mud pump dampener function manufacturer

Mud Pump Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump.

Mud Pump Pulsation Dampener is a pneumatic device built into the outflow line of each UUD pump to dampen the pressure fluctuations resulting from the action of the pump. Although presented as a surge tank, this device is really a device that can be tuned to greatly diminish the output pulsations transmitted downstream from the mud pump. Unfortunately, the effectiveness of the pulsation dampener is a function of both output pump pressure and frequency of the pump pulsations.

All pulsation dampeners utilize one of two methods for mitigating energy produced by reciprocating pumps; compression or exchange. The traditional gas-charged dampeners use a compressible gas cushion, either by a gas over liquid or gas-filled diaphragms, bladders, or cartridge. As the reciprocating pump produces pressure spikes, the gas compresses, thus absorbing the pressure difference and smoothing the pumped media flow. For maintenance free pulsation dampeners, rely on energy exchange. There is a common misconception regarding maintenance free pulsation control devices that the pumped media is compressible enough to absorb the reciprocating pumps’ pressure spikes. This is not true. However, the maintenance free pulsation dampeners work by utilizing the kinetic energy exchange. This kinetic energy exchange can only happen if the pulsation dampener’s volume is large enough to dissipate enough energy to reduce the adverse effects caused by the reciprocating pump. This is why maintenance free pulsation devices require massive volumes to be effective. Sigma Drilling Technologies has developed a pulsation dampening system that utilizes both methods for reducing the harmful effects of positive displacement pumps, both compression and exchange.

In order to reduce the fluctuation of pressure and displacement of the drilling mud pump, air bag are usually installed on the discharge line. The air bag manufactured by our company has advanced structure and reliable performance, which can make the mud pump achieve the best inhalation effect and is widely used in petroleum, high-pressure pipeline of chemical transportation. This product can also be used as a stabilizer and shock absorber for air extractors.

The pulsation dampener can be divided into discharge pulsation dampener and Suction Dampener.Discharge pulsation dampener- reduces displacement of pump and fluctuation of pressure.

In order to reduce the pressure and displacement of drilling mud pumps, air bags are usually installed on the discharge pipeline. The suction air bags produced by our company have advanced structure and reliable performance, which can make the mud pump achieve the best suction. The effect is widely used in high-pressure pipelines for petroleum and chemical transportation. It can balance the peak pressure of high-pressure fluid in mud pumps, stabilize the pressure, and reduce losses. This product can also be used as a stabilizer and shock absorber for air extractors.

The mud pump is installed on the discharge line, which can balance the peak pressure of the high pressure fluid of the mud pump, play a role in stabilizing the pressure, reducing losses and ensuring safety, so that the mud pump can achieve the best suction effect.

Drain buffer: Installed at the drain end of pumps and compressors, it can avoid fatigue damage of cylinder pistons, valves, bases and pipelines due to pressure fluctuations, thereby extending the service life of the equipment.

Reverse Oscillation: When the head of the water pump reaches a certain height, the reverse oscillation caused by the impact of the fluid into the pump valve will cause the pump to suddenly shut down. A suction air bag is installed to absorb part of the vibration.

BW Series Mud Pumps are mainly used for supplying flushing fluid to the borehole in core, geothermal, water resource, shallow oil, CBM and other drilling process. The fluid can be divided into mud, water, etc. They also can be used as transfer pumps of the above-mentioned medium. This series of mud pumps are with simple structure and easy to maintain and operate. Piston, lip-shaped and self-sealing type, is made of rubber or PTFE and nylon pads, equipped with shock-resistant pressure gauge, necessary spare parts and special tools. Bi-metal liner can be used to extend service life of pump greatly.

NBB Series Mud pumps are mainly used for the core, coal geology, metallurgy geology, hydrogeology engineering hole drilling fluid is supplied, flushing fluid can be divided into mud, water, etc., may be used as the above medium pump.

The mud pump is crank structure, horizontal triplex single acting piston pump, the piston is self-sealing lip, made of rubber or PTFE and nylon protective pads pressed, the pump adopts auto gearbox, variable five kinds of flow, the pump is compact, high efficiency, durable, safe, reliable, easy maintenance, low maintenance costs.

ZB Series grouting pumps are mainly used for kinds of weak corrosivity viscous and nonviscous liquid grouting(such as water, mud), especially for vertical shaft working face grouting, goaf filling, coal mine water inrush governance and so on.

The pump is triplex single-acting plunger high pressure pump, fitted with international first-class gearbox, which is of features like compact structure, multistage speed regulation, realizing different flow rate and pressure, meeting the grouting requirements of different formation. Electric motor drives triplex pump through transmission system. It has many advantages, like convenient adjustment for pressure and flow rate, long service life and so on.

3NB & 5NB Series Mud Pumps are mainly used for oil, water well, geothermy, CBM, shale gas, coalfield exploration, freezing well as well as well other drilling ,well cementation, work-over and other operations in industrial and mining enterprises. It is used for transferring mud, clay gum, mortar and other medium to the borehole. The pump adopts international advanced technology. It is characterized by advanced structure, reliable operation, good suction performance, long service life of wearing parts, easy for maintenance and repairing and so on.

F Series Mud Pumps are mainly used in oil field and geological prospecting for well drilling, well work-over, cementing, water shut off, water flooding and sending mud, clay, grout and so on.

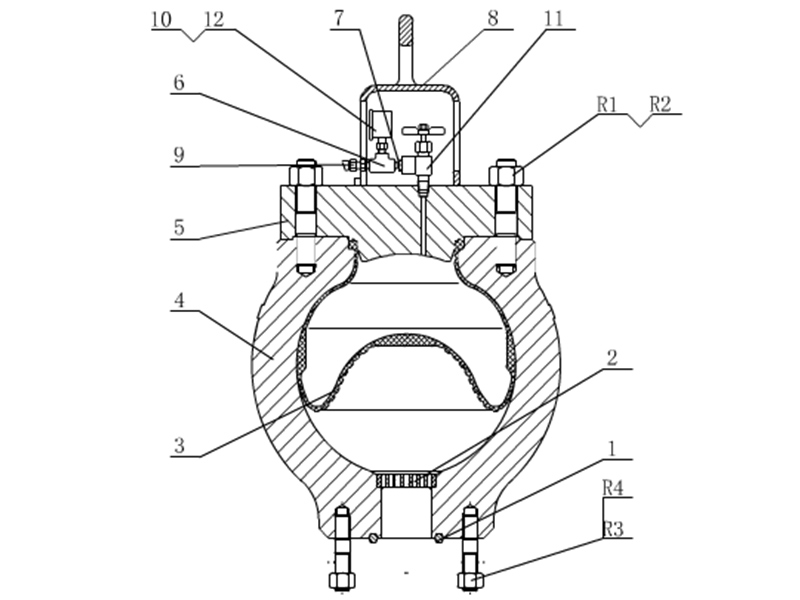

Pulsation Dampener (Surge damper) is installed on the discharge pipeline of the mud pump to balance the peak value of the high-pressure fluid pressure of the mud pump, so as to stabilize the pressure and reduce losses.

Pulsation dampeners (also called pulsation dampers) are used for stabilizing the flow and the pressure in circuits with volumetric or dosing pumps. They are used in a wide range of applications.

In every pulsation dampener there is a separator element between the gas it is charged with and the liquid of the circuit; its basic function being to avoid the leaking of the gas into the circuit. This separator element is basically made of two kinds of materials: Rubber (NBR, EPDM, FPM, butyl, silicone, etc…) or a thermoplastic material (normally PTFE); although it can also be made in stainless steel.

When a rubber separator element is used, the dampener is called bladder type. If the material is PTFE, we refer to membrane type and bellows type dampeners, depending on the shape of the separator element.

Choosing between different types of dampener depends on characteristics of the circuit like working pressure, temperature and chemical compatibility between the liquid and the material of the separator.

All our pulsation dampenersare made according to the European PED97/23/CE pressure vessels regulations, and their design meets the AD-2000 and ASME VIII Div.1 & 8 codes requirements (“U” stamp pending).

We can supply all of our dampeners with different circuit connection gauges as well as fitted with whatever flange, either screwed on, welded or integrated, to suit the customer’s needs.

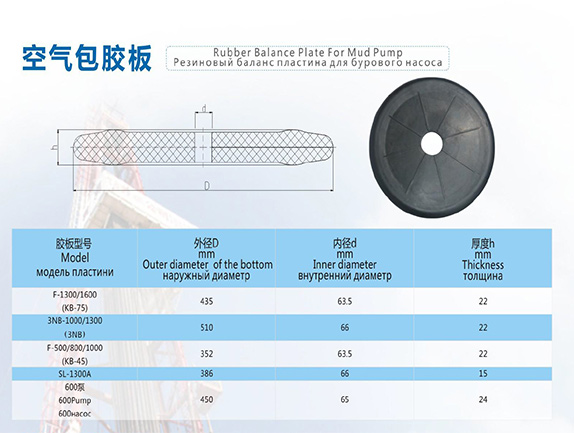

Mud pump pulsation dampeneris the mud pump discharge end main component, installs in the hydraulic end discharge pipe one end, plays the stable pressure and the pressure compensation function, the air bag work pressure is the mud pump work pressure 80%.Attention should be paid to the use of air bag, must be the first pressure relief.The mud pump of F500/F800 USES kb-45 air bag, and the mud pump of F1000/F1300/F1600 USES kb-75 air bag.The middle tie rod produced by our company is made of 35CrMo material, which has a smooth surface after chrome plating and fine grinding, greatly improving the wear resistance and corrosion resistance.

Proper installation and use of pulsation dampener can effectively reduce pressure fluctuations in the discharge system, thus achieving a more uniform fluid flow.In order to achieve a high service life of the air bag, always maintain the recommended ratio between the pump pressure and the air bag precharge pressure (generally not more than 2/3 of the pump discharge pressure, the maximum should not exceed 4.5mpa).

2. In the maintenance of air bag, air bag pressure must be zero, the pump pressure must be zero.Cannot rely on the pressure gauge to judge, because the residual pressure is small, the pressure gauge can not be displayed, but this low pressure will also lead to accidents!

Rundong provides discharge pulsation dampener assembly, discharge pulsation dampener capsule and suction pulsation dampener capsule and related accessories, which all could be applied on different types of mud pumps such as F series, PZ series and P series, etc.

A Pulsation Dampener is an inline dampening device used to smooth out pulsations in a pump’s output. They are used alongside a pump as a mounted accessory to help achieve certain flow rates for an application. They can be used with a variety of Positive Displacement Pumps which typically generate a pulsed flow (Diaphragm Pumps, Peristaltic Pumps, Dosing Pumps, Piston Pumps etc)

Pulsation Dampeners are required in some process applications when the customer needs smooth flow into the next phase of the production line, for example, to get an accurate reading through a flow meter or to fill a hopper consistently. On the flip side, Dampeners can be used to reduce water hammer effects through pipework. Water hammer is where the pump causes the pipes to vibrate and potentially fail, a smooth flow from a Pulsation Dampener reduces this.

For example, Diaphragm Pumps inherently produce a very turbulent discharge flow meaning that in some instances a Pulsation Dampeners are required to give a smooth pulse-free flow.

In the Tapflo UK range, we focus on Pulsation Dampeners for Diaphragm and Peristaltic Pumps, although we can also supply them for other pump technologies.

The Active Pulsation Dampener works by supplying an equal pressure to the pulsation supplied by the pump. The Dampener supplies this pressure during the low-pressure points of the pump’s operation, as the pressure drops between pump strokes creating a pulsating flow. The pressure supplied by the dampener decreases pressure variations, therefore producing a steady flow from your Diaphragm Pump. You can see the pressure drops and Pulsation Dampener benefits in action in the diagram below.

Tapflo supplied a 2” Air Operated Diaphragm Pump to a bleach factory, the customer used the T400 PTT for a couple of days and then called us to explain that the bleach line, running along the roof of his production facility, was shaking. Due to the nature of the product being pumped health and safety on site could not allow this to continue.

To support our Peristaltic Pump customers, Tapflo offers an in-line Pulsation Dampener for our PT and PTL Series’. They can reduce the pulsation of your PT Pump by as much as 90% to reduce the vibration and water hammer effects on pipework. Another benefit of this accessory is its ability to be installed on-site horizontally or vertically for flexible installation.

A pulsation dampener reduces or eliminates the variations in pressure and flow produced by reciprocating pumps. In many applications, low frequency pressure waves cause problems within a given piping system and/or process. Eccentric, cam-driven pumps are probably the most commonly applied for services that require pulsation dampening, e.g., metering pumps and reciprocating (power) pumps.

Pulsation dampeners are found in a variety of designs, but for our purposes we will focus on only gas-charged pulsation dampeners, which rely on a calculated volume of compressed gas, usually Nitrogen, which is alternately compressed and expanded in synchronization with the pump plunger to reduce or eliminate pressure pulsations. This gas volume is normally separated from the process fluid by a flexible membrane. Common membrane designs include elastomeric bladders, PTFE diaphragms, PTFE bellows or stainless steel bellows.

Pressure waves or pulses are a consequence of the alternating acceleration and deceleration of fluid velocity corresponding to the travel of the piston or plunger. The pattern and amplitude of these pulses varies with pump configuration, specifically the number and size of pistons, as well as fluid compressibility factors.

It is precisely the fluid volume above mean on the discharge cycle of each stroke, which induces these pressure pulsations into a piping system. The number of pistons offered by the pump—given that all are of identical diameter and equally phased—displace a known peak volume above mean. These constants may be influenced by fluid compressibility, but for the purpose of this explanation we’ll assume none at this point. A pulsation dampener absorbs only that portion of piston displacement above mean flow, and then stores it momentarily before discharging it during the portion of the cycle below mean flow (on the suction stroke).

A simplex pump displaces a volume of fluid above mean that is equal to about 60 percent of total displacement. A duplex pump displaces a lower fluid volume above mean, approximately half that of a simplex pump. Pumps of three or more pistons of equal diameter, stroke length and proportionally phased will always present a very small fluid volume above mean to the piping system. A triplex pump, for example, produces about a 4 percent peak, as long as fluid compressibility factors and pump efficiencies are not at issue.

These smaller fluid volumes are accounted for by the crank angle of each of the cylinders. Triplex pumps are offset by 120-deg. Quadruplex pumps are set apart at 90-deg offsets; quintuplex pumps are offset 72-deg, and so on. It is the resulting overlap in pulses that yield the smaller fluid volumes above mean.

Fluid velocity gradients follow the same mechanical velocity gradients of the eccentric cam that drives the piston(s). Halfway through the piston’s forward travel (discharge stroke), fluid velocity between the discharge check valve and the pulsation dampener begins to decay. The corresponding drop in pressure causes the membrane inside the dampener to expand since the internal gas pre-charge pressure is now higher than the line pressure. The (stored) fluid now being displaced by the pulsation dampener maintains velocity downstream of the dampener thereby reducing, if not eliminating, any downstream pulsations.

Note: A pulsation dampener removes pulses only from the line downstream of the dampener—not upstream. That’s why it’s always recommended that discharge dampeners be installed as close to pump discharge nozzles as possible. In an application of a dampener for suction stabilization (reduction of acceleration head losses), it is the velocity gradient between the supply vessel and the suction nozzle that is minimized.

Let’s begin by defining the pump details required to properly size a pulsation dampener. We will use these values in a sample calculation to help clarify the process.

The result of the previous calculation is then divided by a constant. As noted previously, the constant is a function of pump configuration. We use a conservative 1.5 for simplex pumps, 2 for duplex pumps, and 7 for triplex pumps. Remember—if the fluid is compressible, then the constant may have to be adjusted downward.

Fluid volumes above mean are well within the range of these constants. The fluid pulse above mean flow from a simplex pump, for example, is about 60 percent. When we divide full stroke displacement by 1.5 the result is a conservative 67 percent. The divisor 7 that we use for triplex pumps allows for a nominal 14 percent fluid volume above mean. While 14 percent is far above the actual 4 percent produced by triplex pumps, the higher volume is an allowance for practical reasons, specifically size and nozzle limits. Otherwise, the result would be a very small dampener relative to pump size.

Ranges of (process) temperature and pressure must be considered in any sizing calculations for pulsation dampeners. Compensations must be made for temperature variations, which affect gas density, and dynamic variations in system pressure, since sizing is based on a set pre-charge pressure.

The objective is to select a dampener that is adequately sized to handle a range of operating pressures with a single pre-charge pressure. Remember that the gas pre-charge pressure should always be based on the minimum operating pressure as the pulsation dampener will have no effect when the system pressure is below the pre-charge pressure.

Changes in ambient temperature can also influence gas density, but they’re generally disregarded for the purposes of pulsation dampener sizing. It is usually sufficient to make seasonal adjustments to pre-charge pressures, if necessary. Temperature and pressure calculations are recommended to be done using absolute values (Kelvin for temperature and BarA or PSIA for pressure).

Some fluids are highly compressible, such as cryogenics, olefins, liquefied gases, anhydrous ammonia, etc. In these instances, the benefit of lower pulsations from multiple piston pumps may be somewhat compromised. Fluid compression occurs during the leading edge of the (eccentric) crank angle. Given sufficient pressure and a high enough compressibility factor, there may be little or no overlap of pulses at all—in which case, adjustments have to be made and pulsation dampeners with larger gas volumes should be selected.

By installing a properly-sized pulsation dampener, users can reduce or eliminate pipe shake, vibration and noise. The result is a continuous flow of product which is required in many metering, mixing and spraying applications. Reduced pressure pulsations minimize long-term damage to instrumentation and pump components while improving the accuracy of many flowmeters and increasing pump efficiency.

8613371530291

8613371530291