mud pump components pdf in stock

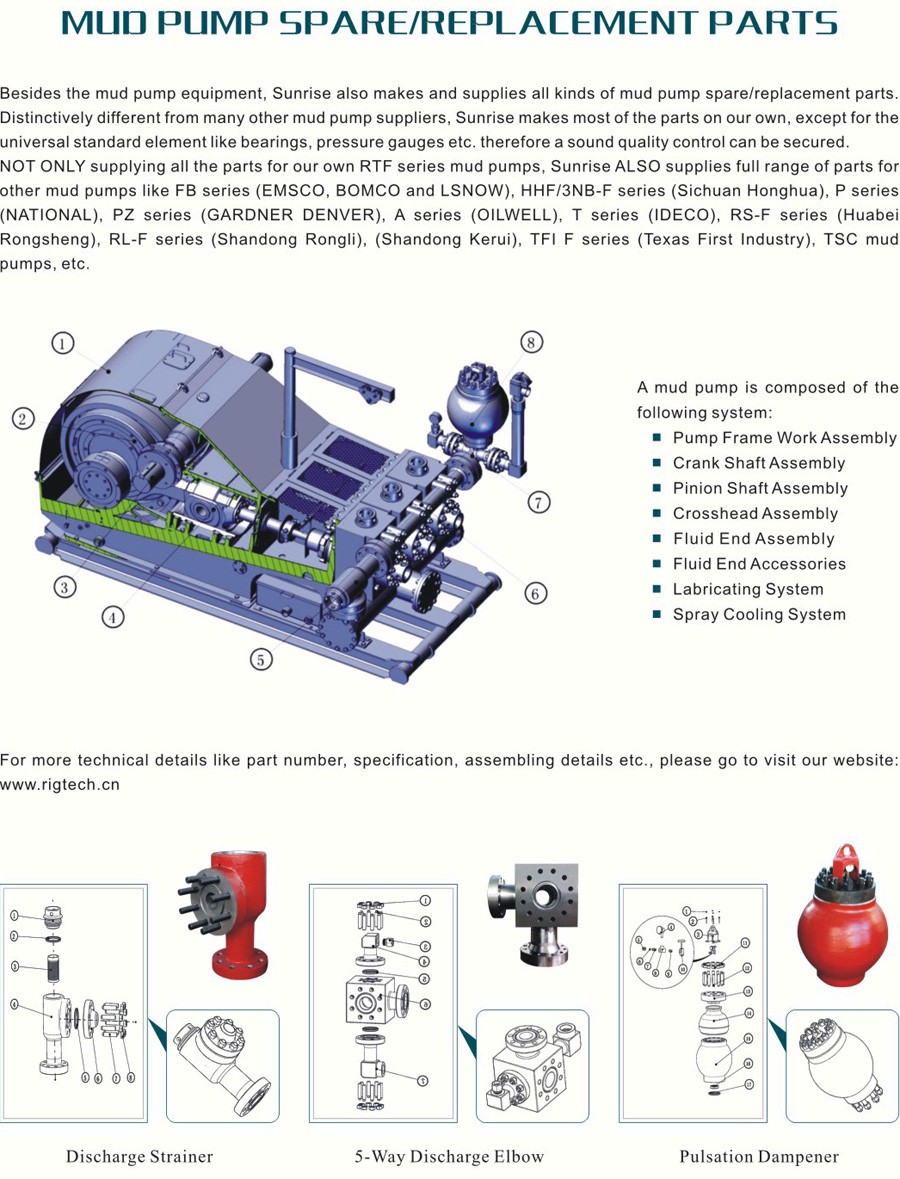

A Mud Pump may have many changeable parts, such as liner, piston, extension rod, pulsation dampener, valve, clamp, etc. Lake Petro could provide 100% interchangeable parts of many common brands of pump. We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials. Piston assembly is the important spare parts and expendable parts of oil drilling mud pumps. Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump. Fluid End Module is an important component of the hydraulic pump end of the mud pump.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

We stock fluid end parts for the5×6 mud pump, 5×6-1/4 FM45 mud pump, 5×8 mud pump, 5-1/2×8 mud pump, 5X10 mud pump, 4-1/2×5 mud pump, 7-1/2×8 mud pump, and 7-1/2X10 mud pump. The Gardner Denver mud pump model numbers for the above pumps are as follows: 5X6-FGFXG, 5X8-FDFXX, 5-1/2X8-FDFXX, 5X10-FDFXD, 4-1/2X5-FFFXF, 7-1/2X8-FYFXX, 7-1/2X10-FYFXD. We also handle Wheatley, Gaso, Worthington, Failing and Centerline parts and pumps. We also stock Foot Valve, Liner Puller, Valve Seat Puller, (4″ Inline Check Valve. Our Gardner Denver mud pump parts are not only competitively priced, they are also made in the USA. Oil Recommended by Gardner Denver. Call any of our experienced representatives to get the help and knowledge you deserve.

GDEP is the original creator of the drilling pump and continues to set the standard for durable, high-quality drilling pumps that can withstand the world’s toughest drilling environments. Starting with our PZ7 and rounding out with the market"s most popular pump, the PZ1600, our PZ Series of pumps are the perfect choice for today"s high-pressure drilling applications.

The components listed below requires maintenance as mentioned in its manufacturers The manufacturers manuals forms part of this document and can be found in Volume II.

Description Place of WIRTH Type Manufacturer Volume installation Ident-no. / Supplier / Chapter Main motor PUMP – GEAR 21028668 GE 752 GE II / 1 DRIVE ARB 3 Proximity Switch - 232389 MD Totco II / 2 Coupling 21029765 Rotex 28 KTR II / 3 Heat exchanger 21021366 CM 824 Universal II / 4 Hydraulik E-Motor 21029819 5HP Marathon II / 5 Gear pump 21029731 KF 63 RF1 Kracht II / 6 Pressure switch 21024770 15/1,5 bar Georgin II / 7 Centrifugal pump CYLINDER 21006540 1“x1 ½“ C- National II / 8 COOLING 11 Oilwell Coupling N-EUPEX 21031461 B 95 Flender II / 9 E-Motor 21029557 5HP Marathon II / 5 E-Motor LUBRICATION 21029919 5HP Marathon II / 5© WIRTH Maschinen- und Bohrgeräte-Fabrik GmbH / Änderungen vorbehalten – subject to modifications

SYSTEM Gear pumpe 21029731 KF 63 RF1 Kracht II / 6 Pressure limiting valve 21018076 SPVF Kracht III / 10 Medium pressure filter 21020268 HH 8910 Pall III / 11 C24 Accumulator PRESSURE 21000552 K20-5000 Hydril III / 12 MANIFOLD CE Pressure gauge 21028901 Type C Labom/ III / 13 Cameron Safety relief valve SAFETY B0019748/ C1500 Retsco III / 14 RELIEF VALVE 11 Spur wheel flange SLEWING 20234277 VS 1/1 – Yale III / 15 course CRANE 1000 kg Roll chassis 20234276 HTP-1000 Yale III / 16 Hand lever pump ACCESSORIES 21032541 728619 E SKF III / 17

PAGE DRAWING NO. REV. DRAWING DESCRIPTION 1 PL 1292332 C FLUID END ASSEMBLY (STANDARD) 2 PL 1292613 -- FLUID END ASSEMBLY WITH PREMIUM MODULES 3 PL 1292737 -- FLUID END ASSEMBLY WITH H.P. MODULES 4 PL 1292000 U FLUID END ASSEMBLY (SHEET 1 OF 3) WITH TAPR-LOK VALVE COVERS 5 PL 1292000 U FLUID END ASSEMBLY (SHEET 2 OF 3) TOP VIEW OF ROD CHAMBERS 6 PL 1292000 U FLUID END ASSEMBLY (SHEET 3 OF 3) SECTION THRU ROD CHAMBERS 7 PL 1292120 D LINER SPRAY SYSTEM 8 PL 1292001 X POWER END ASSEMBLY (SHEET 1 OF 3) SECTION THRU POWER END 9 PL 1292001 X POWER END ASSEMBLY (SHEET 2 OF 3) SECTION THRU CRANKSHAFT 10 PL 1292001 X POWER END ASSEMBLY (SHEET 3 OF 3) SECTION THRU PINION AND CROSSHEADS 11 -- -- SUCTION STABILIZER ASSEMBLIES (OPTIONAL) 12 PL 1292312 G DAMPENER MANIFOLD, DOUBLE SIDE INLET (OPTIONAL) 13 -- -- DAMPENER MANIFOLD ASSEMBLIES (OPTIONAL) 14 -- -- LINER FLUSHING SYSTEM (OPTIONAL) 15 PL 1292316 -- LINER FLUSHING SYSTEM, RIGHT ANGLE DRIVE (OPTIONAL) 16 PL 1291157 B LINER FLUSHING PUMP, RIGHT ANGLE DRIVE (OPTIONAL) 17 -- -- STRAINER CROSS ASSEMBLIES (OPTIONAL) 18 -- -- TOOL AND ACCESSORIES 19 PL 1292004 E OUTLINE DRAWING

Triplex: This mud pump is used for drilling applications needing high pump pressure. This model works by decreasing the working fluid volume being discharged to generate pressure for producing the flow. There are three pistons in the triplex pump, with the middle piston generating more pressure on the crankshaft. High piston load can lead to excessive pressure and crankshaft failure if the components are not properly sourced.

Quintuplex:Quintuplex mud pump is perfect for pumping fluid at the time of drilling operations. It works as a continuous duty return piston. This is used in terms of its external bearings to provide crankshaft support to ensure the proper functioning of the sheaves.

Duplex: These mud pumps ensure that the mud circulation reaches the well"s bottom from the mud cleaning system. Duplex pumps have binocular floating seals as well as safety valves.

Saigao offers high-quality OEM mud pump spares, consumables, expendables and spare parts. Our mud pump parts are made with the highest standards of quality, offering competitive pricing and exceptional durability.

Drilling consumables such as mud pump systems and their components can drastically increase your uptime while reducing costs and health/safety/environmental (HSE) risks. To support your drilling needs, Forum’s patented P-Quip® mud pump system offers a single-source solution that integrates high-quality fluid end components for maximum longevity and performance.

With more than 20 years of successful operation in severe environments, P-Quip offers a proven track record for the lowest cost of ownership in the industry. As part of our commitment to quality, our mud pump parts use patented Banded Bore™ technology that significantly reduces stress concentrations and leads to longer module life.

One of Forum’s most committed core values is that “no one gets hurt,” and the P-Quip system is designed to support that principle. Streamlined and easy to use, it reduces or eliminates the need for manual force during maintenance, shrinking the time needed to replace high-use components and minimizing safety risks.

The positive displacement mud pump is a key component of the drilling process and its lifespan and reliability are critical to a successful operation.

The fluid end is the most easily damaged part of the mud pump. The pumping process occurs within the fluid end with valves, pistons, and liners. Because these components are high-wear items, many pumps are designed to allow quick replacement of these parts.

Due to the nature of its operation, pistons, liners, and valve assemblies will wear and are considered expendable components. There will be some corrosion and metallurgy imperfections, but the majority of pump failures can be traced back to poor maintenance, errors during the repair process, and pumping drilling fluid with excessive solids content.

A few signs include cut piston rubber, discoloration, pistons that are hard to remove, scored liners, valve and seat pitting or cracks, valve inserts severely worn, cracked, or completely missing, and even drilling fluids making their way to the power end of the pump.

The fluid end of a positive displacement triplex pump presents many opportunities for issues. The results of these issues in such a high-pressure system can mean expensive downtime on the pump itself and, possibly, the entire rig — not to mention the costly repair or replacement of the pump. To reduce severe vibration caused by the pumping process, many pumps incorporate both a suction and discharge pulsation dampener; these are connected to the suction and discharge manifolds of the fluid end. These dampeners reduce the cavitation effect on the entire pump which increases the life of everything within the pump.

The fluid end is the most easily damaged part of the mud pump. The pumping process occurs within the fluid end with valves, pistons, and liners. Because these components are high-wear items, many pumps are designed to allow quick replacement of these parts.

Additionally, the throat (inside diameter) can begin to wash out from extended usage hours or rather quickly when the fluid solids content is excessive. When this happens it can cut all the way through the seat and into the fluid end module/seat deck. This causes excessive expense not only from a parts standpoint but also extended downtime for parts delivery and labor hours to remove and replace the fluid module. With that said, a properly operated and maintained mud recycling system is vital to not only the pump but everything the drilling fluid comes in contact with downstream.

8613371530291

8613371530291