mud pump fluid ends brands

Premium Oilfield Technologies takes the responsibility of listening to our clients’ concerns very seriously. Acting on those needs enables Premium to offer robust solutions to customer issues at the rig. The Caliber® DS-7500 Fluid Ends bring together our years of field experience and unmatched client interface to represent the NEW standard for your Gardner Denver pumps.

For maximum performance and durability, our modules are made from individually forged, heat-treated alloy steel and feature an API 7 valve assembly for improved flow. Our L-shaped design features bore-seal technology for improved seal performance in higher pressures and is compatible with numerous “F-Series” drilling pumps including Honghua®, Bomco® Rongsheng®, Workforce® and other similar designs.

Fluid end modules are workhorses of mud pump systems, but extreme working environments make them especially vulnerable to stress, wear and damage. In choosing durable fluid end parts that resist cracking and corrosion, you’re making a wise long-term investment for your operations.

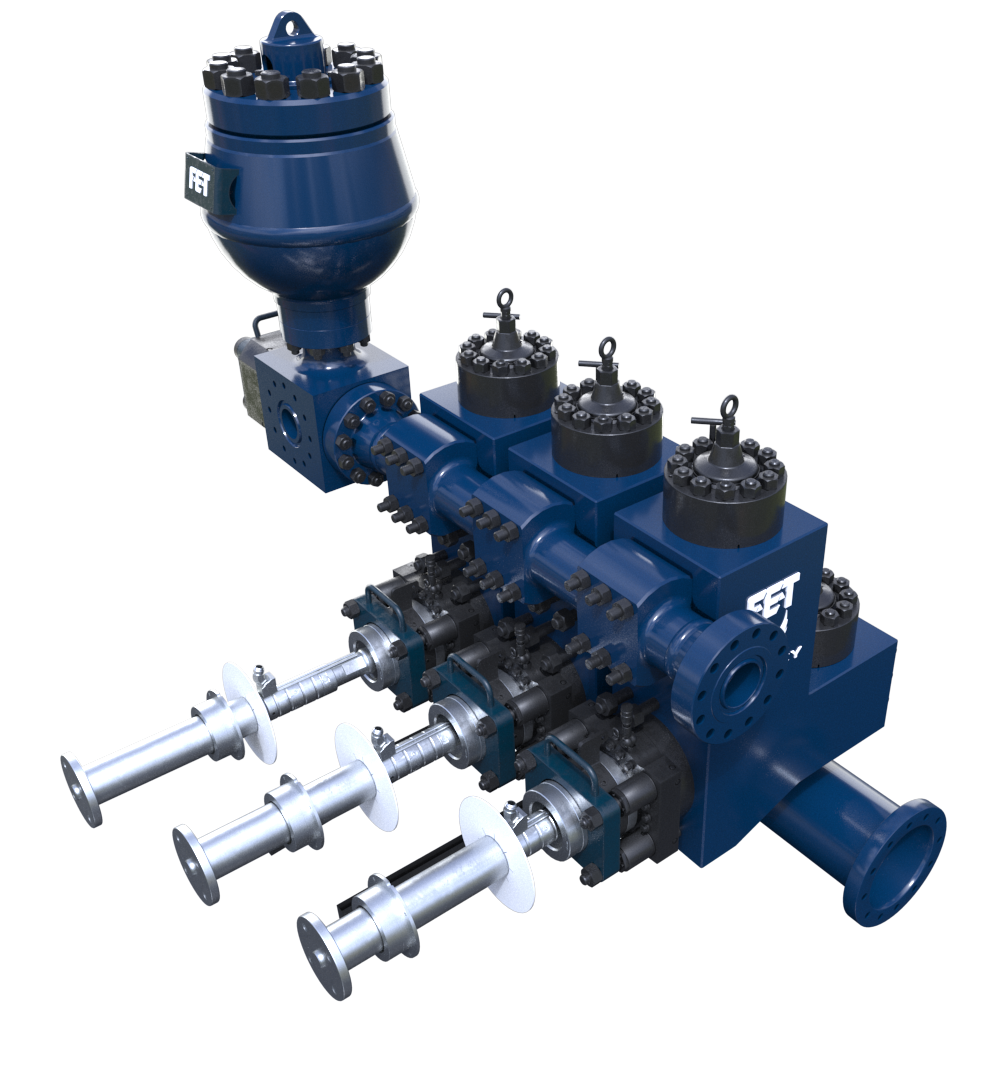

Forum offers a full line of high-quality fluid end modules that are entirely manufactured in the United States. Designed for the challenges of higher-pressure drilling, they are crafted with industry-leading materials and technologies to resist cracking and reduce stress concentrations for significantly longer life. Complementary features include our industry-leading P-Quip® liner retention and rod systems. Additional benefits and features include:

Mud Pump Fluid End Module is forged by high-quality alloy steel 35CrMo or 40CrMnMo. It has no defects such as interlayer, crack, impurity, looseness and over-burning. Welding is not allowed. The Mud Pump Fluid End Module is in full compliance with API7K standard and is inspected according to the third-grade forging and internal hardening treatment, high durability. Above process is strictly checked and strict non-destructive testing.

For over 60 years, Southwest Oilfield Products has been providing the industry with high-quality mud pump parts and we are excited to expand our product offering to include well service pump fluid ends and consumable parts. With over 15 domestic store locations, we are certain to have a convenient location that is ready to serve you.

Packing: Our well-service pump packing options are all-inclusive from moderate to severe service sealing designs. We offer both replacement and complete packing sets.

RPS’s high-strength, triple reduction, forged steel triplex fluid end modules are made from 4135 alloy steel, heat-treated for a long working life, machined to perfection, and packaged for delivery with anti-corrosion protection. The precision-made jewelry, like the exterior finish, reflects the superior quality inside.

RPS offers a complete line of interchangeable fluid end modules and accessories for triplex mud pumps. Fluid ends and components are interchangeable to OEM’s such asNational, Emsco, Gardner Denver, Bomco, Ideco, Weatherford, Drillmec, Eweco, Baker, Texma, Mud King, Honghua, RG, RS, GPM, LS-NOW, Wirth, and Oilwell. We offer both standard OEM style replacement parts and Two-piece “L” Shaped fluid ends. Manufactured to the highest quality, our products offer the best performance and durability. 5000psi & 7500psi available.

TSC"s high-strength, triple reduction, forged steel triplex fluid end modules are made from 4135 alloy steel and heat treated for long working life. These modules are machined to perfection and packaged for delivery.

At Kerr Pumps, we know that the fluid end is the heart of pumping performance. We take great pride in our proven designs and manufacture the highest quality fluid ends. The tolerances achieved by our CNC machines are equal to or better than anyone in the industry. To achieve the smoothest flow, each forging is precision machined with our proprietary tooling that mills a precise combination of taper, radius, and polish enabling a Kerr fluid end to outperform and last longer than the competition.

Manufactured to withstand the toughest drilling and environmental conditions, our K-Series triplex mud pumps are ideal for all drilling applications. This legacy product features a balanced forged-steel crankshaft and Southwest Oilfield Products ‘L” Shaped modules which is essential to minimize wear, noise, and operating vibrations. These attributes are essential when drilling deeper high pressure formations, long laterals and when handling corrosive or abrasive fluids and slurries.

Every American Block triplex mud pump is manufactured and fully load tested before leaving our manufacturing campus, and is available in sizes ranging from 800 HP to 2200 HP. The American Block K1600 HP Mud Pump is also available in a 2000 HP up-grade version, when more HP is needed in the same 1600 HP footprint.

We carry mud pumps, connecting rods, and more than 2,000 drawings and blueprints of oilfield equipment and supplies. We can fill your orders with one-of-a-kind designs for:

Our vast inventory of fluid-end and gear-end parts for duplex pumps includes more than 500 duplex liners, as well as cages and stuffing boxes. If you can’t find the model you are looking for below, let us find it for you.

We carry more than 1,500 duplex piston rods and 200 duplex pony rods in our inventory. Though we keep in stock connecting rods primarily for GA550 and GA750 models, other options are available, including custom connecting rods for most duplex and triplex mud pumps.

We now offer crossheads and guides for both EMSCO D-375 and DB-550 duplex pumps. We also have slides and shoes for certain models. If you don’t see a part you need, let us find it for you.

Houston, Texas -- To eliminate equipment compatibility issues and the prospect of additional spare-parts inventories for drilling contractors, the LeTourneau Ellis Williams Company (LEWCO) can factory-equip its heavy-duty W-Series and general-duty WH-Series mud pumps with virtually any major brand of fluid end module. Customers not specifying a particular brand receive LEWCO"s standard one-piece or two-piece fluid end modules made of quenched and tempered forged steel, featuring "off the shelf" expendables readily available from domestic and international sources.

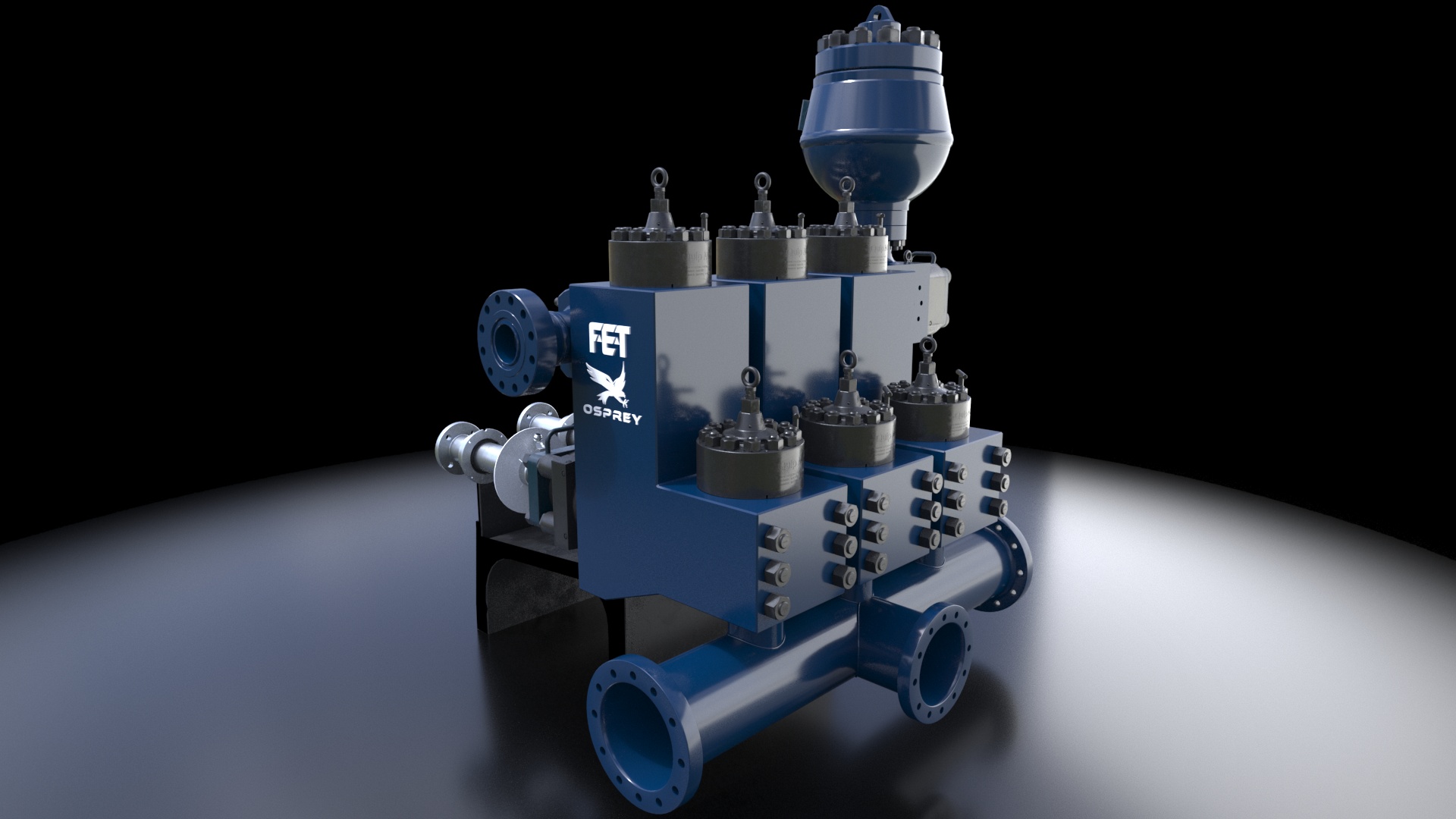

LEWCO mud pumps are in-house manufactured. For maximum quality assurance -- with job-ready performance verified in advance -- every pump is tested under full load prior to shipment, in the company"s fully equipped, million-dollar "mud pump laboratory." LEWCO pumps provide input ratings of 300 to 3,000 horsepower (224 kW to 2,237 kW) and deep-drilling discharge pressures as great as 7,500 pounds per square inch (527 kg/cm2). Their premium components include a pressurized lubrication system that force-feeds lubricant to all power-end bearings including upper and lower crosshead slides; a balanced forged steel crankshaft that reduces noise and vibration and helps extend component life throughout the pump; and a robust frame of double-wall, welded-steel, mounted on a heavy-duty oilfield skid.

The LeTourneau Ellis Williams Company builds high-performance mud pumps for oil and gas drilling (on land and offshore), petroleum production and processing, well-servicing, and horizontal directional drilling; as well as ancillary drilling products including pulsation dampeners; drawworks; rotary tables, transmissions, and drives; and swivels. Located in Houston, Texas, LEWCO is a wholly owned subsidiary of LeTourneau Incorporated, a leading manufacturer of self-elevating offshore drilling rigs, forestry equipment, and wheel loaders.

For more information, contact the LEWCO Sales Department at 6500 Brittmoore Road, Houston, TX 77241-1343; telephone 1-888-MUD-PUMP (683-7867), fax 713-856-5341; e-mail pumps@lewco-equip.com. Or visit www.lewco-equip.com.

All sealing parts are tightened, featuring good sealing performance. Vertical fluid end features good suction performance. Our mud pump fluid end parts are interchangeable with other abroad brands. Call us if you have such requirements on mud pump parts.

All Fluid end is made of forged alloy steel and three fluid ends of each pump are interchangeable. On customers" request, the fluid end surface can be nickel-plated to improve the abrasion resistance.

The suction valve and discharge valve of F-series mud pump are interchangeable. F-500 mud pump uses API 5# valve, F-800/1000 mud pumps use API 6# valve. F-1300/1600/1600HL mud pumps use API 7# valve. D-2200/2200HL mud pumps use API 8# valve.

Fluid end, liner, piston, valve and seat, valve spring, seal ring and gasket, valve cover and cylinder head fluid end assembly for F-800 and F-1000 mud pumps are interchangeable.

Complete range of interchangeable fluid end modules and accessories for triplex mud pumps. Fluid ends and components are interchangeable to OEM’s such as South West National, Emsco, Gardner Denver, Bomco, Ideco and Oilwell. In both standard OEM style replacement parts and Two piece “L” Shaped fluid ends. Manufactured to the highest quality, best performance and durability. 5000psi & 7500psi available.

8613371530291

8613371530291