through all of the typical trials and tribulations that come with a new product integration. Over the course of the first several years, Miller found out that even the best of the highest quality hydraulic cylinders, valves and seals were not truly what they were represented to be. He then set off on an endeavor to bring everything in-house and began manufacturing all of his own components, including hydraulic valves. This gave him complete control over the quality of components that go into the finished product.

The second generation design for the Centerline Mud Pump is expected later this year, and I believe it will be a true game changer for this industry. It also will open up the application to many other industries that require a heavier-duty cycle for a piston pump application.

more at http://www.drillyourownwell.com This is an example of a Mud Pump Water Well Drilling Setup utilizing a Portable Mud pit. This particular well was ...

The drilling rig is built on the basis of a diesel engine. The hydraulic circuit is divided into three streams, each with its own hydraulic pump. When using multiple drives at the same time and increasing the load, the operating parameters are retained.

The drilling rig has a compact, versatile design. It can be installed on different types of chassis: trailer, pickup, truck, tracked chassis, etc. At the same time, a flow switch is provided in the hydraulic system of the unit to control the movement of the chassis.

Pump for supplying drilling fluid to the bottom of the well. The piston is driven by a hydraulic cylinder, which is controlled by an electrically controlled hydraulic valve. The mud pump provides a pressure of 15 atm and pumps 400 l / min.

The trailer wheels are rotated by two hydraulic motors. A hydraulic cylinder is used to hold down the clutches. The friction drive allows for maneuvers and turns for precise positioning of the drilling rig.

Bedrock wells are drilled below the topsoil and groundwater into bedrock, tapping the cracks in the rock that carry water deep underground. The average bedrock well in New Hampshire is between 100-feet and 500-feet deep, but drilling depth can go up to 1,000 feet.

To access the water, a pipe is installed into the bedrock, called a casing, and a pump to carry the water to the surface and into the home. The casing protects the well from possible contaminants at or near the level of ground water. Learn more about well drilling.

8613371530291

8613371530291