f1600 mud pump crosshead factory

1,.Crosshead is the significant parts of the power end system for drilling mud pump, the pump transmit power to the fluid end system through the cross head assembly.

The hydraulic cylinder, cylinder liner, piston, valve body, valve seat, valve spring, seal, valve cover, cylinder head of F1300 and F1600 are interchangeable

With the introduction of American Emsco technology, GEPEC could service the customer with six specifications pumps from 500 to 2200HP, and two pressure rating from 35 to 52MPa. F-1300 and F-1600 drilling pumps become the best choice for the middle...

Tiger produces a series of API7K-compliant mud pumps ranging from F-500 to F-2200. F-2200 is a tri-cylinder, single-action, heavy-duty, high-pressure drilling pump with a maximum power of 2,200HP, maximum working pressure of 52MPa, and maximum displacement of 77.65L/s.

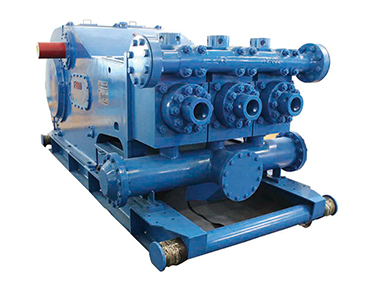

F-1300, F-1600, F-1300L and F-1600 mud pumps have a Max. Pump pressure of 34.5MPa (5000Psi) and a displacement of 46.5L/S with a liner of Φ180mm. These two models are the first choice for medium and deep drilling rig as an assorted component.

F-1600,F-2200 mud pumps with high-power and high-pressure are developed to meet drilling requirements of offshore deep-water, terrestrial and horizontal wells, especially in desert areas.

You won"t find anywhere else for the best rig expect us in china.We are professional drilling rig manufacturer, we produce world-class drilling rig such as ZJ30,ZJ40,ZJ50,ZJ70,ZJ90 and rig parts:Mud pump,Hook,Rotary Table,Swivel,Crown block,Travelling Block,iron roughneck….

If you are supplying pump supplies, you can find the most favorable prices at Alibaba.com. Whether you will be working with piston type or diaphragm type systems, reciprocating or centrifugal, Alibaba.com has everything you need. You can also shop for different sizes bomco f1600 mud pump wholesale for your metering applications. If you operate a construction site, then you could need to find some concrete pump solutions that you can find at affordable rates at Alibaba.com. Visit the platform and browse through the collection of submersible and inline pump system, among other replaceable models.

A bomco f1600 mud pump comes in different makes and sizes, and you buy the tool depending on the application. The pump used by a filling station is not the one you use to fill up your tanks. There are high flow rate low pressure systems used to transfer fluids axially. On the other hand, you can go with radial ones dealing with a low flow rate and high-pressure fluid. The mixed flow pump variety combines radial and axial transfer mechanisms and works with medium flow and pressure fluids. Depending on what it will be pumping, you can then choose the bomco f1600 mud pump of choice from the collection at Alibaba.com.

Alibaba.com has been an excellent wholesale supplier of bomco f1600 mud pump for years. The supply consists of a vast number of brands to choose from, comes in different sizes, operations, and power sources. You can get a pump for residential and large commercial applications from the collection. Whether you want a water pump for your home, or run a repair and maintenance business, and need a supply of bom co f1600, mud pump, you can find the product you want from the vast collection at Alibaba.com.therther it is for refrigeration, air conditioning, transfer, or a simple car wash business, anything you want, Alibcom. it has easy to find the right youco for your00.

F 1600 mud pump for oil drilling have features of solid and compact structure, small volume, good and reliable performance. It can meet the drilling requirements such as high pressure and big displacements whether in land drilling or off-shore drilling.

F 1600 mud pumps have a longer stroke and can be operated at a lower stroke, thus improved the water supplying performance effectively and extended the lifetime of mud pump fluid end parts greatly.

Application: When the pump is in working process, the excircle of the crosshead will move up and down in the slide. In order to ensure good working condition of the pump, our company strictly follows the shape and position tolerances requirements of the excircle and tapered bore. And the crosshead and extension rod is connected with flange bolting.

We can also provide mud pump parts ,include mud pump liner ,mud pump ceramic liner,mud pump bimetal liner ,mud pump piston,mud pump piston assembly ,mud pump piston rod ,mud pump valve assembly ,mud pump valve,mud pump valve body and valve seat,mud pump valve rubber,,valve and seats,Plug Board Assembly,Clamp Assembly,Cylinder Head Plug,Cylinder Liner Gland ,Low guide,Oil Seal Ring,Wear Plate,Shear Safety Valve,Hoisting Device,Piston Rod,Pulsation Dampener Assembly,Steel Ring,Hydraulic Cylinder

The Triplex Single Acting Mud pump is machined as per the designs provided by LTV Co on Emsco F Series pump with all fluid end parts interchangeable to that being machined by Emsco OEM plants.

Crosshead and Extension Rod are made of ASTM A48-83 meehanite cast iron featured by good abrasion resistance and long service life. Upper and lower guides are used for F-800 and F-1000 mud pumps, so that the concentricity can be adjusted by adding shimes beneath the lower guide. F-500 mud pump is the cylindrical structure. The connection between the crosshead and the extension rod is made by using bolted flange. The rigid connection ensures the concentricity of the crosshead and the extension rod. The coupling is used for connecting the extension rod to the piston rod. The light-weight coupling enables the extension rod and the piston rod to connect to each other easily and reliably.

Cylinders are made of forged alloy steel, three cylinders of each pump are interchangeable. Valve-over-valve (through type cylinder)design reduces the cylinder volume and promote the volumetric efficiency. At customers"request, the cylinder surface may be nickel plated to improve the abrasion resistance. Dischange pulsation dampener, shear relief valve and discharge strainer are furnished at the outlet. F-500 pump suction inlet is fitted with 8"flange, F-500 pump suction inlet with 10"flange and F-1000 pump suction inlet with 12"flange.

The suction valve and the dischange valve for above three mud pumps are interchangeable. F-500 mud pump uses API#5 valve pot, F-800 and F-1000 mud pumps use API#6 valve pots.

Notes: Cylinders, liners, pistons, valves, valve seats, valve springs, seal rings, valve covers and cylinder covers at the fluid end of F-800 and F-1000 mud pumps are all interchangeable.

The spraying system consists mainly of spray pump, cooling water box, and spray pipe, the function is to cool and rinse liners and pistons to promote their service life.

The power end uses the combined lubricating system of forced lubrication ad splash lubrication. The pressure oil is conveyed through lubricating pipeline, crosshead, extension rod, crosshead guide and all bearings by a gear oil pump within the oil box to realize the forced lubrication. The working condition of the gear oil pump may be understood from the pressure gauge behind the frame.

To prevent the air lock occurring for low pump inlet pressure, every mud pump is furnished with a complete charging system. It consists of charging pump, pump base, butterfly valve and corresponding manifold. Mounted on the suction manifold of the mud pump, the charging pump is driven by the special purpose motor or the input shaft of the mud pump through V-belts to reduce the power consumption.

Designed and manufactured by Baoji Plant, F-1300 and F-1600 mud pumps can meet the requirements of the same manufacturing technique and quality level as those of F series mud pumps of LTV Co. They feature advanced structural design, reliable use, easy maintenance and compact occupied area. To reduce drilling workers" labour intensity and make the operation easy on site, liners are designed to be fitted into the frame from the frame top. A mini hoist with 500Kg lifting capacity is mounted on the frame for disassembling and changing liners.

Suction inlets of F-1300 and F-1600 mud pumps are fitted with 12"flanges, F-1300 and F-1600 mud pumps are fitted with API#7 valve pots. The suction valve and the discharge valve are interchangeable. Cylinders are made of forged alloy steel and nickel plated to improve their corrosion resistance. Three cylinders of each pump are interchangeable. Valve-over-valve (through type cylinder) design reduces the cyliner volume and promote the volumetric efficiency.

Notes: Cylinders, liners, pistons, valve and seats, valve springs, seal rings, valve covers and cylinder covers at the fluid end of F-1300 and F-1600 mud pumps are all interchangeable.

8613371530291

8613371530291