mud pump crane supplier

The Mount Wilson Solar Observatory was first funded by the Carnegie Institution of Washington in 1904. The site is an astronomical observatory in Los Angeles, California and contains two historically important telescopes: the 60-inch Hale telescope built in 1908 and the 100-inch Hooker telescope. The facility is used for astronomical research and offers visitors guided tours. In 1911, A Deming Triplex pump with a 15 HP motor was installed to supply the pressure for the fire hydrant system. It operated continuously for an estimated 50 years until an entire system upgrade in the 1960’s obsoleted the pump. In 2008, there was a need for a backup firefighting unit while the new system was being serviced. The 1911 Deming Triplex pump was resurrected for the application. After routine servicing the pump operated without any issues. The Deming brand was the first pump line manufactured by Crane Pumps & Systems and offers a full line of highly regarded municipal and industrial pumps today.

Crane Pumps & Systems is a world-class manufacturer of quality pumps and accessories offering a wide range of solutions and services for the municipal, residential building, commercial building, military, and industrial markets.

Its trusted brands; Barnes, Burks, Crown, Deming, Prosser and Weinman provide innovative designs and durable construction. Hudson Pump & Equipment a Division of Tencarva Machinery is proud to be the Authorized Crane Pumps & Systems distributor in Florida.

Wherever there is a need for fluid handling equipment a Crane Pumps & Systems product is hard at work – from the sump in a basement to a municipal pressure sewer system, from a split case in a commercial boiler room to a self priming pump on a marine pier or a grinder pump for a poultry process. Other applications include processing plants, power generating stations, constructions sites, utility maintenance fleets, and military.

Crane Engineering offers every type of fluid process pump available in the market place; centrifugal, positive displacement, gear, air-operated diaphragm and metering. We offer the full range of materials of construction to meet application requirements in metallic and non-metallic designs. While mechanical seals or packing are the most common methods for shaft sealing, sealless magnetic drive arrangements are available on many models.

Crane Engineering"s pump portfolio is anchored byGoulds, Viking, Gorman-Rupp, Netzsch, Warren-Rupp, Sulzer/ABS, Waukesha/Cherry-Burrell, WeirandPulsafeeder. Our large scope of supply, allows us to select the best pump for the application; taking into account operating criteria, plant standards, and budget requirements.

McFarland-Tritan, LLC"s positive displacement reciprocating plunger pumps are durable and reliably engineered as a hydrostatic test pump and chemical metering pump. Intrinsically safe, due to their non-electric air/gas driven design, these pumps use corrosion resistant materials for use in difficult and hazardous areas, such as offshore oil/gas platforms. McFarland-Tritan, LLC offers air operated/gas driven pumps in sizes ranging from the single head plunger pump, Mac-24, for intermediate high pressure testing and injection, to larger versions at higher pressures and dual stage pumps, Mac-14 and Mac-28 Two-Stage. See descriptions below for sizes in between.

Pump Express is a stocking CRANE PUMP DISTRIBUTOR offering the lowest prices on all CRANE PUMPS FOR SALE. We sell CRANE PUMPS DIRECT, so you pay less for all of your CRANE PUMP PRODUCTS. For help selecting and sizing the right pump or pump replacement parts call our CRANE PUMP HELP LINE at 1-800-429-0800

Our First Mate, Ensign 500, and Commander 500 portable davit cranes with capacities of 500–850 lbs are recommended for lifts under 1,000 lbs. Each of these models will provide users with features such as extra hook height, streamlined set-up/disassembly, ergonomic operation, and more. Contact us for product suggestions that are customized to your unique requirements, technical specifications, and facility design.

Our Ensign 1000, Commander 1000, and Commander 2000 portable davit cranes with capacities of 1,200–2,000 lbs are recommended for lifts over 1,000 lbs. Depending on the model, the cranes offer varying features such as multiple boom lengths/angles, streamlined set-up/disassembly, ergonomic operation, and more. Contact us for product suggestions that are customized to your unique requirements, technical specifications, and facility design.

For pump lifts of up to 3,000 lbs, our stationary Captain 2000, Captain 2500, and Admiral 3000 cranes are an ideal solution. Each of these models will provide users with features such as extended boom lengths, 360° rotation, a quick-disconnect anchor, and more. Contact us for product suggestions that are customized to your unique requirements, technical specifications, and facility design.

Our First Mate portable davit crane is affordable, lightweight, and perfect for a wide variety of simple jobs, up to 850 lbs, where adjustable reach is not required. Other economical options to lift a lighter load include our Ensign 500 and Commander 500 portable davit cranes with capacities of 500 lbs and 650 lbs, respectively. The Ensign 500 is specially designed for clearance, lift height, and ergonomic operation, while the Commander 500 is a popular lightweight model with an adjustable boom that’s ideal for smaller loads. Contact us for product suggestions that are customized to your unique requirements, technical specifications, and facility design.

Since this can be a complicated question that requires a more in-depth conversation, we encourage you to contact us directly. Depending on your situation, you may benefit from buying many bases and fewer cranes to meet your project goals and budget. Larger cranes may also be ideal based on the sizes of the pumps.

Start a conversation with us to discuss base placement and the reach required to lift each pump. We can provide product suggestions that are customized to your unique requirements, technical specifications, and facility design.

Thern’s entire collection of portable davit cranes offer easy assembly and quick disassembly for effortless transport from base to base or storage. Contact us for product suggestions that are customized to your unique requirements, technical specifications, and facility design.

Our economical Ensign 500 and Ensign 1000 portable davit cranes are specially designed for clearance, lift height, and ergonomic operation. Our Commander series also offers maximum flexibility with multiple boom lengths and angles to choose from. An optional base extension is available to provide additional hook height without affecting the rating of the crane for our First Mate and Commander Series. Contact us for product suggestions that are customized to your unique requirements, technical specifications, and facility design.

Why APPI:Drilling mud is hard on pumps as it’s both viscous and caustic. For manufacturers, this means it needs to be quick and easy to access pumps that require repair or replacement.

When Brandon Westenberg, owner of Portable Mud Systems, specified a pump for one of his mud systems he matched it with one of our HF4700 AC electric mud pump hoists with an optional strap to do the lifting.

It is mounted on a beam that goes over the pump and has epoxy based paint with stainless steel fasteners to help protect it from the elements – including the mud being slung on the jobsite.

Allied Power Products, Inc. has specialized in providing winches, hoists, capstans and cranes to meet our customers’ specific application requirements for more than 30 years.

We know that cost savings on identical spare parts is important for offshore rig Companies today. Therefore we provide our services and spare parts at considerable cost reductions compared to sourcing from the major OEMs. Tratec can guarantee identical parts with all required part certificates. We maintaing the highest quality, using state-of-the art service facilities and experienced, specialist mud pump engineers for service work.

Tratec has supplied more than 20 mud pump spare part, overhaul and recertification projects the last 5 years. References include rig companies Odfjell Drilling, Maersk Drilling, Archer, Saipem, KCA Deutag, and others.

Tratec can supply overhaul and parts compatible with the following Mud Pump makers and trademarks: National Oilwell Varco (NOV), MHWirth, Continental Emsco, Gardner Denver, Lewco, Drillmec, and others. Tratec is an independent supplier of drilling equipment parts. Tratec is neither a licensee, nor is affiliated with any of the named original equipment manufacturers (OEM). The manufacturer’s names, equipment names, or trademarks used herein are solely for identification purposes, and are not intended by Tratec to cause confusion as to the source, sponsorship, or quality of the parts supplied by Tratec. The original equipment manufacturers named above and throughout this website do not sponsor, promote, warranty or endorse Tratec’s supply of parts.

At BOPM, we constantly maintain 5 million worth of mud pump parts on the shelf at our Houston warehouse location. It includes modules, liners, extension rods, piston rods, pistons , threaded rings, caps, valve covers, valve guides, valves, seats etc. for all major brands of pumps: Gardner Denver®, Ideco®, Emsco®, National®, Oilwell®, Skytop Brewster®, Lanshi(3NB1300C) ®, Bomco ®, HH ®.

BOPM offers a complete line of interchangeable fluid end modules and accessories for triplex mud pumps, such as National, Emsco, Gardner Denver, Bomco, Ideco and Oilwell. We offer both standard OEM style replacement parts and Two piece “L” Shaped fluid ends.

BOPM piston rods are made with premium grade, heat treated alloy steel. The rods offer excellent resistance to fatigue, corrosion and heavy loads. A full line of piston rods are available for various pumps.

BOPM extension rods are made from high strength alloy steel, and are either heat treated or chrome plated. The rod offers excellent resistance to fatigue, corrosion and heavy loads. BOPM extension rods are machined and polished to ensure a perfect seal to protect the mud pump gear end.

All of our gear set adopt high-end carburization heat treatment and precise grinding machining to offer unparalleled durability; first we use high strength alloy steel, then adopt the Carburization heat treatment to enhance the hardness and wearability, finally adopt the grinding fine machining to ensure the smooth gear teeth surface; Resulting in consistent and rugged performance throughout pump operation.

BOPM bonded urethane pistonsare constructed of urethane, bonded to a steel hub. The double durometer urethane is designed to provide optimal performance in oil or water based mud and high drilling pressures.

BOPM Replaceable Rubber Pistonis made with tough and durable Buna N rubber for all pressures, and is ideally suited for water-base mud. A special processing of the fabric provides an unusually waterproof bond of fabric to piston which assures longer life.

BOPM Bonded Rubber Pistonis made with tough and durable Buna N rubber for all pressures, and is ideally suited for water-base mud. A special processing of the fabric provides an unusually waterproof bond of fabric to piston which assures longer life.

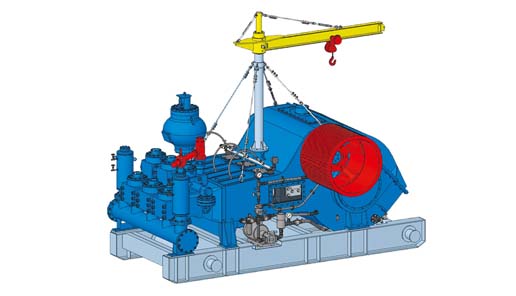

Bentec completely redeveloped the concept of Mud Pumps. Being equipped with a direct-driven gearbox, an own developed motor, and a state-of-the-art pump housing, there is no need for an internal gear coming with many disadvantages and no more belt tensioning.

Bentec Mud Pumps are light weight and have a small footprint. The AC-powered motor is top or rear mounted – suitable for any drilling rig arrangement. The pump is available with 5 000 or 7 500 psi fluid ends, and all its parts that are subject to wear and tear meet API standards and are available worldwide.

A handling crane makes it easy to handle the fluid end components. Furthermore, Bentec uses a patented liner and valve clamping technology to reduce the maintenance time significantly. A quick-change liner and piston system serves for easy maintenance. A special feature of the Bentec MUD PUMP is the side-mounted gear drive.

Liner cooling and gear oiler systems are included; a supercharge pump and a noise reduction package can be installed upon request. The Bentec MUD PUMP is the right choice especially when it comes to noise-sensitive environments such offshore or densely populated environments.

Beyond the supply of Mud Pumps, Bentec acts as system supplier. The pumps can be delivered together with a Bentec Power Control System and a Bentec Soft Pump System.

Since 2001, TSC Manufacturing and Supply, LLC has been a leading global manufacturer and supplier of fluid end expendables, as well as mud pump spare parts for oilfield applications. Today, we continue to keep our proud tradition of excellence going, as we strive to better ourselves in order to better our customers" experience. Our global network of inventory locations provides unrivaled quality, customer service, on-time delivery, and unmatched technical integrity.

When it comes to mud pump fluid end expendable parts, TSC Manufacturing and Supply, LLC, has it all. TSC can, and will, match your needs, so that you won’t be lacking in anything. TSC mud pump liners are designed and manufactured to meet or exceed original equipment specification and API standards for almost all types of mud pumps in use today. With advanced technology, metallurgical control, and rigid inspection, we offer unmatched performance and durability, according to customer testimonies, in the most severe drilling conditions; both triplex and duplex liners are available in a wide range of sizes.

There are two categories of pumps utilized in construction and dewatering applications: centrifugal, which includes self-priming trash, dewatering, high-pressure and submersible pumps; and positive displacement, which includes diaphragm pumps of various types.

8613371530291

8613371530291