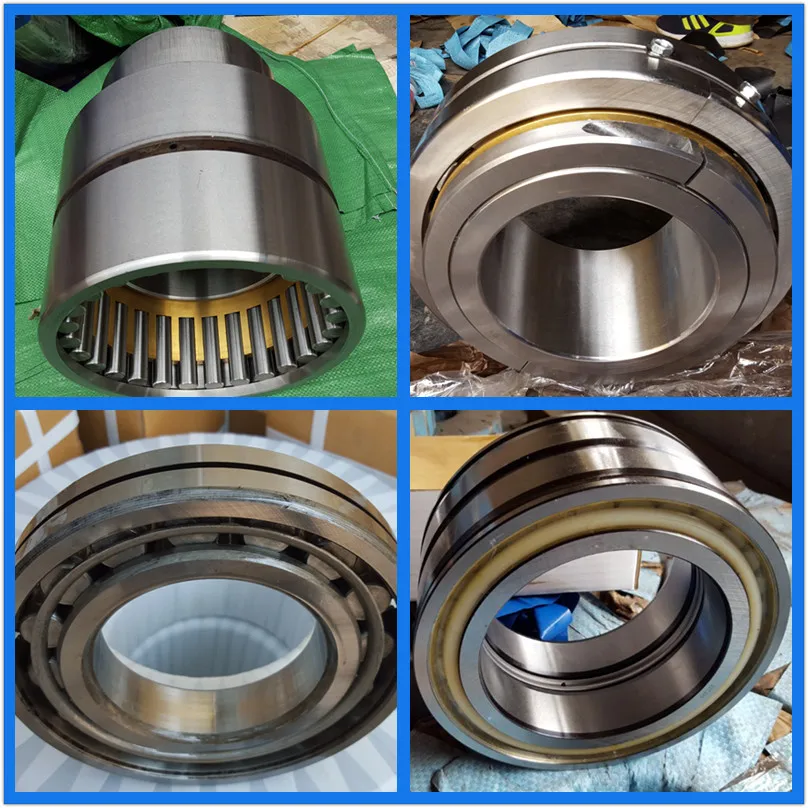

mud pump bearing in stock

Among all the other bearings that people use in various applications in daily lives, rolling element bearings are one of the most common types of bearing that can be found practically anywhere. Rolling element bearings can be found in a great variety of applications, including automobiles, household appliances, industrial applications, and among many types of office equipment. Ball bearings are one of the two main categories of rolling element bearings, and they are widely used in skateboard bearings and various types of bearings for cars. Roller skate bearings, along with bearings used on other household items such as bicycles and washing machines, are among the most popular bearings on the market.

Another type of rolling-element bearing is the roller bearing, which is classified into three main types: spherical roller bearings, cylindrical roller bearings, and tapered roller bearings. Spherical roller bearings can be mostly found among the construction and a variety of paper and maritime industry equipment, whereas cylindrical roller bearings are used in a variety of heavy-duty machinery applications. Tapered roller bearings, on the other hand, are commonly used in vehicle wheels and for a variety of heavy-duty applications. Needle roller bearings, often known as needle bearings, are another type of roller bearing that is widely utilized in automobile components. Because of its small size, it can be used for a variety of small tasks.

p>Now is the time to go through Alibaba.com"s wholesale mud pump bearing listings to see what are the options available! And, of course, don"t forget to check out exceptional deals with large savings among the numerous promotions that various bearing suppliers provide from time to time. Take action now and shop for mud pump bearing right here!

Mud pumps, used for oil and gas drilling operations, get their name from the specially prepared fluid (mud) that is pumped through the drill pipe to evacuate cuttings from the hole, as well as to cool and lubricate the drill bit. These are generally low-speed, high-displacement reciprocating pumps and can be either single- or double-acting, with the majority in use today being singleacting. Mud pumps can also feature from one to five cylinders, with a triplex arrangement being the most common. Normally, the pumps are skid mounted for transportation purposes, with the majority being horizontal in design and incorporating a fluid and power end, which are separate for maintenance purposes. This article explores the power end where roller bearings are located

Mud pumps, used for oil and gas drilling operations, get their name from the specially prepared fluid (mud) that is pumped through the drill pipe to evacuate cuttings from the hole, as well as to cool and lubricate the drill bit. These are generally low-speed, high-displacement reciprocating pumps and can be either single- or double-acting, with the majority in use today being singleacting. Mud pumps can also feature from one to five cylinders, with a triplex arrangement being the most common. Normally, the pumps are skid mounted for transportation purposes, with the majority being horizontal in design and incorporating a fluid and power end, which are separate for maintenance purposes. This article explores the power end where roller bearings are located

FES 6301-0038-00 Bearing for Oil Production & Drilling is supplied by Dalian FES Bearing Technology Co.,LTD, all of our Mud pump bearing are made according to international standard

There"s 426 pcs of KWVE35-B-E-V2-G4 bearings are available in stock now, the prompt response, competitive prices, superior quality and service are waiting for you.

170 Million used TIMKEN Bearings ZB-10750 Bearings For Oil Production & Drilling(Mud Pump Bearing) instantly searchable. Shop our large selection of parts based on Industrial Bearings Inc brand, price, description, and location. Order the Oilfield mud pump bearings with stock ...

With over 70 full-service dealerships, Industrial Bearings Inc has the extensive and proven parts and service resources to keep your equipment up and running and your business profitable.

What is C3 and C4 in bearing?C3 and C4 are two types of internal clearance in a bearing. Both the C3 and C4 are related to the internal clearance, but they are different.

The Application Of The BearingThe application of the bearing is very wide. As we all know, it is used in cars, motorcycles, airplanes and other vehicles. But it is also used in our daily life. Where do you use bearings?

What is bearing and its type?A bearing, sometimes referred to as a linear guide, is a mechanical component used to support and guide the relative motion of objects in which there is a circular cross section. The term "bearing" is often narrowly defined to describe only the...

170 Million used TIMKEN Bearings ZB-10750 Bearings For Oil Production & Drilling(Mud Pump Bearing) instantly searchable. Shop our large selection of parts based on Industrial Bearings Inc brand, price, description, and location. Order the Oilfield mud pump bearings with stock ...

With over 70 full-service dealerships, Industrial Bearings Inc has the extensive and proven parts and service resources to keep your equipment up and running and your business profitable.

What is C3 and C4 in bearing?C3 and C4 are two types of internal clearance in a bearing. Both the C3 and C4 are related to the internal clearance, but they are different.

The Application Of The BearingThe application of the bearing is very wide. As we all know, it is used in cars, motorcycles, airplanes and other vehicles. But it is also used in our daily life. Where do you use bearings?

What is bearing and its type?A bearing, sometimes referred to as a linear guide, is a mechanical component used to support and guide the relative motion of objects in which there is a circular cross section. The term "bearing" is often narrowly defined to describe only the...

EOE bearings are used in professional bearing manufacturers in major equipment industries such as metallurgy, cement, petroleum, military industry, heavy machinery, wind power, port machinery and so on.

Since horizontal directional drilling (HDD) work tends to be slower in the winter months, particularly when the ground is frozen, winter is a prime time to inspect the power end of the pump and prevent downtime on the job later.

If one waits until an audible problem can be detected, it is often very expensive to repair. All smaller HDD pumps – 100 hp and smaller — tend to use the same type of internal components regardless of the manufacturer.

The largest load bearing area of the pump is the crosshead pin and bushing area. Wear can be detected by locking the intermittent or piston rod with a pipe wrench and rotating the crank shaft slightly. If one can feel any slack it can only be coming from the pin and bushing or the connecting rod bearing. It then becomes necessary to remove the connecting rod assembly consisting of the connecting rod and cross head. If slack is determined in the pin bushing, it will be necessary to press out the pin and inspect the bushing and the crosshead pin in the eye of the connecting rod. Some manufacturers ship bushings that are designed to fit. Others ship them and they have to be reamed to fit the pin after the bushing is installed. The installation instructions and dimensional fits are provided by the manufacturer in the pump manual.

1. Crankshaft 2. Main bearing 3. Shim set 4. Connecting rod bearing half 5. Crankshaft oil seal 6. Rod cap shim 7. Connecting rod 8. Wrist pin 9. Cross head 10. Intermittent rod 11. Wiper box gland 12. Wiper box seals 13. Wiper snap ring

The next area of concern is the connecting rod bearings themselves. If visual wear can be seen, use a micrometer and measure the crankshaft journals to make sure they are not out of round. If the journals check out, then all is needed is new connecting rod bearings. Some manufactures utilize shims to get the correct fit to the journal. Others provide automotive style bearings that only require correct torque to the rod cap for correct installation. There are pros and cons concerning automotive style vs shim bearings. Shim type bearings does allow for oversized connecting rod bearing should the journals be worn. This allows for turning down the crank journals a few thousands and utilizing a larger connecting rod bearing. If a pump uses automotive style precision bearings and the journals are out of round, it is necessary to replace the crankshaft.

The tapered roller bearing should last for years. If the rollers and races are not pitted, utilizing the same set of roller bearings is allowable. Checking the end play on the crankshaft is a simple task. With the use of a dial indicator, check for the lateral movement of the shaft. It if falls within the manufacturer’s tolerances, nothing needs to be done, If not, then it will be necessary to add or remove shims. Shims packs are provided by the manufacturer so one can get the proper end play on the crankshaft. The shims themselves come in different thickness allowing one to add or remove to get the correct end play.

Wiper box packing keeps the oil within the power frame and external contamination from entering the power end. The packing is easy to inspect and essential for longevity of the power end. The wiper box packing must remain in excellent condition at all times. Allowing the pump to set for extended periods of time or letting external contamination build on the packing shortens the lifespan.

If one waits until an audible problem can be detected, it is often very expensive to repair. All smaller HDD pumps – 100 hp and smaller — tend to use the same type of internal components regardless of the manufacturer.

Inspection of the power end allows the owner to dictate when repairs are necessary rather than allowing the pump to dictate during the middle of a job when repair is required. If problems are detected early, repair is relatively inexpensive. If a problem is not detected early, that problem often leads to more unnecessary wear and affects other components of the pump. An early fix to any problem is relatively inexpensive. Allowing the problem to continue can often cost several thousands of dollars and downtime on a job.

8613371530291

8613371530291