f1000 mud pump specifications brands

Increase is a quality trading company of replacement parts for the wide variety of mud pumps, centrifugal pumps, rig parts, and swivel parts found on the World market today.

Over a 1,000,000 of interchangeable mud pump parts, centrifugal pump parts, rig parts and swivel parts in stock for all major manufactures such as: mud pump spares and the mud pump spare parts / mud pump replacement parts that we offer.

These parts include; mud pump liners, mud pump pistons, triplex single action pistons, piston rods and clamps, pony rods, threaded rings and caps, valve guides, liner packing cage assemblies, duplex pump spares and duplex mud pump parts, triplex pump spares and triplex mud pump , piston rods, gland brass and junk rings, full open valves and valve seats, web valves and web valve seats, stuffing box and gland nut, and mud pump gasket and mud pump rubbers.

4 in Intake, 4 in Discharge, Triplex Mud Pump, Cat 3508 8 Cylinder 671 kW Diesel Engine, Seller statement: Cat 3508 Electronic, 1,200 RPM (14,700 hrs. approx.). National C-300 Torque Converters, Belt Driven w/ Pillow Block Bearing Setup, Hydril 5K PSI Pulsa-tion Dampner, Oteco 0-5,000 psi Gauges, Liner Flushing Pumps, Belt Drive Assembly (Includes Drive Sheave, Bull Sheave, Hubs, Lay Shaft, Bearing Housings, Bearings, Seals, Air Clutch, Clutch Drum, Clutch Support, Drive Belts, Belt Guard). 5,000 psi Discharge Strainer Cross, 3 in x 5,000 psi Shear Relief Valve, Pinion Driven 5x6 Charging Pump, Pinion Driven Liner Wash System w/ 1 in x 1-1/2 in Pump, Air Volume Tank, Diesel Day Tank, Fluid End Expendables, All above mounted on 4-Runner Master Skid, Sandblasted, Primed, and Painted to customers color specs. Bear-ing reports upon request. Pumps will be tested prior to shipment. Skid measurements 31" L x 10" 2" W x 9" 5" H

Triplex pumps are positive-displacement reciprocating pumps that are configured with three plungers. They are the most common configuration of pump used in both drilling and well service operations. Triplex pumps used in well service activities generally are capable of handling a wide range of fluid types, including:

Triplex pumps are used in applications that require continuous pumping. For example, a triplex pump is a common component in large-capacity commercial car wash equipment. The plunger pump design of a triplex pump offers a reinforced seal and uses ceramic plungers for tight alignment and long life in high-pressure applications, such as oil well stimulation, surface preparation or rust removal, and gas turbine misting. Triplex pumps used in low-pressure applications also include a submersible liquid pump and an end-suction centrifugal pump. A submersible pump is typically constructed of stainless steel for corrosion resistance and can typically handle wastewater with suspended particles as large as 2 inches in diameter.

Triplex pumps are also suited to pump liquids other than fresh water or wastewater. They can be used to pump salt water in desalination applications, chemicals, and high vapor liquids like carbon dioxide. They can also be configured to pump mud in land-based or offshore oil drilling applications. A mud pump is a heavy-duty, high-pressure pump designed to provide a smooth discharge of mud and debris from oil wells. A triplex well pump can also be used as a well stimulation or servicing pump in oil fields and other industrial applications, such as cementing.

Industrial triplex pumps are used in public places that require a consistent water pressure with variable flow rates, such as hotels and office buildings, schools, hospitals, and in general industrial processes such as boosting the water supply for rural areas or municipalities or for irrigation. Because they are able to handle a wide range of fluid types, a triplex pump may also serve as a sump pump or in conjunction with other pumps to drain sump pits and wastewater storage lagoons.

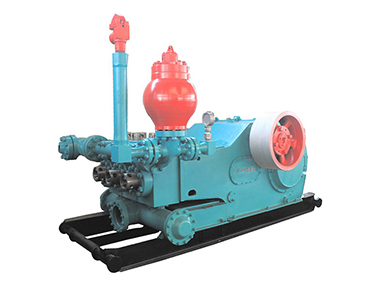

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi or 52,000 kPa) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling and manufactured according to API specification 7K.

The advantages of the drilling mud pump include the ability to move high-solids-content fluids laden with abrasives, the ability to pump large particles, ease of operation and maintenance, reliability, and the ability to operate over a wide range of pressures and flow rates by changing the diameter of pump liners and pistons.

As an important equipment for oilfield drilling operation, a drilling mud pump delivers circulating high-pressure drilling fluid or drilling mud to the bottom of the oil well, flushes the bottom of the well, breaks the rock, cools, lubricates and clean the drill bit, and carries the cuttings back to the ground.

The drilling mud is also used to suspend and carry out drill cuttings from the drill bits as it is brought in and out of the hole. This ensures that the drill bit does not clog and overheat, and makes the entire drilling operation smooth and safe.

Rotational power is supplied to the mud pump through an external power source like a diesel engine or electric motor. The power end of the mud pump converts the rotational energy through a crankshaft to a reciprocating motion of pistons.

The pistons move back and forth in mud pump liners, exerting a force on the cylinder chamber. During the retraction of the piston, valves open to allow the fluid to be drawn into the cylinder. Once the piston has fully retracted, it is pushed back into the cylinder.

Mud pump is one of the most important equipments in the drilling operation which discharge high viscosity,heavy density and low sand contented fluid to well bottom in order to cool drill bit,flush well ,crush the rock and take out debris.

Mud pump is designed and manufactured in compliance with API Speck 7K"Specification for Drilling Equipment".All wearing parts of fluid end(valve,valve seat,liner and ect) can be interchanged acc to API specification.

8613371530291

8613371530291