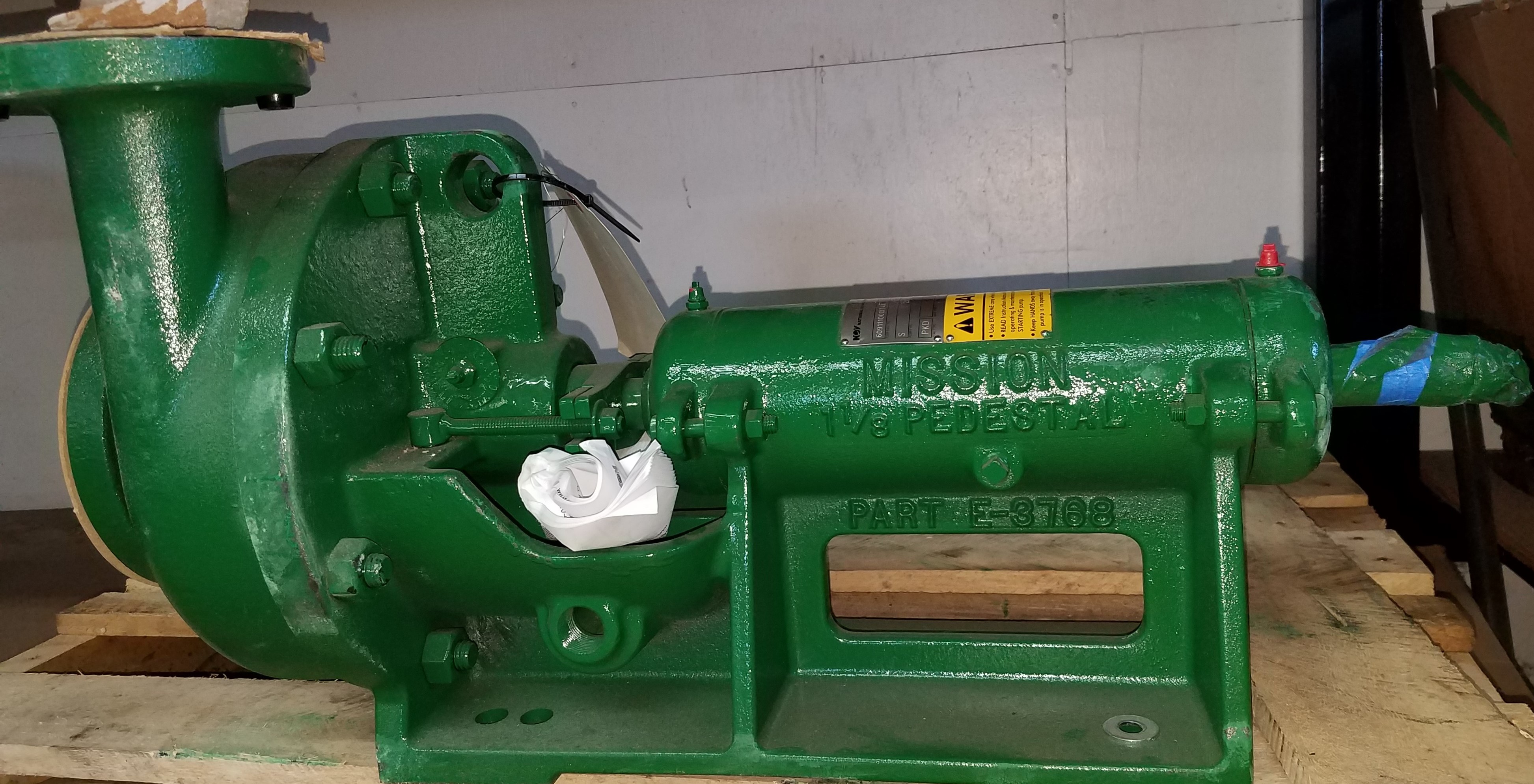

mission mud pump for sale in stock

Power Zone is a leading global supplier of new, used and reconditioned pumps for sale. Our inventory of pumps includes multi-stage centrifugal pumps, positive displacement pumps, reciprocating pumps, single stage centrifugal pumps and screw pumps in a variety of design standards including API 610 Centrifugal Pumps, API 674 Reciprocating Pumps and API 676 Rotary Pumps. We have an assortment of pumps that are used in various applications including water treatment, pipelines, frac water supply, salt water disposal and flood control in industries like municipal, manufacturing, oil & gas, mining and agriculture. We supply pumps of all major suppliers such as Sulzer, Flowserve, ITT Goulds, Aurora and National.

A wide variety of mission mud pump options are available to you, such as 1 year, not available and 3 years.You can also choose from new, mission mud pump,As well as from energy & mining, construction works , and machinery repair shops. and whether mission mud pump is 1.5 years, 6 months, or unavailable.

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is applicable). Packaging should be the same as what is found in a retail store, unless the item was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller"s listing for full details.See all condition definitionsopens in a new window or tab

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Mission Magnum XP Blender Pump and MCM XL Pump are ideally suited for pumping high volumes of heavy slurries that are abrasive, corrosive, and difficult to pump. The compact overall dimensions make it an excellent choice for high volume mobile and stationary applications where a small footprint is critical. High chrome alloy or hard iron material options for different applications

Tobee"s Mission Magnum I Pump 8x6x14 and wet parts are made from Hard Iron or High Chrome alloy materials that they are 100% interchangeable with original Nov Mission Magnum 8x6x14 Pumps and Parts.

The revolutionary design of the MAGNUM I provides supreme-duty performance in all types of fluid pumping operations. Although it offers greater capacity and higher heads, the MAGNUM I remains the competitive pump of choice for aggressive applications.

The Magnum has an open impeller design that contains wide-tipped vanes and a more tangential circumference of the suction allowing the pump to create a smoother flow pattern when handling abrasive fluids. The Magnum is available in Magnachrome™, hard iron, stainless steel, and aluminum bronze fluid ends. The pumps can be unitized with electric motors, diesel engines, and hydraulic motors (horizontal, vertical, or close-coupled configuration).

According to the different working conditions, Mission centrifugal pumps can be used as Frac discharge pump, Frac suction pump, Oil drilling centrifugal pump, electric centrifugal transfer pump, Skid mounted mixing pump, Transfer pump, Trash pump, Grinding pump, Circulating mud pump, Centrifugal sludge pump, Drilling fluid centrifugal pump, Horizontal directional drilling pump, Denver pump, Filling pump, Feeding pump, etc

The revolutionary design of the MAGNUM I provides supreme-duty performance in all types of fluid pumping operations. Although it offers greater capacity and higher heads, the MAGNUM I remains the competitive pump of choice for aggressive applications.

The Magnum has an open impeller design that contains wide-tipped vanes and a more tangential circumference of the suction allowing the pump to create a smoother flow pattern when handling abrasive fluids. The Magnum is available in Magnachrome™, hard iron, stainless steel, and aluminum bronze fluid ends. The pumps can be unitized with electric motors, diesel engines, and hydraulic motors (horizontal, vertical, or close-coupled configuration).

According to the different working conditions, Mission centrifugal pumps can be used as Frac discharge pump, Frac suction pump, Oil drilling centrifugal pump, electric centrifugal transfer pump, Skid mounted mixing pump, Transfer pump, Trash pump, Grinding pump, Circulating mud pump, Centrifugal sludge pump, Drilling fluid centrifugal pump, Horizontal directional drilling pump, Denver pump, Filling pump, Feeding pump, etc

During the 1950’s the Mission” 1780 type “W” pumps were introduced to replace duplex pumps while creating the first low pressure mud system. The use of a high quality concentric type centrifugal pump allowed abrasive fluids to be mixed and transferred while reducing initial and maintenance costs for the drilling industry. The low-pressure mud system with Mission 1 780 Type “W” centrifugal pumps became the industry standard.

As well depths increased so did the need for heavier mud weights. When the mud weight began exceeding 14 ppg the need for a pump that could withstand greater horsepower loads arose. During the 1970’s Mission organized a design team that engineered the Mission Magnum. The Magnum was designed to have the same footprint, flange locations, and drive shaft diameter as the 1780 “W”. This allowed a 1780 to be replaced by a Magnum without any skid modifications. The Magnums were originally engineered with a 2-1/2″ shaft (3″ between the bearings), double row bearings with an engineered life of over 2 years at 200 HP, larger impellers and heavier frames. The Magnum allowed drilling contractors to upgrade their centrifugal pumps and mix heavier fluids.

The National Oilwell Varco” Mission centrifugal pump line has proven to be the best centrifugal design for handling abrasive mud. This pump line offers a broad selection of innovative features for a variety of routine, demanding, abrasive and corrosive applications. These pumps are designed for a wide range of flow rates, from a few gallons per minute to thousands of gallons per minute.

Each pump contains the finest materials, engineering and craftsmanship available in the industry. Described are like features of these pump lines and unique features are described on the following pages.

National Oilwell Varco utilizes unique design features developed for slurries. Three major differences from most pump designs include the concentric casing, wider impellers and increased re-circulation areas. Each feature contributes to reducing wear when handling abrasive fluids.

All of the pumps feature a concentric casing. This casing averages 37% thicker than conventional pump casings, and up to 50% thicker for the larger, mud pumping models. They are pressure rated at 1 .5 times the flange rating and are designed with a 1 /8″ erosion allowance. The concentric style casing has proven to offer the greatest pump life and reduced downtime. The walls of a concentric style casing are an equal distance from the impeller throughout the impeller circumference, which results in a smooth flow pattern. A volute style casing has a cutwater point that disturbs the fluid flow pattern creating an eddy. The concentric casing eliminates vibration, turbulence and aeration that is caused by the cutwater point in conventional volute pumps. It also reduces the high bearing loads and shaft deflection even at near shutoff flows.

The shaft is much larger in diameter than conventional pump shafts for heavy-duty performance, minimum deflection and increased operating life of the seal or packing. With a 2-1/2″ diameter at the seal area and 3″ diameter between the bearings these pumps can be direct connected or belt driven.

3x2x13 6x5x14 4x3x13 8x6x11 5x4x14 8x6x14 6x5x11 10x8x14 • Barite, ferric oxide, and mineral oil • Base drilling muds • Glass fibers • Sugar processing • Ash or coal conveyers • Cement • Mine de-watering • Lime slurries • Kaolin clay • Crystalline forms Email: Sales7@tobeepump.com Web: www.tobeepump.com | www.slurrypumpsupply.com | www.tobee.cc | www.hydroman.cn

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

(Centrifugal Pump, Trash Pump, Mud Pump, Drilling, Drilling Ring, Cooper, Work Over Rig, Shaker, Mud Tank, Water Tank, Frac Tank, Diesel Tank, Tongs, BOPE, Power Swivel, Elevators, Top Drive, Pipe Wrangler, Substructure, Mud Pump, Hydraulic, Drill Pipe)

Centrifugal Pumps - New/never-used 2014 model Mission 2500 Supreme centrifugal pumps. 22 units available. Located in Oklahoma. Stored in a secure/protected warehouse. More Info

Centrifugal Pumps - Mission 5x6R Centrifugal Pump, Pumps & Parts, Used Mission 5x6R Centrifugal Pump, 12" impeller, material C1, fig# C58 00-80, mfg 5/80 , More Info

Centrifugal Pumps - Mission Magnum 5x6x14 Centrifugal Pump, Pumps & Parts, Used Mission 5x6x14 Centrifugal Pump, on skid with Detroit 6-71 diesel engine, Rockford over center clutch 14-9, c/... More Info

Centrifugal Pumps - Mission Magnum 6X5X14 Centrifugal Pump, Pumps & Parts, Used Mission Magnum 6x5x14 Centrifugal Pump, Modular# A111B10C12D11EI 19121-A0-37, Impeller Diameter 14" Fluid End ... More Info

Centrifugal Pumps - MONOFLOW C16D, Pumps & Parts, Used Monoflow C16D Screw Pump, 5 3/4" Discharge, 6" Suction, Belt Driven on Skid, Stainless Steel Housing. , More Info

Centrifugal Pumps - Northern Pump Ltd. 1 1/4 x 1 1/4, Pumps & Parts, Used rotary pump, 1 1/4x 1 1/4, shaft extends on both sides, packing on both sides, thread ports , More Info

Centrifugal Pumps - MONARCH IND F30K4HSTRBF, Pumps & Parts, Used Monarch F30K4HSTRBF Centrifugal Pump, 3 x 4 Impeller Diameter, 7" Power Adapter, PA-32 Seal Kit, 8K1 Power Frame TR3 Max RPM ... More Info

Oil Works, Inc. offers service from minor repairs to complete overhauls on centrifugal pumps. We also stock parts and complete remanufactured units a... More Info

Centrifugal Pumps - MONARCH IND T30K4HS, Pumps & Parts, Used Monarch T30K4HS Centrifugal Pump, 3 x 4 Impeller Diameter 7" Power Adapter, PA-32 Seal Kit 8K1 Power Frame TR3 Max RPM 3530 on Ba... More Info

Centrifugal Pumps - Layne Bowler Pump Co. Vertical Can Pump, Pumps & Parts, Used vertical can pump, burte-line pump,3570 RPM, 730 GPM, 1730" HD, Wilson equipment model # 8LT 600/10, # 214677... More Info

Centrifugal Pumps - New surplus MCM mud pump package for 600 gpm @ 600 head feet. MCM 250 Series 4X3X13 pump with hard Iron fluid, 11.5 inch impeller, casing with replaceable wear pad and st... More Info

Standard Industrial Manufacturing started in 1979. Our mission was to manufacture and supply pump parts to a few select pump retailers and OEMs. During the 1980s the company expanded its customer base to include all pump retailers and OEMs. Today, Standard has broadened its product lines to include most fluid-end expendables for all major pump brands.

8613371530291

8613371530291