duplex mud pump parts d 50 national quotation

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Pump Parts - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Pump Parts - National 125T-4L Triplex Injection Pump (Oilwell A-344H), Pumps & Parts, Used National J125T-4L Triplex Pump, Reconditioned, 4" Metal Plungers x 4" Stroke, Bronze Fluid E... More Info

Pump Parts - National 125T-4L Triplex Injection Pump (Oilwell A-344H), Pumps & Parts, Used National 125T-4L Triplex Pump, Reconditioned, 4" Metal Plungers x 4" Stroke, Bronze Fluid En... More Info

Pump Parts - National 300Q-5MCS Quintuplex Injection Pump, Pumps & Parts, Used Stainless Steel Fluid End for National 300Q-5MCS Quintuplex Pump, c/w top plugs, no valves or stuffing b... More Info

Triplex Pumps - Used National 55T-3SC, 3" stroke, 55 hp triplex pump, cast ductile iron fluid end with 2" plungers, 2 1/2" 150# suction, 2" 600# discharge, with 7.5" electric motor. 1175... More Info

Pump Parts - National 8P-80 Triplex Drilling Mud Pump Package, Pumps & Parts, Used National 8P-80 Triplex Mud Pump, 6" Pistons x 8.5" Stroke, Skid Mounted and Packaged with Cat D379 D... More Info

Triplex Pumps - Rebuilt National J-150L aluminum bronze fluid end. 6" 150# FF suction, 3" 2000# RJ discharge. 4" plungers, delrin disc valves, 838 packing with bronze adapters. More Info

Pump Parts - National Oiwell NOV J-250-H Quintuplex Injection Pump, Pumps & Parts, Used National Oilwell NOV J-250-H Quintuplex Injection Pump, (J-275-H, 300Q-5H), s/n 220, 1 3/4" Met... More Info

Pumps - Misc. - National J-60 mist pump mounted on 3 runner oil field skid, 80 barrel stainless steel tank powered by Cat 3054C diesel engine More Info

Pump Parts - National JWS-125, 3.5x5 Triplex Mud Pump Package, Pumps & Parts, Used National JWS-125 Triplex Mud Pump Package, steel fluid end, 3.5" metal plungers x 5" stroke, complet... More Info

Pump Parts - National JWS-165-L, 4x5 Triplex Mud Pump Package, Pumps & Parts, Used National JWS-165L, 4x5 Triplex Mud Pump Package, 4" Metal Plungers x 5" Stroke, Steel Fluid End, Fac... More Info

Pump Parts - Ajax T-150, Pumps & Parts, Used crankshaft for Ajax T-150, crankshaft journal diameter 4.5", crankshaft extension diameter 4" , More Info

Pump Parts - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Pump Parts - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Pump Parts - BUTTERWORTH T-375M Triplex Water Blaster Pump, Pumps & Parts, Used Butterworth T-375M Triplex Water Blaster Pump, 1.4375" plungers x 3.75" stroke, max 10,000 PSI, missing... More Info

Pump Parts - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Pump Parts - Chinese 3DS-18.5/21.5, Pumps & Parts, Brand new triplex pump, 1.921" plungers, 4.117" crank extension, 5.285" stroke, 4"#150FF suction flange, 2" 5000 PSI API discharge f... More Info

Pump Parts - DOWELL PG03 4.5x5 Triplex Cementing Pump, Pumps & Parts, Used Dowell PG-03 Triplex Cementing Pump, 4 1/2" Metal Plungers x 5" Stroke, c/w Factory Chain Case, Magnesium Po... More Info

Pump Parts - DOWELL PG03 4.5x5 Triplex Cementing Pump, Pumps & Parts, Used Dowell PG-03 Triplex Cementing Pump, 4.5" metal plungers x 5" stroke, steel block fluid end for cementing or... More Info

Pump Parts - DOWELL PG05 4.5x5 Triplex Cementing Pump, Pumps & Parts, Used Dowell PG-05 Triplex Cementing Pump, 4 1/2" Metal Plungers x 5" Stroke, Steel Fluid End c/w Factory Chain Ca... More Info

Pump Parts - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Pump Parts - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Pump Parts - EMSCO D-300, 4.75-7.25 x 14 Duplex Mud Pump Package, Pumps & Parts, Used Emsco D-300 Duplex Mud Pump Package, 5.5" liners x 14" Stroke, c/w Detroit Series 60 Diesel Engin... More Info

Pump Parts - EMSCO F650 Triplex Mud Pump, Pumps & Parts, Used Continental Emsco F650 Triplex Mud Pump, 5 1/2" Pistons x 8" Stroke c/w Mud Gauge, Relief Valve, Pulsation Dampener, Quic... More Info

Pump Parts - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Pump Parts - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Pump Parts - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Pump Parts - Gardner Denver GD45T Triplex Injection Pump, Pumps & Parts, Used frame for Gardner Denver GD45T (PS-25) triplex pump, bare case , More Info

Pump Parts - Gardner Denver PA-8 Triplex Mud Pump, Pumps & Parts, Used Gardner Denver PA-8 Triplex Mud Pump (predecessor to the Gardner Denver PAH), 4.5" metal plungers x 8" stroke, c... More Info

Pump Parts - Gardner Denver PAH 4 1/2 x 8 Triplex Mud Pump, Pumps & Parts, Used Gardner Denver PAH 4 1/2 x 8 Triplex Mud Pump Package, 4.5" Metal plungers x 8" stroke, Detroit 8V-71 d... More Info

Pump Parts - Gardner Denver PE-5 3x5 Triplex Mud Pump, Pumps & Parts, Used power end for Gardner Denver (SMC) PE-5 (T-165-5) triplex pump, 5" stroke, no fluid end , More Info

EnglishAf-SoomaaliAfrikaansAsụsụ IgboBahasa IndonesiaBahasa MelayuBasa SundaBinisayaCatalàChinyanjaCorsuCymraegCрпски језикDanskDeutschEesti keelEspañolEsperantoEuskaraFrançaisFryskGaeilgeGalegoGàidhligHarshen HausaHmoobHmoob DawHrvatskiItalianoKiswahiliKreyòl ayisyenKurdîLatviešu valodaLatīnaLietuvių kalbaLëtzebuergeschMagyarMalagasy fitenyMaltiMàaya T"àanNederlandsNorskOʻzbek tiliPapiamentuPolskiPortuguêsQuerétaro OtomiReo Mā`ohi"RomânăSesothoShqipSlovenčinaSlovenščinaSuomiSvenskaTagalogTe Reo MāoriTiếng ViệtTürkçeWikang Filipinoazərbaycan dilibasa Jawabosanski jezikchiShonafaka Tongagagana fa"a SamoaisiXhosaisiZuluvosa VakavitiÍslenskaèdè YorùbáČeštinaʻŌlelo HawaiʻiΕλληνικάБеларускаяБългарскиМары йӹлмӹМонголРусскийТоҷикӣУкраїнськабашҡорт телекыргыз тилимакедонски јазикмарий йылметатарчаудмурт кылҚазақ тіліՀայերենייִדישעבריתاردوالعربيةسنڌيپارسیनेपालीमराठीहिन्दी; हिंदीবাংলাਪੰਜਾਬੀગુજરાતીதமிழ்తెలుగుಕನ್ನಡമലയാളംසිංහලภาษาไทยພາສາລາວမြန်မာစာქართულიአማርኛភាសាខ្មែរ中文(漢字)中文(简体)日本語粤语한국어

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Lake Petro provides high quality Mud Pump Parts including Mud Pump Liners, Mud Pump Fluid End Module, piston, Valve and Seat etc. With more than 10 years of experience in the oil and gas industry, we are dedicated to help and support our loyal clients with the most cost-effective and quality Liners and Pistons. We also provide mud pump price and mud pump for sale.

We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials for all common brands of the mud pump and triplex mud pump.

Bi-metal liners (double metal liners) are made of forged steel shell and wear-resistant sleeve of high chromium iron. In the production process, the size accuracy should be strictly controlled, which can ensure that they can be easily and stably installed. The inner sleeve with high finish and hardness is wear-resistant, corrosion-resistant and has a long service life. The bi-metal liners are suitable for a lot of bad working conditions. Its service life is more than 800 hours.

Ceramic Liners are made of a ceramic inner sleeve and a forged steel outer shell. The service life of ceramic liners is about 4000 to 10000 hours, the minimum time is at least 2000 hours, which is a lot more than bi-metal liners. Because of the phase transformation toughen technology, the ceramic liners have the features of wear-resistance, erosion-resistance, high-pressure-resistance, high hardness and strength. Zirconia type and Alumina type are common type of ceramic sleeve. Compared with Alumina type, Zirconia type liners have better toughness properties and a much longer service life. Piston wear and water consumption for lubrication can be reduced as well.

Seal Rings for Liner packing are also important. Liner Seal Rings is designed and made with hard corner which is an integral part of seal rings and soft nitrile element rubber center. We could provide reliable liner Seal Rings for our customers could order them at the same time.

All Lake Petro liner products are interchangeable with O.E.M. products. Meanwhile, we provide customized Liners according to drawings. Our liners, also with our other mud pump spares, are supplied for use in Honghua, F-Series, Bomco, Emsco and National lines of triplex drilling pumps. Let Lake Petro be your one-stop shop for your whole fleet of pumps. Please refer to “Suitable Pump Models” Lable for more details.

You can find our high-performance mud pumps at some of the largest oil and natural gas drilling operations on the planet. Now, we’re ready to supply one of our mud pumps to you.

Looking for a mud pump for sale? Bridges Equipment has the biggest inventory of rebuilt duplex and triplex mud pumps and pump packages ready to ship. Unlike some suppliers, we completely rebuild our mud pumps to OEM standards and guarantee our work from 90 days up to six months against major failure.

Our fabrication facility customizes mud pumps, equipment, and pump packages to meet the needs of operations large and small, across the nation and around the world. Whether you need a custom-fabricated mud pit or a unitized pump package, we have the expertise to get it done.

Nothing wastes time and money like waiting on parts. With two supply stores stocked with the fluid ends and other mud pump parts you need to keep your operation running, and the field mechanics to install them, we can help keep your operation up and running.

Customizability. Functionality. Quality. Reliability. You’ll find these attributes and more in every mud pump, mud pump part or mud pump package we have available for sale or rental.

Adjust or replace these bearings at first sign of wear. The bearings in the crank end are babbitt lined steel shells, adjustable for wear by removing shims and easily replaced when completely worn. These bearings should be watched closely and adjusted at first signs of looseness.. You will note on series 3400, 3800, 3500, and 3900 pumps, that the shims do not completely fill the outer gap between rod and cap casting, although the connecting rod bolts are tight. This is because the faces of the shell bearings project slightly beyond the faces of the rod and cap castings, and the shims are gripped only between the faces of the bearing halves. Do not try to close this outer gap by tightening the connecting rod bolt as it will put an excessive strain on the bolts.

To check for wear, place a wrench on the top connecting rod bolt and shake the rod parallel to the crankshaft. (The pressure must be relieved from the liquid end of the pump, so that the pump"s mechanism is free to move.) If the rod bearing moves without resistance, the bearing may be too loose and need adjusting. If the bearing does need adjusting, remove shims until you cannot shake the rod, then add .005" shims one at a time until there is little side movement. Be sure to torque rod bolt nuts to proper value for each adjustment. Oil clearance should be checked with Plastigage (available in most parts stores). Wipe crankshaft journal clean of any oil, place a strip of Plastigage on the crankshaft journal and tighten rod cap to the proper torque value. Once tightened, remove rod cap and measure oil clearance with scale on Plastigage package. See oil clearance chart. (NOTE: If you are making this adjustment after having had the crossheads out, be sure that the oil holes in the rod are pointing up. The "up" side is indicated by matching numbers stamped on the cap and rod at the split between them. These numbers should be the same on each rod and should be on the top side of the crankshaft.) Rotate the shaft by hand and if there is any hard drag or tight spots in the bearing, add another 0.005" shim. After this bearing is properly adjusted, loosen bolts a few turns and repeat the above operation on the other bearings. After all bearings have been adjusted.

Torque all connecting rod bolt nuts back to proper value. Again rotate the pump by hand to check for excessive drag and tight spots. If none, the pump should be ready for operation.

If the pump cannot be rotated by hand due to the drive being enclosed, care must-be taken: not to over-tighten the bearings, since they cannot be checked by rotating the pump. When bearings are adjusted by this method, watch carefully for overheating when the pump is put into operation.

It is usually better to have a bearing a little too loose than too tight. A slightly loose bearing will cause very little trouble because of the slow operating speeds of the pump, but a tight bearing will overheat and the babbitt may melt or pull. Normal precautions must be taken to insure cleanliness of parts upon their assembly.

Inspect connecting rod bearings and adjust as necessary every six months or when crankcase lubricant is changed. The bearings in the crank end are babbitt lined steel shells, adjustable for wear by removing shims and easily replaced when completely worn. These bearings should be watched closely and adjusted to compensate for wear. You will note that shims do not completely fill the outer gap between rod and cap casting although the connecting rod bolts are tight. This is because the faces of the shell bearings project slightly beyond the faces of the rod and cap castings and the shims are gripped only between the faces of the bearing halves. Do not try to close this outer gap by tightening the connecting rod bolt as it will put an excessive strain on them.

To check for wear, place a wrench on the top connecting rod bolt and shake the rod parallel to the crankshaft. (The pressure must be relieved from the liquid end of the pump so that the pump"s mechanism is free to move.) If the rod bearing moves without resistance, the bearing may be too loose and need adjusting. If the bearing does need adjusting, remove shims until you cannot shake the rod, then add .005" shims one at a time until there is a little side movement. Be sure to torque rod bolt nuts to proper value for each adjustment. (NOTE: If you are making this adjustment after having had the crossheads out, be sure that the oil holes in the rod are pointing up. The "up" side is indicated by matching numbers stamped on the cap and rod at the split between them. These numbers should be the same on each rod and should be on the top side of the crankshaft.) Turn the shaft by hand and if there is any hard drag or tight spots in the bearing, add another .005"" shim. After this bearing is properly adjusted, loosen bolts a few turns and repeat the above operation on the other bearings. After all bearings have been adjusted, torque all connecting rod bolt nuts back to proper amount. Again turn the pump by hand to check for excessive drag and tight spots. If none, the pump should then be ready for operation.

If the pump cannot be rotated by hand due to the drive being enclosed, the bearings may be completely adjusted by shaking the bearing on the shaft as stated above. Care must be taken not to over-tighten the bearings since they cannot be checked by rotating the pump by hand. When bearings are adjusted by this method, they must be watched carefully for overheating when the pump is put into operation.

Alternatively, plastic gauge strips, found in most parts stores may be used to adjust these bearings. It is usually better to have a bearing a little too loose than too tight. A slightly loose bearing will cause very little trouble because of the slow operating speeds of the pump, but a tight bearing will overheat and the babbitt may melt or pull. with experience, an operator can tell by feel when the bearings are properly adjusted. Normal precautions must be taken to insure cleanliness of parts upon their assembly. All wrenches used in adjusting these bearings are standard wrenches.

A mud pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi (52,000 kPa)) down the drill string and back up the annulus. A duplex mud pump is an important part of the equipment used for oil well drilling.

Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers. The advantages that Duplex mud pumps have over convention triplex pumps is a lower mud noise which assists with better Measurement while drilling and Logging while drilling decoding.

Use duplex mud pumps to make sure that the circulation of the mud being drilled or the supply of liquid reaches the bottom of the well from the mud cleaning system. Despite being older technology than the triplex mud pump, the duplex mud pumps can use either electricity or diesel, and maintenance is easy due to their binocular floating seals and safety valves.

A mud pump is composed of many parts including mud pump liner, mud pump piston, modules, hydraulic seat pullers, and other parts. Parts of a mud pump:housing itself

Duplex pumps are used to provide a secondary means of fuel transfer in the event of a failure of the primary pump. Each pump in a duplex set is sized to meet the full flow requirements of the system. Pump controllers can be set for any of the following common operating modes:Lead / Lag (Primary / Secondary): The lead (primary) pump is selected by the user and the lag (secondary pump operates when a failure of the primary pump is detected.

Alternating: Operates per Lead / Lag (Primary / Secondary) except that the operating pump and lead / lag status alternate on consecutive starts. A variation is to alternate the pumps based on the operating time (hour meter) of the lead pump.

We have listed the best mud pumps along with their manufacturers/suppliers. This will help the customers find relevant mud pumps according to their requirement. You can also reach out to us through contact@energydais.com and we will connect you with the manufacturers that can fulfil all your requirements.

The companies whose products are listed on our mud pump page are manually verified by our team. And hence, we can assure that these are some of the best manufacturers and suppliers of the Mud Pump. These companies have been trusted by the industry to provide the best mud pumps.

A custom quote for mud pump will be according to your requirement. This will allow you to get the best rates from mud pump companies across the globe. We work on a zero commission and zero referral fee business model, eliminating any unnecessary expenses. We maintain complete transparency, which means that the buyers and suppliers can directly communicate through our platform and negotiate the prices.

Being able to garner the trust of our valued customers, we manufacture (Down Hole Tolls i.e. Cross over, Sub Saver, Lifting Sub. etc.), import, trade and supply best quality Steel Products. Having an experience of almost a decade, we offer a wide range of products that includes Drilling Bits (for Oil & Gas), C.S and M.S. Pipes & TubesandRotary Substitutes (Down Hole Tools for Oil & Gas). These products are generally used in exploring mine and gas or drilling wells, sugar industries, chemical plants, fertilizer plants, pharmaceutical, railway coaches, refrigeration and metallurgical industries. Known for their dimensional accuracy, high tensile strength and durability, these products are made by experts in compliance with the industry standards.

We have a strong infrastructure base that is equipped with latest technological tools and machines. We are powered with a trained and experienced team of professionals, who have expertise in their respective domains and work areas. These experts work with dedication and efficiency on our set standards to maintain the trust of our clients. Therefore, our clients trust us for offering top quality products and making their timely deliveries at clients" end.

Browse through more than 1,500 duplex piston rods and 200 duplex pony rods in our inventory. EC Tool gives you a quote before your order, so you know what you’re getting for your money every time. While we primarily keep connecting rods for GA550 and GA750 models in stock, there are other options at your disposal as well. This includes custom connecting rods for most duplex and triplex mud pumps.

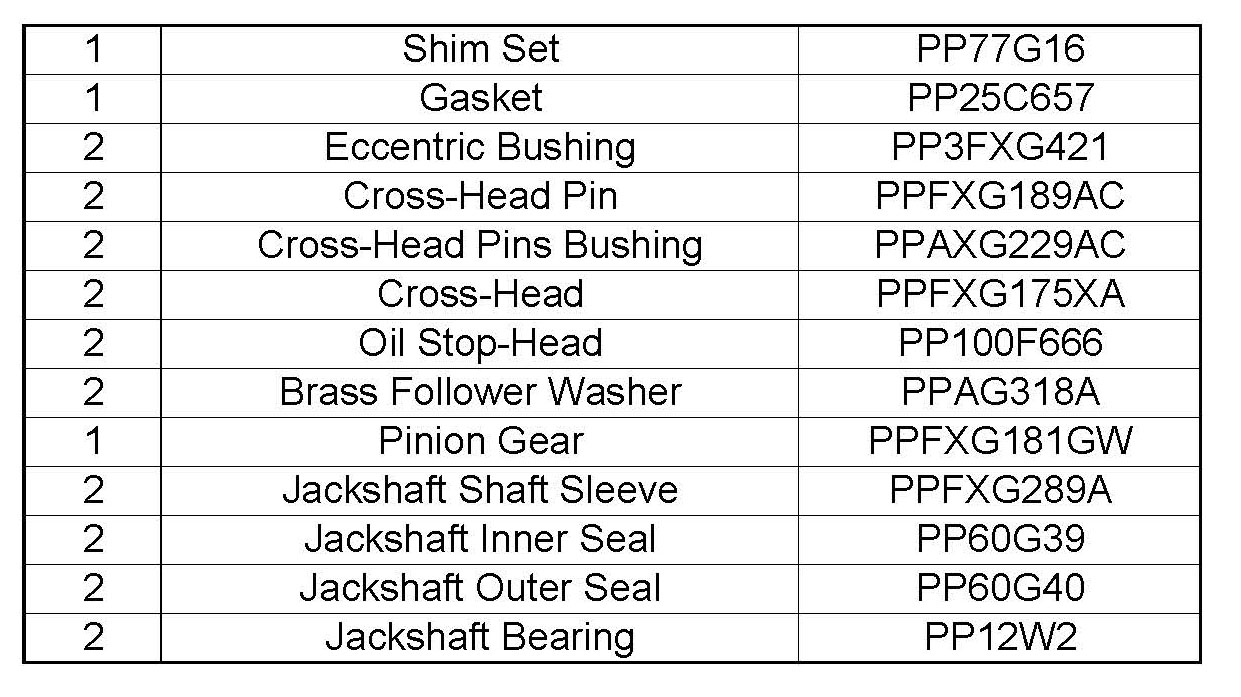

We now offer new crossheads and capsules for both EMSCO D-375 and DB-550 duplex pumps. You can also find slides and shoes for certain models. Available parts currently in our inventory include:

We carry a large inventory of valve cap plugs made for OEM and MATTCO fluid ends. You’ll also find different drop-in plugs for most gland-type valve caps.

8613371530291

8613371530291