hydraulic mud pump pricelist quotation

Explore a wide variety of hydraulic mud pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These hydraulic mud pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these hydraulic mud pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right hydraulic mud pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of hydraulic mud pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

Mud pump, refers to the drilling process to the drilling mud or water and other washing liquid machinery. The main components are volute, impeller, pump seat, pump case, support cylinder, motor seat, motor and other components. Impeller nut is cast iron, so corrosion resistance is good, and convenient processing technology. Pump seat is equipped with four skeleton oil seal and shaft sleeve, prevent shaft wear, prolong the service life of the shaft.

High quality vertical mud pumps with thick, solid shaft and copper motor can be provided in ATO shop. Various models are available, such as 2 inch mud pump, 3 inch mud pump, 4 inch mud pump and 6 inch mud pump. Here is the price list of vertical mud pump.

Sewage mud pump is used in mining, papermaking, printing and dyeing, environmental protection, ceramics, refining, petroleum, chemical industry, farm, dyeing, brewing, food, construction, gold mine, mud, quicksand, mud pond, sewage pond, turbid fluid to send suction thick liquid, loading and suspended matter sewage operation, can also be used for mine drainage and fluid containing mud blocks.

If the mud pump and high-pressure water pump, water gun with the composition of hydraulic mechanized earthwork unit, can be used for land leveling, river and pond dredging, digging and other small water conservancy projects, as well as urban air defense engineering, underground engineering.

We provide a qualitative range of Mud Monoblock Pumps, which are immensely used in construction, agriculture, waste water management and many other industries

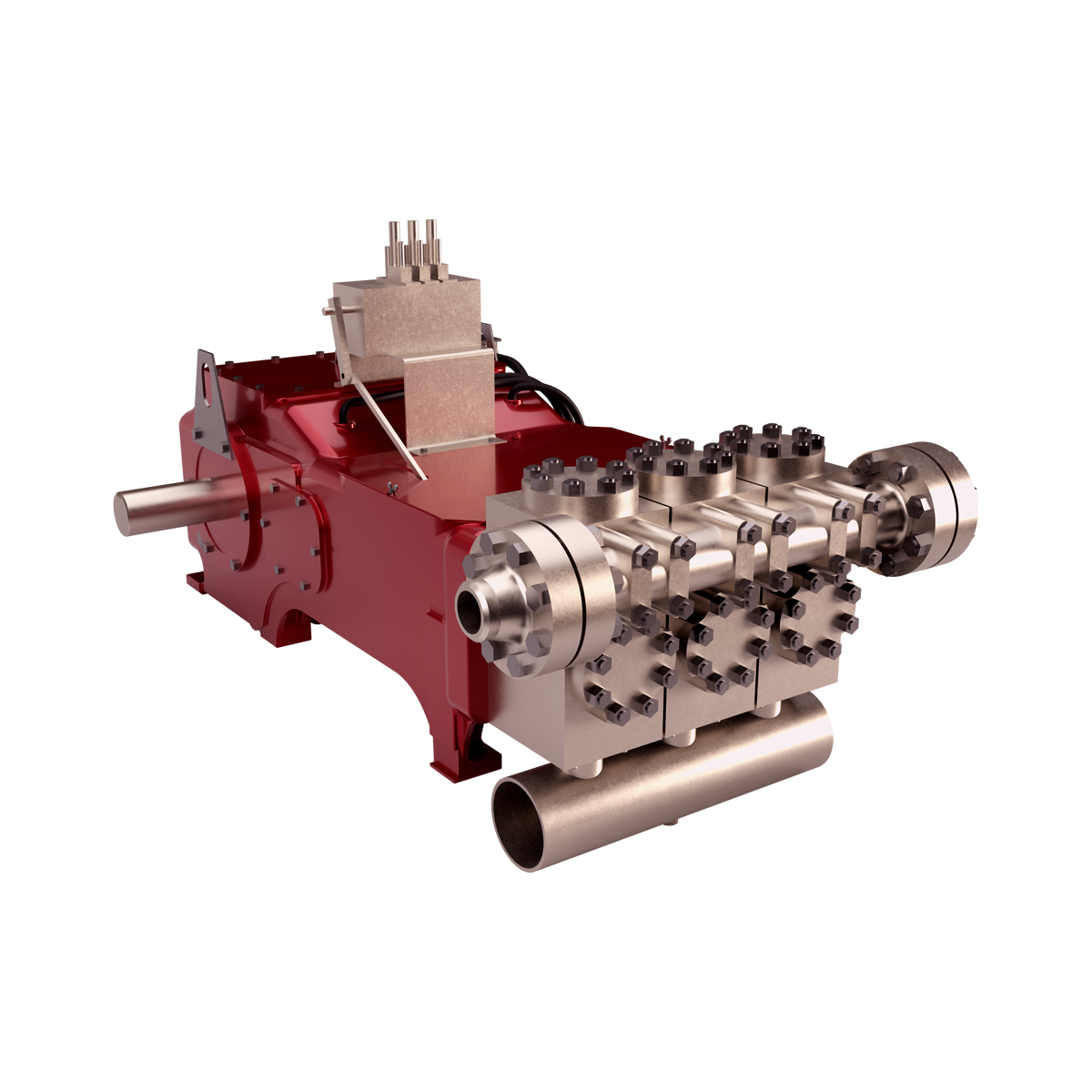

A mud pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi (52,000 kPa)) down the drill string and back up the annulus. A duplex mud pump is an important part of the equipment used for oil well drilling.

Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers. The advantages that Duplex mud pumps have over convention triplex pumps is a lower mud noise which assists with better Measurement while drilling and Logging while drilling decoding.

Use duplex mud pumps to make sure that the circulation of the mud being drilled or the supply of liquid reaches the bottom of the well from the mud cleaning system. Despite being older technology than the triplex mud pump, the duplex mud pumps can use either electricity or diesel, and maintenance is easy due to their binocular floating seals and safety valves.

A mud pump is composed of many parts including mud pump liner, mud pump piston, modules, hydraulic seat pullers, and other parts. Parts of a mud pump:housing itself

Duplex pumps are used to provide a secondary means of fuel transfer in the event of a failure of the primary pump. Each pump in a duplex set is sized to meet the full flow requirements of the system. Pump controllers can be set for any of the following common operating modes:Lead / Lag (Primary / Secondary): The lead (primary) pump is selected by the user and the lag (secondary pump operates when a failure of the primary pump is detected.

Alternating: Operates per Lead / Lag (Primary / Secondary) except that the operating pump and lead / lag status alternate on consecutive starts. A variation is to alternate the pumps based on the operating time (hour meter) of the lead pump.

The PZ 2400 features a Y-shaped module design, meaning less stress is placed on the pumps internal components and higher flow rates can be achieved with improved fatigue life.

2022 Vermeer® High-Pressure Mud Pumps SA400The SA400 is a high-pressure mud pump powered by a Tier 4i (EU Stage IIIB) or Tier 3 (EU Stage IIIA) engine.

The SA400 is a high-pressure mud pump powered by a Tier 4i (EU Stage IIIB) or Tier 3 (EU Stage IIIA) engine. It features an engine-mounted lubrication pump to provide constant flow through the system at any pump speed. During drill rod makeup/breakout, a clutch with continuous duty throw-out bearing allows extended clutch disengagement and a suction inlet valve suspends charged flow.

Features may include:Remote pendant controlA remote pendant control allows the operator to place control where it makes sense for them.Light shieldingThe SA400 features light shielding – each panel weighs less than 50 lb (22.8 kg) – making maintenance a one-person task.Liner wash tankA liner wash tank integrated into the machine’s design eliminates the need for extra water containers or electricity when running the pump.

We have attained huge reputation as prominent manufacturer and supplier of Portable Dewatering Submersible Pumps. These pumps are well accepted in the market for their light weight, robust construction and excellent functional accuracy. We design these pumps by utilizing latest tools and techniques as per latest industrial norms with quality tested raw materials. We supply these machines in wide specifications at affordable price range to our customers.

• Portable submersible pumps are one of its kinds. We have a wide range of selection within the same Horse Power rating for these pumps. Our construction is robust compared to other make pumps and has proved its self in the market with its trouble free Operation

• Motor – submersible pumps are available in Single phase and three-phase squirrel cage induction dry motor with ‘F" class insulation and IP 68 protection

• We provide pumps with Aluminum MOC, which will make the pump very light and will be extremely handy for the operator. Trolley mounted construction is also an available option

Lake Petro provides high quality Mud Pump Parts including Mud Pump Liners, Mud Pump Fluid End Module, piston, Valve and Seat etc. With more than 10 years of experience in the oil and gas industry, we are dedicated to help and support our loyal clients with the most cost-effective and quality Liners and Pistons. We also provide mud pump price and mud pump for sale.

We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials for all common brands of the mud pump and triplex mud pump.

All Lake Petro liner products are interchangeable with O.E.M. products. Meanwhile, we provide customized Liners according to drawings. Our liners, also with our other mud pump spares, are supplied for use in Honghua, F-Series, Bomco, Emsco and National lines of triplex drilling pumps. Let Lake Petro be your one-stop shop for your whole fleet of pumps. Please refer to “Suitable Pump Models” Lable for more details.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

Weir provides the oil and gas industry with the best in full open valve and seat technology and manufactures a wide variety of valves and seats for workover pumps, high pressure well service fracturing pumps, cementing pumps and mud pumps through its Novatech™ pressure pumping equipment line.

Novatech leads the industry in full open valve and seat technology and manufactures valves and seats for workover pumps, high pressure well service fracturing pumps, cementing pumps and mud pumps. Novatech also manufactures caged assemblies for almost all well service pumps and applications, including workover, cementing, acidizing and fracking. Novatech developed the first valve and seat in the industry rated for continuous service at 7,500 psi. Products are 100% made in U.S.A.

Reasontek carry Weir/Novatech products for oilfield applications including valves, seats, inserts replacement of pump maintenance. Please check the catalogue below and let us know your request.

The DAE Pumps Submersible Drainage Pumps support a variety of dewatering applications. Their robust design provides the highest level of performance, reliability, and ease of use. The submersible drainage pumps offer a range of sizes up to 10-inches with over 80 HP and a volume capability of pumping as much as 6100 GPM.

Submersible Sludge Pumps are peak performers in pumping thick mud, clay, and waste. These energy-efficient pumps run at low horsepower, pumping as much as 420 GPM. Available in 3-inch and 4-inch sizes, the heavy-duty DAE Pumps Submersible Sludge Pumps are capable of moving abrasive solids as large as 2-inches. Our Submersible Sludge Pumps provide the support you need for for your toughest jobs.

The DAE Pumps Submersible Slurry Pumps are the toughest and most durable submersible pump. Built for pumping the worst slurry and materials, these pumps have the highest rating in ruggedness. Our Submersible Slurry Pumps are made for dredging the most abrasive media with high solid content in quarries and mining operations. With up to 102 horsepower, these powerful unit are capable of moving 2112 GPM of solids as large as 2.5-inches, and are available in 3-inch, 4-inch, 6-inch, and 8-inch sizes.

The DAE Pumps Payload Electric Dredge Pump is a highly durable and reliable dredge pump for transporting solids and a variety of other materials. This unit can be deployed from an exvacator or a cable. Our industry-leading top dredge pumps are capable of moving up to 2000 cubic meters of solids per hour. The Payload Series provides non-clogging suction power to excavate and pump some of the most challenging dredging situations. The suction power handles solids up to 3.9-inches.

The DAE Pumps Hydraulic Submersible Slurry Pumps are the industry’s best-performing hydraulic submersible pumps. Capable of pumping up to 1325 GPM our hydraulic pumps provide the reliability you need. Because these 3-inch and 4-inch pumps are compact, their lightweight design makes them necessary tools for all site operations. They are non-clogging and are also available in a high head performance of up to 350 feet

The DAE Pumps Hauler Hydraulic Dredge Pump is a highly durable and reliable dredge pump for transporting solids and a variety of other materials. This unit can be deployed from an exvacator or a cable. Our industry-leading top dredge pumps are capable of moving up to 2000 cubic meters of solids per hour. The Hauler Series provides non-clogging suction power to excavate and pump some of the most challenging dredging situations. The suction power handles solids up to 3.9-inches.

DAE Pumps is committed to providing you with the highest quality of pumps at affordable prices. We build our submersible pumps with you in mind. We use the strongest material inside and out to withstand the harshest conditions for getting the job done. Over the years, we built a modular platform of submersible pump that allows us to provide the highest performing pump with the same durability and reliability from one size and power to the next. This means you get the best pump each time.

Our low-cost submersible pump lines are an extension of our commitment to affordably priced pumps. These pumps are built with the same types of metal inside and out as our modular lines, but use a different technology design that brings the performance of these pumps close to those of the other models. We offer these pumps with a lower guarantee so you can get very high-grade pumps at the best prices.

Submersible pumps are the industry’s most durable pumps for underwater operations moving solids and liquids. They can withstanding everyday use of processing water, rocks, sand, mud, sludge, slurry, and other abrasive materials. DAE Pumps provides a variety of submersible pumps for mining, dredging, minerals processing, ash pumping, wastewater, dewatering, and pumping chemicals, oil, sludge, paste, and many other applications. We offer light-duty to heavy-duty submersible drainage pumps, submersible sludge pumps, and submersible slurry pumps.

The submersible drainage pump is built for general dewatering, groundwater, raw water, and construction site use. Construction companies and various municipalities use drainage pumps for removing water from heavily flooded areas and as sump pumps when rainwater or groundwater collects in low-lying and below ground work areas.

DAE Pumps drainage pumps are designed for flexibility and ease of use. Capable of pumping solids up to .5-inches, the durable design is made to move large amounts of water. DAE Pumps drainage pumps handle clean and dirty water with the best performance and efficiency on the market. Our drainage pumps provide powerful performance with minimal maintenance, and their durable body ensures continued use in harsh environments. We offer a variety of drainage pumps in 3-inch, 4-inch, 6-inch, and 10-inch discharge outlets with a horsepower of over 80 HP, and capable of pumping up to 6100 GPM.

Made to pump thick mud and other similarly viscous mixtures of liquids and solids, submersible sludge pumps are used for moving sludge or light slurry, tank clean-outs, trench and pond cleaning, mining dewatering operations, and various other applications. The sludge pump moves the material that can clog ordinary drainage pumps.

DAE Pumps heavy-duty sludge pumps can move water, but they are made for moving solid material and are built with a high wear resistance inside and out. The high-chrome (55HRC) impellers and base of the pump ensures stability while allowing the passage of large solids. The high-quality components for the mechanical seal guarantees a watertight seal and trouble-free operation. Our submersible sludge pumps move up to 420 GPM and come in multiple sizes and power options. These sturdy sludge pumps provide the reliability you need and the performance you can trust for your dewatering, cleaning, and transferring needs.

The submersible slurry pump is the catch-all of submersibles. Capable of pumping the most abrasive media with high solids content, the slurry pump is the workhorse for quarries and settling pond operations. These ultimate pumps are used for everything from dewatering to dredging.

DAE Pumps non-clogging submersible slurry pumps provide the ultimate in toughness.They have the largest apertures to facilitate the handling of slurry with the most challenging solids and the high-efficiency high chrome agitator can lift settled solids up to 2.5-inches. The robust design uses heavy-duty bearings to withstand shocks and overloads and a double silicon carbide mechanical seal for duty application. Our slurry pumps are available in 3-inch, 4-inch, and 6-inch models, with the ability to move up to 2112 GPM.

Sand is one of the most abrasive materials for any type of pump to manage. The beating of sand on the impeller, volute, and even the hose cause extreme wear and tear on pump components. Thesubmersible sand pump is designed to minimize the effects of blasting sand. However, over a period of extended time, the submersible sand pumps will show signs of wear on these parts from the constant pounding of sand and will require replacement.

Our submersible sand pump wear components are built with a high chromium iron, an extremely strong alloy that is mainly used in mining, milling, earth-handling, and manufacturing industries which require materials with exceptional wear and corrosion resistance. The exceptional wear resistance of high chromium cast iron is due to the high volume fraction of hard chromium carbides. The toughness of the matrix also contributes to the wear resistance and makesit very suitable for pumping sand.

DAE Pumps non-clogging submersible sand pumps provide the ultimate in toughness and sand pumping capabilities. Ourpumps move up to 1664 gallons per minute of material and are available in 3-inch, 4-inch, and 6-inch models.

triplex mud pumps and triplex mud pump parts meet the industry standards established by the American Petroleum Institute (API). As a global supplier of quality oilfield equipment to the oil and gas industry, we ship our products around the world.

Besides triplex mud pumps and triplex mud pump parts, we supply drilling rigs, workover rigs, top drives, drilling equipment, blowout preventers, BOP control systems, choke and kill manifolds, well service pumps for well cementing and hydraulic fracturing, wellhead equipment, casing heads, tubing heads, X-mas trees, FC type gate valves, etc. Please visit our company website

We supply unitized mud pump packages driven by DC or AC electric motors or diesel engines for electric and mechanical drilling rigs. The client can select DC or AC motors and diesel engine brands such as Caterpillar, Detroit, Cummins or others. Our unitized mud pump packages including everything on the skid and usually they are ready to work at delivery.

Sunken, settled, and uneven concrete slabs are not uncommon in Ohio.Mudjackingandpolyjacking are two common concrete leveling solutions for property owners looking for an alternative to costly replacement. Is one concrete leveling method better than the other? Let’s compare mudjacking vs. polyjacking.

Mudjacking is a concrete leveling method that pumps mud under a building, driveway or other sunken concrete to lift it. A specialized hydraulic pump pushes the mud mix into holes drilled in the slabs.

Mr. Level considers mudjacking the “Flintstones” approach to concrete leveling. With mudjacking, your sunken concrete is drilled with dime-size holes, pumped with mud and then the mud hardens up. To support the lifted concrete, mudjacking relies on underlying soils, which are impacted by the same elements that lead to cracking and sinking, so contractors are not able to guarantee the work.

Recently, we were hired to come in and correct a mudjacking job. In this video, you can see the product they used to pump the uneven patio hardened up, and the slab ended up back in its old sunken state. The mudjacking product distorted the property and rendered the patio unusable.

An alternative concrete leveling option, polyjacking uses polyurethane foam in place of mud. We call this the “Jetsons” approach. The foam expands after filling the holes drilled in the concrete slab. As the polyurethane expands, the concrete is lifted.

Ready to put these two concrete leveling methods to the test? See how mudjacking andpolyjackingcompare in terms of appearance, longevity, environmental friendliness, and price.

With polyurethane, fewer and smaller holes (an inch smaller, to be exact) are drilled into the concrete slabs. Compare that to the much larger and more numerous holes required for mudjacking. Ultimately, polyjacking results in a cleaner, more polished final product. Additionally, fewer resources and heavy equipment are required, so the job site is neater, the surrounding landscape isn’t damaged, and the disruption

Polyurethane is fast compared to mudjacking. Polyurethane foam cures in minutes, so it’s ready to be walked and driven on right away. Mudjacking, on the other hand, can take 24 to 72 hours to cure and allow for foot traffic on the lifted concrete. This is not only inconvenient but can cause hurt commercial owners who rely on their parking lots for business.

Mudjacking relies on underlying soils to support the lifted concrete. Heaving from a dramatic freeze and thaw cycle or settling from decaying tree roots or water damage can cause the underlying soils to shift and crack your concrete. There’s no guarantee your concrete will remain smooth and level with mudjacking.

Polyjacking is hydrophobic, meaning that the polyurethane can be used underwater or in wet conditions. The foam-like material creates a moisture barrier that is resistant to water penetration. This can not only keep your concrete level but can also help prevent water from leaking into your home or building. Mudjacking, which as previously discussed can shift, doesn’t offer any water resistance to protect your concrete or structure.

Settled concrete is often the result of poor soil conditions under the slab. You’ll want a lightweight material, so you don’t further burden the already weak soil. Mudjacking typically weighs 100 lbs. per cubic foot, whereas polyurethane is far more lightweight, weighing only 2 to 4 lbs. per cubic foot.

The cost of mudjacking runs cheap compared to polyurethane. However, because there is no warranty or guarantee your concrete will remain leveled, you’ll likely need to pay to repeat the process.

8613371530291

8613371530291