mud pump clipper seals supplier

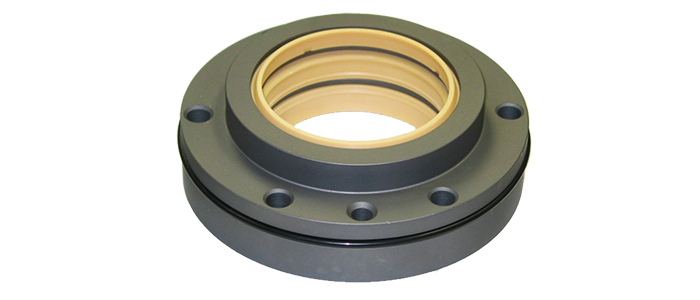

The Clipper Oil Seal design features an integrally molded rubber fiber outer case and an elastomeric seal lip. The unique, nonmetallic construction will not rust or corrode and forms a gasket-type seal between the equipment housing and the seal outside diameter (OD).

Clipper Split Seals are known for being the easiest split seal to install because they do not require a cover plate to keep them in the housing. The composite OD provides the best retention of any split seal available. Replacing failed seals in with Clipper Split Seals saves on downtime and lost production expenses.

Clipper seals are available for shaft diameters from 0.250″ (6.35 mm) to over 65″ (1651 mm) in both standard and high-performance elastomer compounds. With over 10,000 tooled sizes, Clipper seals are readily available for most applications in either a solid or split design.

Stainless Steel Springs Are Standard on all Clipper Oil. Seals where the industry standard is a lower quality carbon steel. Clipper’s spring material provides improved lip loading at higher temperatures and resists the rust and corrosion that is common with lower-quality materials. The upgraded spring ensures consistent lip loading over the life of the seal.

Split Clipper® Oil Seals have the same superior characteristics as solid general purpose Clipper Oil Seals, but are factory-split at one place in the circumference. This permits installation over the side of a shaft, rather than over the end, and often can save dismantling the equipment in order to replace the existing rotary shaft seal.

Solid Clipper Oil Seals should be used whenever practical to provide maximum bearing protection in rotating shaft applications. However, installing a solid seal in a failed application can be costly and time consuming. In such cases, Split Clipper Oil Seals can be used to minimize unscheduled downtime, specifically where equipment cannot be uncoupled. These seals will provide long and efficient service until major or scheduled machine overhaul permits convenient installation of a regular non-split seal.

Split Clipper Oil Seals are available in Series R, RPD and RUP profiles, depending upon shaft diameter. RUP and RPD profiles are general purpose spring loaded with a single lip and are widely used as replacement seals because they provide superior bearing protection and embody a unique principle of design. The tough, dense outer case and a soft, flexible lip are concentrically molded as a single unit. The seal"s nonmetallic outer case forms a leak-free, press fit in the housing, conforming to minor surface irregularities.

the anchor of Parker"s rotary shaft seal product line and is available in a wide range of profiles and material options. The Clipper design features an

Synthetic yarn that’s comparable in strength to aramid is combined with graphite for soft seals that dissipate heat away from the shaft to extend the life of pumps.

Seals have a crucial impact on system performance. By choosing SKF Seals, you can make a difference to the capability, durability and performance of your equipment - reduce friction, extend maintenance intervals and achieve greater value while increasing sustainability. With a seal by its side, there’s nothing our bearings can’t do.

Backed by more than 100 years of industrial application experience, SKF sees every sealing challenge as an opportunity to boost performance. Our customers benefit from our unmatched understanding of both the interaction between bearings, seals and lubrication, as well as the dynamics of reciprocating systems.

For example CR Seals has been setting performance and service life standards for industrial and automotive shaft seals. CR Seals has also been part of SKF since 1990, a span during which we’ve developed new materials, manufacturing processes and designs to create some of the most robust seals on the market.

We recognize and understand the vital role of mud pump oil seal in their application. With purposes including securely fastening components within systems, and contaminants prevention such as gases and liquids from navigating through enclosed and sealed areas. That is why we offer wholesale mud pump oil seal in different variations and diversities to ensure the integrity and efficiency of systems they will be applied to will function successfully and optimally. The different seals" types available include static that does not move along with other seals and dynamic seals that move collaboratively.

Depending on the industry and selected purpose, we consider mud pump oil seal requirements. Requirements are like pressure, that is pressure changes, to ensure they can withstand and do not deform by the sealed fluid, the load and how it can withstand deflection, dynamics such as the alignment and vibration, and temperature covering the environmental conditions and the heating arising from the friction of the seal operation and fluid movement.

The seals are either bolts, nuts, or washers. Seal bots are commonly used because of their benefits in being reusable, preventing fluids and contaminants from escaping even under high pressure. Nuts are essential on temperature withstanding and compatibility with screws, studs, and bolts, in addition to, easy installation. Moreover, washers can withstand high pressures and are compatible with other seals.

Pumps, mixers, motors, turbines and gear boxes in a variety of industries are susceptible to problems that can be caused by an inadequate sealing system.

The Seal Specialists at Web Seal can recommend the best sealing solutions for your needs. We offer more than 700 English and metric Parker and Clipper oil shaft seals for all applications, in sizes ranging from .250” up to 72”. Traditional metal canned and rubber-coated designs are available along with one-piece bonded seals (typically PTFE-to-elastomer).

Sealing Specialties offers a complete approach to your radial shaft seal (oil seal) needs. Our oil seals include the highest quality brands from SKF (CR) and Parker’s JM Clipper line. Whether your application requires inch standard or metric, small diameter or very large diameter, single or double lip, we will be able to assist you. Seals are available in all standard materials for immediate delivery.

In addition to offering a wide range of sizes and configurations, we also have oil seals available in all standard materials for immediate delivery. This means that you can get the seals you need when you need them, without any delays.

At Sealing Specialties, we are dedicated to providing high-quality oil seals and exceptional customer service to help you achieve reliable and effective sealing performance in your applications. Whether you are in need of standard or custom oil seals, we have the expertise and resources to assist you.

8613371530291

8613371530291