fmc mud pump parts free sample

We are the largest stocking dealer on the East Coast for FMC®. We have pumps and parts in stock for AO4, EO4, and IO4 Piston Pumps. We have access to the full FMC line. Give us a call and let us know what your looking for if we don"t have it we can have it direct shipped to you from the factory.

Exceptional design, workmanship, materials, and over 100 years experience building piston pumps are features you will find built into every FMC Technolgoies" pump. Some benefits and features of the A04 include:

Exceptional design, workmanship, materials, and over 100 years experience building piston pumps are features you’ll find built into every FMC Technologies" pump.

Whale Purging Pumps provide an easy-to-use, high-quality, economical solution for purging and well development to a depth of 90 ft (27 m). Its 1 7/16” (36 mm) diameter is ideal for use in 2” or larger monitoring wells.

1955 saw the birth of the AODD pump, invented by engineer Jim Wilden, founder of Wilden pump, in technical terms a reciprocating, positive-displacement pump, performed where existing pumps using other design principles would not.

The AODD pump is ideal where water or a particulate mixture needs to be moved in a hurry, and is driven by compressed air. Wilden pumps are versatile, and a single pump can deliver a wide range of flow rates and outlet pressure. Originally adopted by the construction and mining industries for pumping slurries, cement and mud, double-diaphragm pumps rapidly became popular in other sectors.

Simple to maintain and highly reliable in operation, Wilden air-operated double-diaphragm pumps are installed worldwide in a huge number of different applications. Ceramics, chemicals, oil & gas, paper and water treatment are only a few of the industries that rely on Wilden’s modern-day descendant of the original Wilden pump.

Wilden manufactures AODD pumps with either metal or plastic bodies to suit the needs of specific operating conditions. The ‘Original’ series of pumps feature clamped joints, very much in the mould of Jim Wilden’s classic design. ‘Advanced’ series pumps utilise bolted, flanged connections for additional joint integrity and security.

For nearly 50 years, versatile Moyno L-Frame pumps have stood the test of time meeting thousands of application challenges with performance-enhancing, cost-saving features.

Myers offers a broad line of residential water pumps to meet your needs. The Myers quality jet and submersible pumps provide a highly reliable source of water and pressure for today"s family living needs.

Gardner Denver"s line of duplex steam, air, or gas operated pumps have been used for decades in an assortment of pumping applications. From boiler feed to chemical transfer, these pumps have endured the test of time and stand as a testimony to Gardner Denver quality and reliability.

Established in the year 2004, TianyuMfg has been manufacturing high-quality well service pumps and parts for hydraulic fracturing and downhole drilling for over 16 years. We are supplying aftermarket frac pump parts and high-pressure flow irons of all major pump makers including Weir SPM, Gardner Denver, Halliburton, FMC, OPI. All our products are 100% interchangeable with these original makes and we are supplying them with the market-leading quality warranty.

FMC Technologies" reciprocating pumps are chosen for the most demanding applications due to their high quality, ease of service, pump longevity, and low cost of ownership. Extremely versatile, the FMC plunger pumps can be readily adapted for optimum performance within a wide range of markets and service conditions. All pumps have been carefully designed with oversized bearings and heavy-duty components to provide years of operational life.

The heavy-duty designs, engineering, reliable craftsmanship, component customization, and pumping experience have helped FMC Technologies" partners deliver value and performance on the global stage. Partners and customers continue to look at FMC Technologies" pumps first to provide them with real-life solutions for their real-life problems. FMC Technologies" commitment to detail continues to lead the industry for reciprocating plunger pump applications.

Before adding items to the cart, please confirm the pump configuration (left or right-hand drive) and drive type (shaft drive or hydraulic integral mount drive) as this may affect the parts used. Drive orientation may not be represented by the sample photos contained herein. Some parts have longer lead times, if not in stock.

They can be compressed with air, and compressed air. The pump is also multifunctional and can be used for many purposes, such as in pistonumatic pumps, electric mini pumps, and much more are designed for home use. They are also multifunctional and are suitable for many use.@@@@@

A piston pump is another type of electric fcc pumps. It has a one-stage piston pump, and the other is the electric fcc pumps. The piston pump is also centrifugal, and has good watering ability to avoid suction, and check the pressure of the pump.@@@@@

Controllingporter pumps are a great choice because they are more efficient than other pumps. They are designed for both pumping and checking the ambient temperature and the voltage of the water in different way. As a result, the controllingporter pumps are great because they are more efficient and don"t require the maintenance of their equipment, they can also be used in pumping applications.@@@@@

These f transfer pumps provide excellent leverage, and they don ’ t require much maintenance. If the pumps are properly used, they don"t need to manipulate the water and allow the pump to leverage forward and backward. In addition, the pumps can leverage forward and backward.

Permian Pump & Power stocks and sources OEM and aftermarket power end parts for most major power pump brands. If we don’t have the parts on the shelf, here in Odessa Texas, we can source them through other vendors in our vast network of suppliers nationwide.

PPP offers most used, rebuilt and new power end pump parts for sale, including main bearings, rod bearings, crankshafts, wrist pins, bushings, connecting rods and seals and gaskets.

FET manufactures a full range of valves and seats for every drilling and well-servicing application as part of our full line of Osprey® mud pump system solutions. All of our valves and seats can be used in water, water base, oil base and synthetic base mud applications. FET offers additional valves and seats not listed below, including drilling valves, frac valves and well service valves. FET’s QC standards for the dimensional and material specs are extremely rigid in comparison to other manufacturers. Contact your FET representative to learn more.

Centrifugal Pump, Monoblock (single Phase-3phase), Electric Pump, Domestic Pump, Submersible Single Phase -3phase Pumpsets, Sump Pumps, Drainage Pumps, Mud Pumps, Rainbow Brand Coupled Pumps, and DTH Boring Machine, Borewell and Openwell Submersible

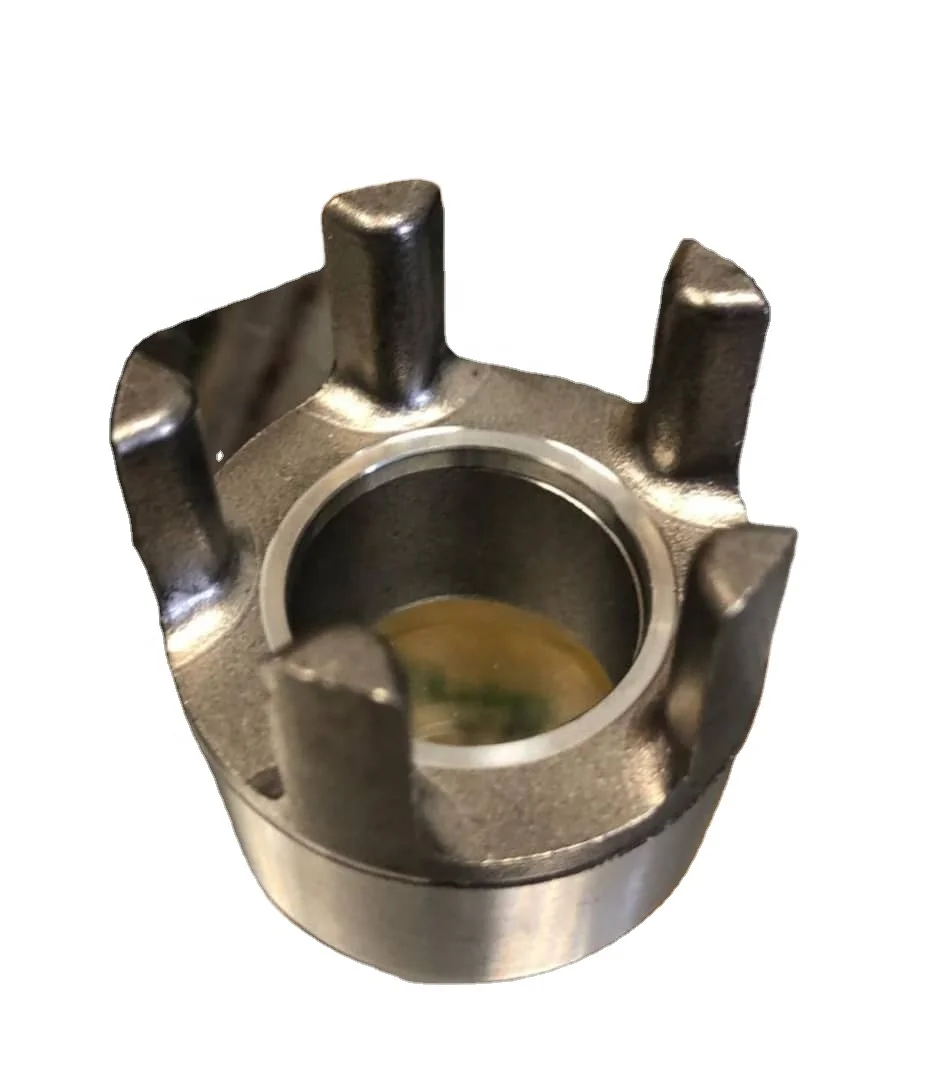

Hole Products offers a complete line of American Manufacturing and FMC Technologies® "Bean" piston pumps and interchangeable pump parts for use in a variety of mud pumping and drilling applications. All piston pumps are designed for continuous duty industrial applications and are capable of handling even the most abrasive drilling fluids. Piston pumps feature simple designs that incorporate less wearable parts and provide for ease of service. Piston pumps are available in duplex, triplex, and quadruplex configurations with a wide range of capacities and pressures. Pumps can incorporate ductile iron, aluminum bronze, and other materials as required. Please contact your Hole Products representative for specific pump performance details and ordering assistance.

Over time, breast pump parts experience wear and tear. This can affect your pump’s suction, potentially causing a decrease in milk production. Here’s how often you should replace your breast pump parts to avoid issues with your milk supply.

The frequency with which you’ll need to replace your pump parts depends on the piece as well as how often you pump. Below is a breakdown of how often each individual pump part should be replaced.

However, it’s a good idea to check with your breast pump manufacturer to confirm how frequently they suggest replacement, as this can differ between brands. (Specific recommendations for some of the popular breast pump manufacturers are included at the bottom of this post.)

(also called duckbills) are made of silicone, and they stretch and release each time the pump motor pulls at the valve, creating the suction necessary to remove breast milk from your breasts.

How often to replace duck valves: If you pump 3 or more times per day, replace duck valves every month. If you pump less than 3 times per day, replace every 2-3 months.

How often to replace valve membranes: If you pump 3 or more times per day, replace valve membranes every 2-4 weeks. If you pump less than 3 times per day, replace every 2 months.

How often to replace backflow protectors: If you pump 3 or more times per day, replace backflow protectors every 3 months. If you pump less than 3 times per day, replace every 6 months.

are also called flanges, and are the parts that attach to your breasts. (Note that you may need a different size than the one that comes with your pump. More info on how to find the correct size here.)

Sometimes residue builds up on these pump parts, especially in hard to reach spots on connectors. This buildup can reduce the effectiveness of the pump.

How tubing should be treated varies depending on the pump manufacturer. Spectra tubing, for example, should be replaced immediately if breast milk or moisture gets into the pump because it can damage the motor. Medela tubing can be washed if this happens.

How often to replace tubing: If tubing slides on and off easily when you’re not moving around, or when milk or moisture gets into the tubing of a closed system pump.

In their FAQ chatbot, Medela says that their new breast pump parts (shown below) should be replaced when damaged/as needed. They do not need to be replaced in a certain timeframe.

8613371530291

8613371530291