efficient mud pump replacement motors quotation

Explore a wide variety of dc mud pump motor on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These dc mud pump motor are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these dc mud pump motor is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right dc mud pump motor for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of dc mud pump motor to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

Our motors meet the toughest industry specifications and standards and are built to the highest quality for our valued customers. We sell our motors individually, in combination with your pump as a bundle, or as a comprehensive package (including pump(s), motor(s), and control panel) to meet the needs of your specific application for the ultimate in cost-effectiveness no matter what your industrial automation needs entail. The future of the commodities markets lies in improving efficiency. Whether you are extracting, transporting, or refining energy, or operating a small to commercial-scale agricultural business, Replicate Pumps can assist you by dramatically improving your productivity level. Let us help you reach the heights that can place your business into the global market with a total industrial or agricultural automation system.

All of our motors and control panels are available completely assembled and ready to ship. In fact, we offer the fastest delivery in the industry. Our logistics team will work with you to ensure that you have the power you need, when and where you need it. We can also ship replacement parts. We sell most types of motors and pumps. If you don’t see what you need, contact us. We offer complete customization services for all industries throughout the world.

Replicate Pumps is a trusted pump and motor supplier for the oil and gas industry in Odessa, TX, across the nation, and around the world. We carry some of the most powerful and reliable pumps to provide clean water on oil platforms, as well as mix and transport all petrochemicals both on and off-shore. We offer a selection of stock pumps and motors or can custom-build exactly what your business needs to get the job completed safely and efficiently. A range of pumps and motors designed specifically to handle a wide range of needs specific to the oil and gas industry are available. Safety, extreme durability, corrosion resistance, and superior power are standard for all of our energy industry pumps and motors. Some of our most requested products include:

All motors, panels, and components are tested prior to shipment and very carefully packaged to virtually eliminate the possibility of damage during transport. Distribution centers are located throughout the United States for prompt nationwide and global shipping.

If you have already placed your order and require customer support, or are ready to order, contact Replicate Pumps directly. Our customers are our main priority and we are waiting to provide you with exceptional customer service. Call our friendly and knowledgeable staff at: (432) 258-3092. Expedited shipping is available for all in-stock parts.

Jandy®, ePump®, FloPro®, PlusHP®, Stealth®, MaxHP® are trademarks and/or registered trademarks of Jandy® Water Pool & Spa Inc. and or its affiliated companies.

Jandy®, ePump®, FloPro®, PlusHP®, Stealth®, MaxHP®,FHP Series® are trademarks and/or registered trademarks of Jandy® Water Pool & Spa Inc. and or its affiliated companies.

Jandy®, ePump®, FloPro®, PlusHP®, Stealth®, MaxHP®,FHP Series® are trademarks and/or registered trademarks of Jandy® Water Pool & Spa Inc. and or its affiliated companies.

Hayward®, TriStar®, MaxFLo®, Super Pump®, Super Pump II®, and HCP 3000 Series® are trademarks and/or registered trademarks of Hayward® Water Pool and Spa, Inc. and/or its affiliated companies.

Having a quality mud pump is a critical part of keeping your oil well drilling system running as smoothly as possible. Dragon carries a wide range of mud pumps for systems of all kinds and jobs of all sizes. We also carry a 50 BPM mud mixing table to make drilling fluid mixing more efficient and accurate so you can always get the job done safely and correctly. View our full well service pump and mud pump selection to find the right system for your job site, or check out the rest of our drilling rigs for even more options.

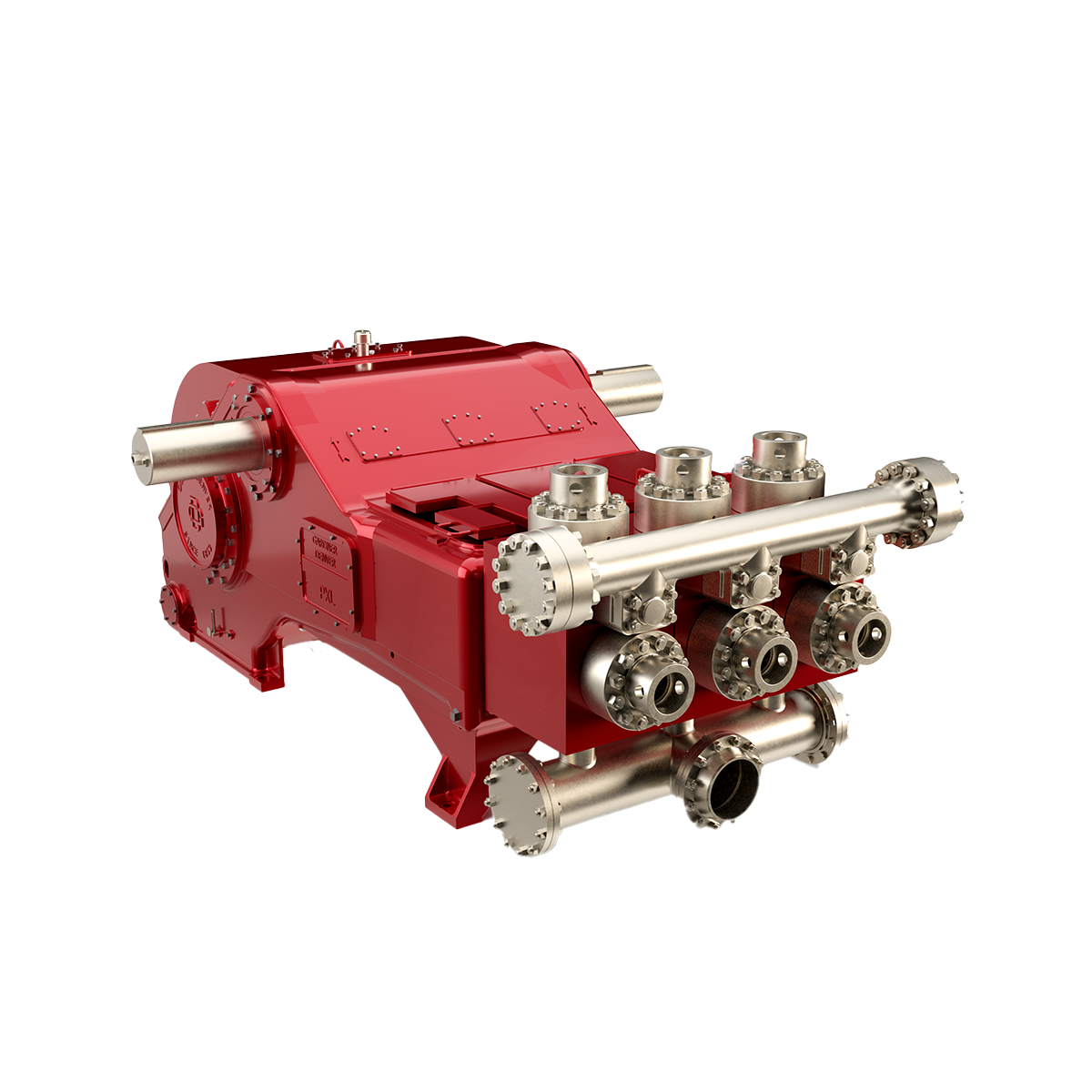

GDEP is the original creator of the drilling pump and continues to set the standard for durable, high-quality drilling pumps that can withstand the world’s toughest drilling environments. Starting with our PZ7 and rounding out with the market"s most popular pump, the PZ1600, our PZ Series of pumps are the perfect choice for today"s high-pressure drilling applications.

T-300M for 15,000 PSI -The T-300M features the "L" fluid end design, which performs at pressures from 8,000 to 15,000 PSI, and flows from 10.3 to 18.4 GPM. Four different plunger sizes allow this pump to adapt to the specific flow and pressure requirements for each job. This pump is the standard for waterblasting. It covers the standard range of pressures and flows for a 100 HP pump. Overall maintenance and parts are inexpensive to maintain. Keep operating costs down with this GD Energy Products high-pressure waterjetting pump.

A Mud Pump may have many changeable parts, such as liner, piston, extension rod, pulsation dampener, valve, clamp, etc. Lake Petro could provide 100% interchangeable parts of many common brands of pump. We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials. Piston assembly is the important spare parts and expendable parts of oil drilling mud pumps. Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump. Fluid End Module is an important component of the hydraulic pump end of the mud pump.

Electronic Pump Stroke Counters are a vital part to any drilling rig operation. When a mud pump is in operation, the driller must know how much mud is flowing down hole in order to keep the operation running at peak efficiency. Pump stroke counters assist the driller by measuring the mud pump’s strokes per minute and total strokes. So, how does a pump stroke counter tally the mud pump’s strokes

Electronic Pump Stroke Counters are a vital part to any drilling rig operation. When a mud pump is in operation, the driller must know how much mud is flowing down hole in order to keep the operation running at peak efficiency. Pump stroke counters assist the driller by measuring the mud pump’s strokes per minute and total strokes. So, how does a pump stroke counter tally the mud pump’s strokes, and why it is important? In order to understand that, you’ll need to know some basic information about mud pumps.

Knowing how a mud pump functions is important in understanding the role a pump stroke counter plays in rig operations. Mud pumps act as the heart of the drilling rig, similar to how our heart works. Just as our heart circulates blood throughout our bodies, a mud pump circulates essential drilling mud down the hole and back up to the surface. Mud tanks house drilling mud, and a mud pump draws the fluid from the mud pump. A piston draws mud in on the backstroke through the open intake valve and pushes mud through the discharge valve and sends it towards the rig. By circulating fluid, the mud pump ensures that the drill bit is cool and lubricated and that cuttings are flushed from the hole. The two main kinds of pumps used are duplex and triplex pumps, where the duplex pump has two pistons and the triplex pump has three. Whether the rig is using a duplex or triplex pump, it is important to know how many strokes per second the pistons are moving. The driller monitors strokes per minute to determine how much costly, yet essential, mud is being pumped into the system with the use of a mud pump stroke counter system. Now, that you know about mud pumps, you’ll need to know what’s in a stroke counter system.

Stroke Counter — The stroke counter stainless steel box is mounted on the driller’s console and is either square or rectangular in shape, depending on the number of pumps it is monitoring. Stroke counters will show strokes per minute and total strokes, and when a particular mud pump is operating the strokes/minute and total strokes will be displayed. Power is supplied by a 3.6 volt lithium battery, and the counter contains a crystal-controlled real time clock with 100 parts per million accuracy or better. Each counter is mounted to the console with 1/4” stainless steel hex head bolts, lock washers and nuts.

Micro Limit Switch — The micro switch is connected to a c clamp near the mud pump piston. The micro switch stainless steel rod (sometimes called a whisker) sticks out in the piston housing near the piston. As the piston passes the rod, it moves the rod and the switch sends an electronic signal back to the counter. The counter increases by one each time the piston moves the rod, counting the mud pump’s strokes. The switch’s signal is then transmitted to the stroke counter. These micro switches are built to stand up to demanding outdoor conditions. They can withstand shock, equipment vibration, extreme temperatures, water and dust.

Cable and Junction Box – A cable is connected to the back of the pump stroke counter and then to the junction box. From the junction box, the cables travel to the limit switches.

Pump Stroke Counters are like a blood pressure machine. Each time our heart pumps, a blood pressure machine reads our systolic and diastolic blood pressure by way of our pulse. A mud pump stroke counter functions in much the same way. Just as a blood pressure machine detects our pulse so too does a limit switch rod detect the movement of the piston. When the stainless steel rod is moved, the micro limit switch detects the movement. The signal is sensed as a contact closure, and it is transmitted to the stroke counter where the contact closure is converted to a logic pulse. The pulse feeds two separate circuits. The total strokes circuit reads and displays the closures one at a time, totaling them up to reveal the total strokes in the LED window. The second pulse is sent along a separate circuit which is a rate circuit. This rate circuit will average the closures against the real time clock. The result is displayed as the total strokes per minute.

Pump stroke counters are essential to drilling rig operations because they measure the efficiency of mud pumps. Knowing strokes per minute and total strokes of the pistons helps the driller to determine if the correct amount of mud is going down hole. Having this information aids in running a drilling rig at peak efficiency, assists in extending drill bit life, and avoids costly overuse of drilling rig mud. Unsure which pump stroke counter is right for your application? Give our friendly, knowledgeable staff a call or email. We’ll keep you turning right.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

GE manufactures rugged electric drilling motors for the toughest applications in the oil and gas industry. The company has pioneered the electrification of the drilling rig and continues today to lead the way in manufacturing DC and AC drilling motors for land and offshore drilling rigs.

GE engineers, manufactures, and tests GE drilling motors to withstand the harshest requirements. They are used today driving drawworks, mud pumps, cement pumps, rotary tables, top drives, and anchor-handling winches on all types of drilling rigs, all over the world.

GE’s ongoing research and development efforts provide innovative and increasingly efficient technology continue to produce electric motors that are a more reliable and efficient power supply – especially in extreme weather conditions – and able to decrease noise on the rig, making a safer working environment. Combined with a potentially smaller “envelope,” this makes GE motors a better solution to meeting your rigs’ power supply requirements.

GE drilling motors are performing worldwide on all types of drill rigs, providing dependable operations of the rig’s primary equipment. GE drilling motors have been reported by rig operators to run for years without service or failure.

The company has a worldwide network of authorized service facilities such as, Gulf Electroquip in Houston, Texas, USA, for both its AC and DC drilling motors. These service facilities are audited and GE’s personnel have been trained to assure that they meet the quality standards required to repair GE’s drilling motors.

8613371530291

8613371530291