f1600 mud pump piston made in china

A wide variety of f1600 mud pump parts options are available to you, such as 1 year, not available and 2 years.You can also choose from new, f1600 mud pump parts,as well as from energy & mining, construction works , and machinery repair shops f1600 mud pump parts, and whether f1600 mud pump parts is 1.5 years, 6 months, or unavailable.

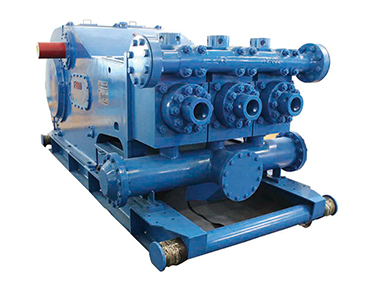

We mainly manufacturer emsco f-500, f-800, f-1000, f-1300, f-1600, gardner denver pz-9 and national 12-p-160 mud pumps. The quality products, competitive prices, respensive service and short delivery time earn a lot of reputation for us.

F series mud pump is applicable to the requirement of high pump pressure in oilfield and high displacement technology of well drilling with its solid and compact structure, small vallume and outstanding operation performance .It has long stroke maintaining operation at lower frequency resulting in enhancing the performance of giving water efficiency and prolonging the lifetime of the consumable hydrokinetic parts. The air-suction kit is advanced in structure and reliable at operation to reach the optimized absorbing target of air suction into linepipe.

F series pump powering side adopts the combined lubrication of forced and flashing lubrication featured with reliable lubrication and adding the operacation lifetime of powering part.

The series pump is producted strictly according to api spec 7k"the equipment specification of well drilling and repairing" , and performed the ex-work test under the specification thereof.

TENACITY produces a series of API 7K-compliant mud pumps ranging from F-500 to F-2200. F-2200 is atri-cylinder, single-action, heavy-duty, high-pressure drilling pump with amaximum power of 2,200HP, maximum working pressure of 52MPa, and maximum displacement of 77.65L/s.

F-1300, F-1600,F-1300L and F-1600 mud pumps have a Max Pump pressure of 34.5 MPa (5000Psi) and adisplacement of 46.5L/S with a liner of Φ180mm. These two models are the first choice for medium and deep drilling rig as an assortedcomponent.

F-1600, F-2200 mud pumps with high-power and high-pressure are developed to meet drilling requirements of offshore deep-water, terrestrial andhorizontal wells, especially in desert areas.

Our premium pistons are fully interchangeable with other API standard designedpistons and deliver maximum performance in almost all drilling conditions. Hightensile strength, resistance to chemicals, hydrocarbons, and abrasion, longService,and full interchangeability with other API designed pistons make our premiumpiston a sound value.

This one piece bonded constructed piston has no joints to leak. Eliminates abrasive fluids between piston and liner. The fluid expanded lip is not damaged by high pressure and fast pump strokes. This Fail-Safe piston seals off to greater diameter as liner wears.

Currently running in pumps using exotic muds and highest drilling pressures! Bonded construction - no joints, no leakage. Longer piston and liner life. This pistonwill run in higher-pressure, fast stroking pumps, and is resistant to oil basemuds and other additives currently being used. This Premium Piston has been inservice for years, providing unmatched performance under extreme drilling conditions. This one piece bonded unit provides the same series of advantages. being imprevious to oil and other chemicals

The piston rubber is made from specially formulated compounds which are resistant tothe effects of heat, oil and water. The multi-ply fabric reinforced backingsused in the production of the piston rubbers provide positive, wear resistantseals.

The structural features and properties of F series mud pumps are more advanced. Wearing parts of fluid end can be universally used with those of API standards.

F series mud pumps are firm and compact in structure and small in size, with good functional performances, which can adapt to drilling technological requirements such as oilfield high pump pressure and large displacement etc. The F series mud pumps can be maintained at lower stroke rate for their long stroke, which effectively improves the feeding water performance of mud pumps and prolongs the service life of the fluid end. The suction stabilizer, with advanced structure and reliable service, can achieve the best buffering effect. Power ends of the F series mud pumps adopt the reliable combination of forced lubrication and splash lubrication to increase the service life of power ends.

This series of pumps is manufactured strictly in accordance with API Spec 7K Drilling and Workover Equipment Specifications and carried out delivery test in accordance with the standard.

The Made-in-China F series mud pumps have same reliable quality and performance as other USA products. Now, F series mud pumps (from F-500 to F-2200) have been produced in batches and sold to many abroad oilfields. Your order for F series mud pumps is cordially welcome.

Huaxin"s export-orientated mud pump parts, including liners, pistons, piston inserts, valve inserts, oil seals, rod packing, fluid ends etc. All of them meet or exceed DIN and API standards and have been exported to U.K., Germany, USA, Canada, Pakistan, Middle East, and so on.

The mud pump piston assembly is one of the main parts of the hydraulic end system of the mud pump.The discharge pressure of the mud pump is generated by reciprocating linear motion of the piston assembly in the piston.Piston assembly by the piston core, rubber, spring, pressure plate, etc.

Our mud pump pistons are strictly manufactured according to API Standard, which with a high performance in various well drilling environment. The hub is forged from high quality steel, and the piston rubber is made from specially formulated compounds which are of heat, oil and water resistance. It is interchangeable with all other API standard designed pistons. And the valve rubber is easy to install.

The mud pump piston assembly is one of the main parts of the hydraulic end system of the mud pump.The discharge pressure of the mud pump is generated by reciprocating linear motion of the piston assembly in the piston.Piston assembly by the piston core, rubber, spring, pressure plate, etc.

Our mud pump pistons are strictly manufactured according to API Standard, which with a high performance in various well drilling environment. The hub is forged from high quality steel, and the piston rubber is made from specially formulated compounds which are of heat, oil and water resistance. It is interchangeable with all other API standard designed pistons. And the valve rubber is easy to install.

Hebel Xinhuafa Petroleum Machinery Co. LTD was established in 2006,with 5000m2 plant.The company focuses on R&D of mud pump fittings and several R&D results were horned with awards as well as patented for invention. The company is engaged in product design, manufacturing and service on all the quality oilfield replacement parts, including mud pump fluid end parts including Fluid end modules, liners, pistons, valves,&seats, extension rods, piston rods, valve covers etc.

Our products are certified by ISO9001 quality control. We supply products not only our oilfields company of domestic, but also dozens of countries all over the world, such as USA,Russia, Indonesia and Iran. With several years" persistence, we are widely accepted as a professional supplier of high quality mud pump cylinder liners and other parts in fluid end modules.

We are professional manufacturer and exporter of Mud Pump & Parts for 20 years. And we can supply you whole set on flat which suitable for oilfields in any worse environment outside. All are tested and can work well stable without monitoring. Parts also can be supplied to all pumps. All items are manufactured to API 7K quality standards.

Hebei Xinhuafa Petroleum Machinery Co.,Ltdfocuses on R&D of mud pump fittings and several R&D results were horned with awards as well as patented for invention. The company is engaged in product design, manufacturing and service on all the quality oilfield replacement parts, including mud pump fluid end parts including Fluid end modules, liners, pistons, valves,&seats, extension rods, piston rods, valve covers etc.

Hydraulic cylinder is forged of alloy steel. Three cylinders of one pump are interchangeable with each other. According to customers’ special requirements, to enhance the anti-corrosion performance, the surface of the hydraulic cylinder is supposed to be processed with chemical plating nickel. Pulsation dampener, shear relief valve and discharge strainer are separately mounted on the outlet.

This system is consisted of spray pump, cooling water tank and spray pipelines with the function of the necessary cooling and splashing to liners and pistons to prolong their lifetime.

The splashing pump is the centrifugal pump which can be driven by the belt mounted on the end of input shaft, or can be individually driven by a motor with water as the cooling and lubrication media.

The combination of forced lubrication and splashing lubrication is used for the power end. For the purpose of forced lubrication, the gear oil pump located at the oil tank feeds compressed oil to crossheads, extension rods and bearings respectively via the lubrication pipe lines. More ever, the operation situation of the gear oil pump can be observed by the manometer embedded in the after body of mud pumps.

The piston assembly is constituted by the piston core, rubber, spring, clamp, etc. Pistoncore is made of 42CrMo and the piston rubber is made of nitrile rubber or polyurethane rubber. The piston assembly is resistant to high temperature, abrasion, corrosion, and has a long service life, in line with API7K standards.

8613371530291

8613371530291