duplex mud pump manufacturers pricelist

Welcome to Pickett Oilfield’s mud pumps web page. Our company has been in the oil & gas drilling equipment industry for over 38 years, supplying new and used mud pumps and mud pump parts to customers in practically every producing region in the world. We are here to serve all your drilling equipment needs – if you don’t see it on this site, just give us a call or email. We can get it, if you need it!

Pickett Oilfield, LLC offers prospective buyers and extensive selection of quality new and used oil & gas drilling equipment, including mud pumps and parts to choose from at competitive prices. Browse our inventory of mud pumps and mud pump parts for sale at competitive rates.For more information or to request a quote, please Contact Us at 936-336-5154 or email to Sales@PickettOilfield.com.

A mud pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi (52,000 kPa)) down the drill string and back up the annulus. A duplex mud pump is an important part of the equipment used for oil well drilling.

Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers. The advantages that Duplex mud pumps have over convention triplex pumps is a lower mud noise which assists with better Measurement while drilling and Logging while drilling decoding.

Use duplex mud pumps to make sure that the circulation of the mud being drilled or the supply of liquid reaches the bottom of the well from the mud cleaning system. Despite being older technology than the triplex mud pump, the duplex mud pumps can use either electricity or diesel, and maintenance is easy due to their binocular floating seals and safety valves.

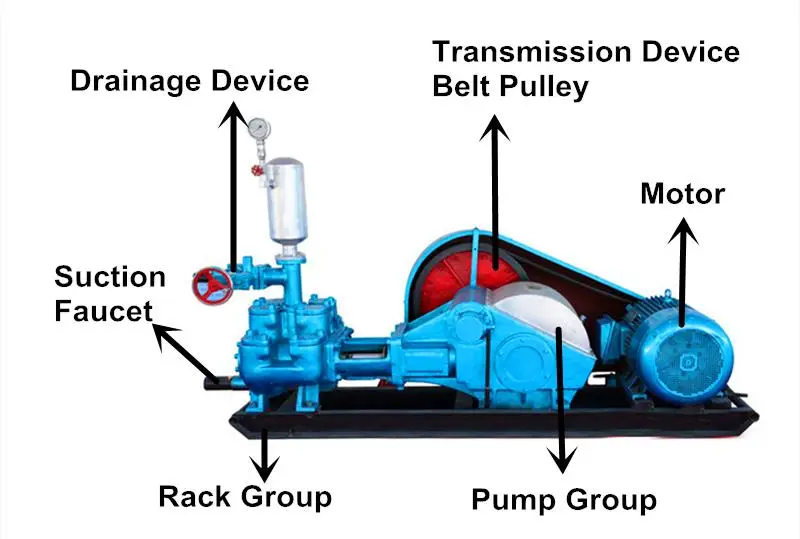

A mud pump is composed of many parts including mud pump liner, mud pump piston, modules, hydraulic seat pullers, and other parts. Parts of a mud pump:housing itself

Duplex pumps are used to provide a secondary means of fuel transfer in the event of a failure of the primary pump. Each pump in a duplex set is sized to meet the full flow requirements of the system. Pump controllers can be set for any of the following common operating modes:Lead / Lag (Primary / Secondary): The lead (primary) pump is selected by the user and the lag (secondary pump operates when a failure of the primary pump is detected.

Alternating: Operates per Lead / Lag (Primary / Secondary) except that the operating pump and lead / lag status alternate on consecutive starts. A variation is to alternate the pumps based on the operating time (hour meter) of the lead pump.

If you are supplying pump supplies, you can find the most favorable prices at Alibaba.com. Whether you will be working with piston type or diaphragm type systems, reciprocating or centrifugal, Alibaba.com has everything you need. You can also shop for different sizes drilling mud pump price wholesale for your metering applications. If you operate a construction site, then you could need to find some concrete pump solutions that you can find at affordable rates at Alibaba.com. Visit the platform and browse through the collection of submersible and inline pump system, among other replaceable models.

A drilling mud pump price comes in different makes and sizes, and you buy the tool depending on the application. The pump used by a filling station is not the one you use to fill up your tanks. There are high flow rate low pressure systems used to transfer fluids axially. On the other hand, you can go with radial ones dealing with a low flow rate and high-pressure fluid. The mixed flow pump variety combines radial and axial transfer mechanisms and works with medium flow and pressure fluids. Depending on what it will be pumping, you can then choose the drilling mud pump price of choice from the collection at Alibaba.com.

Alibaba.com has been an excellent wholesale supplier of drilling mud pump price for years. The supply consists of a vast number of brands to choose from, comes in different sizes, operations, and power sources. You can get a pump for residential and large commercial applications from the collection. Whether you want a water pump for your home, or run a repair and maintenance business, and need a supply of dr drill mud pump prices, you can find the product you want from the vast collection at Alibaba.com.ther it is for refrigeration, air conditioning, transfer, or a simple car wash business, anything you want, Alibaba.com has it.

triplex mud pumps and triplex mud pump parts meet the industry standards established by the American Petroleum Institute (API). As a global supplier of quality oilfield equipment to the oil and gas industry, we ship our products around the world.

Besides triplex mud pumps and triplex mud pump parts, we supply drilling rigs, workover rigs, top drives, drilling equipment, blowout preventers, BOP control systems, choke and kill manifolds, well service pumps for well cementing and hydraulic fracturing, wellhead equipment, casing heads, tubing heads, X-mas trees, FC type gate valves, etc. Please visit our company website

We supply unitized mud pump packages driven by DC or AC electric motors or diesel engines for electric and mechanical drilling rigs. The client can select DC or AC motors and diesel engine brands such as Caterpillar, Detroit, Cummins or others. Our unitized mud pump packages including everything on the skid and usually they are ready to work at delivery.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

We “Flow Control Engineers are engaged in trading a high-quality assortment of Industrial Pumps, Automotive Oil, Woltmann Meter, Gear Boxes, Electromagnetic Flow Meters and Industrial Valves. We are a Sole Proprietorship company that is established in the year 2016 at Ahmedabad (Gujarat, India) and are connected with theread more... Brochure

Compact duplex system designed for residential and light commercial sewage application. Perfect for basement additions and remodeling projects. Brochure

GPS series, duplex, double acting, piston type, high pressure, reciprocating slush pumps are widely used for oil line, mining, industrial, geophysical survey, water well & core drilling applications, for handling drilling mud, cement slurry, sewerage and general water service. Typical applications include oil line pumping,read more...

We are one of the prominent manufacturer of Duplex Heating & Pumping Units. We offer Duplex Heating & Pumping Units, which are made of qualitative components, pre-engineered and are properly packed. These are custom design to meet the requirement of our customers.

We offer heat treatment solution for Pumping Unit Oil Circulated Duplex. Basically it is done in order to increase the hardness and withstand high temperature which is needed.

Backed by rich industry experience and market understanding, we are involved in offering a wide array of Duplex Pump Heating Unit to our valued patrons.

Fabricated using premium quality raw material, our technically advanced Duplex Hydraulic Operated Diaphragm Pump, work on a similar principle of simplex hydraulic operated pump. This pump is highly beneficial to be used in case of corrosive liquids being pumped where in the liquid is kept out of the pump body in the primaryread more...

Piston pumps can be used for low viscosity and medium-flow media (in the range of 80 m³/h). Additionally, pumping solid particles is impossible with this type of equipment because the pump can ensure proper operation only if the seal between the cylinder and the piston is perfect.

For high-pressure uses, you can opt for a plunger pump, they differ from piston pumps in that the seal does not move with the piston, it is fixed and therefore able to withstand...

... heavy duty frac pump designed to operate at higher pressures for longer periods of time. Its compact design and 11” stroke results in less fatigue cycles and extended consumable life. With a legacy of ...

The HS is a horizontal triplex and quintuplex positive displacement reciprocating pump with very high efficiency and is offered in a wide range of hydraulic, mechanical, and material options.

Flojet Triplex Hi-Flow series pumps are designed for a wide range of applications and are constructed from a selection of materials suitable for handling a broad range of chemicals. ...

... cost-saving alternative to our diaphragm pump series: The LEWA plunger pump is a high-performance and versatile plunger pump for high-pressure applications in various industries.

Three-es manufactures pumping sets with various flow and pressure characteristics, plug&play and optimised for any washing system. Each pumping unit is assembled using only high quality components.

... plunger pumps for pressure testing, large three, four or five plunger pumps of various designs are available with specific advantages for specific applications.

... plunger pumps for pressure testing, large three, four or five plunger pumps of various designs are available with specific advantages for specific applications.

... plunger pumps for pressure testing, large three, four or five plunger pumps of various designs are available with specific advantages for specific applications.

Triplex pump with connecting rod system. Pistons in ceramic-coated steel. Double gasket sealing system. Pump head in pressed brass. Automatic safety valve with pressure shut-off at pump ...

Drilling pump is also called mud pump, which transport high pressure, high specific gravity, high sand concentration drilling fluid to bottom of hole. Drilling fluid is used to cool bit, wash out bottom ...

Pumps of the WANGEN KL-R Triplex series impress with their consistent dosing option, as an intermittent input is compensated by the buffer volume in the collecting container. No bridge building. The small ...

... consists of 5 pump sizes in triplex execution. The 31.40 model is manufactured also in quintuplex (model 31.40/Q) and septuplex (model 31.40/S) execution, where the same components of the triplex ...

PressureJet pumps are triplex (three plungers), positive displacement, industrial high pressure triplex plunger pumps. We offer both the triplex piston ...

The RDP range of Reciprocating Plunger Pumps by Ruhrpumpen comes in various sizes and in triplex and quintuplex formats. They are designed and manufactured in accordance to the lates edition of API 674 ...

JR500W pump is a horizontal single-acting reciprocating triplex plunger pump. Power end is self-lubricated by oil pump built onto the worm gear. Driven by worm pair, ...

... 1600 mud pump is a single-acting reciprocating triplex mud pump that delivers increased reliability, improved maintainability, and reduced weight and footprint.

The crank gear and connecting rods drive a rotary movement that is transferred by the motor transmission. The pressure is produced by the piston in the cylinder due to which the mud is sucked. Following the operation, the suction valve is closed when it moves to left. As the pressure increase in the pipeline, the valve is forced to open and mud is released.

In accordance with the operating liquid displacer type being incorporated, the pumps are subdivided into piston units and plunger-type units. The liquid discharge uniformity is independent of head. The pumping plants are used actively for the processes with the liquids containing solid inclusions in high amounts. Incorporating the self-suction function in piston unit, the liquid is sucked and discharged twice in mud pumps during the single shaft turn, making themselves the double-action pumps whereas, the mud plunger pumps are single-action pumps where the liquid is sucked and discharged only once during a shaft turn.

The single direct-action three-piston pumps prove to be better than other types of drilling. These pumps demonstrate much more uniformity in mud delivery, lesser weight, and easy mounting when compared with two-cylinder units.

Depending on the number of cylinders, the pumping plants are classified into the following categories, single-cylinder, double-cylinder, three-cylinder and multi-cylinder pumping plants. These cylinders may be vertical or horizontal. Comparatively, the multi-cylinder pumping plants will cost higher but don’t feature any significant advantages other than the single-cylinder.

When drilling, there might occur the necessity of mud pumping out- and flushing-out, so there are various types of pumps available for such operations which are required to be installed on drilling rigs.

Sucker-rod pumps: In sucker-rod pumps, the pumpjack is a driver. This pump is installed at the bottom of the well. The reciprocating movements of the pumpjack are converted into liquid flow by the pump, which results in delivery of liquid on the surface. These pumps move oil with various admixtures demonstrating high level of capacity.

Screw pumps:The screw pumps are small-sized and are generally used to deliver mud into a centrifuge. These pumps have the rotor and stator as the major structural components and the material used to manufacture these components suit right for smooth pumping of liquids with solid inclusions and high level of viscosity. The pumped liquid flows with stable pressure, shaft slowly and the flow is free of vortexes. These pumps comparatively require minimum service.

Well pumps: These pumps are submerged into wells. The ground part of the plant is a transformer substation equipped for start and adjustment. The pump has a vertical structure, with a fixed cylinder and single-action. A plunger and valve are moving parts. The pumped liquid may contain water content of up to 99% at the temperature as high as 130ºC.

All the mud pumps have few general advantages that include the capability to process liquids and substances with high level of viscosity and with admixtures. Also, enabling the smooth flow of substances, free of pulsations or suspensions mixing are counted under the major advantages of incorporating mud pumps. The pumps have high suction power and small weight, easing out the transportation and installation at remote oil fields. They are highly reliable and also affordable.

There are various types of mud pumps available for different purposes. So, it is important to incorporate the right one for your purpose. A Professional help in getting the right mud pump would be a good and safe option.

BW320 Triplex Piston Mud Pump has two cylinder diameters, four changeable gear speeds and eight flows can be chosen. It can support for the hydraulic impact drilling for the hole depth within 1000 meters, the screw drilling or turbine drilling for the hole depth within 1500 meters and geological core drilling for the hole depth of 2500 meters.

Black gold is truly the best description to sum up the value of oil. One of the most important contributors to change and industrialization, it drives the wheels of progress. ShalePumps is headquartered in Houston, the global oil capital. Headed by experts, it has a vision to support the industry with superior completion equipment. Frac operators, drilling contractors and well service companies source rely on ShalePumps for superior quality.

The key personnel of ShalePumps have a combined experience of more than a hundred years. This experience is reflected in the quality of our equipment. The fracking pumps, components and all services are much sought after for reliability and long life. This is because of the processes we follow. The design, materials, precision engineering and expertise contribute to an advanced assembly line.

After many years of thought and conscientious engineering, the team at ShalePumps is proud to add the Q5K™ 5000 HP Frac Pump to their list of many product offerings. Perfectly capable and suited for the next generation of hydraulic fracking market demands and technology. The Q5K is the only frac pump that has been designed and developed from the ground up to be capable of accepting true 5000 HP in a continuous duty frac application.

ShalePumps has consistently delivered high quality completion equipment to all stakeholders. The mission is to develop faster, rugged and efficient equipment to help the Oil and Exploration Industry. The vision is to continue leading the race with the best quality in completion equipment.

Our 20,000 sq.m production facility in China has designed and manufactured solely quality and specialty pumps for oil exploration and refinery sin1992

Danco Pump is your one-stop pump shop. We can provide complete service for all your pumping equipment. We have all power end and fluid end parts for all major high pressure reciprocating plunger and piston pumps. Wheatley Pumps; new, used and reconditioned pumps.

High pressure plunger and reciprocating piston pumps are used in many applications. Salt water injection and disposal, crude oil transfer and well servicing all use high pressure plunger pumps and piston pumps. Waste water treatment plants and sewer cleaning would require high pressure pumps as well to process the waste and water. Carwash, mud pumps and filter wash are other applications in which the pumps would be utilized.

We are the source for all your plunger and piston pump requirements. We have components for most major pump lines such as Gaso, Wheatley, Kerr, Gardener-Denver, Weatherford, National, Oilwell, Bethlehem , Tulsa Pump models.

Titan Oil Tools offers high quality mud pump expendables and mud pump replacement parts for the wide variety of mud pumps, centrifugal pumps found on the world market today. These quality pump parts offer great performance and our pricing will save you money.

We are your oilfield supplier of choice for mud pump spares and mud pump parts: mud pump piston liners and pistons. All mud pump parts can be sourced for fast delivery; Come to us for mud pump liners, pistons, piston rods and parts, pony rods, threaded rings and caps,and more. Try us for duplex and triples pump spares and duplex and triplex mud pump parts, and also valve parts like valve seats. gland nut, and mud pump gaskets.

Mud pump liners may come in chrome, alumina ceramic and zirconia ceramic. Chrome liners and alumina ceramic liners are less costly, their cost of replacement over one year as the chart below shows, is much more than zirconia ceramic liners.

The table below shows a Mud Pump Liner Cost of Ownership which shows a reasonable cost comparison for a rig in continuous service for 36 months. This of course does not include the high cost of maintenance downtime and the cost of labor.

The prices below are based on cost/cylinder. Savings increase when you add up the number of pump cylinders on your rigs and extend the savings to understand the big difference it can make for your budget.

14 P-220 Mud Pumps 3 available completely overhauled. The pumps have been machine inspected and all data will be provided. These 2200 HP pumps complete with Southwest fluid end modules which have been reworked and pressure tested by Southwest and P-QUIP liner retention systems. The drives can be set up for AC or DC power. All Master Rig equipment meets or exceeds O.E.M. standards and a complete data pack is furnished with purchase. Please call if you have any questions.

READY TO SHIP - Three (3) completely refurbished 1600 HP Continental Emsco 7500 PSI Mud Pump Packages - liner spray system, suction manifold and dampener, discharge strainer cross, reset relief valve, 20 gallon pulsation dampener, 75 HP charge pump, two (2) GE 752 1000 HP rear mounted motors, 10 HP blower, mounted on a 3 runner skid with loading hitches and much more. Units come with complete data books and have been tested. MRI is a API facility and units comply with API standards.

Duplex mud pump package completely refurbished and never operated. Tri-Services Manufacturing TSM-500 pump, CAT engine. Data book provided with complete refurbishment details.

We know that cost savings on identical spare parts is important for offshore rig Companies today. Therefore we provide our services and spare parts at considerable cost reductions compared to sourcing from the major OEMs. Tratec can guarantee identical parts with all required part certificates. We maintaing the highest quality, using state-of-the art service facilities and experienced, specialist mud pump engineers for service work.

Tratec has supplied more than 20 mud pump spare part, overhaul and recertification projects the last 5 years. References include rig companies Odfjell Drilling, Maersk Drilling, Archer, Saipem, KCA Deutag, and others.

Tratec can supply overhaul and parts compatible with the following Mud Pump makers and trademarks: National Oilwell Varco (NOV), MHWirth, Continental Emsco, Gardner Denver, Lewco, Drillmec, and others. Tratec is an independent supplier of drilling equipment parts. Tratec is neither a licensee, nor is affiliated with any of the named original equipment manufacturers (OEM). The manufacturer’s names, equipment names, or trademarks used herein are solely for identification purposes, and are not intended by Tratec to cause confusion as to the source, sponsorship, or quality of the parts supplied by Tratec. The original equipment manufacturers named above and throughout this website do not sponsor, promote, warranty or endorse Tratec’s supply of parts.

8613371530291

8613371530291