duplex mud pump output supplier

We stock fluid end parts for the5×6 mud pump, 5×6-1/4 FM45 mud pump, 5×8 mud pump, 5-1/2×8 mud pump, 5X10 mud pump, 4-1/2×5 mud pump, 7-1/2×8 mud pump, and 7-1/2X10 mud pump. The Gardner Denver mud pump model numbers for the above pumps are as follows: 5X6-FGFXG, 5X8-FDFXX, 5-1/2X8-FDFXX, 5X10-FDFXD, 4-1/2X5-FFFXF, 7-1/2X8-FYFXX, 7-1/2X10-FYFXD. We also handle Wheatley, Gaso, Worthington, Failing and Centerline parts and pumps. We also stock Foot Valve, Liner Puller, Valve Seat Puller, (4″ Inline Check Valve. Our Gardner Denver mud pump parts are not only competitively priced, they are also made in the USA. Oil Recommended by Gardner Denver. Call any of our experienced representatives to get the help and knowledge you deserve.

A mud pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi (52,000 kPa)) down the drill string and back up the annulus. A duplex mud pump is an important part of the equipment used for oil well drilling.

Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers. The advantages that Duplex mud pumps have over convention triplex pumps is a lower mud noise which assists with better Measurement while drilling and Logging while drilling decoding.

Use duplex mud pumps to make sure that the circulation of the mud being drilled or the supply of liquid reaches the bottom of the well from the mud cleaning system. Despite being older technology than the triplex mud pump, the duplex mud pumps can use either electricity or diesel, and maintenance is easy due to their binocular floating seals and safety valves.

A mud pump is composed of many parts including mud pump liner, mud pump piston, modules, hydraulic seat pullers, and other parts. Parts of a mud pump:housing itself

Duplex pumps are used to provide a secondary means of fuel transfer in the event of a failure of the primary pump. Each pump in a duplex set is sized to meet the full flow requirements of the system. Pump controllers can be set for any of the following common operating modes:Lead / Lag (Primary / Secondary): The lead (primary) pump is selected by the user and the lag (secondary pump operates when a failure of the primary pump is detected.

Alternating: Operates per Lead / Lag (Primary / Secondary) except that the operating pump and lead / lag status alternate on consecutive starts. A variation is to alternate the pumps based on the operating time (hour meter) of the lead pump.

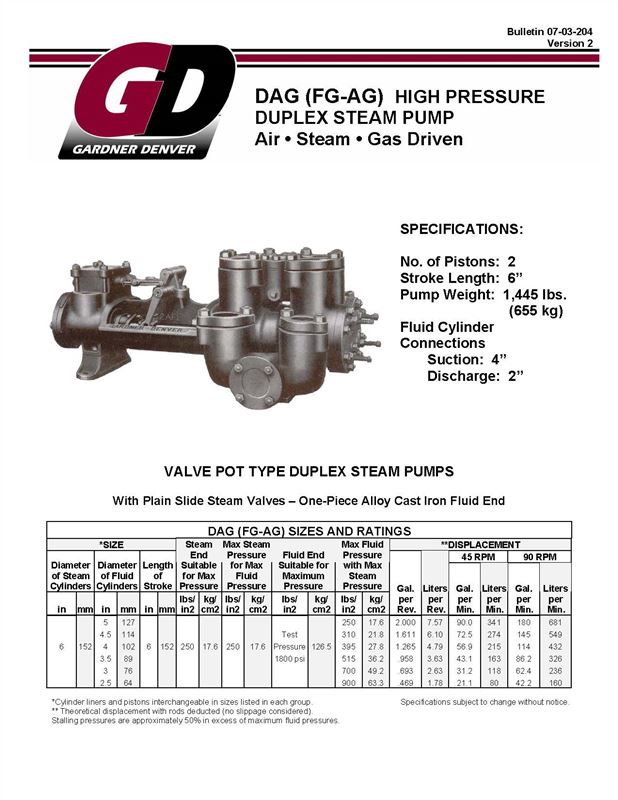

We have a large stock of Double-Acting Duplex Pumps that are used for various applications such as fluid (including heavy oil) transfers in pipelines, mud pumping, cement pumping, water well drilling etc. in the Oil & Gas, Agriculture, Mining, Municipal & Manufacturing sectors. Duplex Pumps have two cylinders and are capable of handling different pressures, volumes and flow rates. We supply new, used and refurbished API 674 Double Acting Duplex Pumps of all leading manufacturers including Gaso, Wheatley, Gardner Denver, National & Oilwell.

Centerline Manufacturing is committed to the highest level of customer service quality. Every Centerline pump is comprehensively and repeatedly tested at diverse pressure levels to assure that it goes to our customer in perfect operational order. Centerline technicians work to ensure that our customers fully understand the operation of the model being delivered. If a customer"s pump is down, we understand the importance of timely response and parts availability. Centerline technicians will assess the problem and make repairs to bring the pump back into new specification. The Centerline mud pump technicians are well versed and qualified to operate and repair any product that is provided to the customer.

Rig pump output, normally in volume per stroke, of mud pumps on the rig is one of important figures that we really need to know because we will use pump out put figures to calculate many parameters such as bottom up strokes, wash out depth, tracking drilling fluid, etc. In this post, you will learn how to calculate pump out put for triplex pump and duplex pump in bothOilfield and Metric Unit.

GDEP is the original creator of the drilling pump and continues to set the standard for durable, high-quality drilling pumps that can withstand the world’s toughest drilling environments. Starting with our PZ7 and rounding out with the market"s most popular pump, the PZ1600, our PZ Series of pumps are the perfect choice for today"s high-pressure drilling applications.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

The l-series of l. K-duplex mud pumps is the result of over two decades of incessant research and development by a young team of pains taking engineers, workingread more...

the l-series of l. K-duplex mud pumps is the result of over two decades of incessant research and development by a young team of pains taking engineers, working with an "india-can-doit" mood. They are backed by their close association with advanced pump technology and actualread more...

We provide a qualitative range of mud pumps, which are immensely used in construction, agriculture, waste water management and many other industries. These High Pressure Duplex Double Acting Mud Pumps are primarily reciprocating plunger devices designed forread more...

Established in year 1996, Maskill Enterprises is the leading Wholesaler Trader of Submersible Pump, Self Priming Pump and Double Wall Corrugated Pipe.

" GSL" Make Reciprocating Duplex Double Acting Mud Pump idle for water well drilling, core drilling, shallow crude oil drilling. Also sutable for Cement Slurry, Crude Oil, Boiler Feed, Sweage Mud pumps are suitble for mounting on skid, Trailer and on drilling rigs.

BW250 triplex mud pump is horizontal,tri-cylinder, reciprocating triplex-acting piston pump. Could be adjusted to different pressure and flow. Its max pressure can reach as high as 6 Mpa (60 Bar).

It has the main features of multe-speed shaft gears, power saving, simple and compact design, light in. weight and high efficiency, and durability, easy and safe in operation, maintenance and low operation costs. it works usually under the conditions of(18-25)sec.mud viscosity not more than 4% sand laden in mud, (7-10)PH-value and(0-50)℃ temperature

BW-250 Mud Pumps is equipped with drilling rigs to drill holes with mud. During drilling mud pump pumps slurry to the hole to provide coat to the wall, to lubricate the drilling tools and to carry the rock debris up to the ground. It is applied to geological core drilling and prospecting drilling with depth less than 1500 meter.

8613371530291

8613371530291