f1000 mud pump specifications manufacturer

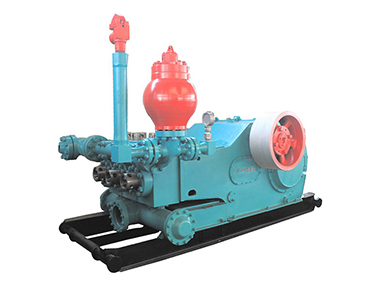

F 1000 mud pump for oil drilling have features of solid and compact structure, small volume, good and reliable performance. It can meet the drilling requirements such as high pressure and big displacements whether in land drilling or off-shore drilling.

F 1000 mud pumps have a longer stroke and can be operated at a lower stroke, thus improved the water supplying performance effectively and extended the lifetime of mud pump fluid end parts greatly.

A wide variety of emsco f1000 mud pump options are available to you, such as 1 year, not available.You can also choose from new, emsco f1000 mud pump,as well as from energy & mining, construction works , and machinery repair shops emsco f1000 mud pump, and whether emsco f1000 mud pump is 1.5 years, 6 months, or unavailable.

Mud pump is one of the most important equipments in the drilling operation which discharge high viscosity,heavy density and low sand contented fluid to well bottom in order to cool drill bit,flush well ,crush the rock and take out debris.

Mud pump is designed and manufactured in compliance with API Speck 7K"Specification for Drilling Equipment".All wearing parts of fluid end(valve,valve seat,liner and ect) can be interchanged acc to API specification.

Triplex pumps are positive-displacement reciprocating pumps that are configured with three plungers. They are the most common configuration of pump used in both drilling and well service operations. Triplex pumps used in well service activities generally are capable of handling a wide range of fluid types, including:

Triplex pumps are used in applications that require continuous pumping. For example, a triplex pump is a common component in large-capacity commercial car wash equipment. The plunger pump design of a triplex pump offers a reinforced seal and uses ceramic plungers for tight alignment and long life in high-pressure applications, such as oil well stimulation, surface preparation or rust removal, and gas turbine misting. Triplex pumps used in low-pressure applications also include a submersible liquid pump and an end-suction centrifugal pump. A submersible pump is typically constructed of stainless steel for corrosion resistance and can typically handle wastewater with suspended particles as large as 2 inches in diameter.

Triplex pumps are also suited to pump liquids other than fresh water or wastewater. They can be used to pump salt water in desalination applications, chemicals, and high vapor liquids like carbon dioxide. They can also be configured to pump mud in land-based or offshore oil drilling applications. A mud pump is a heavy-duty, high-pressure pump designed to provide a smooth discharge of mud and debris from oil wells. A triplex well pump can also be used as a well stimulation or servicing pump in oil fields and other industrial applications, such as cementing.

Industrial triplex pumps are used in public places that require a consistent water pressure with variable flow rates, such as hotels and office buildings, schools, hospitals, and in general industrial processes such as boosting the water supply for rural areas or municipalities or for irrigation. Because they are able to handle a wide range of fluid types, a triplex pump may also serve as a sump pump or in conjunction with other pumps to drain sump pits and wastewater storage lagoons.

8613371530291

8613371530291