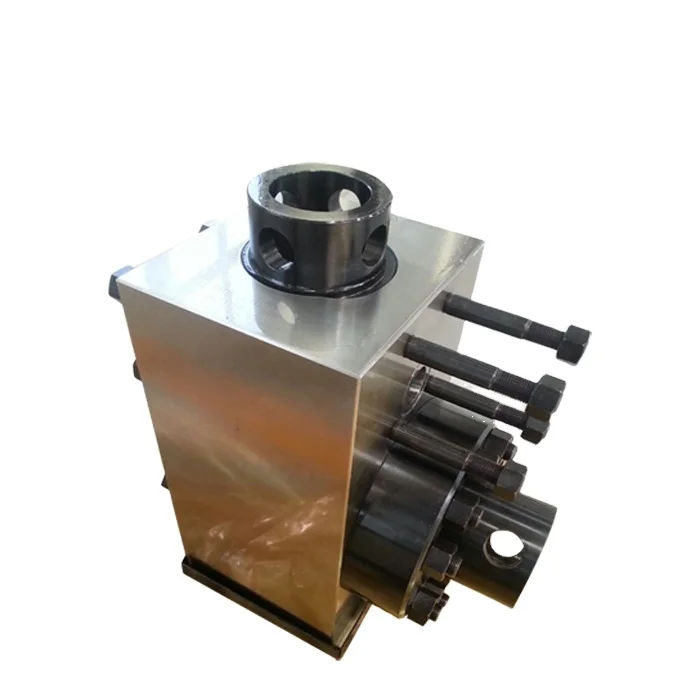

mud pump fluid ends free sample

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

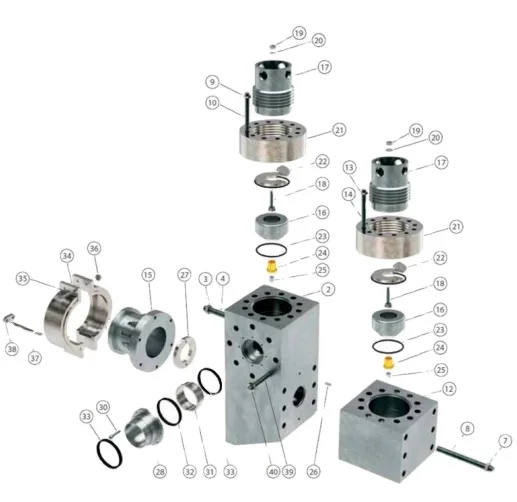

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

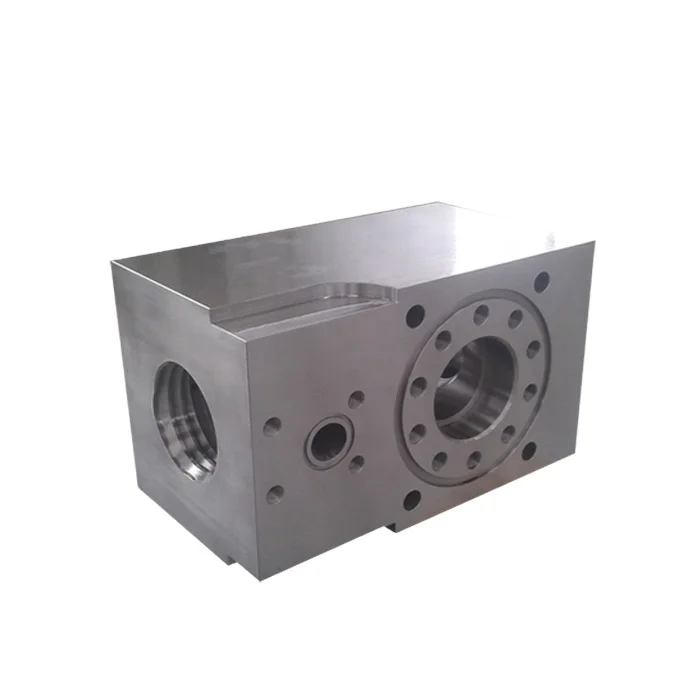

At Kerr Pumps, we know that the fluid end is the heart of pumping performance. We take great pride in our proven designs and manufacture the highest quality fluid ends. The tolerances achieved by our CNC machines are equal to or better than anyone in the industry. To achieve the smoothest flow, each forging is precision machined with our proprietary tooling that mills a precise combination of taper, radius, and polish enabling a Kerr fluid end to outperform and last longer than the competition.

Fluid end modules are workhorses of mud pump systems, but extreme working environments make them especially vulnerable to stress, wear and damage. In choosing durable fluid end parts that resist cracking and corrosion, you’re making a wise long-term investment for your operations.

Forum offers a full line of high-quality fluid end modules that are entirely manufactured in the United States. Designed for the challenges of higher-pressure drilling, they are crafted with industry-leading materials and technologies to resist cracking and reduce stress concentrations for significantly longer life. Complementary features include our industry-leading P-Quip® liner retention and rod systems. Additional benefits and features include:

I’ve run into several instances of insufficient suction stabilization on rigs where a “standpipe” is installed off the suction manifold. The thought behind this design was to create a gas-over-fluid column for the reciprocating pump and eliminate cavitation.

When the standpipe is installed on the suction manifold’s deadhead side, there’s little opportunity to get fluid into all the cylinders to prevent cavitation. Also, the reciprocating pump and charge pump are not isolated.

The gas over fluid internal systems has limitations too. The standpipe loses compression due to gas being consumed by the drilling fluid. In the absence of gas, the standpipe becomes virtually defunct because gravity (14.7 psi) is the only force driving the cylinders’ fluid. Also, gas is rarely replenished or charged in the standpipe.

Installing a suction stabilizer from the suction manifold port supports the manifold’s capacity to pull adequate fluid and eliminates the chance of manifold fluid deficiency, which ultimately prevents cavitation.

Another benefit of installing a suction stabilizer is eliminating the negative energies in fluids caused by the water hammer effect from valves quickly closing and opening.

The suction stabilizer’s compressible feature is designed to absorb the negative energies and promote smooth fluid flow. As a result, pump isolation is achieved between the charge pump and the reciprocating pump.

The isolation eliminates pump chatter, and because the reciprocating pump’s negative energies never reach the charge pump, the pump’s expendable life is extended.

Investing in suction stabilizers will ensure your pumps operate consistently and efficiently. They can also prevent most challenges related to pressure surges or pulsations in the most difficult piping environments.

Cavitation is an undesirable condition that reduces pump efficiency and leads to excessive wear and damage to pump components. Factors that can contribute to cavitation, such as fluid velocity and pressure, can sometimes be attributed to an inadequate mud system design and/or the diminishing performance of the mud pump’s feed system.

Although cavitation is avoidable, without proper inspection of the feed system, it can accelerate the wear of fluid end parts. Over time, cavitation can also lead to expensive maintenance issues and a potentially catastrophic failure.

When a mud pump has entered full cavitation, rig crews and field service technicians will see the equipment shaking and hear the pump “knocking,” which typically sounds like marbles and stones being thrown around inside the equipment. However, the process of cavitation starts long before audible signs reveal themselves – hence the name “the silent killer.”

Mild cavitation begins to occur when the mud pump is starved for fluid. While the pump itself may not be making noise, damage is still being done to the internal components of the fluid end. In the early stages, cavitation can damage a pump’s module, piston and valve assembly.

The imperceptible but intense shock waves generated by cavitation travel directly from the fluid end to the pump’s power end, causing premature vibrational damage to the crosshead slides. The vibrations are then passed onto the shaft, bull gear and into the main bearings.

If not corrected, the vibrations caused by cavitation will work their way directly to critical power end components, which will result in the premature failure of the mud pump. A busted mud pump means expensive downtime and repair costs.

Washouts are one of the leading causes of module failure and take place when the high-pressure fluid cuts through the module’s surface and damages a sealing surface. These unexpected failures are expensive and can lead to a minimum of eight hours of rig downtime for module replacement.

To stop cavitation before it starts, install and tune high-speed pressure sensors on the mud suction line set to sound an alarm if the pressure falls below 30 psi.

Although the pump may not be knocking loudly when cavitation first presents, regular inspections by a properly trained field technician may be able to detect moderate vibrations and slight knocking sounds.

Gardner Denver offers Pump University, a mobile classroom that travels to facilities and/or drilling rigs and trains rig crews on best practices for pumping equipment maintenance.

Program participants have found that, by improving their maintenance skills, they have extended the life of fluid end expendables on their sites. They have also reported decreases in both production and repair costs, as well as reductions in workplace hazards.

Severe cavitation will drastically decrease module life and will eventually lead to catastrophic pump failure. Along with downtime and repair costs, the failure of the drilling pump can also cause damage to the suction and discharge piping.

When a mud pump has entered full cavitation, rig crews and field service technicians will see the equipment shaking and hear the pump ‘knocking’… However, the process of cavitation starts long before audible signs reveal themselves – hence the name ‘the silent killer.’In 2017, a leading North American drilling contractor was encountering chronic mud system issues on multiple rigs. The contractor engaged in more than 25 premature module washes in one year and suffered a major power-end failure.

Gardner Denver’s engineering team spent time on the contractor’s rigs, observing the pumps during operation and surveying the mud system’s design and configuration.

The engineering team discovered that the suction systems were undersized, feed lines were too small and there was no dampening on the suction side of the pump.

There were also issues with feed line maintenance – lines weren’t cleaned out on a regular basis, resulting in solids from the fluid forming a thick cake on the bottom of the pipe, which further reduced its diameter.

Following the implementation of these recommendations, the contractor saw significant performance improvements from the drilling pumps. Consumables life was extended significantly, and module washes were reduced by nearly 85%.

Although pump age does not affect its susceptibility to cavitation, the age of the rig can. An older rig’s mud systems may not be equipped for the way pumps are run today – at maximum horsepower.

A wide variety of mud pump fluid end modules options are available to you, such as 1 year, not available and 3 years.You can also choose from new, mud pump fluid end modules,As well as from energy & mining, construction works , and machinery repair shops. and whether mud pump fluid end modules is 1.5 years, 6 months, or unavailable.

Heating, Ventilation and Air Conditioning Landlord shall furnish to the Premises heating, ventilation and air-conditioning (“HVAC”) in accordance with the Design Standards set forth in Exhibit D during Ordinary Business Hours. Landlord shall have access to all air-cooling, fan, ventilating and machine rooms and electrical closets and all other mechanical installations of Landlord (collectively, “Mechanical Installations”), and Tenant shall not construct partitions or other obstructions which may interfere with Landlord’s access thereto or the moving of Landlord’s equipment to and from the Mechanical Installations. No Tenant Party shall at any time enter the Mechanical Installations or tamper with, adjust, or otherwise affect such Mechanical Installations. Landlord shall not be responsible if the HVAC System fails to provide cooled or heated air, as the case may be, to the Premises in accordance with the Design Standards by reason of (i) any equipment installed by, for or on behalf of Tenant, which has an electrical load in excess of the average electrical load and human occupancy factors for the HVAC System as designed, or (ii) any rearrangement of partitioning or other Alterations made or performed by, for or on behalf of Tenant. Tenant shall install, if missing, blinds or shades on all windows, which blinds and shades shall be subject to Landlord’s approval, and shall keep operable windows in the Premises closed, and lower the blinds when necessary because of the sun’s position, whenever the HVAC System is in operation or as and when required by any Requirement. Tenant shall cooperate with Landlord and shall abide by the rules and regulations which Landlord may reasonably prescribe for the proper functioning and protection of the HVAC System. Tenant acknowledges that the server room in the Premises currently has three heat pumps installed, being two 4-ton units, and one 2.5-ton unit (the “Existing Heat Pumps”). The 2.5-ton unit is currently connected and operational. Tenant shall determine whether it is satisfied with the condition of the Existing Heat Pumps and Landlord shall not have any responsibility or liability for the condition, operation, maintenance, repair or replacement of the Existing Heat Pumps. Tenant may operate the Existing Heat Pumps. Tenant shall be responsible for, and pay directly for, all necessary maintenance and repairs to the Existing Heat Pumps. Tenant shall reimburse Landlord monthly for the cost of all utility services used to operate the Existing Heat Pumps within 10 Business Days after receipt of Landlord’s invoice for such amount. Landlord may measure Tenant’s usage of such utility services by either a sub-meter or by other reasonable methods such as by temporary check meters or by survey. Tenant, at its cost, may replace the Existing Heat Pumps with one or more new heat pumps, provided, however, that the capacity of such replacement heat pump(s) shall not exceed the 10.5-ton capacity cooling capacity of the Existing Heat Pumps.

Loop Makeup Response Time - Electronic This report measures the average interval and the percent within the interval from the electronic submission of a Loop Makeup Service Inquiry (LMUSI) to the distribution of Loop Makeup information back to the CLEC. Exclusions Manually submitted inquiries Canceled Requests Business Rules The response interval starts when the CLEC’s Mechanized Loop Makeup Service Inquiry (LMUSI) is submitted electronically through the Operational Support Systems interface, TAG. It ends when BellSouth’s Loop Facility Assignment and Control System (LFACS) responds electronically to the CLEC with the requested Loop Makeup data via the TAG Interface. LSRs submitted via LENs will be reflected in the results for the TAG interface.

8613371530291

8613371530291