mud pump displacement calculator for sale

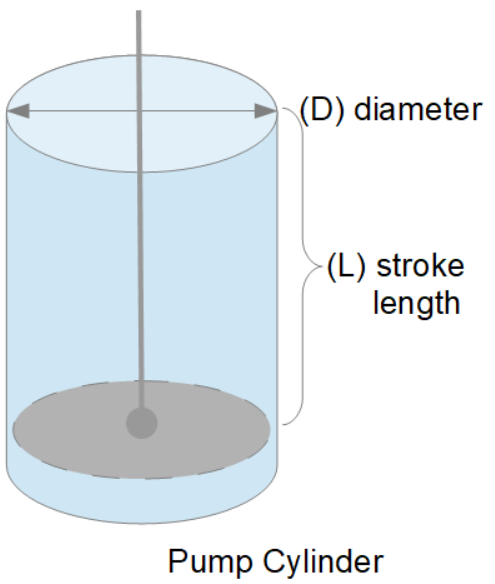

Pump Output per Stroke (PO): The calculator returns the pump output per stroke in barrels (bbl). However this can be automatically converted to other volume units (e.g. gallons or liters) via the pull-down menu.

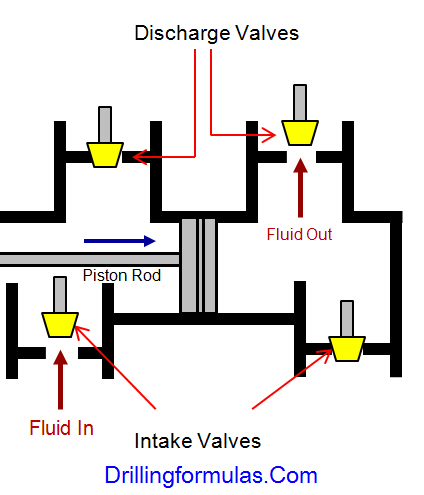

A triplex mud (or slush) pump has three horizontal plungers (cylinders) driven off of one crankshaft. Triplex mud pumps are often used for oil drilling.

Rig pump output, normally in volume per stroke, of mud pumps on the rig is one of important figures that we really need to know because we will use pump out put figures to calculate many parameters such as bottom up strokes, wash out depth, tracking drilling fluid, etc. In this post, you will learn how to calculate pump out put for triplex pump and duplex pump in bothOilfield and Metric Unit.

Disclaimer: These calculators are for estimation purposes only. They are not intended to provide complete answers to complex problems, but rather for quick reference and estimations.

Although Power Zone strives to keep these calculators up to date and accurate, Power Zone is not liable for mistakes made as a result of errors or misinterpretations of these calculators.

We provide hydraulic components & repair services for industrial applications like paper mills, saw mills, steel mills, recycling plants, oil & gas applications and mobile applications, including construction, utility, mining, agricultural and marine equipment. This includes hydraulic pumps, motors, valves, servo/prop valves, PTOs, cylinders & parts.

Impeller sizes are determined by calculating the TOR (sometimes called the time of rollover) for each compartment. This is the time, in seconds, required to completely move the fluid in a compartment (Table 10.1) and can be calculated by knowing the tank volume and impeller displacement:

Pumps are an integral part of almost all industries today. From construction and mining to automotive and aerospace, pumps play a vital role in keeping these industries moving forward. While there are many essential parameters in pumps, one critical parameter is the pump flow rate which becomes a guiding factor for pump manufacturers.

The pump flow rate is one of the most important factors to consider when selecting a pump. It measures how much water the pump can move in a given period of time and is typically expressed in cubic meters/hour (m3/ h). If you’re looking for a pump to use in your home or business, it’s essential to know the flow rate needed to meet your needs. Otherwise, you may end up with a pump that isn’t powerful enough or one that uses more energy than necessary.

The first step is to determine what your needs are. For example, if you’re using the pump to provide water for irrigation, you’ll need to know the maximum flow rate that will be required. Once you know your needs, you can start looking for pumps that have the required flow rate, as you will now be able to give more precise directions to the pump manufacturers about your requirement.

To choose the right pump, it’s also important to consider other factors, such as pump size and efficiency. For instance, a large pump with a high flow rate may be more expensive to purchase and operate than a smaller pump with a lower flow rate. However, it may still be the better option if your water usage is consistently high or you have multiple zones in your irrigation system that need water simultaneously.

Overall, choosing the right pump for your home or business requires careful consideration of all aspects of pumping performance. With the right pump from reliable pump manufacturers, you can rest assured that you’ll always have an adequate supply of water on demand.

Pump flow rate simply refers to the volume of fluid that is moving through a pump in a given time period. There are various units through which it is measured, and they include cubic meter/hour (m3/h), litre/sec (l/s) or gallons per minute (GPM). Different pump manufacturers refer to different pump flow units.

The flow rate of a pump can be affected by several factors, including the size and type of pump, the speed at which it is operating, and the resistance of the system it is pumping into.

Pump Speed: This is the number of times the pump can complete an entire cycle in a minute and is measured in rotations per minute (rpm). The faster the pump speed, the higher the flow rate.

Pump Size: Larger pumps can move more liquid than smaller pumps. This is why it’s essential to choose an appropriately sized pump for your application.

Now that you know the basics of pump flow rate, you can begin to select a pump that is appropriate for your application. Keep in mind that the factors listed above will all affect pump flow rate, so it’s essential to consider each one when you give your requirements to the pump manufacturers.

Pump speed is measured in revolutions per minute (rpm). To convert from rpm to hertz, divide by 60. For example, if a pump operates at 1000 rpm, its frequency would be 16.67 Hz.

Let’s say you have a pump that is operating at 1000 rpm, has an impeller size of 6 inches, and is pumping water with a density of 62.4 lb/ft3. So the flow rate would be:

The good news is that there are many online flow rate calculators available for free, which you can consider using if you do want to get into too much mathematics.

There are a few key ways to increase the flow rate efficiency in pumps. One is to choose the right pump for the application. Another way is to ensure that the pump is sized correctly for the application. Additionally, regular maintenance can help keep a pump operating at peak efficiency.

When choosing a pump, it is vital to consider the application’s specific needs. For example, if a pump is handling a corrosive fluid, you should select stainless steel or other corrosion-resistant models. Similarly, if the fluid being pumped will be unusually viscous, then a positive displacement pump may be the best option.

Ensuring that a pump is appropriately sized for its application is also critical to maximizing flow rate efficiency. If a pump is too small for the task at hand, it will have to work much harder and will be less efficient. On the other hand, if a pump is too large for the application, it will not operate at peak efficiency.

Finally, regular maintenance is essential to keeping a pump operating at its best. This includes things like inspecting and cleaning the pump regularly and making sure that all of the moving parts are adequately lubricated. By taking these steps, it is possible to keep a pump running at peak efficiency for many years.

Honda Power Equipment offers pumps to meet a wide variety of applications. Use the chart and information below to select the right pump for your specific needs or

For general de-watering needs, Honda"s popular WB series pumps offer the best features at a value price. These models offer commercial grade components like silicon carbide seals, anti-vibration mounts, and a fixed-mount cast iron

The WH series are perfect for applications needing high pressure, such as sprinklers or nozzles. These pumps are lightweight and compact, making them highly portable. Possible applications include irrigation and fire suppression,

Honda Trash Pumps are the ultimate choice for contractors and rental applications. The WT series can handle solids up to 1 1/16” in diameter. These pumps are designed to move water, and lots of it – up to 433 gallons

Pumping water from excavations, crawl spaces, underground passageways, grain elevators, farm stock tanks, construction sites, cooling towers and parking lot sumps.

Both the EMP40™ and PITPUMP™ feature advanced telematics for active health monitoring in support of proactive preventative maintenance programs. The variable pump speed of PITPUMP™ allows it to work seamlessly with the smart generator architecture of the EMPOWER™ line. Current job site use has resulted in decreased fuel consumption of over 40% when the EMP40™ is used in tandem with PITPUMP™ across both entry- and exit-side operations.

In our important role as hydraulic pump manufacturers, we are aware of the large number of variables that need to be considered when choosing the right pump for the specific application. The purpose of this first article is to begin to shed light on the large number of technical indicators within the hydraulic pump universe, starting with the parameter “pump head”.

The head of a pump is a physical quantity that expresses the pump’s ability to lift a given volume of fluid, usually expressed in meters of water column, to a higher level from the point where the pump is positioned. In a nutshell, we can also define head as the maximum lifting height that the pump is able to transmit to the pumped fluid. The clearest example is that of a vertical pipe rising directly from the delivery outlet. Fluid will be pumped down the pipe 5 meters from the discharge outlet by a pump with a head of 5 meters. The head of a pump is inversely correlated with the flow rate. The higher the flow rate of the pump, the lower the head.

What is the head of a pump? As mentioned earlier, the head corresponds to the actual energy that the pump delivers to the fluid. The Bernoulli equation is applied between the pump’s inlet and outlet sections:

However, during the design stage, P1 and P2 are never known (as there is no physical element yet and therefore it is not possible to effectively measure the pump’s inlet and outlet pressure).

At this point we can easily calculate the head losses of the system, and therefore choose the correct size of the pump to achieve the desired flow rate at the resulting equivalent head.

The pump head indicator is present and can be found in the data sheets of all our main products. To obtain more information on the technical data of our pumps, please contact the technical and sales team.

Determining the flow rate you will need is an essential part of planning your system design, before you go ahead and order or install your new pump. If you get this wrong, then you might have to invest money in replacement equipment which could seriously impact your budget.

Once your system is installed and you have chosen the correct pump for the job, you will need to assess the system"s performance. There are a number of factors you could measure, but right now we will stick with flow rate. To measure the flow rate of your system you can:

Use a Flow Meter: This is a simple device which can measure the amount of fluid passing through it. Attach this to your discharge pipe, as close as possible to your pump and it should give you a reliable reading of your flow rate.

If the flow rate is not what it should be, given the expected performance of your installed pump, then you can move on and begin to assess each piece of your system for flaws. You may be interested in this blog:

Or, It could be that your pump is simply in need of replacement. If so, Global Pumps has a range of excellent industrial pumps available for any circumstance.

8613371530291

8613371530291