mud pump displacement calculator quotation

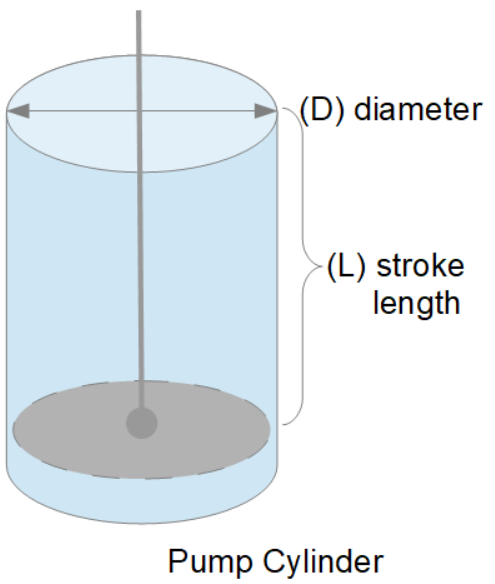

Rig pump output, normally in volume per stroke, of mud pumps on the rig is one of important figures that we really need to know because we will use pump out put figures to calculate many parameters such as bottom up strokes, wash out depth, tracking drilling fluid, etc. In this post, you will learn how to calculate pump out put for triplex pump and duplex pump in bothOilfield and Metric Unit.

The shaft power - the power required transferred from the motor to the shaft of the pump - depends on the efficiency of the pump and can be calculated as Ps(kW) = Ph(kW)/ η (3)

To size and select a pump, we first determine the flow rate. In an industrial setting, the flow rate will often depend on the production level of the plant. Selecting the right flow rate may be as simple as determining that it takes 100 gpm (6.3 L/s) to fill a tank in a reasonable amount of time or the flow rate may depend on some interaction between processes that needs to be carefully analyzed.

We provide hydraulic components & repair services for industrial applications like paper mills, saw mills, steel mills, recycling plants, oil & gas applications and mobile applications, including construction, utility, mining, agricultural and marine equipment. This includes hydraulic pumps, motors, valves, servo/prop valves, PTOs, cylinders & parts.

Pump Output per Stroke (PO): The calculator returns the pump output per stroke in barrels (bbl). However this can be automatically converted to other volume units (e.g. gallons or liters) via the pull-down menu.

A triplex mud (or slush) pump has three horizontal plungers (cylinders) driven off of one crankshaft. Triplex mud pumps are often used for oil drilling.

When it comes to pumping terminology, one crucial term to know is GPM — a measurement that will help you determine if you’re choosing the right pump. So what is GPM, and how do you calculate it?

GPM stands for gallons per minute and is a measurement of how many gallons a pump can move per minute. It is also referred to as flow rate. GPM is variable based on another measurement known as the Head, which refers to the height the water must reach to get pumped through the system. It is also referred to as flow rate. GPM is variable based on another measurement known as the Head, which refers to the height the water must reach to get pumped through the system.

Pumps are typically measured by their GPM at a certain Head measurement. For example, a pump specification may read 150 GPM at 50 Feet of Head, which means the pump will work at 150 gallons per minute when pumping water at a height of 50 feet.

GPM identifies the unique capabilities of a pump so you can select the right one for your specific needs. If you need a pump for a larger public area such as a golf course, marina or lake, you will need a pump with a much higher GPM than one used for your home’s well. Plus, choosing the correct pump is essential for reducing your costs and increasing your pump’s lifespan.

At GeoForm International, we are a leading manufacturer of high-quality submersible pumps, dredges, digester packages and aerators, all of which are made in the U.S. With our pump expertise, we know just how essential GPM is in the pumping and dredging industry from how much equipment costs to how long jobs will take.

The technique consists of injecting a small amount of air/gas into the liquid to lighten the hydrostatic liquid column. As the lighter fluid goes around the bit and starts up the annulus, the bottom hole pressure decreases. As the bottom hole pressure decreases, increase the air/gas injection and reduce the liquid injection until pumping only air/gas and the well is unloaded. Because of the compressible nature of the gaseous fraction, calculations are involved that are generally not adaptable for use with hand held calculators.

Included, are examples of wells (ranging in depth from 10,000 to 20,000-feet) that utilize various liquid-pump rates and methods (i.e. mud pump, mist pump and pump truck). The reader can reproduce the starting point calculation for any well using the examples provided.Objective

The "U" tube principle (different densities plus applied pressure equates to equilibrium) and the resultant frictional effects are the main mathematics involved. Intuitively, given enough pressure, wells full of liquid could be unloaded by simply applying gas pressure and displacing the liquid. The downside of this approach includes handling the kick at surface and the cost of the pressure source. Typically, for underbalanced wells, the compressors and mist pump are on site and consequentially, there is no incremental cost for their use.

Centrifugal pump affinity laws provide a method to determine a new pump operating point when a performance curve that indicates performance with different impeller diameters or operating speeds is not available.

Now that we understand what centrifugal pump affinity laws are, let"s take a look at the equations that will help you determine your new pump operating point.

The desire is to determine what the pump output would be using a 9" impeller and what the corresponding reduced speed would be to provide the same pump output with a 13" impeller. Using the affinity laws, the following results were obtained:

Need to make some flow/head adjustments to your existing pump? Ask us about it! We gladly provide technical assistance to businesses in Wisconsin and Upper Michigan.

Pump curves are calculated based on water which has an SG of 1. If a fluid has a higher specific gravity than water, then the head will show the same, but the pressure will increase since Pressure is a function relative to fluid calculated by multiplying Head x Specific Gravity.

The pressure supplied by a pump for each application is fluid dependent and relative to fluid density thus pressure will change according to the fluid’s specific gravity

Care must be taken where a pump curve shows a high NPSH is required. A fluid with a low specific gravity, must be checked against the NPSH required carefully.

Cavitation can occur if the inlet pressure is below that required by the pump, which can arise when the SG of the fluid is not accounted for correctly, when determining the NPSH available.

Positive Displacement Pump CurveA PD Pump curve will not be affected in the same way as a centrifugal pump curve by the specific gravity of a fluid, as flow rate will remain constant. However, the absorbed power will increase, with the pressure produced remaining fluid dependent.

8613371530291

8613371530291