how do you take apart mud pump for sale

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

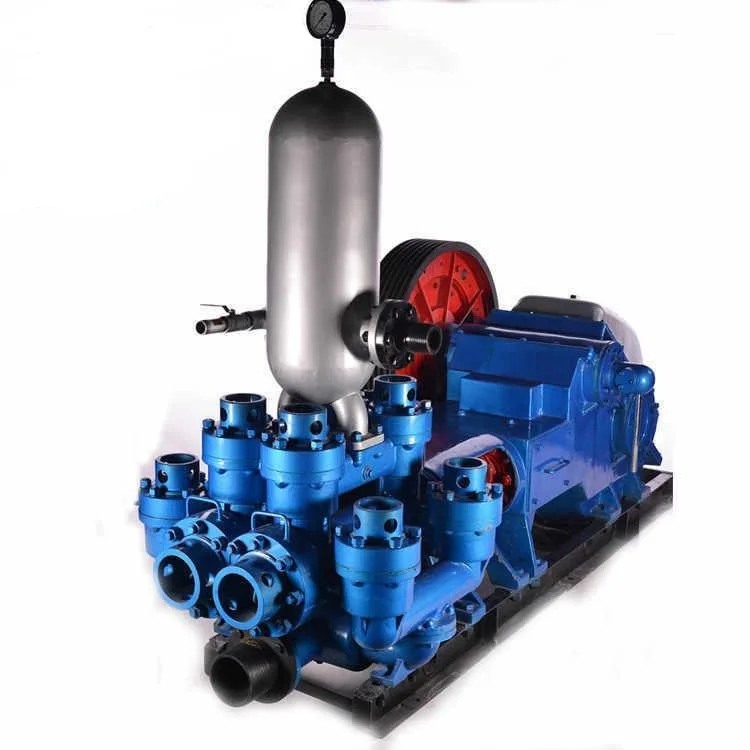

The positive displacement mud pump is a key component of the drilling process and its lifespan and reliability are critical to a successful operation.

The fluid end is the most easily damaged part of the mud pump. The pumping process occurs within the fluid end with valves, pistons, and liners. Because these components are high-wear items, many pumps are designed to allow quick replacement of these parts.

Due to the nature of its operation, pistons, liners, and valve assemblies will wear and are considered expendable components. There will be some corrosion and metallurgy imperfections, but the majority of pump failures can be traced back to poor maintenance, errors during the repair process, and pumping drilling fluid with excessive solids content.

A few signs include cut piston rubber, discoloration, pistons that are hard to remove, scored liners, valve and seat pitting or cracks, valve inserts severely worn, cracked, or completely missing, and even drilling fluids making their way to the power end of the pump.

The fluid end of a positive displacement triplex pump presents many opportunities for issues. The results of these issues in such a high-pressure system can mean expensive downtime on the pump itself and, possibly, the entire rig — not to mention the costly repair or replacement of the pump. To reduce severe vibration caused by the pumping process, many pumps incorporate both a suction and discharge pulsation dampener; these are connected to the suction and discharge manifolds of the fluid end. These dampeners reduce the cavitation effect on the entire pump which increases the life of everything within the pump.

Poor maintenance — such as improper valve and seat installation — is another factor. Improper cleaning when replacing a valve seat can leave sand or debris in the valve seat area; preventing the new seat from properly forming a seal with the fluid cylinder, causing a pathway for a washout to occur. It is important to pull up on a seat firmly by hand and make sure it doesn’t pop out and is properly seated. The seats must be seated well, before resuming repairs. You should never reuse a valve seat if at all possible.

The fluid end is the most easily damaged part of the mud pump. The pumping process occurs within the fluid end with valves, pistons, and liners. Because these components are high-wear items, many pumps are designed to allow quick replacement of these parts.

A washout occurs when fluid and solids enter the area behind or underneath a valve seat and erode the sealing surface. Washouts are usually caused by one of three issues: a worn or cracked valve seat, improper cleaning of the valve seat and deck which creates a poor seat seal, and excessive sand content in your drilling fluid. Worn or cracked valve seats can allow fluid to enter the area around the valve seat and seat deck, creating a wash point on the valve seat and causing it to cut into the fluid cylinder and seat deck.

Additionally, the throat (inside diameter) can begin to wash out from extended usage hours or rather quickly when the fluid solids content is excessive. When this happens it can cut all the way through the seat and into the fluid end module/seat deck. This causes excessive expense not only from a parts standpoint but also extended downtime for parts delivery and labor hours to remove and replace the fluid module. With that said, a properly operated and maintained mud recycling system is vital to not only the pump but everything the drilling fluid comes in contact with downstream.

If you spot a washout on any of the fluid end parts, you need to replace the part immediately. A washout can get much worse very quickly, leading to costly repairs.

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

When it comes to the process of Mud pump repair, our expertise is second to none. Unlike smaller machine shops, We are pump repair specialists with expertise in repairing and rebuilding Mud pumps. We offer several level of rebuild options in order to make your Mud pump repair is as efficient and as economical as possible. We can manufacture many of the required components in-house for a Mud pump repair and or Mud pump rebuild as well.

You can trust the knowledge and expertise of your Mud pump repair in our hands. We have decades of qualified experience in the troubleshooting of your Mud pump repair, view our

We know the ins and outs of what made the Mud gearbox to fail, from the erosion that happens, to wear and tear of seals, it’s a common thing. That’s why trusting your Mud pump repair in our shop can only bring life to your Mud.

It’s not uncommon for other machine shops just trying to figure it out. Not here. We don’t have to figure out what happened to your Mud pump, again we have years and years of experience with Mud pumps and the Mud pump repair process. Although sometimes the Mud pump rebuild is a little bit different, we can ensure you that your Mud pump will be restored. It’s not uncommon for the Mud pump repair to suddenly turn into a process of rebuilding the Mud pump due to a further analysis of the breakdown in our shop.

We don’t take a first option of a rebuild due to it’s expense, because sometimes that can become a re-manufacturing process especially if the pump is very aged, but in the end, if a rebuild is needed for any type of re-manufacturing needs, you can count on MER to get the job done, that’s why we have a full facility dedicated to re-manufacturing these types of equipment to ensure the proper repair of your Mud pump. Nevertheless, we will let you know in what category it falls in before we even start the process of the Mud pump repair or the Mud pump rebuild.

Automatic Taping Tools are more powerful and efficient than traditional hand tools. Whether you"re a drywall professional, remodeler, or DIY, automatic taping tools achieve better results in half the time. Drywall Loading Pumps (mud pumps) are compound pumps that use Gooseneck and Box Fillers Adaptors to fill drywall taping and finishing tools. All-Wall offers the largest selection of Loading Pumps from top brands such as TapeTech, Columbia, Asgard, Graco, and Drywall Master.

Mud pumps are large reciprocating pumps that are used to move heavy drilling fluid within the hole during oil drilling. The pump works by circulating the mud; it pushes the fluid down into the hole and then moves it back up again. Being reciprocating by design, they use plungers or oscillating pistons in order to displace the drilling fluid. Mud pumps are single acting pumps, which means that the fluid moves only in one direction.

The mud pump them pushes the mud down the piping and into the bottom of the well, and the pressure forces the mud up the space surrounding the piping (called the annulus). During oil and gas explorations, the mud used consists of clay, emulsified oil or water, and chemicals. It’s tailor-made for the particular conditions of the drilling for safety reasons. The purpose of this mud is to float clean the bottom of the well by floating out rock cuttings. It also cools the drilling equipment and functions as a barrier should there be a blowout.

Mud pumps, such as a Gardner Denver PZ 11, are crucial equipment for drilling oil. As drills cut through rocks, mud pumps move cuttings up the hole. These rock cuttings are then put through shakers that remove them from the drilling fluid or mud, which is them reused by the mud pumps. The process continues until the hole is drilled to the full depth. Modern mud pumps are typically triplex-style with three cylinders. Duplex pumps are still used sometimes in older oil rigs. Some of the newest mud pumps have six cylinders.

If you need a mud pump for sale, don’t hesitate to contact Henderson where we specialize in the procurement and brokerage of capital drilling equipment. Known for the transparency of their procurement process, if we don’t have what you need in stock we can recommend alternative sourcing options to help you cut costs as well as increase efficiency.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

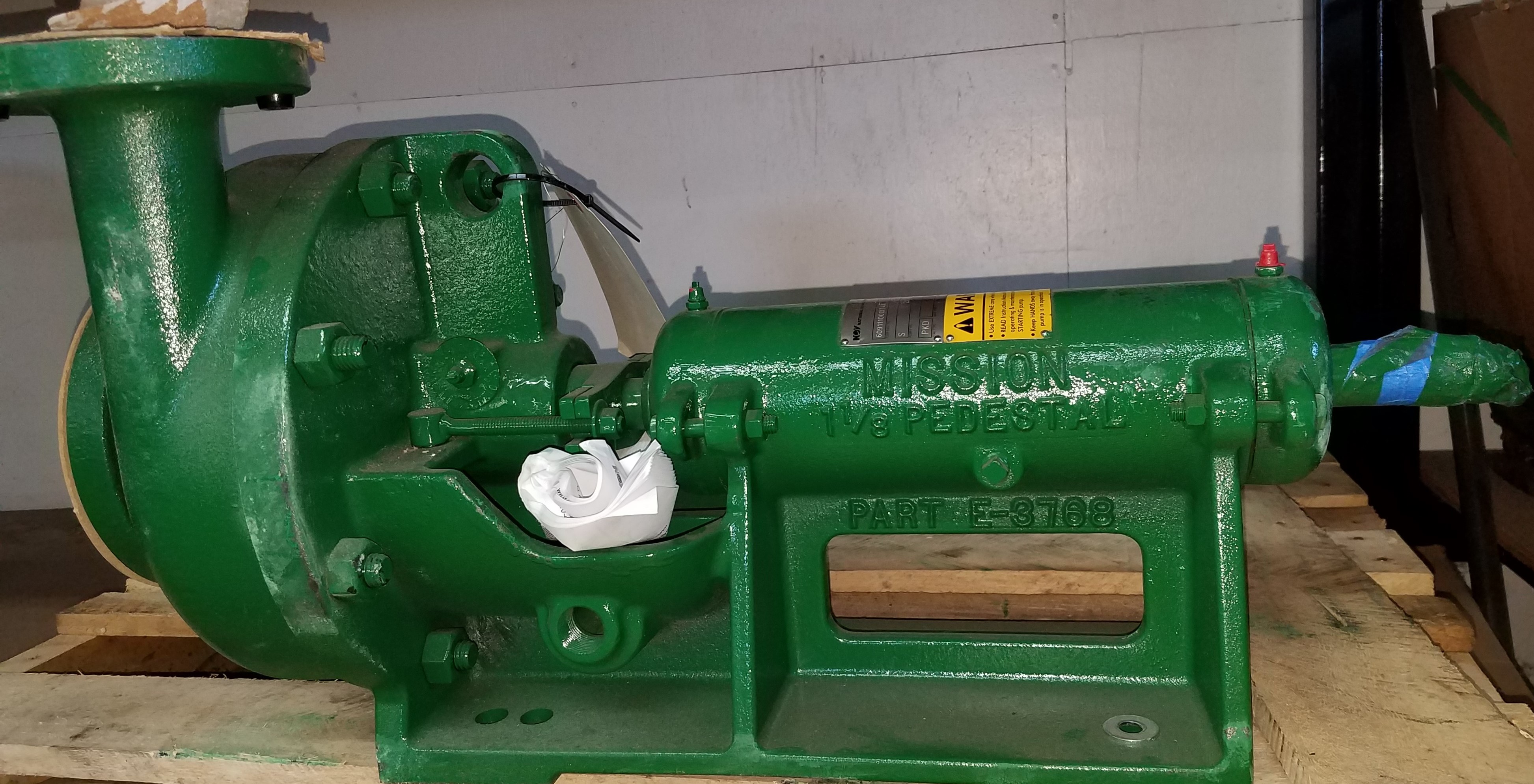

(2) Pumps - Triplex W/ Forged Steel Fluid End & Quick Change Caps, 5M Pulsation Dampner, Oteco 3" Shear Relief Valve, Pressure Gauge, Mission 6 X 5 Charge Pump P/B Cat C-18 Diesel Engine, Allison CLT6061 Transmission, Fitted W/ 7" Liners, & Pistons, Master Skidded, (1) Pump No Power or Transmission. Good Condition.

All New Parts In Both Gear & Fluid End, Pump Will Have New Style Gear End, Primered & Painted Buyers Choice, Hyd. Gearbox Available. Rebuilt Condition.

Along with our complete pump packaging capabilities, Forum can perform complete module repair for both triplex and duplex fluid ends. Our fully trained repair team also provide gear end repair for pumps in all oilfield applications.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

You can find our high-performance mud pumps at some of the largest oil and natural gas drilling operations on the planet. Now, we’re ready to supply one of our mud pumps to you.

Looking for a mud pump for sale? Bridges Equipment has the biggest inventory of rebuilt duplex and triplex mud pumps and pump packages ready to ship. Unlike some suppliers, we completely rebuild our mud pumps to OEM standards and guarantee our work from 90 days up to six months against major failure.

Our fabrication facility customizes mud pumps, equipment, and pump packages to meet the needs of operations large and small, across the nation and around the world. Whether you need a custom-fabricated mud pit or a unitized pump package, we have the expertise to get it done.

Nothing wastes time and money like waiting on parts. With two supply stores stocked with the fluid ends and other mud pump parts you need to keep your operation running, and the field mechanics to install them, we can help keep your operation up and running.

Customizability. Functionality. Quality. Reliability. You’ll find these attributes and more in every mud pump, mud pump part or mud pump package we have available for sale or rental.

Our pump stroke counter systems (CPS101 Series) measure the stroke rate and number of strokes on mud pumps. The oilfield pump stroke system is user-friendly and reliable and is configurable to measure up to three mud pumps at once. Our digital pump stroke counter systems are manufactured here in the U.S. by Crown Oilfield Instrumentation, and Crown’s Pump Stroke Counter provides easy monitoring of strokes per minute on multiple mud pumps. Each mud pumps’s stroke rate can be selected individually and the display is updated regularly for accurate monitoring. LCD displays indicate both pumps strokes per minute and the total number of strokes. Located at the bottom of the panel, push buttons provide easy operation and reseting of each pump. When you need to accurately monitor and maintain the amount of mud being pumped, you can trust Crown’s oilfield stroke counters.

You’re researching foundation repair options and have come across the term “mud-pumping” and you want to know what it means. Or maybe you are thinking about when a foundation is lifted, what happens with the space underneath your home? There’s a void there now and does it get filled in or what?

Mud-pumping is a finishing step of foundation repair, but not every foundation repair contractor adds this final step. It’s not automatically done so you might be wondering why some companies would use this technique or what its advantages and disadvantages are.

At Anchor Foundation Repair, we have been repairing foundations since 1985 and began adding mud-pumping to all slab-on-grade foundation repairs in 1998. We decided to take every reasonable step to provide the most security and stability in foundation repairs to Brazos Valley homeowners and bought our first hydraulic mud pump at that time.

We know mud-pumping has great value and importance in a foundation repair project, it’s a standard part of our slab foundation repairs. But we can tell you about it in an objective way so that you can decide if it’s as important to you as it is to us.

We know that not everyone is trying to meet the same goals in selecting a foundation repair method or provider. We just want to give you all the information and options so that you can choose what works best for you and your home.

This initial compression causes the home to sink into the ground a bit. This is called settlement, and it’s not a bad thing unless it causesfoundation problemsfor your home.

Settlement can also occur because of the expansive clay soil we have in this area. Expansive clay expands when wet and contracts when dry. The drier the soil gets, the more it can contract, also causing a home to sink. It might not all sink evenly. This is how slab foundations can crack and possibly need repair.

Now, you could just scream into the void underneath your home. But more productively, you can consider filling it with mud-pumping material so that there is not a bunch of empty space between the bottom of your home and the earth. Mud-pumping helps lessen the opportunity for more foundation settlement or problems to arise.

Mud-pumping is not typically needed for pier and beam foundations, but for slab-on-grade foundation repair, it is an option. While mud-pumping is not *required* in foundation repair, it has many benefits for the homeowner.

So no, mud-pumping is not necessary to complete a foundation repair project, and manyfoundation repair companiesdon’t do it. Even though foundation repair contractors often skip this final step, you may want to seriously consider it. All the “whys” are in the next section.

Nature doesn’t like empty things, nature wants to fill them up. This is that “nature abhors a vacuum” thing. If the void under your home doesn’t get filled with mud-pumping material. It will very likely get filled with something else, like:

PRO #1: So one of the pros of filling voids with mud-pumping is that it takes up that empty space and prevents those areas from getting filled with something less desirable. The slurry material flows and fills every little space, permeating even the smallest pockets of air. But there are a couple more compelling reasons for you too . . .

PRO #2: Empty space creates weaker points and added stress to the foundation where it is not directly supported. Mud-pumping provides extra stability and holding power to your foundation without empty spaces under it. Having something solid underneath your whole slab is more supportive than drilled piers or pressed piles alone.

PRO #3: Mud-pumping the voids under your foundation also minimizes the risk of further movement and settling. When things are all snug and surrounded by other material, it’s less likely for them to wiggle and move around. It’s kinda like tucking your kid in at night. You burrito that little one in good with the hopes that they will stop moving and fall asleep, right?

Side Effect Bonus PRO #4: The step before mud-pumping is testing your under-slab plumbing to make sure there are no leaks. If leaks are found, they need to be fixed first. So if mud-pumping is used on your foundation repair, you will have the added comfort of knowing that there are no leaks or that they have been repaired. This is another way to make sure that further problems don’t come up later for your foundation or underneath it.

Like anything else, there are a few cons to mud-pumping as part of your foundation repair. Even though we are a fan of mud-pumping, it does have some risks and downsides that we want you to be aware of.

CON #1: Mud-pumping costs more. This is an additional step that takes added time and more materials, SO there will be extra cost to you. Mud-pumping adds between $2,000 and $4,000 to the price of your average-sized foundation repair.

CON #2 (minor): There is a small risk of over-pumping the mud and adding too much material under the home. This can cause a hump in your floor. But with an experienced team working on your foundation repair project, this has a low chance of happening. Just want you to know this is a potential problem that could happen with an inexperienced or less careful contractor.

CON #3: Just like that kid that you tucked into bed with a burrito blanket, there’s no guarantee that no more movement will take place. Mud-pumping is a safeguard, an insurance policy, a risk minimizer, but it’s not an absolute settlement solution with no potential for failure.

Like many forms of insurance or safeguards, you don’t really know if you’re going to need it or not. You might only know the value of mud-pumping afterward in hindsight since we can’t predict what will happen later with your home.

As mentioned, mud-pumping is a final step in a foundation repair project, but it has a few steps of its own to complete the process. Here’s a breakdown of how it works:Raise the foundation and secure it in place with shims

The mud-pumping process takes about half a day or small projects and several delays for larger jobs at the end of a foundation repair project. So it doesn’t add a lot of time to the job but it can add some peace of mind.

What’s the worst-case scenario if you don’t do mud-pumping? Well, you could spend thousands of dollars on a foundation repair only to have it settle all over again due to missing that final step and leaving voids under your foundation.

On the flip side, your home can still settle no matter what you do (or it might not, there’s no way to know for sure) but the risk is minimized as much as humanly possible if you add mud-pumping to the repair. This seems like a tricky decision, so let’s try and make it a little easier with some “if-then” statements.If you love your home and plan to be in it for the long haul and want the very best, get the mud-pumping.

If you are selling your home and won’t be living in it any longer, then you’re not worried about the longevity of the repair and could skip the mud-pumping.

Here’s one more “if-then” statement for you: if you want to use Anchor Foundation Repair for your slab-on-grade foundation repair project, then mud-pumping is part of the deal. We don’t leave repair projects without the last step because we also have a lifetime warranty and service agreement.

At Anchor Foundation Repair, we have seen firsthand the consequences of not filling voids after repairs in our 35 years in business. We have inspected and repaired dozens of homes that had previous foundation repairs (by other companies) without mud-pumping. We have felt the hollow-sounding floors and seen homeowners having to go through the repair process again to get it right the second time.

To get it right the first time, Anchor employs more than one “risk-minimizing” tactic to provide the longest-lasting foundation repair possible. Check out our article highlighting4 service features that set us apartfrom other foundation repair contractors.

Manufactured to withstand the toughest drilling and environmental conditions, our K-Series triplex mud pumps are ideal for all drilling applications. This legacy product features a balanced forged-steel crankshaft and Southwest Oilfield Products ‘L” Shaped modules which is essential to minimize wear, noise, and operating vibrations. These attributes are essential when drilling deeper high pressure formations, long laterals and when handling corrosive or abrasive fluids and slurries.

Every American Block triplex mud pump is manufactured and fully load tested before leaving our manufacturing campus, and is available in sizes ranging from 800 HP to 2200 HP. The American Block K1600 HP Mud Pump is also available in a 2000 HP up-grade version, when more HP is needed in the same 1600 HP footprint.

8613371530291

8613371530291