f 1300 mud pump specifications brands

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

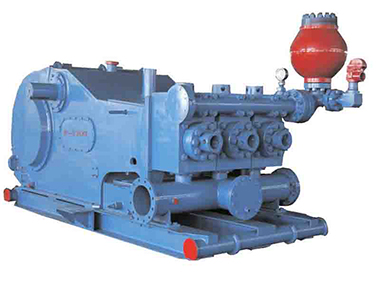

F 1300 mud pump for oil drilling have features of solid and compact structure, small volume, good and reliable performance. It can meet the drilling requirements such as high pressure and big displacements whether in land drilling or off-shore drilling.

F 1300 mud pumps have a longer stroke and can be operated at a lower stroke, thus improved the water supplying performance effectively and extended the lifetime of mud pump fluid end parts greatly.

ERUI has an independent third-party inspection team, which strictly controls the quality of products, guarantees genuine products and eliminates fakes.

ERUI has been deeply engaged in the field of oil and gas energy for many years, integrating a large number of high-quality supply channels. Our products are comprehensive and the price advantage is obvious.

The time depends on the MOQ of the order. The delivery time for parts is generally 1-3 days, and equipment is 7-30 days. In addition, contact us to get the full time of the order.

We are a large drilling tools, Drilling rig spares, Water well drilling and mining pump part, Drilling mud pumps and Fluid End Expendables and mud pump spare parts manufacturer in China.

We make all fluid end modules, Ceramic liners, Hy-chrome liners, rubber replaceable and bonded urethane pistons and all spares for popular brand mud pumps.

Thanks for using F series mud pumps produced by Baoji Oilfield Machinery Co., Ltd. The outline dimension, frame, and fluid end of F-1300 and 1600 mud pump are the same, only the bearing and gear pair of power end are different. For convenience of customer, this manual introduces these two kinds mud pumps at the same time.

(3.206) Note: 1. Based on 100% volumetric efficiency and 90% mechanical efficiency. Recommended strokes and input power for continuous service. Table 1B Performance data of F-1300/1600 Mud Pump Liner Diameter, in & Rating pressure, MPa(Psi) 6 3/4 6 1/2 6 1/4...

Fig. 2 1.2.1. Ground Installation When ground installation is going on, 8 pieces of 76mm×305mm boards is cushioned in the direction of pump skid, as indicated in Fig.2. The base of boards should be 300mm wider than that of pump skid beam.

Fig. 3 1.2.3. Installations of Driving Device The drive between the mud pumps and prime mover should be adopted V-belts or multi-row chains drive, which is installed with precision to assure longest service life and minimum possibility of unexpected or undesirable shutdowns due to drive failures. When installing the drive sheave or sprocket, make sure all grease or rust preventative is removed clearly from the shaft end and the matched bore.

Stationary spray pipes have been used on F-series pumps Ref. Fig 5. It consists of a fixture frame (1), steel pipe (2) and spray nozzle (3), it makes cooling fluid spray to piston and liner. Adjust cooling water supply to the manifold and inspect spray nozzle operation very often to make sure the nozzle is pointed directly at the piston.

Instruction Manual for F1300/1600 Mud Pump 1.6.2. Liners Installs wear-resisting plate seal (1) in counter bore of fluid end (see Fig. 8). Install wear-resisting plate (2) through studs until it seats against fluid end. Mount liner flange (3) over studs with the starting thread at the 5 o’clock position and tighten bolts with 640~690N.m (470~510ft.lbs) torque.

Instruction Manual for F1300/1600 Mud Pump 1.6.6. Valve Cover Install valve cover seal ring (18) into bore, and after grease the valve cover seal area and threads area, tighten the valve covers into place using a sledge hammer and bar. 1.6.7 Discharge Manifold API 5"...

Instruction Manual for F1300/1600 Mud Pump shield ○ 8 is used for lifting dampener assembly. Before assembly thoroughly clean ring groove, gasket ring ○ 1 and groove of mating flange and coat with grease. Lifting the dampener to the corresponding position of mud pump discharge line, screw nut (R4) with 950~1265N.m (700~935ft.lbs) torque.

Instruction Manual for F1300/1600 Mud Pump Fig.15 (1) Filter (2) Oil distributor (3) Oil line (3A) Spray nozzle (4) Main bearing oil line (4A) Oil distributor (5)Pressure gauge (6) Relief valve (7) Oil trough (8) Oil tube (9) Lubrication pump A pressure relief valve (6) is mounted to the oil distributor (2) to prevent excess pressure from damaging oil pump and drive.

Instruction Manual for F1300/1600 Mud Pump Fig.18 (1) Cover (2) Bolt (3) Retainer ring (4) Bolt (5) Bearing retainer ring (7) Retainer ring (8) Bolt (8A) Inner hex bolts (9) Main bearing (10) Right bearing sleeve (11) Left bearing sleeve (12) Outer retainer ring (13) Connecting rod bearing (14) Inner retainer ring (15) Bolt (16) Main bearing retainer (17) Inner race retainer (18) Bolt (19) Crosshead bearing 1) Install gear ring and check run-out.

Instruction Manual for F1300/1600 Mud Pump valve spring, change the damaged one. Check if the locknuts of piston are corrosive or damaged. Change if they are Weekly damaged (normally, change after using three times). Weekly Check the filter screen of lubricating system. Clean it if it is plugged. Weekly Loosen the plug of drain flange, discharge the dirt and water in the oil pool.

Instruction Manual for F1300/1600 Mud Pump become sealed off and the air gets charging piping or change the discharge reduces or no mud into the pump. gasket. discharged. 2. The suction filter screen is 2. Stop the pump and clean the plugged.

Instruction Manual for F1300/1600 Mud Pump F-1300/1600 Spare Parts List F-1300/1600 Tool List F-1300/1600 Mud Pump General Assembly 11 43 54 6 56 17 8 36 B向...

Instruction Manual for F1300/1600 Mud Pump F-1300/1600 Drilling Mud Pump Drawing No. Item Description F-1300 F-1600 Frame assembly AH1301020100 AH1301020100 Crank shaft assembly AH1301020200 AH1601020100 Pinion shaft assembly AH1301020300 AH1601020200 Crosshead assembly AH1301020400 AH1301020400 Fluid end assembly AH1301020500 AH1301020500 Power...

Instruction Manual for F1300/1600 Mud Pump Drawing No. Item Description F-1300 F-1600 Flange T508-1002 T508-1002 KB-75 Dampener AK75350200 AK75350200 JA-3 Shear relieve valve AH0000060200 AH0000060200 Connection tube T510-1002 T510-1002 Cover plate AH1301011800 AH1301011800 Right-angle joint T511-1002 T511-1002 Bolt 1/2-13UNCX1 T500-1001...

Instruction Manual for F1300/1600 Mud Pump Crankshaft Assembly Fluid End 13 14 Drawing No. Item Description F-1300 F-1600 Main bearing AH130101020100 AH130101020100 cover Bearing sleeve, AH1301010202 AH1601020101 right Gasket AH1301010203 AH1301010203 Inner race AH1301010204 AH1301010204 retainer Outer race AH130101020500 AH160101010200...

Instruction Manual for F1300/1600 Mud Pump Drawing No. Item Description F-1300 F-1600 AH130101020100 AH130101020100 Locating ring (I) AH1301020201 AH1601020101 Hollow crankshaft AH1301010203 AH1301010203 Locating ring (II) AH1301010204 AH1301010204 Gear ring AH130101020500 AH160101010200 Piston 1/2-8UN Bolt 1 1/2-8UNx5 AH1301020202 AH1601020102 AH1301020203...

Instruction Manual for F1300/1600 Mud Pump Drawing No. Item Description F-1300 F-1600 AH1301010218 AH1601010108 Gear ring (split one) 420501036160200000 420501036160200000 Bolt 1 1/2-8UN× F-1300/1600 Pinion Shaft Assembly 11 16 Fluid End Drawing No. Item Description F-1300 F-1600 AH1301020301 AH1301020301 Key 2″×2″×11 3/8″ AH1301020302 AH1601020201...

Instruction Manual for F1300/1600 Mud Pump Drawing No. Item Description F-1300 F-1600 T500-1027 T500-1027 Bolt 7/8-9UNCX2 AH1301010311 AH1301010311 seal 9.125"X10.375"X0.625" AH1301010312 AH1301010312 Bearing 4G32844H 420503011221600000 420503011221600000 Spring washer 22 (GB93) 420503011141600000 420503011141600000 Spring washer 14 (GB93) AH1301010313 AH1301010313 Flange T500-2003...

Instruction Manual for F1300/1600 Mud Pump F-1300/1600 Crosshead Assembly 30 20 Link 2426 Item No. Qty. Description Drawing No. Crosshead AH1301020401 Crosshead guide (upper) AH1301010402 Shim set AH100101041700 Shim AH1301010403 Stuffing box AH1301010404 Sealing ring AH1301010405 O-ring φ190×3.55 (GB3452.1) 530301011900035507...

Instruction Manual for F1300/1600 Mud Pump Item No. Qty. Description Drawing No. Double lip seal 5"X6.25"X0.625" AH1301010406 Locking spring AH1301010407 Mud guard plate AH1301010408 Crosshead extension rod AH1301010409 Crosshead pin AH1301020403 O-ring φ125×7 (GB3452.1) 530301011250070007 Bolt 3/4-10UNCX2 1/2 T500-3010 Plate gasket AH1301010411 O-ring φ160×7 (GB3452.1) 530301011600070007...

Item Qty. Description Drawing No. AH130102050100 Fluid end Assembly AH1301010502 Cylinder head flange AH1301010503 Cylinder head AH130101050400 Plug assembly AH130101050500 Valve rod guide (lower) AH130101050600 Cylinder head plug AH1301010507 Locating plate AH1301010508 Cylinder head seal ring AH1301010509 Discharge manifold AH00000101 Valve spring 530301010950053007 O-ring φ95×5.3 (GB3452.1)

Instruction Manual for F1300/1600 Mud Pump Item Qty. Description Drawing No. AH130101052300 Shim set AH1001010527 Gasket 39 AH1001010510 Valve rod guide T500-7002 Stud bolt 1 1/2-8UNCX10 1/2 T501-2001 Nut 1 1/2-8UN AH1001010512 Retainer AH0501020509 Bolt 3/8-16UNCX3/4 530301010412035507 O-ring 41.2x3.55 (GB3452.1) T501-303.0 Piston nut 1 1/2-8UN 530301011850070007...

Instruction Manual for F1300/1600 Mud Pump Item Description Drawing No. Key 3/16×3/16×1 T516-2001 Oil pump gear assembly AH080102060100 90° elbow NPT1/4×NPT 3/8 T001-2204 Bolt A12(GB5650) 520902540320120100 Inner hexagon screw 5/16-18UNCX1 T500-3003 Connector A16 (JB/ZQ4410) 520901010350040040 Connector A8 (JB/ZQ4410) 520901010350050050 90° elbow NPT1/4×NPT1/4 T001-2203 Copper tube 051102010080010002...

Instruction Manual for F1300/1600 Mud Pump Item Description Drawing No. Washer A12 (GB5651) 520902551280120100 Bolt 1/4-20UNCX3/4 T500-1007 Oil jet AH1301010601 Copper tube Φ12×610 (GB1527) 051102010012010002 Copper tube Φ8×813 (GB1527) 051102010080010002 Connector A8 (GB5628.1) 520901010050050050 Pipe clamp-double Φ8 AH050102060200 051102010010010002 Copper tube Φ10×1956 (GB1527)...

Instruction Manual for F1300/1600 Mud Pump AH130102080100 Guard AH130102080300 Sheave AH1301010802 Support Assembly AH100102080200 Connector Z1″-G1″ AH1001010804 Connector Z1″ AH1001010805 Connector G1″-M33×2 AH1001010806 Connector ZG2-1/2″ AH1001010807 Connector ZG2 1/2″-Z2 1/2 AH1001010808 Hose Φ22×Φ37 140501010220100000 Hose connector Φ22×Φ37 AH100101080900 Elbow 90° Z1" AH1001010810 Connection plate AH1001020803...

Instruction Manual for F1300/1600 Mud Pump F-1300/1600 Suction Dampener Item No. Description Drawing No. Suction dampener assembly AH0000050100 Bladder AH0000050101 Cover AH0000050102...

Instruction Manual for F1300/1600 Mud Pump F-1300/1600 Discharge Strainer Assembly Item Description Part No. O-ring φ165×7 530301011650070007 Strainer Assembly AH100101190200 Housing AH1001011901 Stud M39×2-M39×3×135 T503-4007 Nut M39×3 T507-2011 Flange 5 1/8×35MPa T508-1002 Gasket ring R44 T508-5002 Discharge cross joint AH100101200300...

Instruction Manual for F1300/1600 Mud Pump Gasket T514-1001 Stud bolt 1 1/2X4 3/4 T500-6002 Nut 1 1/2-8UN T501-2001 Stud nut 1 1/4X4 1/4 T500-6003 Nut 1 1/4-8UN T500-2002 Pulsation Dampener Charging Hose Assembly Item Description Drawing No. Pulsation dampener charging AH100102130100 hose assembly Nut G5/8″...

JA-3 Shear Relief Valve A - A 19 20 Item No. Description Part No. JA-3 Shear relief valve AH0000060200 Joint AH0000060101 Retainer ring AH0000060102 Plunger assembly AH000006010300 Valve body AH0000060104 Plunger stem AH0000060105 Bumper AH0000060106 Roll pin AH0000060107 Locking spring AH0000060108 Guard AH0000060109...

Instruction Manual for F1300/1600 Mud Pump Screw M4×16 420101021104001600 Bolt T500-1016 3/8-16UNCX4 1/4 T501-1005 3/8-16UNC Screw M3×8 420101020703000800...

F-1300/1600 Spare Parts List Item Description Drawing No. Spare parts AH1301021100 Oil seal 9.125″×10.375″×0.625″ AH1301010311 O-ring Φ190×3.55(GB3452.1) 530301011900035000 O-ring Φ160×7(GB3452.1) 530301011600070007 Double lip oil seal 5″×6.25″×0.625″ AH1301010406 O-ring Φ95×5.3 (GB3452.1) 530301010950053007 Valve cover seal ring AH1301010510 Liner seal AH1301010512 Cylinder head seal AH1301010508 O-ring Φ200×7 (GB3452.1)...

Instruction Manual for F1300/1600 Mud Pump F-1300/1600 Tool List Item No. Description Drawing No. Attachment tools AH1301021000 Liner lifting tool AH130102100100 Cylinder head rod AH100101210100 Sleeve 2 3/8″ AH1001012108 Sleeve 2″ AH1001012109 Sleeve 3 5/8″ AH1301011602 Sleeve 1 1/2″ AH1301011603...

GDEP is the original creator of the drilling pump and continues to set the standard for durable, high-quality drilling pumps that can withstand the world’s toughest drilling environments. Starting with our PZ7 and rounding out with the market"s most popular pump, the PZ1600, our PZ Series of pumps are the perfect choice for today"s high-pressure drilling applications.

F series mud pump is applicable to the requirement of high pump pressure in oilfield and high displacement technology of well drilling with its solid and compact structure, small volume and outstanding operation performance.

F series mud pump has long stroke maintaining operation at lower frequency resulting in enhancing the performance of giving water effectively and prolonging the lifetime of the consumable hydroki-netic parts. The air-suction kit is advanced in structure and reliable at operation to reach the optimized absorbing target of air suction into linepipe.

F series pump powering side adopts the combined lubrication of forced and flashing lubrication featured with reliable lubrication and adding the operation lifetime of powering part.

This series pump is widely used in oil field and other lines of industrial and mining enterprises, operation of drilling well and well repairing etc. F-1300 mainly with the adapted drilling machine 32-45.

The series pump is produced strictly according to API Spec 7K “the Equipment Specification of Well Drilling and Repairing”, and performed the EX-Work test under the specification thereof.

In drilling oil and natural gas wells, it is used to pump drilling fluid mud to make it circulate and flow for impact. According to the importance of its

Kingwell Mud pumps are single horzontal triplex piston pumps, in the deep and ultra-deep wells, the drilling process cycle of drilling fluid, cleaning the bottom of the well to carry cuttings, cooling and lubricationg bits and reinforced sidewall, used in conjunction with high pressure water jet bit rock crusher help improve drilling speed; Meanwhile, can also provide a mobile drilling mud pit as a driving force.

Xi"an Kingwell Oilfield Machinery Co.,Ltdis a highly reputable supplier for oilfield equipment and services to Oil & Gas industries and provide complete solutions.

With over 10 years developing, we were developed from the beginning drilling service supplier to a manufacture who have own factory and specially produce Rig parts and accessories, API mud pump and spare parts, DST tools products.

We have experienced team, stronger enough to meet any challenge, we do believe honest is the base of business and cooperation; our aim is to build solid relationship with any part of honest. We can provide highly efficient services to each client resulting in accurate and timely deliveries at the best prices. We sincerely hope to make cooperation and mutual benefit wih any people who are in Oil & Gas industry.

Equipped with latest machining facilities. Our company could meet long term production target and be governed efficiently by well-qualified and experienced Board of Directors and Engineers.

We have a team of well qualified and experienced field support personnel for Training. According to customer"s requirements, we provide operation training service for our customers who cooperated with us.

We believe in Customer delight, achieved by the supply of Quality Products & Services and Continual Improvement in our Manufacturing Processes for timely delivery at competitive prices. We work in a professional, competitive, and cost-effective manner consistent with the Customer requirement

Any interest of above products or relative parts, PLS feel free contact back, and we will offer a good price and show you our best service upon received from you.

8613371530291

8613371530291