mud pump fluid end assemblies quotation

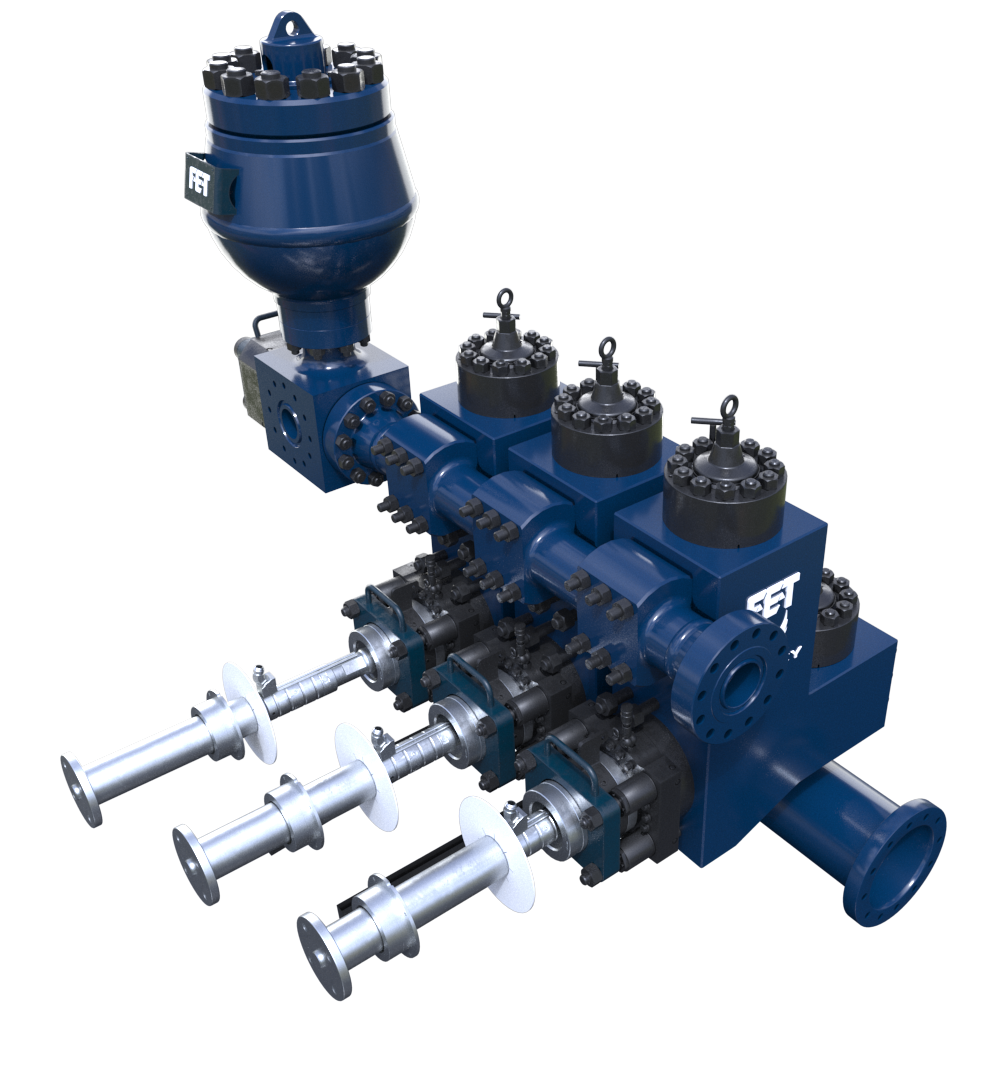

RPS’s high-strength, triple reduction, forged steel triplex fluid end modules are made from 4135 alloy steel, heat-treated for a long working life, machined to perfection, and packaged for delivery with anti-corrosion protection. The precision-made jewelry, like the exterior finish, reflects the superior quality inside.

RPS offers a complete line of interchangeable fluid end modules and accessories for triplex mud pumps. Fluid ends and components are interchangeable to OEM’s such asNational, Emsco, Gardner Denver, Bomco, Ideco, Weatherford, Drillmec, Eweco, Baker, Texma, Mud King, Honghua, RG, RS, GPM, LS-NOW, Wirth, and Oilwell. We offer both standard OEM style replacement parts and Two-piece “L” Shaped fluid ends. Manufactured to the highest quality, our products offer the best performance and durability. 5000psi & 7500psi available.

For maximum performance and durability, our modules are made from individually forged, heat-treated alloy steel and feature an API 7 valve assembly for improved flow. Our L-shaped design features bore-seal technology for improved seal performance in higher pressures and is compatible with numerous “F-Series” drilling pumps including Honghua®, Bomco® Rongsheng®, Workforce® and other similar designs.

Our patented internal bore geometry features an API 7 valve assembly to allow fluid to flow smoothly through the module, providing maximum efficiency. The compact vertical dimensions minimize the percentage of un-swept, or “dead”, volume in the module, further maximizing efficiency.

Fluid end modules are workhorses of mud pump systems, but extreme working environments make them especially vulnerable to stress, wear and damage. In choosing durable fluid end parts that resist cracking and corrosion, you’re making a wise long-term investment for your operations.

Forum offers a full line of high-quality fluid end modules that are entirely manufactured in the United States. Designed for the challenges of higher-pressure drilling, they are crafted with industry-leading materials and technologies to resist cracking and reduce stress concentrations for significantly longer life. Complementary features include our industry-leading P-Quip® liner retention and rod systems. Additional benefits and features include:

Hydraulic cylinder is also called the valve box, it is a major part to the fluid end parts. Blank forged by high strengthalloy steel. After heat treated, with multi-channel processes. The three cylinders of each pump isinterchangeable.

A Mud Pump may have many changeable parts, such as liner, piston, extension rod, pulsation dampener, valve, clamp, etc. Lake Petro could provide 100% interchangeable parts of many common brands of pump. We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials. Piston assembly is the important spare parts and expendable parts of oil drilling mud pumps. Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump. Fluid End Module is an important component of the hydraulic pump end of the mud pump.

The synchronous reciprocating motion of drilling mud pumps operating at optimized speed, symbolize the steady but continuous operations of oil exploration and production. ShalePumps, as a recognized quality producer of high quality drilling mud pumps constantly strives to pull out an improvised and operation enhancing equipment from the assembly lines. SP-2200L drilling mud pumps are an instance of enhanced engineering and precision.

Firing optimized pump speeds, and comprising of superior materials, the drilling mud pumps are designed to operate effortlessly. To enable easy replacement of high wear components, the design incorporates a fast access mechanism, to reduce downtime.

The drilling mud pumps have been developed and manufactured by factoring in the structural demands as a result of long runs. The components are manufactured from superior materials like high strength steel frames, forged steel crankshaft, metal liners and high capacity bearings.

The combination of tested materials and engineering excellence has helped ShalePumps to consistently deliver the needs of the industry in advance. The drilling mud pumps perform in mechanical harmony to standards that overrun industry performance parameters such as displacement and pressure. At ShalePumps, the desired parameters of performance of pumps are by default, pegged higher than industry requirements.

Manufactured to withstand the toughest drilling and environmental conditions, our K-Series triplex mud pumps are ideal for all drilling applications. This legacy product features a balanced forged-steel crankshaft and Southwest Oilfield Products ‘L” Shaped modules which is essential to minimize wear, noise, and operating vibrations. These attributes are essential when drilling deeper high pressure formations, long laterals and when handling corrosive or abrasive fluids and slurries.

Every American Block triplex mud pump is manufactured and fully load tested before leaving our manufacturing campus, and is available in sizes ranging from 800 HP to 2200 HP. The American Block K1600 HP Mud Pump is also available in a 2000 HP up-grade version, when more HP is needed in the same 1600 HP footprint.

NexGen Manufacturing & Supply keeps a wide variety of replacement parts in stock for mud pumps, plunger pumps, swivels, top drives, handling tools, and much more! Additionally, we have more than 3,000 prints and drawings of oilfield equipment and

Fluid End Spare Parts produced by our company is mainly used in oil drilling and geological exploration, especially in deep oil reservoirs, poor surface structure and soil production environment, as well as offshore oil and gas development。

Valve assembly is the critical component of mud pump fluid end , with high operation frequency and great impact subjected. The quality of valve assembly will have a direct effect on the life of hydraulic cylinder.

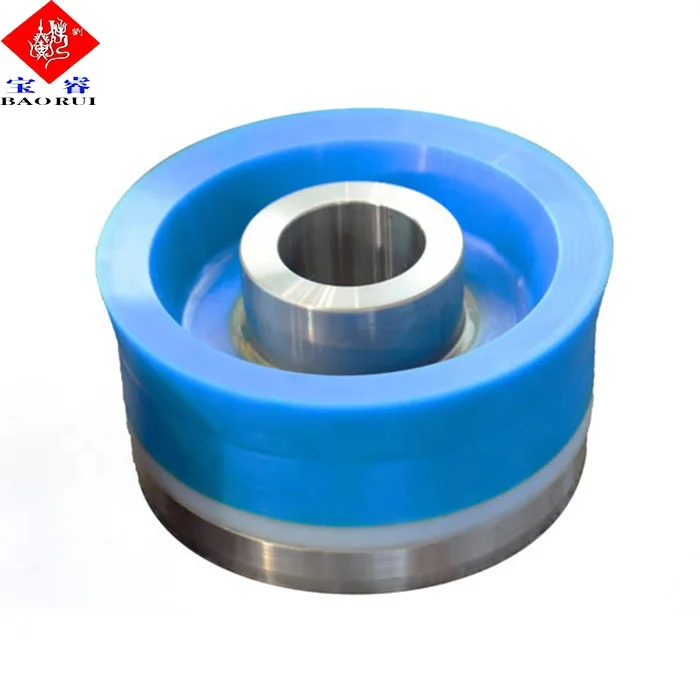

Piston assembly is the major part of the mud pump fluid end. The discharge pressure of mud pump is generated by the up-and-down motion of the piston in the cylinder. Small piston—high pressure and low flow rate; Big piston—low pressure and high flow rate. Metric pump and inch pump adopts metric piston and inch piston respectively.

8613371530291

8613371530291