horizontal mud pump pricelist in stock

Explore a wide variety of mud pump price list on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These mud pump price list are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these mud pump price list is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right mud pump price list for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of mud pump price list to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

There are three types of mud pumps, depending on the type of client and the size they want. For general, mud pumps, there are three basic types of mud pumps, depending on the type of client and budget. The piston pump is another compressed mud pump, which is a pushed electric compressor mud pumps and by compressed air.@@@@@

Electric mud pumps are largely divided into three categories, among them the electric mud pumps and the semi-trash mud pumps. The piston inflated mud pumps are also classified in terms of the type of mud pumps, among them are electric mud pumps and semi-trash mud pumps. In addition, the piston inflates mud and mud pumps will be inflated by the piston, which is inflated mud pumps.

We provide a qualitative range of Mud Monoblock Pumps, which are immensely used in construction, agriculture, waste water management and many other industries

The crank gear and connecting rods drive a rotary movement that is transferred by the motor transmission. The pressure is produced by the piston in the cylinder due to which the mud is sucked. Following the operation, the suction valve is closed when it moves to left. As the pressure increase in the pipeline, the valve is forced to open and mud is released.

In accordance with the operating liquid displacer type being incorporated, the pumps are subdivided into piston units and plunger-type units. The liquid discharge uniformity is independent of head. The pumping plants are used actively for the processes with the liquids containing solid inclusions in high amounts. Incorporating the self-suction function in piston unit, the liquid is sucked and discharged twice in mud pumps during the single shaft turn, making themselves the double-action pumps whereas, the mud plunger pumps are single-action pumps where the liquid is sucked and discharged only once during a shaft turn.

The single direct-action three-piston pumps prove to be better than other types of drilling. These pumps demonstrate much more uniformity in mud delivery, lesser weight, and easy mounting when compared with two-cylinder units.

Depending on the number of cylinders, the pumping plants are classified into the following categories, single-cylinder, double-cylinder, three-cylinder and multi-cylinder pumping plants. These cylinders may be vertical or horizontal. Comparatively, the multi-cylinder pumping plants will cost higher but don’t feature any significant advantages other than the single-cylinder.

When drilling, there might occur the necessity of mud pumping out- and flushing-out, so there are various types of pumps available for such operations which are required to be installed on drilling rigs.

Sucker-rod pumps: In sucker-rod pumps, the pumpjack is a driver. This pump is installed at the bottom of the well. The reciprocating movements of the pumpjack are converted into liquid flow by the pump, which results in delivery of liquid on the surface. These pumps move oil with various admixtures demonstrating high level of capacity.

Screw pumps:The screw pumps are small-sized and are generally used to deliver mud into a centrifuge. These pumps have the rotor and stator as the major structural components and the material used to manufacture these components suit right for smooth pumping of liquids with solid inclusions and high level of viscosity. The pumped liquid flows with stable pressure, shaft slowly and the flow is free of vortexes. These pumps comparatively require minimum service.

Well pumps: These pumps are submerged into wells. The ground part of the plant is a transformer substation equipped for start and adjustment. The pump has a vertical structure, with a fixed cylinder and single-action. A plunger and valve are moving parts. The pumped liquid may contain water content of up to 99% at the temperature as high as 130ºC.

All the mud pumps have few general advantages that include the capability to process liquids and substances with high level of viscosity and with admixtures. Also, enabling the smooth flow of substances, free of pulsations or suspensions mixing are counted under the major advantages of incorporating mud pumps. The pumps have high suction power and small weight, easing out the transportation and installation at remote oil fields. They are highly reliable and also affordable.

There are various types of mud pumps available for different purposes. So, it is important to incorporate the right one for your purpose. A Professional help in getting the right mud pump would be a good and safe option.

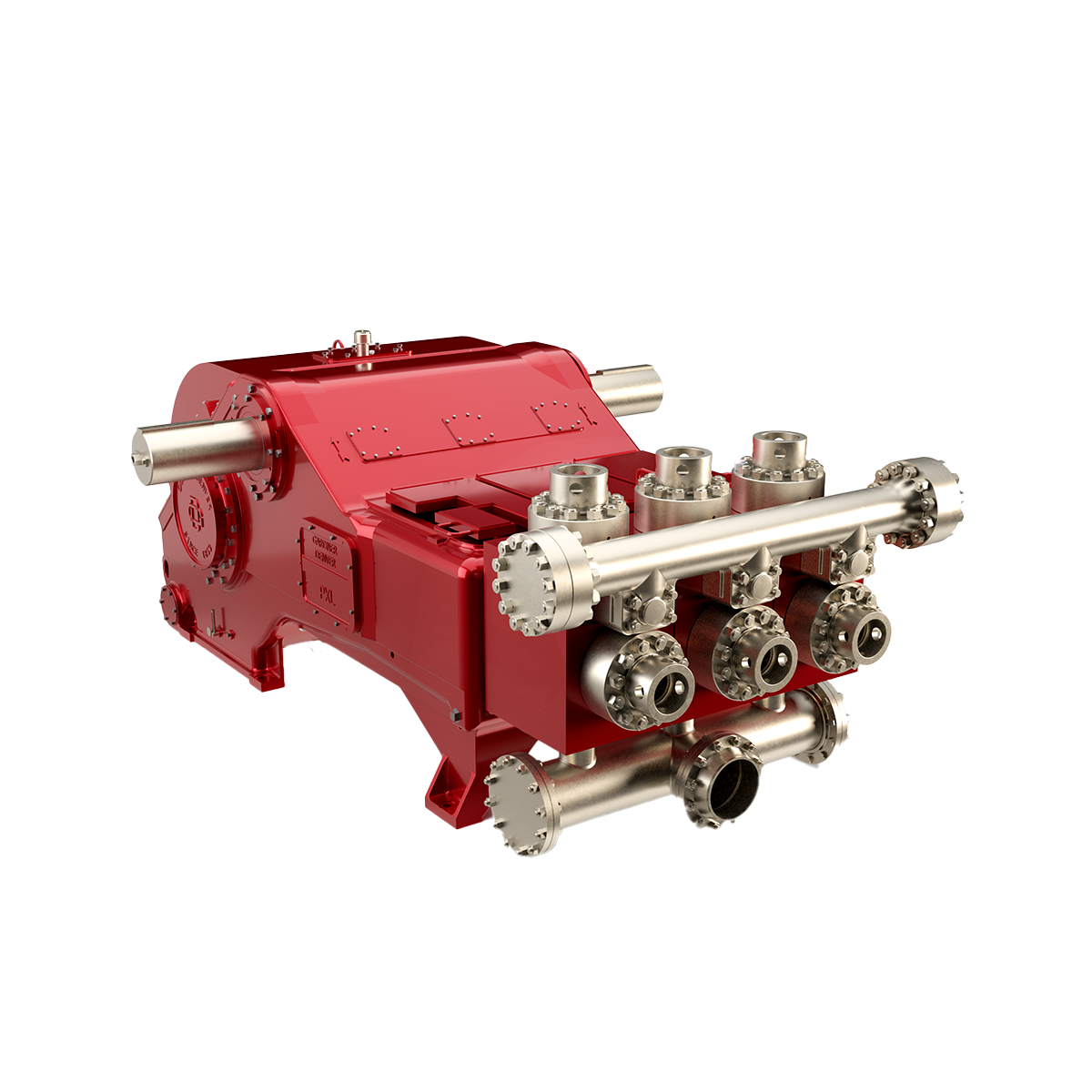

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

The PZ 2400 features a Y-shaped module design, meaning less stress is placed on the pumps internal components and higher flow rates can be achieved with improved fatigue life.

A mud pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi (52,000 kPa)) down the drill string and back up the annulus. A duplex mud pump is an important part of the equipment used for oil well drilling.

Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers. The advantages that Duplex mud pumps have over convention triplex pumps is a lower mud noise which assists with better Measurement while drilling and Logging while drilling decoding.

Use duplex mud pumps to make sure that the circulation of the mud being drilled or the supply of liquid reaches the bottom of the well from the mud cleaning system. Despite being older technology than the triplex mud pump, the duplex mud pumps can use either electricity or diesel, and maintenance is easy due to their binocular floating seals and safety valves.

A mud pump is composed of many parts including mud pump liner, mud pump piston, modules, hydraulic seat pullers, and other parts. Parts of a mud pump:housing itself

Duplex pumps are used to provide a secondary means of fuel transfer in the event of a failure of the primary pump. Each pump in a duplex set is sized to meet the full flow requirements of the system. Pump controllers can be set for any of the following common operating modes:Lead / Lag (Primary / Secondary): The lead (primary) pump is selected by the user and the lag (secondary pump operates when a failure of the primary pump is detected.

Alternating: Operates per Lead / Lag (Primary / Secondary) except that the operating pump and lead / lag status alternate on consecutive starts. A variation is to alternate the pumps based on the operating time (hour meter) of the lead pump.

Easy to install:- only the suction hose is immersed in the liquid, The pump can be set up high and dry in the most convenient position for inspection and maintenance.

The crank gear and connecting rods drive a rotary movement that is transferred by the motor transmission. The pressure is produced by the piston in the cylinder due to which the mud is sucked. Following the operation, the suction valve is closed when it moves to left. As the pressure increase in the pipeline, the valve is forced to open and mud is released.

In accordance with the operating liquid displacer type being incorporated, the pumps are subdivided into piston units and plunger-type units. The liquid discharge uniformity is independent of head. The pumping plants are used actively for the processes with the liquids containing solid inclusions in high amounts. Incorporating the self-suction function in piston unit, the liquid is sucked and discharged twice in mud pumps during the single shaft turn, making themselves the double-action pumps whereas, the mud plunger pumps are single-action pumps where the liquid is sucked and discharged only once during a shaft turn.

The single direct-action three-piston pumps prove to be better than other types of drilling. These pumps demonstrate much more uniformity in mud delivery, lesser weight, and easy mounting when compared with two-cylinder units.

Depending on the number of cylinders, the pumping plants are classified into the following categories, single-cylinder, double-cylinder, three-cylinder and multi-cylinder pumping plants. These cylinders may be vertical or horizontal. Comparatively, the multi-cylinder pumping plants will cost higher but don’t feature any significant advantages other than the single-cylinder.

When drilling, there might occur the necessity of mud pumping out- and flushing-out, so there are various types of pumps available for such operations which are required to be installed on drilling rigs.

Sucker-rod pumps: In sucker-rod pumps, the pumpjack is a driver. This pump is installed at the bottom of the well. The reciprocating movements of the pumpjack are converted into liquid flow by the pump, which results in delivery of liquid on the surface. These pumps move oil with various admixtures demonstrating high level of capacity.

Screw pumps:The screw pumps are small-sized and are generally used to deliver mud into a centrifuge. These pumps have the rotor and stator as the major structural components and the material used to manufacture these components suit right for smooth pumping of liquids with solid inclusions and high level of viscosity. The pumped liquid flows with stable pressure, shaft slowly and the flow is free of vortexes. These pumps comparatively require minimum service.

Well pumps: These pumps are submerged into wells. The ground part of the plant is a transformer substation equipped for start and adjustment. The pump has a vertical structure, with a fixed cylinder and single-action. A plunger and valve are moving parts. The pumped liquid may contain water content of up to 99% at the temperature as high as 130ºC.

All the mud pumps have few general advantages that include the capability to process liquids and substances with high level of viscosity and with admixtures. Also, enabling the smooth flow of substances, free of pulsations or suspensions mixing are counted under the major advantages of incorporating mud pumps. The pumps have high suction power and small weight, easing out the transportation and installation at remote oil fields. They are highly reliable and also affordable.

There are various types of mud pumps available for different purposes. So, it is important to incorporate the right one for your purpose. A Professional help in getting the right mud pump would be a good and safe option.

The rugged DAE Pumps Gulfport D540H drainage pumps move clean and dirty water with small solids up to .32-inches. These submersible drainage pumps with 4-inch discharge can move liquid at 310 GPM up to 135-feet via 8.5 horsepower. This 60Hz pump is available in 575-600V.

Offering the same high-quality, the DAE Pumps Gulfport D540S drainage pumps move clean and dirty water with small solids up to .32-inches. These durable drainage pumps with 4-inch discharge can move liquid at 310 GPM up to 135-feet via 8.5 horsepower. This 60Hz pump is available in 460V and 575-600V.

DAE Pumps Gulfport D640X drainage pumps handle clean and dirty water with small solids up to .32-inches. These rugged drainage pumps with 4-inch discharge can move liquid at 260 GPM up to 250-feet via 11.5 horsepower. This 60Hz pump is available in 575-600V.

DAE Pumps Gulfport D640H drainage pumps move clean and dirty water with small solids up to .32-inches. These reliable drainage pumps with 4-inch discharge can move liquid at 340 GPM up to 170-feet via 11.5 horsepower. This 60Hz pump is available in 575-600V.

The reliable DAE Pumps Gulfport D640S drainage pumps handle clean and dirty water with small solids up to .32-inches. These durable submersible pumps with 4-inch discharge can move liquid at 700 GPM up to 100-feet via 11.5 horsepower. This 60Hz pump is available in 460V and 575-600V.

The high-quality DAE Pumps Gulfport D740H drainage pumps move clean and dirty water with small solids up to .27-inches. These reliable drainage pumps with 4-inch discharge can move liquid at 300 GPM up to 254-feet via 15 horsepower. This 60Hz pump is available in 440-480V.

DAE Pumps Gulfport D840H drainage pumps process clean and dirty water with small solids up to .47-inches. These rugged submersible pumps with 4-inch discharge can move liquid at 760 GPM up to 240-feet via 31 horsepower. This 60Hz pump is available in 460V, 480V, and 575-600V.

DAE Pumps Gulfport D940H drainage pumps handle clean and dirty water with small solids up to .27-inches. The most powerful of our 4-inch drainage pumps come with a 4-inch discharge and move liquid at 560 GPM up to 325-feet via 36 horsepower. This 60Hz pump is available in 440-480V.

The high-performing DAE Pumps Sonora S540 Submersible Sludge Pumps handle thick, soft, wet mud and sludge with solids up to 2-inches. These heavy-duty submersible sludge pumps with 4-inch discharge can move material at 365 GPM up to 92-feet via 7 horsepower. This 60Hz pump is available in 230V and 460V options.

DAE Pumps Sonora S640 Submersible Sludge Pumps offer the ultimate performance in moving mud and sludge with solids up to 2-inches. With a 4-inch discharge, these sludge pumps transfer material at 420 GPM up to 100-feet via a 9.2 HP motor. This 60Hz pump is available in 230V and 460V options.

The rugged DAE Pumps Miramar L540 Submersible Slurry Pumps process abrasive materials with solids up to 1-inch. These durable slurry pumps with 4-inch discharge move material at 308 GPM up to 57-feet via a 7 HP motor. This 60Hz pump is available in 460V.

Offering the same high-quality, the DAE Pumps Miramar L640 Submersible Slurry Pumps move abrasive materials with solids up to 1-inch. With a 4-inch discharge, these heavy-duty slurry pumps process material at 440 GPM up to 75-feet via a 12 HP motor. This 60Hz pump is available in 460V.

The heavy-duty DAE Pumps Miramar L740 Submersible Slurry Pumps transfer abrasive materials with solids up to 1-inch. With a 4-inch discharge, the Miramar L740 slurry pumps move material at 616 GPM up to 85-feet via a 15 HP motor. This 60Hz pump is available in 460V.

DAE Pumps Miramar L840 Submersible Slurry Pumps move abrasive materials with solids up to 1-inch. With a 4-inch discharge, these reliable slurry pumps process material at 660 GPM up to 98-feet via a 20 HP motor. This 60Hz pump is available in 460V.

The high power 4-inch DAE Pumps Miramar L940 Submersible Slurry Pumps move abrasive materials with solids up to 1.5-inches. These 4-inch discharge submersible slurry pumps move liquids and solids at 880 GPM up to 171-feet via a 50 HP motor. This 60Hz pump is available in 460V.

DAE Pumps Tampa 437 Submersible Slurry Pumps are rugged, reliable, and cost-effective pumps for transporting slurry, sand, and a variety of other abrasive materials. The durable DAE Pumps Tampa 437 offers an open stand or strainer, and agitator provides improved suction and movement of solids up to 1-inch through a 4-inch discharge. The ergonomic Tampa 437 submersible slurry pumps transfer solids and liquids at a flow rate of up to 476 GPM and with 5 HP.

DAE Pumps 455-P Submersible Slurry Pumps are rugged, reliable, and cost-effective pumps for transporting slurry, sand, and a variety of other abrasive materials. The DAE Pumps 455-P with an open stand and agitator allows for ideal suction and movement of solids up to 1-inch with a 4-inch discharge. The ergonomic 455-P submersible slurry pumps transfer solids and liquids at a flow rate of up to 594 GPM and with 7.5 HP.

DAE Pumps Tampa 455 Submersible Slurry Pumps are rugged, reliable, and cost-effective pumps for transporting slurry, sand, and a variety of other abrasive materials. DAE Pumps Tampa 455 offers an open stand or strainer, and agitator that provides greater suction and movement of solids up to 1-inch through a 4-inch discharge. The ergonomic Tampa 455 submersible slurry pumps transfer solids and liquids at a flow rate of up to 594 GPM and with 7.5 HP.

DAE Pumps Tampa 4110 Submersible Slurry Pumps are rugged, reliable, and cost-effective pumps for transporting slurry, sand, and a variety of other abrasive materials. The efficient DAE Pumps Tampa 4110 offers an open stand or strainer, and agitator that provides enhanced suction and movement of solids up to 1-inch through a 4-inch discharge. The ergonomic Tampa 4110 submersible slurry pumps transfer solids and liquids at a flow rate of up to 819 GPM and with 15 HP.

The heavy-duty and reliable DAE Pumps Galveston 3304 Submersible Sludge and Slurry Pumps are the latest technology in submersible pumps for transporting slurry, sand, and a variety of other abrasive materials. DAE Pumps Galveston 3304 pumps with a combined strainer with a partially open stand and agitator allows for ideal suction and movement of solids up to 1.5-inches with a 4-inch discharge. The Galveston 3304 submersible slurry pumps transfer solids and liquids at a flow rate of up to 792 GPM and with 30 HP.

JBSP Series pumps take on the toughest applications of sewage water handing and get the job well done. Every component and parts are designed and manufactured to deliver highly efficient performance. Design of impeller is such that most solid objects entering the pump will pass through the impeller between the impeller vanes.

We are JB Pumps-The flow of Happiness manufacturer of Sewage Pumps in Ahmedabad, Gujarat. We have total in house manufacturing facilities. The JB pumps follow Make in India concept. We provide 24×7 after sales service.

Pump Power1HP TO 2HPWe are successfully ranked as the renowned Manufacturer, Trader, and Exporter of a wide collection of Pressure Pump, Sludge Pump, Multi Stage Pump, Booster System etc. We also provide Installation, Repairing, and Maintenance services for these products.

BBA Pumps is not just a manufacturer and supplier; our employees have a tremendous amount of pump knowledge which they would like to share with you. You can contact us in 7 different languagesfor:

8613371530291

8613371530291